CLEVELINGS BLUEBOX 1.0 User manual

Instrukcja

1

Contents

1. GENERAL INFORMATION ........................................................................................................................................................ 2

1.1 Signs used in the instruction........................................................................................................................ 2

1.2 Use............................................................................................................................................................... 2

2. SAFETY.................................................................................................................................................................................... 3

2.1 General safety systems................................................................................................................................ 3

2.2 Workplace safety......................................................................................................................................... 3

2.3 Electrical safety ........................................................................................................................................... 4

2.4 Personnel safety .......................................................................................................................................... 4

2.5 Use............................................................................................................................................................... 4

2.6 Possible danger sources .............................................................................................................................. 4

2.7 Power supply ............................................................................................................................................... 5

2.8 Power generators........................................................................................................................................ 5

2.9 Extension cords............................................................................................................................................ 6

2.10 Servicing ...................................................................................................................................................... 6

3. TECHNICAL SPECIFICATION ..................................................................................................................................................... 6

3.1 Construction ................................................................................................................................................ 7

3.1.1 Construction (outside) .........................................................................................................................7

3.1.2 Front panel layout................................................................................................................................8

3.1.3 Connection adaptors............................................................................................................................8

3.1.4 Identification plates .............................................................................................................................9

3.1.5 Barcode scanner...................................................................................................................................9

3.1.6 Acoustic signal....................................................................................................................................10

3.1.7 Keypad................................................................................................................................................10

3.2 Start-up...................................................................................................................................................... 10

3.2.1 Transport, packing and storage .........................................................................................................10

3.2.2. Operating personnel..........................................................................................................................10

3.2.3. Start-up procedure.............................................................................................................................10

4. WELDING PROCESS............................................................................................................................................................... 11

5. OPERATING INSTRUCTIONS .................................................................................................................................................. 12

5.1 Starting messages ..................................................................................................................................... 12

5.2 Welding......................................................................................................................................................13

5.3 Settings...................................................................................................................................................... 15

6. TROUBLESHOOTING ............................................................................................................................................................. 17

7. MAINTENANCE ..................................................................................................................................................................... 19

8. FINAL REMARKS.................................................................................................................................................................... 20

9. FORBIDDEN ACTIONS............................................................................................................................................................ 20

10. FIREFIGHTING INSTRUCTIONS............................................................................................................................................. 20

2

1. GENERAL INFORMATION

NOTE

Before proceeding to work with the device make sure to read closely this user manual, which constitutes

integral part of the device. The instruction shall be used before work, during and after the launch and

anytime it’s deemed to be necessary.

Following above instructions is the only way to achieve three main objectives of this instruction manual i.e.:

•Optimization of work effects and performance of the device

•Protection against injuries

•Protection against damage and destruction of the device

1.1 Signs used in the instruction

Present instruction include following safety signs and warnings.

Symbol

Description

WARNING

This symbol refers to a direct threat to the life or health of a person.

Ignoring the warning results in serious injuries and may even have fatal consequences.

CAUTION

This symbol provides important information referring to proper operating of the device. Ignoring this

message might lead to a malfunction, damaging the material or damages done to the environment.

INFORMATION

This symbol provides instructions and valuable information. Such information will help you to use the

machine functions in optimal way.

1.2 Use

Electrofusion welding unit serves for joining of plastic pipes and fittings. Using the device for purposes other than the ones

described in this manual is forbidden and can be dangerous to the operator and assisting personnel or can lead to damaging the

device or other equipment located in the area.

In order to use the device accordingly make sure to follow:

•all recommendations included in this user manual

•general and detailed guidelines on electrofusion fittings

•applicable health and safety regulations, environmental protection regulations, legal regulations and all standards, laws

and directives in force in a given country

Electrofusion welding consist in joining two (PP, PE) pipe ends with the use of electrofusion fitting like e.g. couplers, tees,

reductions, saddles, etc. During welding process the device provides electric energy of strictly defined parameters to the resistance

wire located on the inner surface of the fitting. Electric energy is transformed into heat causing the polyethylene on the fitting and

fitting to melt and bond by filling up the space between both elements. After cooling and crystallization of polyethylene, the

connection is durable, firm and reliable.

Electrofusion welding process is performed correctly only if device applied for this purpose allows for full control of process

parameters such as:

•welding voltage

•duration of subsequent stages of welding process

Instrukcja

3

Stage of

process

Description

I

Preparation of pipes

II

Installation of pipe-fitting assembly in aligning tool

III

Welding

IV

Cooling

2. SAFETY

2.1 General safety systems

WARNING

Every operator is obliged to read the user manual before

proceeding to work with the device. During work operator shall use

direct protection measures required in the workplace.

Electrofusion welding unit is designed accordingly with current regulations and shall be used exclusively for welding pipes and

fittings made of polyolefins. Electrofusion welding process does not pose any danger to the operator provided that the safety rules

are followed. However, using the device by unqualified personnel or not following the safety rules could lead to injuries.

All people not involved into the process shall make sure to maintain safe distance while the device is working.

Improper handling or improper use of the device could lead to:

•Threat to the health and life of the operator

•Damage to the electrofusion welding unit

•Decrease in work efficiency of the welding unit

•Obtaining low quality connections

2.2 Workplace safety

•Workplace shall be kept clean and properly lit. Disorder and improper lighting in the workplace can lead to accidents.

•Do not use power tools in the explosive zone areas with flammable gases, liquids or dusts. Power tools might generate

sparks which could ignite them.

•Do not allow children of any 3rd parties in the working area. Their presence could distract the operator which could lead

to losing control over the device.

WARNING

Device shall be used only by properly trained personnel with suitable qualifications. Using the device against

its original purpose is forbidden and might be dangerous to the operator and assisting personnel and could

lead to damaging the device or other equipment in the closest area.

CAUTION

Each unauthorized use of the device, use against its purpose or any interference into its construction will

result with immediate loss of warranty.

4

2.3 Electrical safety

•Power supply plug must fit the socket perfectly and cannot be modified in any way. Power tool that require protective

grounding cannot be powered through extension cords. Use of unmodified plugs and proper sockets significantly reduce

the risk of sustaining an electric shock.

•Avoid touching non-grounded elements, e.g. pipes. Grounding one’s body increases the danger of sustaining an electric

shock.

•Do not expose power tools to moisture or rain. The penetration of water inside the power tool increases the risk of

sustaining an electric shock.

•Power supply cable does not serve for: transport purposes, hanging or lifting the device, pulling the plug out of socket.

Protect the power supply cable against high temperatures, sharp edges, oils and moving elements. Damaged or entangled

cable increases the risk of sustaining an electric shock.

•During work on the outside, when it’s necessary to use extension cables make sure to use extension cables intended for

outside use. Using such type of extension cable decreases the risk of electric shock.

•If you are working in high humidity conditions use a circuit breaker. The use of a current protection switch reduces the risk

of electric shock.

2.4 Personnel safety

•Be attentive, pay attention to performed actions, take reasonable care while working with power tools. Do not use power

tools if you are tired or under the influence of drugs, alcohol or medication.

•Wear personal protective equipment and always safety goggles. The use of personal protective equipment such as non-

slip footwear, a protective helmet or hearing protection, depending on the power tool used, reduces the risk of injury.

•Eliminate the possibility of accidental start of the device. Before connecting to the power outlet and before touching or

moving the device make sure it’s turned off. Moving an electrical device with your finger on the switch or attempting to

connect to a power outlet while the equipment is turned on may lead to an accident.

•Avoid unnatural body positions during work. Ensure a safe standing position and keep your balance at all times. This will

allow you to better control the power tool in unexpected situations.

2.5 Use

•Do not overload the device. For each work use suitably selected tools. Properly selected tools allow for easier and more

confident work in desired power range.

•Do not use power tools with damaged power switch. Device that doesn’t allow for emergency shutdown at any given

moment poses a danger and shall get repaired.

•Before preparing the device for work, replacing accessories or putting the device back make sure to remove the plug

from power outlet. These safety precautions prevent from accidental start of the device.

•Unused power tools shall be stored away from the reach of children. Do not allow people unfamiliar with the device, or

this instruction manual, to operate it. Power tools in the hands of inexperienced personnel could be dangerous.

•Take care of the power tools. Damaged parts shall be replaced by authorized service centers. Many accidents are

attributed to improper maintenance.

•Use the device in accordance with these instructions. The operating conditions and the type of operation to be carried

out must be taken into account. Using power tools for other purposes than intended may lead to dangerous situations.

2.6 Possible danger sources

Electrofusion welding unit is an electrical device and thus it’s forbidden to:

•leave the device unattended

•use damaged device (casing, cables, extensions)

WARNING

Danger of sustaining an electric shock from elements under voltage. Danger to health and life.

Instrukcja

5

•service the device that is under voltage

•work with the device on voltage different that intended

•remove safety equipment during welding process

Electrofusion unit shall be used in accordance with general safety rules. There should be proper ventilation ensured in the place

of work and enough space for operation to be carried in safe manner. If the work is carried outside suitable measures shall be

taken to protect the device against weather conditions. It’s forbidden to use the device in the proximity of flammable substances,

explosive zones, excessively hot or cold conditions or in too high humidity or with high level of dust.

It’s forbidden to clean the device with the use of solvents or other aggressive substances which could permanently damage the

external surface or damage the plastic elements. Only trained personnel can use the device. All repairs shall be performed by

qualified personnel.

2.7 Power supply

1st generation electrofusion welding units are adapted to work with power supply AC 230V (+/-15%), 50Hz (+/-10%) from mains

or power generator. In case of working in outdoors conditions (construction site) electric sockets should ensure stable

parameters of power supply. Power generator or mains to which the device is connected should be equipped (depending on

model) with (delay) safety fuses 16A or 20A.

2.8 Power generators

Before connecting the device to power generator make sure it’s recommended for work on the building site. Follow the user

manual delivered with the generator. Connect the electrofusion unit to the generator at least 1 minute after starting the

generator. Do not connect other power tools to the generator during welding process.

After finishing the welding process firstly turn off the welding unit main switch, then unplug the device from generator and lastly

turn off the power generator. Following this sequence will protect the welding unit from damaging it with voltage peaks which

appear during start-up and shut down of power generator.

Required nominal power of the power generator depends on:

•fitting resistance and welding voltage

•outside conditions

•connection

WARNING

Danger of fire or explosion in case of contact with flammable materials.

INFORMATION

Before connecting the device to power outlet make sure the power supply parameters are within the range

of work of the device –195 do 265 V!

WARNING

230V power supply should have grounding wire, residual current circuit breaker and overcurrent protection. It’s

forbidden to connect the device to power outlets without neutral wire and grounding pin.

6

2.9 Extension cords

Poniższa tabela przedstawia zmianę wymaganego przekroju przedłużacza w zależności od jego długości.

Length

Cross-section

up to 50 m

2,5mm2

up to 100m

4 mm2

2.10 Servicing

3. TECHNICAL SPECIFICATION

*only when full cooling times are maintained

INFORMATION

Different types of power generators often show different regulating characteristics. As a result selecting the power

generator basing solely on nominal power might not be effective. When in doubt whether given power generator

is suitable for work with the electrofusion unit contact authorized service department.

INFORMATION

In order to minimize the risk of overheating the extension cord, make sure to unfold it!

WARNING

Repairs of power tools shall be performed by professionals and only with the use of original spare parts. This allows

to keep the devices safe in use.

Technical parameters

Type:

BLUEBOX 1.0

Approximate diameter range:

~160mm

Power supply [V]:

230

Input voltage [V]:

195 –255

Frequency range [Hz]

45 –55

Max. welding current [A]:

60

Max. fitting power [W]:

1450

Weight [kg]:

13

Protection class:

IP-54

Power supply cable [m]:

3

Welding cables [m]:

3

Dimensions [mm]:

390 x 240 x 160

Voltage regulation range [V]:

8 –44

Volt. regulation step of change [V]:

0,1

Welding time step of change [s]:

1

Cooling time step of change [min]:

1

Working temperature [°C]:

- 5 to + 40

Recommended power generator

[kW]:

3

Welding data registration and

traceability:

-

Memory capacity:

-

Instrukcja

7

3.1 Construction

Electrofusion welding units BLUEBOX 1.0 are equipped with ABS-made casing permanently embedded in steel transport box.. CPU

board, power board, transformer and display are all mounted inside the casing. CPU board is responsible for controlling the

functions of the device by measuring the voltage and current and controls the duration of subsequent stages of welding process.

Device is equipped with outside temperature sensor (located on output cables) and sensor of temperature of transformer which

control its temperature and prevents the device from overheating.

Basic elements of electrofusion unit and its control panel are shown below.

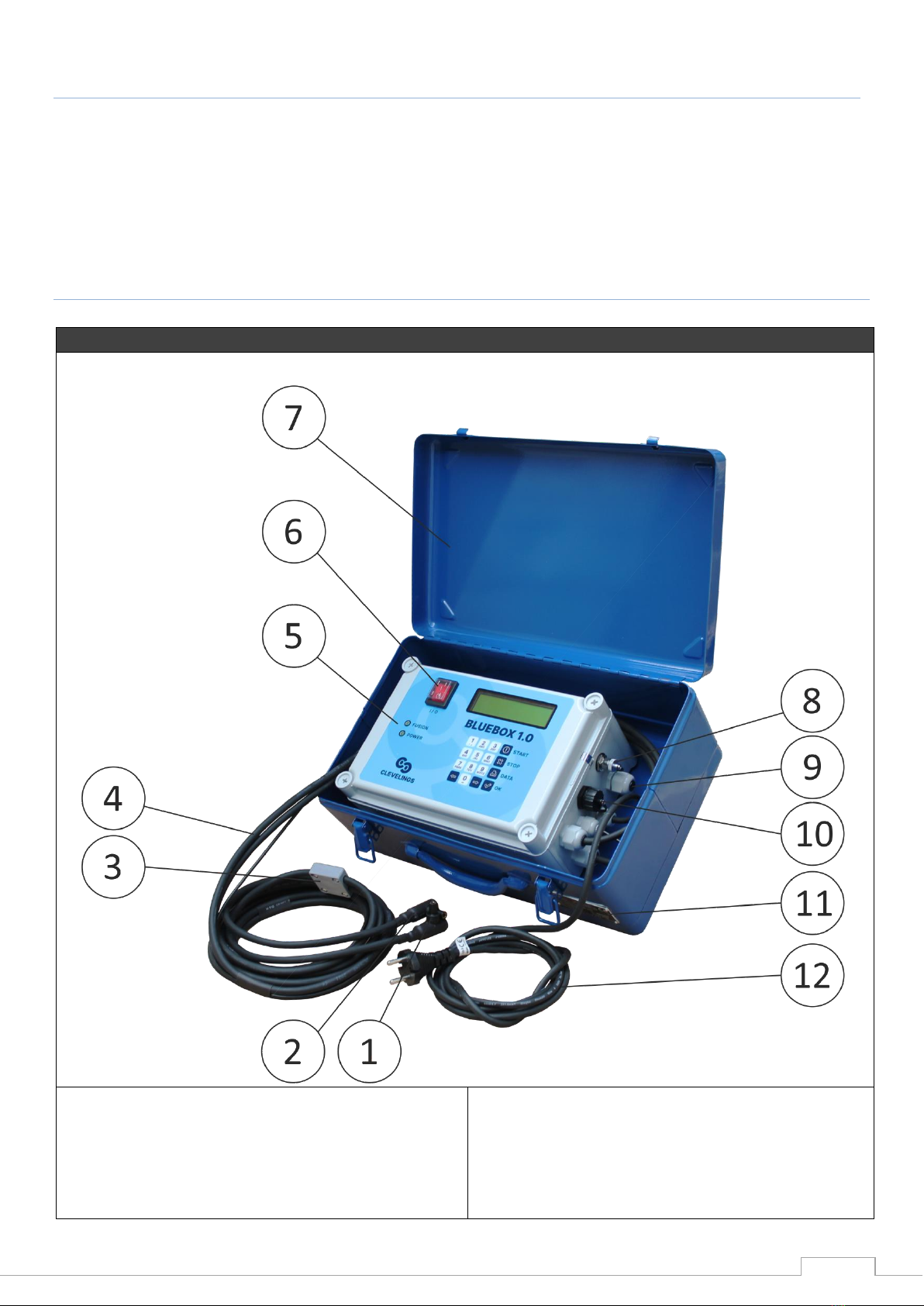

3.1.1 Construction (outside)

BLUEBOX 1.0

1. Adaptor

2. Adaptor connector

3. Outside temperature sensor

4. Output cables

5. Control panel

6. Main power switch

7. Metal transport box

8. M12 port for connectin the barcode scanner / printer

9. Acoustic signal

10. USB-B port (for communicaton with PC)

11. Identification plate

12. Power supply cable

8

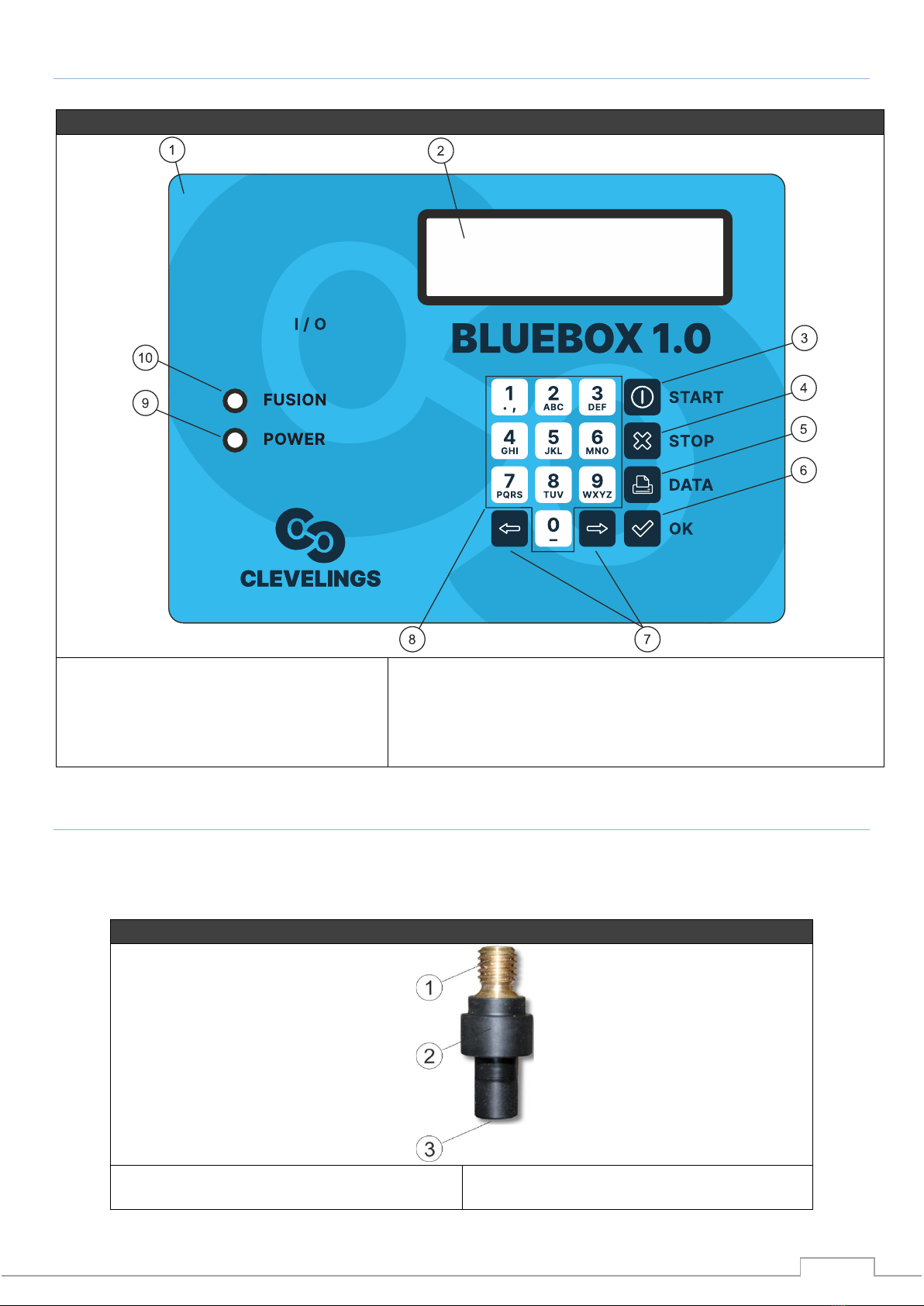

3.1.2 Front panel layout

Control panel

1. Control panel sticker

2. Display

3. START button

4. STOP button

5. PRINT button

6. CONFIRM button

7. Navigation button

8. Alphanumeric keypad

9. Power supply diode

10. ‘Welding in progress’ diode

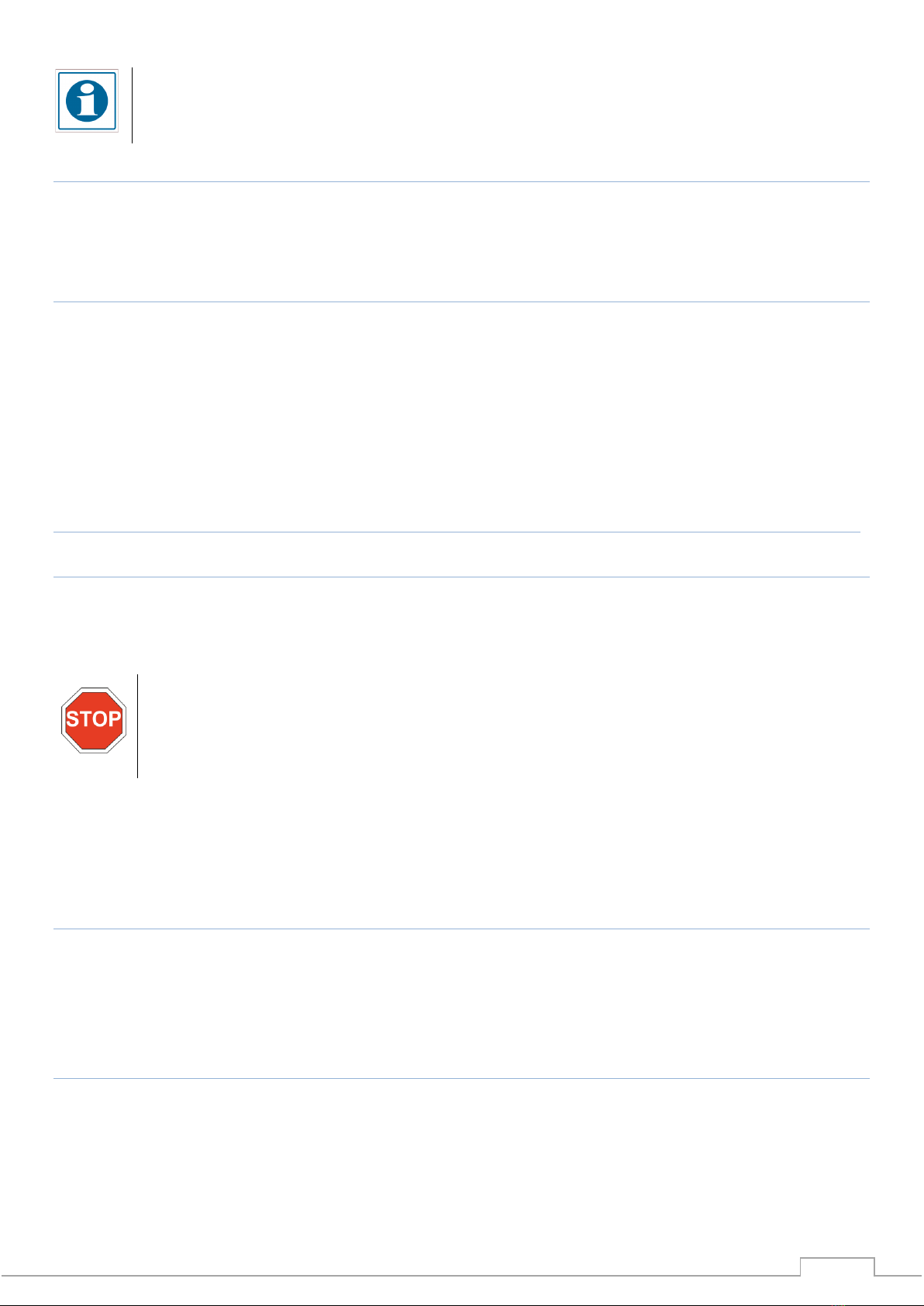

3.1.3 Connection adaptors

Electrofusion welding units are equipped with two output cables ended with threaded connectors on which adaptors are to be

mounted. In standard each device is delivered with set of two adaptors ø4 and two adaptors ø4,7.

Elecrofusion adapters

1. M8 thread

2. Adaptor housing

3. Adaptor socket

Instrukcja

9

3.1.4 Identification plates

Identification plate includes technical characteristics of given model and unique serial number of the device. The plate is attached

to the front part of metal transport case in models BLUEBOX 1.0.

3.1.5 Barcode scanner

Barcode scanner constitutes part of additional equipment options. It’s connected to the welding unit via M12 port. Barcode

scanner uses a laser beam to scan and decode the information contained in the barcode. Barcode scanner is activated when device

is in main menu or in barcode scanner mode. Just point the scanner at the barcode and press the read button. The barcode is

scanned by a red laser beam that must pass through the entire barcode, perpendicular to the barcode line, possibly through the

center of it. The barcode will not be read correctly if the red light beam does not pass through the entire barcode. Optimum

reading results are obtained when the scanner is placed in close proximity to the barcode.

Barcode scanner

Incorrectly printed or slightly damaged barcodes can be read by placing the scanner directly over the barcode, and then, with

the read button pressed, slide the scanner over the barcode. When the barcode is correctly read, the device will emit a sound

signal and the screen will display information about the decoded welding parameters.

INFORMATION

In order to allow for easier identification of adaptor size, adaptors 4,7mm are market with a groove on its housing.

Adaptors 4mm have plain housing with no marks.

INFORMATION

Before each welding process make sure to check the correctness of montage of adaptors on output cables.

Pay special attention on choosing the right adaptors in relation to the pins located on the fitting. In case wrong

adaptors are used it might happen that welding process will not start, will get aborted or will be carried in incorrect

way.

10

3.1.6 Acoustic signal

1st generation electrofusion welding units use acoustic signal as a confirmation of certain actions performed by the operator.

These signals serve as a confirmation of correctly scanned barcode, finishing the welding process or error signalization.

3.1.7 Keypad

1st generation electrofusion welding units are equipped with keypad allowing to control the device, the keypad consists of

following elements:

Buttons 1-9 serve for inserting information about welding parameters, or editing the operator/site names

Arrow buttons –allow to navigate through the menu

START button –start welding process

STOP –stop welding process or return to previous screen

PRINT –start printing the protocol with the use of thermic printer or edit the name of operator/site (option available only in

units with memory)

3.2 Start-up

3.2.1 Transport, packing and storage

Electrofusion welding units, depending on the model, are originally packaged in cartoon or wooden box. The box is suitably

marked to indicate the correct position for transport and storage.

Electrofusion welding unit shall be kept in horizontal position in well air-conditioned spaces, protected against inadequate

weather conditions and meeting the firefighting requirements. Device shall be stored in temperature -10˚C to +55˚C and air

humidity shall not exceed 95%.

3.2.2. Operating personnel

Electrofusion welding unit should be operated by at least one operator with actual certificate of qualification allowing for joining

PE pipes with electrofusion welding method, proper training and being aware that improper steering could, in extreme cases, lead

to injury or even death of bystanders.

3.2.3. Start-up procedure

1. Make sure that power supply cable is disconnected from power outlet and the main switch is in “0” OFF position.

2. Check the overall condition of the device and electric cables

3. Ensure 230V, 50Hz stable power supply source –from the mains or from power generator of suitable power (detailed

info on p. 8)

4. Install suitable adaptors on the output cables

5. Set the welding unit in the welding area

INFORMATION

Protect the tip of the reader and the scanner window from damage and contamination! The state of the scanner

window directly affects the operation of the scanner.

CAUTION

Remember to protect the device against exposure to water (rain, flood), low temperatures and high humidity

during work, transport and storage. It’s advised to transport the device with ‘covered’ means of transport.

Instrukcja

11

6. Connect the power supply cable to the AC power outlet.

7. Turn on the device by turning the main switch to position “1” ON

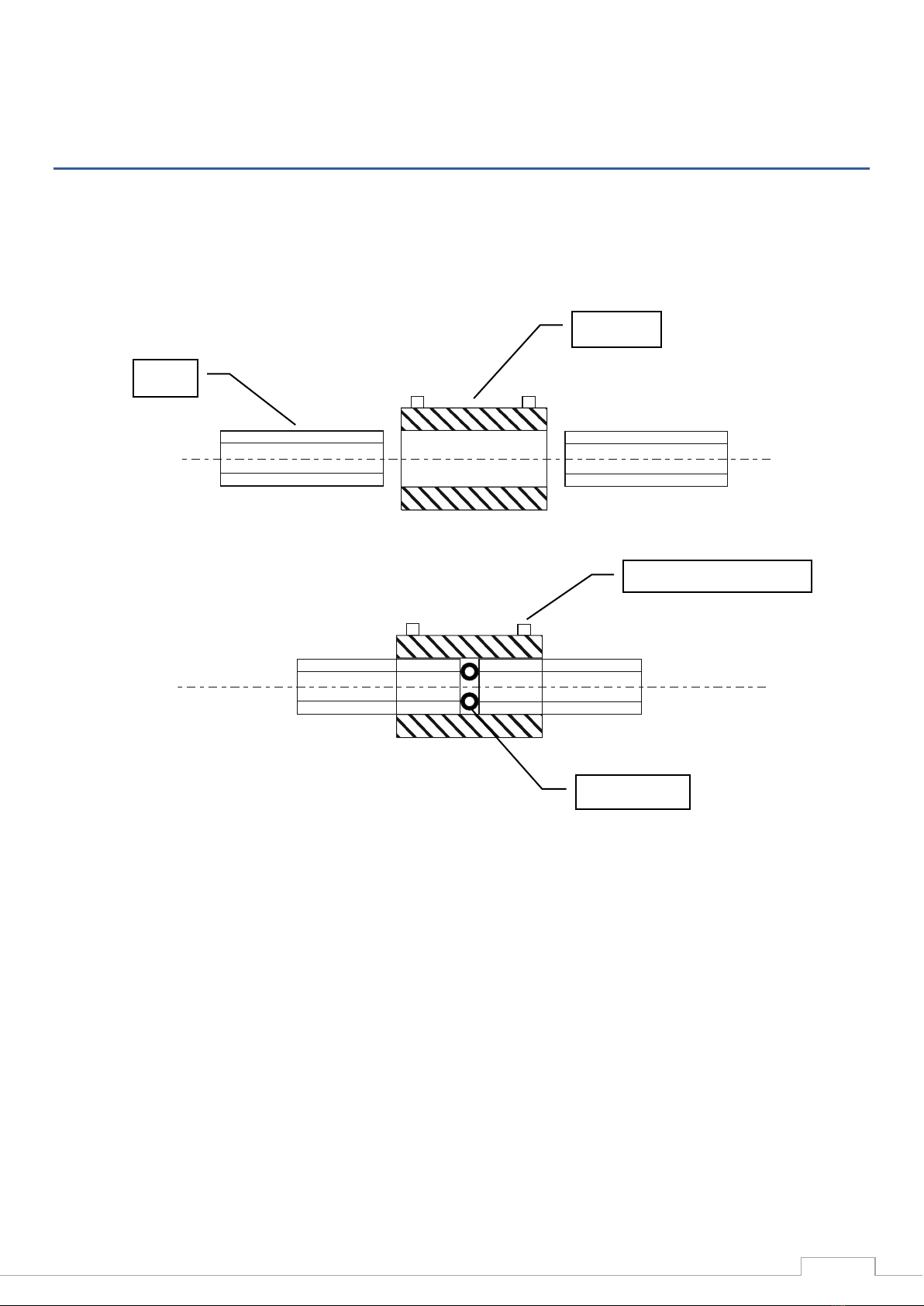

4. WELDING PROCESS

The electrofusion welding process is based on the use of heat, which is released when the current flows through the resistance

wire to heat the inner surface of the fitting and the outer surface of the pipe. The following picture shows how such connection

is formed.

Electrofusion welding process shall be carried accordingly to below general instructions and specific recommendations provided

by the fitting manufacturer:

1. Prepare the welding area

2. Clean the pipe ends

3. Cut the end of the pipe perpendicular to its axis

4. If the pipe isn’t round use special re-rounding tool

5. Verify if the fitting parameters match the pipe (diameter and SDR)

6. Mark the pipe insertion depth, or in case of saddles - the scraping area, with a marker.

7. Scrape the layer of 0,1-0,2 mm until the marker traces are no longer visible. It’s recommended to scrape even further

beyond marked area so that there is no doubt about the operation. Scraping marks should be visible on both sides of

welded fitting, or around the saddle.

8. Verify the correctness of scraping (removing oxidized layer of PE)

9. Clean the pipe inner and outer surface and inner surface of the fitting with suitable cleaning agent e.g. isoprophyl alcohol

soaked in absorbent, lint-free, non-pigmented material.

10. Mark the pipe insertion depth once again

11. Insert the pipes into the fitting and verify the insertion depth. All elements must be dry.

12. Fix the assembly in an aligner to ensure firm holding, in case of saddles –mount them accordingly to the instructions of

manufacturer.

spacer

pipe

Connection pin

fitting

12

13. Make sure if the welding unit has CE marking, valid calibration certificate and verify if the power supply source provides

correct parameters.

14. Connect the output cables to the fitting

15. Make sure the electrofusion adaptors match the fitting’s pins

16. If the device is equipped with additional options such as barcode scanner or thermal printer make sure to connect them

before turning on the welding unit.

17. Turn on the electrofusion welding unit

18. Adjust the welding parameters accordingly to the data provided on the fitting

19. Launch the welding process

20. Make sure that the process went smooth without any interruptions (no warning messages displayed)

21. Leave the assembly inside the aligner for the time of 1,5e [min] (e- pipe wall thickness)

22. Once the process is finished turn off the welding unit and pull out the output cables.

23. Mark the pipe with joint number, date of welding, and number of welder’s qualification certificate

24. Enter the parameters of performed joint onto the welding protocol if the machine has no internal memory storage.

5. OPERATING INSTRUCTIONS

5.1 Starting messages

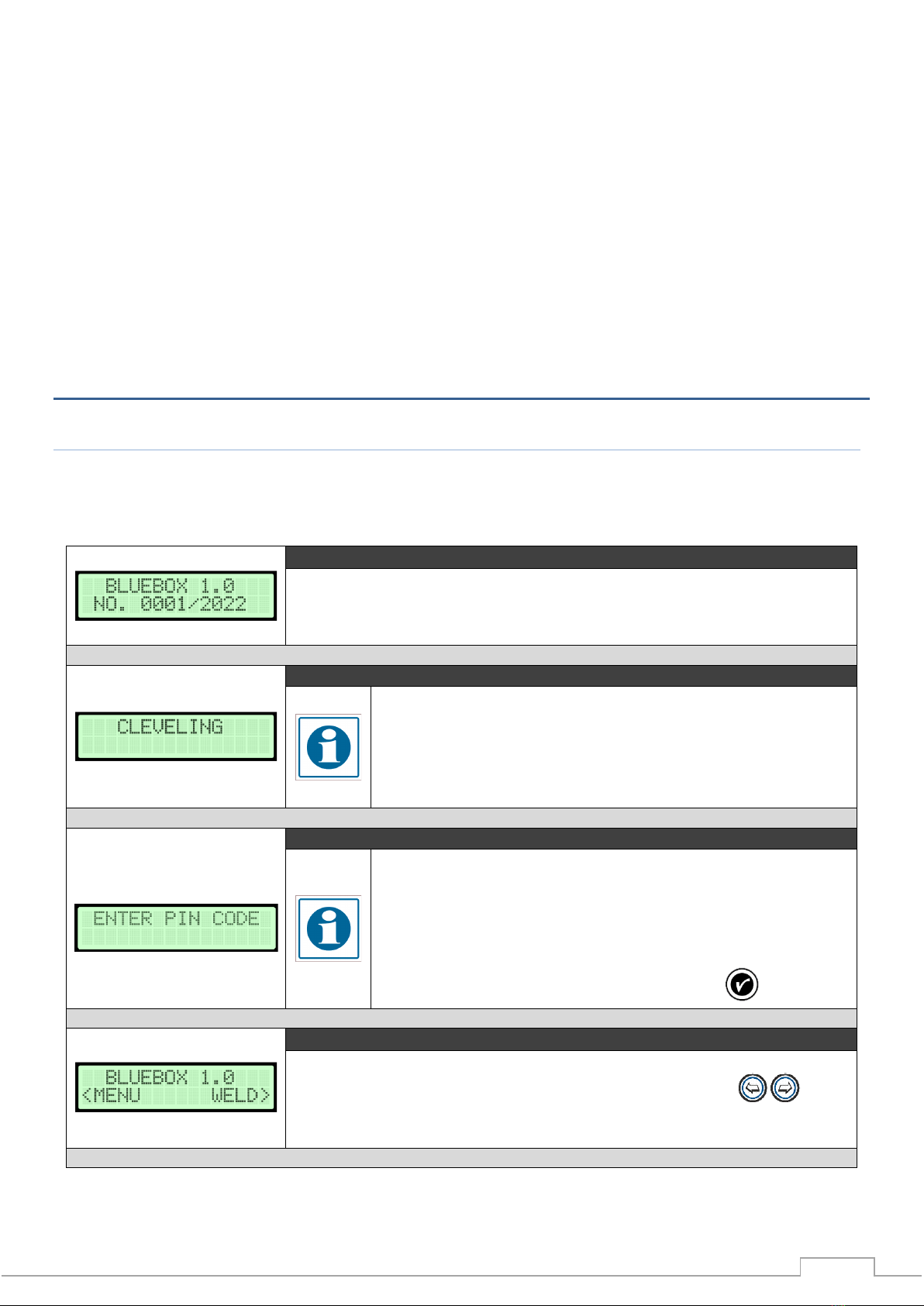

Turn the main switch to position ”1” ON. If the power supply voltage fits within required range device will start and be ready for

work.

LAUNCH SCREEN

On the screen are displayed following information: device type (model) and its serial

number

OWNER INFO

INFORMATION

Changing the owner's name is possible from the level welding

machine settings. Detailed description in the further part of the

manual.

PIN REQUEST

INFORMATION

If the PIN request function is turned on you will need to enter the PIN code

before accessing the main menu. PIN code is located on the warranty card

delivered together with the device. User cannot change the PIN code. Pin

code request can be turned off from the menu level.

In order to enter the code use keypad and then press to confirm.

MAIN SCREEN

Once the device is turned on it will display the main menu screen. Use

buttons to choose between MENU and WELD functions.

Instrukcja

13

5.2 Welding

WORK MODES

Electrofusion welder allows for work in four modes, three of which are operated manually

and these are: ‘manual’, ‘manual barcode’ and ‘as previously’. Barcode scanner is available

only for operators that are equipped with barcode scanner.

Use buttons to choose desired work mode and press to confirm.

MANUAL MODE

In manual mode operator has to enter all relevant parameters of welding process: welding

voltage, welding time, and cooling time. The parameters shall be taken directly from

electrofusion fitting or from special card provided by the manufacturer.

INFORMATION

When entering the heating time make sure to correct this value with

consideration to outside temperature. Outside temperature is indicated

on the screen as ‘To’.

To enter required information use buttons and alphanumeric keypad 0-9. Using

the arrows choose the character you wish to edit (currently edited character will be

highlighted), and then edit the value accordingly. Press to confirm. In order to return

to previous screen press .

SCANNER MODE

INFORMATION

Scanning the barcode can be done from scanner work mode level as well as

directly from the main menu screen.

In order to scan the barcode correctly direct the laser beam toward the barcode (from

suitable distance) and press the button located on the scanner. If the action is performed

correctly device will signalize it with short acoustic signal and proceed to the next step.

INFORMATION

Laser beam must cover entire length of the barcode.

14

INFORMATION

It’s advised to adjust the welding parameters through barcode scanner or by

entering the barcode manually. Both methods speed up the welding process

and eliminate the possibility of human error and automatically adjust the

heating time depending on the outside temperature.

INFORMATION

If there is no information in the barcode about cooling time, second fitting

diameter or fitting type, device will display a message asking to fill these

information manually.

BARCODE MANUAL

In manual barcode mode operator can enter the numerical code located underneath the

barcode manually (in case the scanner is damaged or there isn’t one). Enter the code using

alphanumeric keypad and confirm with .

AS PREVIOUSLY

Last work mode allows the operator to reuse the welding parameters from last correctly

performed weld. Choosing this work mode will allow you to skip entering the welding

parameters and automatically proceed to the next step.

POWER SOURCE

Before beginning the welding process operator has to select the power source to which

the machine is connected.

INFORMATION

Selection of power source is related with control mode that is used during

welding process (see page 21) and choosing wrong type of power source

might affect the welding process.

SUMMARY AND ADDITIONAL INFORMATION

Once the welding parameters are entered device will ask if an aligner is being applied for

the process.

Next, device will proceed to summary screen showing all previously entered parameters.

Press START to begin the welding process

WARNING

Operator should verify if entered parameters are correct. Starting the welding

process using inadequate parameters could pose a direct threat to one’s

health and life. Welding process can be aborted at any given moment by

pressing STOP button or turning it off with main power switch. If the welding

process gets aborted with STOP button such information will be saved in the

welding protocol, whereas when the process is aborted by turning off the

device no information will be saved in the memory.

Instrukcja

15

FITTING TEST

Before starting the welding process the welding unit will perform a short test of connected

fitting to confirm that the right type of fitting is connected. During the test device

measures the fitting resistance and compares it with the resistance encoded in the

barcode.

In case no discrepancies have been detected device will proceed and begin the welding

process. If however device detects discrepancies between the resistance encoded in the

barcode and the actual measured value device will display an error message. Because the

resistance might change depending on outside conditions error message doesn’t

necessarily mean there is a problem, especially in case of smaller diameter fittings. If the

operator is certain that the welding parameters are correct he can force the welding

process by skipping/ignoring the error messages and continuing the work.

INFORMATION

Fitting test will not be carried in three cases:

•Welding parameters were set manually

•The energy delivered to the fitting during the test might damage the fitting

(applies mostly to small diameter fittings e.g. 20, 25mm which have short

heating time and low welding voltage)

•Resistance encoded in the barcode is saved as non-controlled parameter

(resistance equal to 0 Ohm)

Last message before actual welding process the device counts down the time to starting

the welding process. During this time the operator has the possibility to abort the process

by pressing the button.

When the process is complete, the welding machine will automatically start the

programmed cooling time. For welding machines with parameter recording, the

interruption of this process by pressing a button will be recorded in the protocol.

5.3 SETTINGS

SETTINGS

User can modify some of the basic settings in the SETTINGS menu.

DISPLAY

In display settings user can turn on/off the backlight by pressing one of buttons

while in BACKLIGHT menu. Press to proceed to brightness settings. In order to adjust

the brightness use buttons.

16

DATE AND TIME

Next, are the date and time settings. In order to adjust the values use alphanumeric

keypad. Currently edited character is marked by flashing rectangle. Using arrow buttons

choose the character you wish to edit and then, using alphanumeric buttons, edit the

value. Press to confirm. In order to return to previous screen press

OWNER

Changing the owner info can be done in two ways –using the NT Connection software or

directly on the device. In case of the second method use alphanumeric keypad to enter

desired information. Currently edited character is marked by flashing rectangle. Using

arrow buttons choose the character you wish to edit and then, using alphanumeric

buttons, edit the value. Press to confirm. In order to return to previous screen press

.

CALIBRATION CHECK

The user can also check the calibration validity date. Additionally device will display a

reminder few days before expiration of calibration certificate.

INFORMATION

30 days before the calibration ends within each start-up device will display a

message that calibration will soon expire. Once the calibration expires device

will show message: calibration expired. Devices with expired calibration

aren’t automatically stopped. They will continue to work but each weld

recorded in the memory will be described as performed on non-calibrated

device. Manufacturer takes no responsibility for welds performed on devices

without valid calibration certificate.

ABOUT DEVICE

In settings menu you can also check the device information which include: device type,

serial number and software version.

LANGUAGE

Using buttons user can choose between available language versions.

Press to confirm.

CONTROL MODE

Operator, before starting the welding process has the option to choose between two

control modes:

-Fast mode –required welding voltage is reached in shortest time possible

-Normal mode –required welding voltage is reached gradually, in relatively

longer time than in case of fast control mode. The aim of using normal mode is

to eliminate the issues with stable work of power generator.

Instrukcja

17

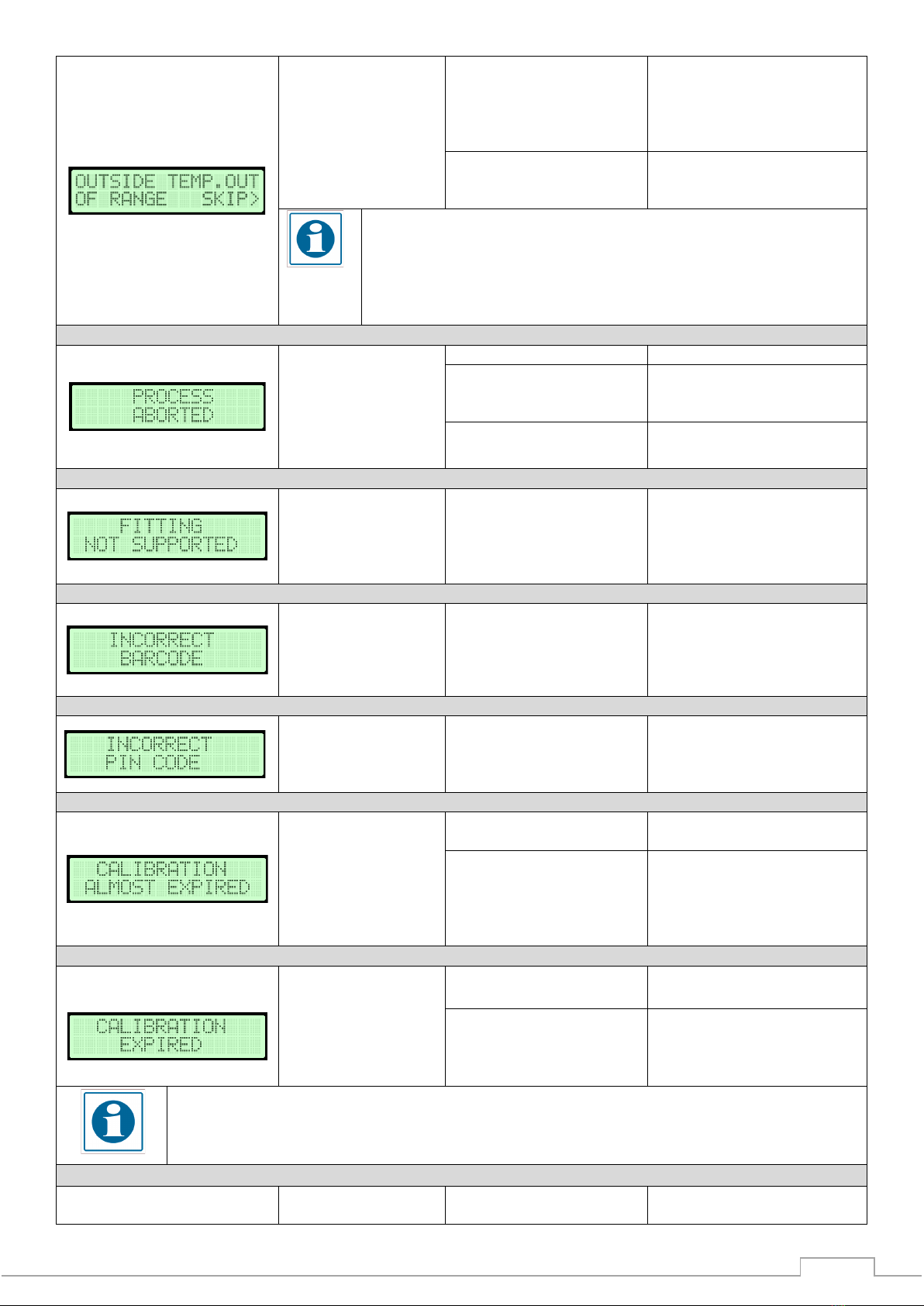

6. TROUBLESHOOTING

Message

Symptom

Possible cause

Solution

1. Device isn’t welding

1. Damaged fitting

1. Use new fitting

2. Damaged or mismatched

output adaptors

2. Check the condition of

adaptors, match the right

adaptors in relation to the

fitting output pin

3. Damaged cable

3. Deliver the device for service

1. Device isn’t welding

1. Too high/low temperature

of the transformer. Large

amount of welds performed

one after another without

breaks for cooling time

1. Leave the device in shaded

area until the temperature

returns to allowed level

2. Damaged temperature

sensor of the transformer

2. Deliver the device for service

INFORMATION

Fast mode is used always when machine is powered from the electrical grid.

Normal mode (if power source was correctly selected in settings menu) is

used only when power source was selected as power generator.

TRACEABILITY*

Device allows to record fitting and/or pipe information saved within the barcode. By

default this option is deactivated. Using buttons user can turn the traceability

on/off.

PIN CODE

Device can be locked with PIN code. If this function is activated, device will ask to enter

the pin code with each start.

INFORMATION

PIN code is located on the warranty card delivered together with the

device. PIN code is a factory set value and cannot be modified by the user.

Devices for some markets are delivered without the feature of PIN

protection.

FITTING TEST

In the device there is an option to turn on/turn off the fitting test, which is make before

the start of welding process (description page 23).

18

1. Too high/low outside

temperature. Allowed

temperature range 0-40°C

1. Make sure to level out the

outside temperature to

adequate by e.g. protecting the

device against direct sunlight,

welding in protective tent.

2. Damaged sensor of outside

temperature

2. Deliver the device for service

INFORMATION

There is an option to perform welding in emergency situations, even if the

temperature is outside allowed range. For that purpose choose SKIP option

by pressing the -> button. Weld performed in such conditions will be saved

in the memory with adequate error code.

1. Welding process got

aborted

1. Damaged fitting

1. Perform new weld

2. Output cable disconnected

from the fitting during

welding process

2. Perform new weld

3. Damaged output cable

3. Deliver the device for service

1. Device doesn’t allow

to start welding

process

1. Welding voltage or fitting

resistance are outside device

working range

1. Replace the fitting with the

one that is within the working

range of the welding unit or use

welding unit with higher

working parameters.

1. Device doesn’t start

welding process

1. Entered barcode is

incorrect

1. Enter the barcode again or

perform the welding process in

manual mode

1. Device doesn’t start

1. Entered PIN code is

incorrect

1. Correct PIN code can be

found on the warranty card

1. Calibration will soon

expire

1. Contact service department

to arrange calibration check

2. Invalid date and time

2. Check date and time settings

in device setting menu. If the

problem keeps occurring

deliver the device for service to

replace the internal battery.

1. Calibration got expired

1. Contact service department

to arrange calibration check

2. Invalid date and time

2. Check date and time settings

in device setting menu. If the

problem keeps occurring

deliver the device for service.

INFORMATION

Whenever the calibration expires, the device won’t stop working, and will return to normal work after

displaying message about expired calibration. Welds performed on welding unit without valid calibration

certificate are saved in the memory with adequate error code.

1. Device doesn’t start

1. Mains voltage is above

acceptable level of 265 V.

1. Check the mains parameters

Instrukcja

19

2. Power generator isn’t

working in stable manner

2. Send the power generator

for service

3. Damaged component

3. Deliver the device for service

1. Device doesn’t start

1. Mains voltage is below

acceptable level of 195 V.

1. Check the mains parameters

2. Power generator isn’t

working in stable manner

2. Send the power generator

for service

3. Damaged component

3. Deliver the device for service

1. Welding cannot be

carried

1. Welding current is outside

working range of the device

1. Short-circuit in welding

circuit

2. Use welding unit of higher

power or fitting with lower

power demand

3. Damaged welding unit –send

the device for service

1. Welding process got

aborted

1. Cables got disconnected

during welding process

1. Repeat the welding cycle

2. Damaged cable/s.

2. Deliver the device for service

1. Welding cannot be

carried

1. Supply current frequency

is outside allowed range

1. Check the mains/generator

2. Damaged welding unit

2. Deliver the device for service

7. MAINTENANCE

DANGER

Each maintenance work shall be performed while the power supply are disconnected from power outlet.

Use and maintenance

Device doesn’t require any special maintenance conditions, except for keeping it in general cleanness. Standard maintenance

works are limited to periodical cleaning of external surfaces of the device.

Electrical components

Pay special attention during storage, use and transport that the electrical components are not exposed to water (rain, drowning)

or moisture.

List of wear parts:

1. Electrical components: power supply cables, output cables;

2. Other: adaptors;

In case of failure turn off the device by pull the plug from power outlet. Such fact shall be immediately reported to the superior.

Warranty and post-warranty repairs are performed after delivering the device to the producer service department as stated in

warranty terms and conditions.

In accordance with requirements and provisions regarding welding devices, the welding unit is subjected to obligatory annual

inspection performed by the producer or other authorized entities. During the inspection a complete examination for correct

Table of contents

Popular Welding System manuals by other brands

Forney

Forney TIG quick start guide

ESAB

ESAB 350mpi instruction manual

Hobart Welding Products

Hobart Welding Products IronMan 275 owner's manual

WeldMate

WeldMate 60A Owner's Manual and Operating Instructions

Lincoln Electric

Lincoln Electric Linc Feed 24M Operator's manual

Hobart Welders

Hobart Welders H100L4-10 owner's manual

EWM

EWM T5.00-AC/DC Comfort 3.0 operating instructions

Lincoln Electric

Lincoln Electric LN-10 HEADS & CONTROLS IM587-B Operator's manual

Fire Power

Fire Power TIG 140 AC/DC operating manual

Fytech

Fytech FY-91G owner's manual

Sel

Sel genesis 200 ac-dc/tlh instruction manual

Lincoln Electric

Lincoln Electric PRO-CUT IM637-A Operator's manual