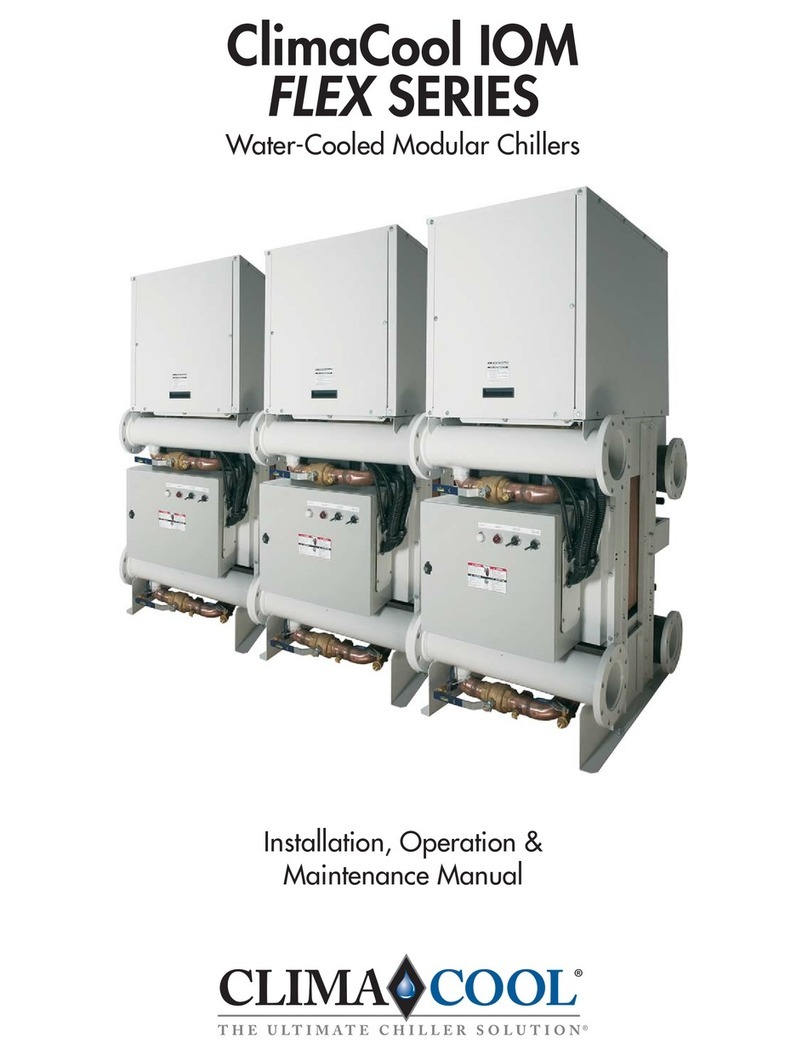

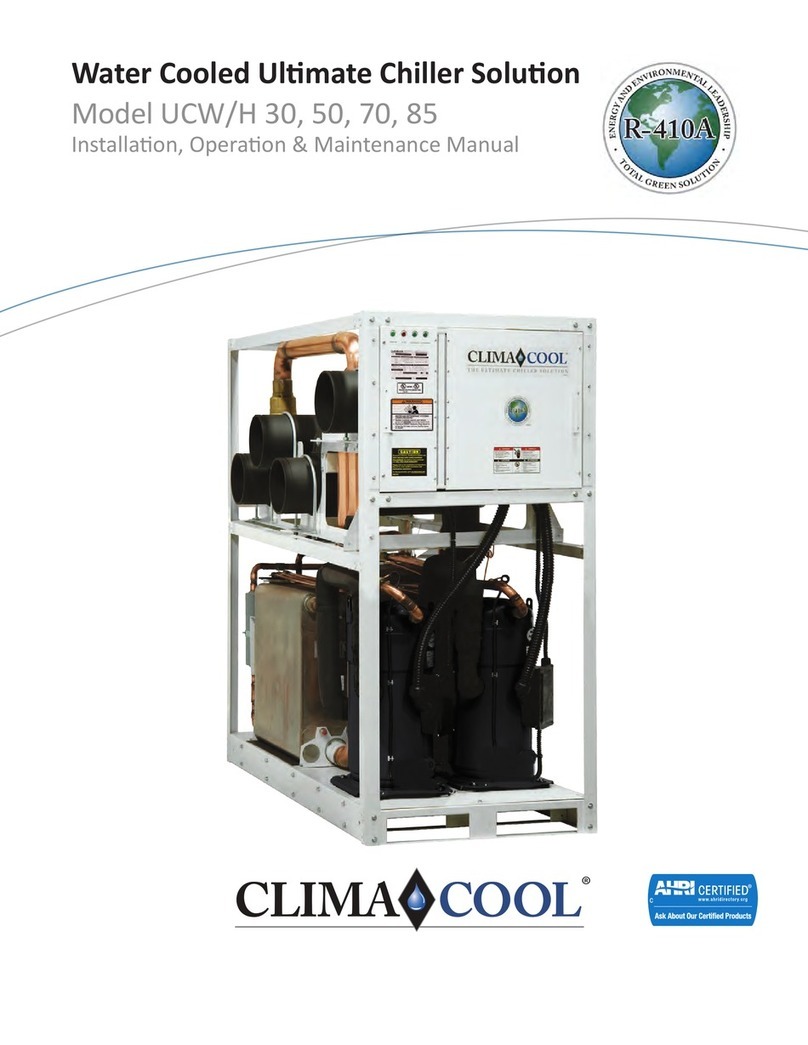

ClimaCool UCA 20 User manual

Packaged Air Cooled Modular Chiller

Water Cooled, Heat Pump, Heat Recovery and

^ŝŵƵůƚĂŶĞŽƵƐ,ĞĂƟŶŐĂŶĚŽŽůŝŶŐ,ĞĂƚWƵŵƉ

Model UCA 20, 30, 50 & 70

/ŶƐƚĂůůĂƟŽŶKƉĞƌĂƟŽŶΘDĂŝŶƚĞŶĂŶĐĞDĂŶƵĂů

on

DEMAND®

SIMULTANEOUS HEATING AND COOLING

Introduction.........................................1

Pre-Installation.......................................2

PhysicalData....................................... 3-5

DimensionalDataandDrawings......................6-8

RiggingandLiftingProcedures.........................9

MountingRailandVibrationIsolation..................10

RecommendedServiceClearances..................... 11

ModelKey..........................................12

UnitInstallation...................................13-14

ElectricalConnection.................................15

WiringDiagram-Voltage/PhaseMonitor ................16

WaterPiping......................................17-18

Ƥ ..........................19

HydronicRefrigeration...............................20

PartLoadPerformanceAdvantage .................... 21

FillingtheWaterSystem..............................22

WaterTreatment....................................23

WaterTemperatureRequirements.....................24

EvaporatorWaterPressureDropCharts.............25-26

Operational Limitations ..............................27

Pre-Startup.........................................28

Pre-StartupCheckList................................29

Startup.......................................... 30-31

Superheat&SubcoolingFlowChart....................32

StartupandWarrantyForm...........................33

OperationandMaintenance ..........................34

CondenserFans.....................................35

HeatExchangers ....................................36

CleaningArrangement ...............................37

CompressorInformation .............................38

RefrigerationCircuitDiagram ...................... 39-41

HeadPressureControlValveOperation(LAC)...........42

RefrigerationSystemsRe-ProcessingandCharging......43

Ƥ ...................44-45

Options&Accessories ...............................46

StainlessSteelStrainerOption ..................... 47-51

WYEStrainers.................................... 52-53

BasketStrainers..................................54-55

ElectricalData....................................56-57

PowerDistributionDrawing...........................58

WiringDiagrams..................................59-87

TroubleshootingGuide...............................88

Warranty...........................................89

Table of Contents

1

R

R

www.climacoolcorp.com

General Description

ClimaCool’sAir Cooled Packaged Modular Chiller, Model

UCA, are available in 20, 30, 50 and 70 tons and can be

Ƥ

requirements from 20 to 420 tons. By simply adding

modules, the UCA can satisfy future incremental growth

needs. This model is a quiet, serviceable and extremely

ƥǤ

Safety

Throughout this manual warning, danger, caution and

attention notices appear. Read these items carefully before

attempting any installation, service or troubleshooting

of the equipment. All labels on unit access panels must

be observed.

WARNING: Indicates potentially hazardous situation which,

ǡǤ

DANGER: Indicates an immediate hazardous situation

ǡǡǤ

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice which, if not avoided, could result in minor

Ǥ

ATTENTION: Ƥǡ

maintenance information which is important, but not

hazard related.

Introduction

If this unit uses a 3 Phase Scroll

Compressor, the following

instructions MUST BE followed:

• Unit power supply MUST BE

wired in the proper sequence to

avoid damage to the 3 Phase

Scroll Compressor;

• Scroll Compressors with

INCORRECT rotation show the

following characteristics:

- High sound level;

- High suction pressure and

low discharge pressure;

- Low current draw.

• If any of the three above

characteristics exist, swap two of

the three supply wires at the

disconnect and recheck

compressor for incorrect rotation.

Si cet appareil utilise

compresseur scroll 3-Phase, les

instructions suivantes doivent être

suivies:

• L’alimentation de l’appareil doit

être monté dans l’ordre correct

pour éviter endommager le

compresseur scroll 3-Phase

• Compresseurs scroll avec

rotation incorrecte montrent les

caractéristiques suivantes:

- Haut niveau de son;

- Pression d’aspiration élevée

et une faible pression de

décharge;

- Faible ampérage

• Si l’un des trois éléments

mentionnés ci-dessus sont

remplies , échanger deux des

trois lignes électriques alimen

tant la interrupteur de sécurité et

YpUL¿HUODURWDWLRQGX

compresseur.

3 PHASE SCROLL

COMPRESSOR UNITS UNITÉ DE COMPRESSEUR

SCROLL 3-PHASE

CAUTION/ATTENTION

CAUTION/ATTENTION

Excessive Chlorine,

undissolved solids and other

improper water conditions

WILL DAMAGE the internal

heat exchanger & WILL VOID

YOUR WARRANTY!

Chlore excessive, solides non

dissous et les autres impropre

conditions de l’eau,

ENDOMMAGERA l’échangeur

de chaleur interne et

ANNULERA VOTRE

GARANTIE!

Very Hot Water! L’eau Trés Chaude!

WARNING/AVERTISSEMENT

CAUTION/ATTENTION

Use only copper conductors

IRU¿HOGLQVWDOOHGZLULQJ8QLW

terminals are not designed to

accept other types of

conductors.

Utilisez uniquement des

conducteurs en cuivre pour le

câblage. Bornes de l’unité ne

sont pas conçus pour

accepter d’autres types de

conducteurs.

Disconnect power supply

(ies) before servicing. Refer

VHUYLFLQJWRTXDOL¿HGVHUYLFH

personnel. Electric shock

hazard. May result in injury

or death!

Unit to be serviced by

TXDOL¿HGSHUVRQQHORQO\

Refrigerant system under

pressure. Relieve pressure

before using torch. Recover

refrigerant and store or

dispose of properly.

Debrancher avant d’entre-

prendre le dépannage de

l’appareil. Consulter un

UpSDUDWHXUTXDOL¿HSRXUOH

dépannage. Risque de choc

électrique. Résiltat de mai

dans dommages ou la mort!

Conifer la maintenance à

XQWHFKQLFLHQTXDOL¿H/H

V\VWpPHIULJRUL¿TXHVRXV

pression. Décomprimer avant

G¶H[SRVHUjODÀDPPH

Récuperer le frigorigene et

le stocker ou le détrulre

correctement.

WARNING/AVERTISSEMENT

CAUTION/ATTENTION

WARNING/AVERTISSEMENT

W

W

W

WATER AND REFRIGERANT

SYSTEMS UNDER PRESSURE

• Isolate/Lockout source

and relieve pressure

BEFORE servicing

equipment.

• Failure to relieve pressure

may result in property

damage, serious bodily

injury or death!

EAU ET FRIGORIGÈNE

EQUIPEMENTS SOUS

PRESSION

• Isoler la source / de

verrouillage et de

soulager la pression

avant entretien de l’équi-

pement.

• Le défaut de soulager la

pression peut entraîner

des dommages matériels,

des blessures corporelles

graves ou la mort!

ATTENTION

To avoid the release of refrigerant into the atmosphere, the

refrigerant circuit of this unit must be serviced only by

WHFKQLFLDQVZKRPHHWORFDOVWDWHDQGIHGHUDOSUR¿FLHQF\

requirements.

All refrigerant discharged from this unit must be recovered

WITHOUT EXCEPTION. Technicians must follow industry

accepted guidelines and all local, state and federal statues for

the recovery and disposal of refrigerants.

If a compressor is removed from the unit, system refrigerant

circuit oil will remain in the compressor. To avoid leakage of

compressor oil, the refrigerant lines of the compressor must be

sealed after it is removed.

Do not defeat, cap, add piping to the outlet of the

valve or attempt to change the relief setting.

ATTENTION

&RQ¿UPDOOSDQHOVDQGHOHFWULFDOFRYHUVDUH

properly installed/sealed, including the condenser

fan motor cover.

ATTENTION

CAUTION/ATTENTION

Single wall heat

exchanger, not suitable

for potable water

connection.

Single paroi echangeur,

non approprié pour le

raccordement d'eau

potable.

R

R

www.climacoolcorp.com

2

Inspection

Upon receipt of equipment, carefully check the shipment

against the bill of lading and inspect each chiller for

any damage incurred during shipment. Thoroughly

check for any visible damage of control panels, electrical and/

or refrigeration components or broken copper lines. Be sure

the nameplate voltage agrees with the site voltage. The carrier

must make proper notation of any damages or shortages

on all copies of the bill of lading and complete a common

Ƥ

shipment. Note:Ƥ

all necessary claims with the carrier. In addition, please

notify the ClimaCool Customer Service Department at

all damage immediately.

Storage

Installation and storage of Packaged Air Cooled chillers, in locations

with ambient temperatures below 40°F, will require a suitable

antifreeze solution.

Handling of Modules

Carefully remove the module’s packaging. The chiller’s steel

base cutouts provide maneuverability by forklift or pallet

Ƥȋ

Figures 7, 8 and 9 on page 9). Verify that all header grooved

couplings, groove by groove 6” nipples and mounting hardware

kits are on site prior to connecting the modules.

Rigging and Lifting

Each module should be lifted by using a fork lift. If it is

necessary to utilize a crane for rigging or lifting each module

shall be lifted by using lifting straps and spreader bars using

Ƥ

on page 9.

Warranty

To ensure proper equipment longevity, design performance

and reliability, all ClimaCool chillers must be installed, operated

and maintained in accordance with ClimaCool IO&M manuals.

Water quality is of the utmost importance for the proper

care and maintenance of your modular chiller system and

regular treatment of the water will increase longevity of your

system. Ƥ

evaporator water will void the ClimaCool module’s warranty.

A factory authorized technician is required to perform the

startup of your ClimaCool chiller. Please contact the ClimaCool

Service Department at 405-815-3000 or at technicalsupport@

climacoolcorp.com to schedule. There is a minimum of (three)

3 weeks notice required to schedule your factory startup.

Pre-Installation

3

R

R

www.climacoolcorp.com

Physical Data

1

20 30 20 30 20 30

18.4 27.5 17.9 26.7 17.9 26.7

EER 10.3 10.3 9.97 9.97 9.97 9.97

22 2 2 2 2

scroll scroll scroll scroll scroll scroll

2222 22

10 15 10 15 10 15

50 56 50 54 50 54

2,250 2,410 2,250 2,410 3,115 3,275

2,035 2,195 2,035 2,195 2,735 2,895

20 30 20 30 20 30

T.E. T.E. T.E. T.E. T.E. T.E.

HP 2.0 2.0 2.0 2.0 2.0 2.0

1212 12

Fan Type Axial Axial Axial Axial Axial Axial

Diameter 31.5" 31.5 31.5" 31.5 31.5" 31.5

Airflow (cfm per circuit) 6000 9,800 6000 9,800 6000 9,800

RPM 1,100 1,100 1,100 1,100 1,100 1,100

650 650 650 650 650 650

20 30 20 30 20 30

Fin Material Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum

Tube Material Copper Copper Copper Copper Copper Copper

Dimensions (Quantity) 22" x 78" (4) 22" x 78" (4) 22" x 78" (4) 22" x 78" (4) 22" x 78" (4) 22" x 78" (4)

Rows Deep 34 3 4 3 4

Fins Per Inch 12 12 12 12 12 12

20 30 20 30 20 30

Brazed Plate Brazed Plate Brazed Plate Brazed Plate Brazed Plate Brazed Plate

2222 22

2.6 2.6 2.6 2.6 2.6 2.6

39.6 39.6 39.6 39.6 76.6 76.6

300 300 300 300 300 300

6" 6" 6" 6" 6" 6"

Notes:

1. SHC - Simultaneous Heating and Cooling Heat Pump

2. Unit tonna

g

e ARI ratin

g

conditions: 44°F leavin

g

chilled water temperature, 95°F enterin

g

condenser air temprature, flow rate is

2.4 GPM per ton throu

g

h the evaporator with a .0001 foulin

g

factor.

3. Module operational wei

g

ht includes water, compressor oil, and refri

g

erant char

g

e. Multiply times the number of modules for a

total system operational wei

g

ht.

4. Unit shippin

g

wei

g

ht includes refri

g

erant char

g

e, compressor oil and packa

g

in

g

; based on transportation.

5. Main header water/fluid connections are ASME, 6" scheduled 40 pipe with

g

rooved couplin

g

s, 300 psi

g

manimum workin

g

pressure.

6. Each refri

g

erant circuit is capable of providin

g

reliable operation down to 20°F ambient with proper freeze protection.

Condenser Fans

Evaporator

Maximum Design Working Pressure - Water Side (PSI)

Model UCA

Condenser Coils

Cooling Only Heat Pump

Header Water Connections - Inlet/Outlet (inches)5

Maximum Design Working Pressure - refrigerant (PSI)

Heat Exchanger (Type)

Independent Refrigerant Circuits (quantity)

Water Storage Volume HX Only (gals.)

Module Shipping Weight (lbs)΄

Water Storage Volume HX Plus 6" Main Headers (gals)

SHC1

Compressor Quantity

Compressor Nominal Hp (per circuit)

Refrigerant Charge R-410A (lbs)

Module Operating Weight w/Water (lbs)³

Quantity

Motor Type

Capacity (Tons)2

Refrigerant Circuits (quantity)

Compressor Type

.

R

R

www.climacoolcorp.com

4

Physical Data

Model UCA

50 70 50 70 50 70

Capacity (Tons)244.0 62.7 41.4 59.0 41.4 59.0

Efficincy (EER)210.5 10.1 9.88 9.47 9.88 9.47

Refrigerant Circuits (quantity) 2.0 2.0 2.0 2.0 2.0 2.0

Compressor Type Scroll Scroll Scroll Scroll Scroll Scroll

Compressor Quantity 222222

Compressor Nominal Hp (per circuit) 25 35 25 35 25 35

Refrigerant Charge R-410A (lbs) (circuit 1/circuite2) 114 124 110 120 110 120

Module Operating Weight w/Water (lbs)³ 4,101 4,275 4,101 4,275 4706 4880

Module Shipping Weight (lbs)΄3,855 4,005 3,855 4,005 4,255 4,405

Condenser Fans 50 70 50 70 50 70

Motor Type T.E. T.E. T.E. T.E. T.E. T.E.

HP 1.5 1.5 1.5 1.5 1.5 1.5

Quantity 444444

Fan Type Axial Axial Axial Axial Axial Axial

Diameter 31.5 31.5 31.5 31.5 31.5 31.5

Airflow (cfm per circuit) 7,000 10,500 7,000 10,500 7,000 10,500

Max RPM 1,100 1,100 1,100 1,100 1,100 1,100

Maximum Design Working Pressure - refrigerant (PSI) 650 650 650 650 650 650

CondenserCoils 507050705070

Fin Material Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum

Tube Material Copper Copper Copper Copper Copper Copper

Dimensions (Quantity) 22" x 78" (8) 22" x 78" (8) 22" x 78" (8) 22" x 78" (8) 22" x 78" (8) 22" x 78" (8)

Rows Deep 444444

Fins Per Inch 12 12 12 12 12 12

Evaporator 50 70 50 70 50 70

Heat Exchanger (Type) Brazed Plate Brazed Plate Brazed Plate Brazed Plate Brazed Plate Brazed Plate

Independent Refrigerant Circuits (quantity) 222222

Water Storage Volume HX Only (gals.) 4.9 7.7 4.9 7.7 4.9 7.7

Water Storage Volume HX Plus 6" Main Headers (gals) 43.5 48.4 43.5 48.4 43.5 48.4

Maximum Design Working Pressure - Water Side (PSI) 300 300 300 300 300 300

Header Water Connections - Inlet/Outlet (inches)² 6" 6" 6" 6" 6" 6"

Cooling Only Heat Pump SHC

Notes:

1. SHC - Simultaneous Heatin

g

and Coolin

g

Heat Pump

2. Unit tonna

g

e and efficiency at AHRI ratin

g

conditions: 44°F leavin

g

chilled water temperature, 95°F enterin

g

condenser air temprature, flow rate is

2.4 GPM per ton throu

g

h the evaporator with a .0001 foulin

g

factor.

3. Module operational wei

g

ht includes water, compressor oil, and refri

g

erant char

g

e. Multiply times the number of modules for a

total system operational wei

g

ht.

4. Unit shippin

g

wei

g

ht includes refri

g

erant char

g

e, compressor oil and packa

g

in

g

; based on transportation.

5. Main header water/fluid connections are ASME, 6" scheduled 40 pipe with

g

rooved couplin

g

s, 300 psi

g

manimum workin

g

pressure.

.

5

R

R

www.climacoolcorp.com

Physical Data

30 70

T.E. T.E.

HP 2.0 2.0

24

Fan Type Axial Axial

Diameter 31.5 31.5

Airflow (cfm per circuit) 20,000 40,000

RPM 1,100 1,100

30 70

Fin Material Aluminum Aluminum

Tube Material Copper Copper

Dimensions (Quantity) 20" x 78" (4) 20" x 78" (8)

Rows Deep 66

Fins Per Inch 88

30 70

300 300

6" 6"

2,000 4,000

1,590 3,180

Notes:

1. Module operational weight includes water. Multiply times the number of modules for a

total system operational weight.

2. Unit shipping weight includes packaging; based on transportation.

Module Shipping Weight2

Free Cooling Coils

Free Cooling Free Cooling

Module Operating Weight 1

Header Water Connections - Inlet/Outlet (inches)

Quantity

Motor Type

Fans

Miscellaneous Information

Maximum Design Working Pressure - Water Side (PSI)

R

R

www.climacoolcorp.com

6

Dimensional Data and Drawings

Model

UCA Voltage A

Unit Width

(in.)

B

Unit Height

(in.)

C

Unit Depth

(in.)

D

Header

Location

(in.)

E

Header

Location

(in.)

Header

Connection

(in.)

020 208/230/460/575/3/60 Ψ 92 Ψ ΨΟΞ ·ΨΟΞ 6

030 208/230/460/575/3/60 Ψ 92 Ψ ΨΟΞ ·ΨΟΞ 6

Model

UCA1Voltage A

Unit Width

(in.)

B

Unit Height

(in.)

C

Unit Depth

(in.)

D

Header

Location

(in.)

E

Header

Location

(in.)

F

Header

Location

(in.)

Header

Connection

(in.)

050 208/230/460/575/3/60 Ψ ΨΦ ΨΠ ΨΟΞ ·ΨΟΞ ΄ΨΣ 6

070 208/230/460/575/3/60 Ψ ΨΦ ΨΠ ΨΟΞ ·ΨΟΞ ΄ΨΣ 6

Note:

1. The model UCA 050 and 070 cannot be coupled back-to-back.

Control

Box

B

A

Air

Discharge

Figure 1 - Cooling Only, UCA 020 & 030

Figure 2 - Cooling Only, UCA 050 & 070

Air

Discharge

Control

Box

B

A

Air

Discharge

C

D

E

F

Air

Intake Air

Intake

Air

Intake Air

Intake

Chilled

Water

Inlet

Chilled

Water

Outlet

Air Intake

Air Intake

C

D

E

Air

Discharge

Chilled

Water

Outlet

Chilled

Water

Inlet

7

R

R

www.climacoolcorp.com

Dimensional Data and Drawings

Notes:

1. All SHC models cannot be coupled back-to-back.

Model

UCA1Voltage A

Unit Width

(in.)

B

Unit Height

(in.)

C

Unit Depth

(in.)

D

Header

Location

(in.)

E

Header

Location

(in.)

F

Header

Location

(in.)

G

Header

Location

(in.)

Header

Connection

(in.)

020 SHC 208/230/460/575/3/60 Ψ 92 ΨΠ ΨΟΞ ·ΨΟΞ ΄ΨΣ ΨΣ 6

030 SHC 208/230/460/575/3/60 Ψ 92 ΨΠ ΨΟΞ ·ΨΟΞ ΄ΨΣ ΨΣ 6

Model

UCA1Voltage A

Unit Width

(in.)

B

Unit Height

(in.)

C

Unit Depth

(in.)

D

Header

Location

(in.)

E

Header

Location

(in.)

F

Header

Location

(in.)

G

Header

Location

(in.)

Header

Connection

(in.)

050 SHC 208/230/460/575/3/60 Ψ ΨΦ ΨΠ ΨΟΞ ·ΨΟΞ ΄ΨΣ ΨΣ 6

070 SHC 208/230/460/575/3/60 Ψ ΨΦ ΨΠ ΨΟΞ ·ΨΟΞ ΄ΨΣ ΨΣ 6

Figure 3 - Simultaneous Heating & Cooling 020 & 030

Figure 4 - Simultaneous Heating & Cooling 050 & 070

A

B

Air

Discharge

Control

Box

Air

Discharge

Air Intake

Air Intake

C

D

FG

E

Chilled

Water

Inlet

Chilled

Water

Outlet Hot

Water

Outlet

Hot

Water

Inlet

Air

Discharge

B

A

Control

Box

Air

Discharge

Air

Discharge

Air

Intake Air

Intake

Air

Intake Air

Intake

Chilled

Water

Inlet

Hot

Water

Outlet

Hot

Water

Inlet

Chilled

Water

Outlet

C

D

E

FG

R

R

www.climacoolcorp.com

8

Model

UCF Voltage

A

Unit Width

(in.)

B

Unit Height

(in.)

C

Unit Depth

(in.)

D

Header

Location

(in.)

E

Header

Location

(in.)

F

Header

Location

(in.)

Header

Connection

(in.)

030 208/230/460/575/3/60 Ψ 92 Ψ ΨΟΞ ·ΨΟΞ ΄ΨΣ 6

Model

UCF1Voltage

A

Unit Width

(in.)

B

Unit Height

(in.)

C

Unit Depth

(in.)

D

Header

Location

(in.)

E

Header

Location

(in.)

F

Header

Location

(in.)

Header

Connection

(in.)

070 208/230/460/575/3/60 Ψ ΨΦ ΨΠ ΨΟΞ ·ΨΟΞ ΄ΨΣ

6

Dimensional Data and Drawings

Figure 5 - Free Cooling, UCF 030

Figure 6 - Free Cooling, UCF 070

Air

Discharge

B

A

Control

Box

C

Air

Intake

Air

Intake

Air

Intake

Air

Intake E

F

D

Chilled

Water

Inlet

Chilled

Water

Outlet

Air

Discharge

Air Intake

Air Intake

C

E

F

D

Chilled

Water

Inlet

Chilled

Water

Outlet

B

A

Control

Box

Note:

1. The model UCF 070 cannot be coupled back-to-back.

9

R

R

www.climacoolcorp.com

Lifting and Transporting Modules

Forklifts are required for lifting and transporting the

module. Each module has base cutouts provided

for ease of maneuverability.

Rigging

Each module should be lifted by using lift straps threaded

through the steel base cutouts and a spreader bar.

Note: If no spreader bar is used, damage to the module

may occur.

Figure 7

Spreader Bar

Spreader Bar

Lifting Strap

Figure 9

Spreader Bar

Lifting Strap

Figure 8

Rigging and Lifting Procedures

R

R

www.climacoolcorp.com

10

4” Rail Minimum

Recommended

(by others)

Concrete Pad (by others)

4” Rail Minimum

Recommended

(by others)

Spring Vibration

Isolators (by others)

Concrete Pad (by others)

Figure 11 - Spring Vibration Iolators Option

ZĞĐŽŵŵĞŶĚĞĚŶĐŚŽƌ>ŽĐĂƟŽŶƐ

0.563” Hole Diameter Typ. 0.56” Typ.

Base Rails

2.19”

81.38”81.38”

3.25”

170.5”

2.19”

36”

1.75”

1”

Figure 12 - Vibration Isolation Pads Option

Concrete Pad (by others)

Figure 10 - Support Rails and Anchor Locations

Figure 11 - Spring Vibration Isolators Option

ClimaCool recommends locking down the chiller to a concrete base or to two (2) 4” base mounting rails using the six bolt

holes provided in each base pan (see Figure 10). Due to the low vibration of the modules, ClimaCool does not require the

application of spring isolators or pads. Should isolators or pads be desired, install in accordance with Figures 11 and 12.

Mounting Rail and Vibration Isolation

Note:ƤǤ

11

R

R

www.climacoolcorp.com

Recommended Service Clearances

Notes:

ǤȀǡǦǦƤdzdz

clearance for rear service access.

ǤȀǡǦǦƤdzǤ

ǤǡǦǦƤdz

service and air intake sides.

ǤƪǤ

5. Local building or electrical codes may require additional clearance. Consult applicable codes.

ǤƤǤ

Rear Service Access

Air Intake Air Intake

Service and Air Intake

Clearance

Top View

See Note

4 for side

clearance

See Note

4 for side

clearance

See Note

4 for side

clearance

See Note

4 for side

clearance

Air Intake

Air Intake

Service and Air Intake

Clearance

Service and Air Intake

Clearance

ǦǦǦƤ

ǦǦǦƤ

36” 36”

42”

42” 42”

42”42”

R

R

www.climacoolcorp.com

12

Model Key

RejectionMeans

A=AirCooledPackage(Outdoor) ModelConfiguration

F=FreeCoolingModule B=BirdScreen

(Availablein30&70Tononly) C=CondenserCoilGuard

D=CoatedCondenser

E=CoatedCondenserwithCoilGuard

NominalTons F=CondenserCoilHailGuard

020(N/AforFreeCoolingModule) G=HeaderlessModulewithCondenserCoilGuard

030 H=HeaderlessModule

050(N/AforFreeCoolingModule) I=CoatedCondenserwithBirdScreen

070 J=CoatedCondenserwithHailGuard

K=HeaderlessModulewithCondenserHailGuard

DesignSeries L=HeaderlessModulewithCondenserCoilCoating

AN=HeaderlessModulewithCondenserCoilCoatingandHailGuard

BP=HeaderlessModulewithCondenserCoilCoating,HailGuardandBirdScreen

R=CoatedCondenserwithHailGuardandBirdScreen

Voltage S=Standard

F=460/3/60 T=HeaderlessModulewithCondenserHailGuardandBirdScreen

H=208Ͳ230/3/60 U=HeaderlessModulewithCoatedCondenserandBirdScreen

N=575/03/60 Y=CondenserCoilHailGuardwithBirdScreen

U=380/3/50 Z=HeaderlessModulewithBirdScreen

RefrigerantOptions

Controls&Electrical 0=NoneͲStandardLowAmbientto0°F

A=StandardControls B=HotGasBypassͲBothCircuits

S=SingleModuleControls M=LowAmbienttoͲ20°FwithHotGasBypassͲBothcircuits

T=SingleModuleControlswithLonWorks N=LowAmbienttoͲ20°F

WaterIsolationValves

0=(None)

CompressorType E=Evap.MotorizedValves&ManualCondsrValves

0=(None)(lessManualCondsrValvesforAirCooled)

F=ScrollwithFullHeightVenturi M=ManualValvesforEvap&Condsr

S=Scroll (lessManualCondsrValvesforAirCooled)

Application

Refrigerant 0=(None)

0=(None)C=Cooling

A=RͲ410A H=HeatRecovery(Desuperheater)

R=ReverseCycle(HeatPump)

S=SimultaneousHeating&CoolingHeatPump(4headers)

Ј ІЈ ІЉ

00

ІЇІІ

UltimateChillerSolutionModelKey

ІЊ

AASACB

ІЇ

UC F S

ЍЉЊЋ Ќ Ў ІЅ

020

13

R

R

www.climacoolcorp.com

Foundation for Unit Placement

The minimum foundation requirement for the ClimaCool

chiller is a level surface capable of bearing the combined

operating weight of the modules (See Physical Data -

page 3-5).

Service Access

Recommended Service Clearances and Bank Dimensions

shown on page 11.

Draining

When performing standard maintenance procedures such

ƪǡ

ơǤơ

optional water isolation valves for this purpose.

Assembling Modules

ClimaCool recommends locking down the chiller to a

concrete base, or to two (2) 4” base mounting rails using

the bolt holes provided in the unit base. Although the

compressors are installed on anti-vibration mountings,

further isolation of the chiller from the structure is

available by installing vibration eliminating springs or

pads under the base rails on which the chiller will rest

(See page 10 – Mounting Rail and Vibration Isolation).

One end of the modules should be chosen as the reference

module and carefully located.

Field installed mounting accessories are provided for

Ǥ

• Header grooved coupling kits containing two (2) for

water cooled and heat pump applications and four (4)

for simultaneous heat pump applications.

• Mounting hardware kit containing necessary bolts,

spacers, nuts and washers.

• Header bank end cap kit containing two (2) each for

water cooled and heat pump and four (4) each for

simultaneous heat pump applications.

• Groove by groove 6” nipples, one (1) required

per header.

Field installing the mounting hardware kit will assist

with alignment of the modules in a bank and eliminate

ơǤǡ

show the end to end and back to back holes for the 1”

spacers between the units. The spacers will allow for an 1”

separation between modules in both the end to end and

ƤǤ

Once the spacers are installed, the distance from the

post upright will be 1”. Using the appropriate tools tighten

hardware assembly until seated.

Inspect the pipe ends to ensure they are free from any

ǡǡ

surface defects such as loose paint, scale, dirt, chips,

grease and rust. Inspect the grooved coupling gasket

for any defects. Apply a thin layer of silicone or other

non-petroleum lubricant to the sealing lips of the gasket

and to the exterior of the gasket. Install gaskets on the pipe

ends of one of the two modules to be mated. Be sure the

gasket is completely on the pipe so damage will not occur

in the next step.

One groove by groove 6” nipple per header is required to

complete the connection between each module. Move the

second module into position and line up the piping. Ensure

you are maintaining alignment for any additional modules to

be added. When pipe ends are aligned, slide the gasket over

the ends and center it between the grooves. No part of the

gasket should protrude into the groove of either pipe end.

Place the coupling halves over the gasket and make sure

that the coupling keys, (the part that goes into the groove),

are engaged into the grooves. Insert the bolts and install

nuts to hand tight. Make sure that the oval neck of the bolt

engages into the bolt hole of the housing. Tighten nuts

alternately and equally until the bolt pads meet and make

metal to metal contact. Tighten nuts by another 1/4 to 1/2

turn to make sure the nuts and bolts are snug and secure;

the use of a torque wrench is usually not required. Uneven

tightening of bolts may cause the gasket to be pinched

resulting in immediate or delayed leaks.

Assembling Modules Back to Back

Ƥǡ

Figure 17.

• dzƪ

header-less unit.

• Loosen the lower 2” grooved coupling from the bottom

header and remove the end cap.

• Lubricate the rubber gasket with approved grooved

coupling lubricant.

• ƪǦ

unit into the 2” grooved coupling on the header where

the end-cap was previously removed.

• Equally tighten the 2 bolts to 15 to 22 ft-lbs of torque.

• Repeat above procedure for the upper

hose connection.

Unit Installation

R

R

www.climacoolcorp.com

14

Header Insulation

Chilled water piping is pre-insulated on each module at

the factory with 3/4” closed cell insulation. After bolting

all modules together and leak testing, the entire coupling

connection will need to be insulated by the installing

contractor.

Access Panels

ƥǡ

ǡ

and always prior to operation of the bank. Lower side acess

panels are available as an option.

Unit Installation

Figure 17 - Back to BackFigure 15 - Hardware Kit

Figure 16 - Spacer Holes

END TO END SPACER HOLES

BACK TO BACK SPACER HOLES

15

R

R

www.climacoolcorp.com

Proper Voltage Balance

Occasionally, in three phase circuits, a voltage imbalance

occurs between phases. It is not recommended to operate

equipment when an imbalance greater that 2% occurs. This

ơ

their longevity. The following example describes how to

calculate the average voltage of the three phases to see if

the imbalance is greater than 2%.

Example: Line 1 = 226v Line 2 = 230v Line 3 = 228v

The average is: (226+230+228)/3 = 228v

Next, [100(228-226)]/228 = 0.9%

The voltage imbalance of the three phase circuit is 0.9%.

This is well under the 2% range.

Voltage/Phase Monitor

ȀƤ

installation with the CoolLogic Master Control Panel. The

voltage/phase monitor helps guard the chiller bank against

ƪǡ

conditions which could void your warranty. The voltage/

phase monitor has three wires that connect to the main

three phase power chiller bank input. Two low voltage

control wires are connected to the CoolLogic Master Control

Panel. Do not install control wiring in the same conduit as

line voltage wiring or with wires that switch highly inductive

loads such as contactor and relay coils. Note: It is mandatory

to install one (1) monitor per bank at main power

distribution panel to monitor voltage and phasing of power

to the modules. See Wiring Diagram on page 16.

The power for modules is taken from a suitable circuit

breaker/fused disconnect power supply within the main

panel. The electrical service enters the individual modules

through the upper right side of the module’s control panel

enclosure. Proper grounding of the module is mandatory.

ǡƤ

main supply is isolated. A typical power wiring is located on

page 55 – Power Distribution Drawing. Knockout drawings

are provided. Do not drill into cabinet; shavings can damage

electronic components. The power for all individual modules

shall be in compliance with all local and national codes.

CoolLogic Control System Wiring

A separate 115 volt power supply is required to power the

CoolLogic Master Control Panel. Communication between

the Master Controller and chiller modules requires a simple

two-conductor, 18 AWG shielded cable rated at 60°C

minimum, daisy chain connection. Control wiring cannot be

installed in the same conduit as line voltage wiring or with

wires that switch highly inductive loads such as contactor

and relay coils. Refer to the Power Distribution schematic on

page 52 and Wiring Diagrams on pages 82-84 of this manual

for more information. All wiring shall be in compliance with

all local and national codes.

Electrical Phase Sequencing

Proper clockwise rotation for scroll compressor motors is

important to prevent damaging the compressors. ClimaCool

recommends the use of a phase sequence indicating

instrument following the manufactures directions. Another

alternative would be to “bump test” the compressors one

at a time with pressure gauges attached to the high and

low gauge ports of the compressors to check for proper

rotation. Energize the compressor for a few seconds to

ƤǤ

If the discharge pressure does not increase, proper rotation

is reversed. Compressor rotation can be reversed by

opening the main electrical disconnect and switching

any two of the main power supply leads feeding that

compressor’s contactor.

Electrical Connection

If this unit uses a 3 Phase Scroll

Compressor, the following

instructions MUST BE followed:

• Unit power supply MUST BE

wired in the proper sequence to

avoid damage to the 3 Phase

Scroll Compressor;

• Scroll Compressors with

INCORRECT rotation show the

following characteristics:

- High sound level;

- High suction pressure and

low discharge pressure;

- Low current draw.

• If any of the three above

characteristics exist, swap two of

the three supply wires at the

disconnect and recheck

compressor for incorrect rotation.

Si cet appareil utilise

compresseur scroll 3-Phase, les

instructions suivantes doivent être

suivies:

• L’alimentation de l’appareil doit

être monté dans l’ordre correct

pour éviter endommager le

compresseur scroll 3-Phase

• Compresseurs scroll avec

rotation incorrecte montrent les

caractéristiques suivantes:

- Haut niveau de son;

- Pression d’aspiration élevée

et une faible pression de

décharge;

- Faible ampérage

• Si l’un des trois éléments

mentionnés ci-dessus sont

remplies , échanger deux des

trois lignes électriques alimen

tant la interrupteur de sécurité et

YpUL¿HUODURWDWLRQGX

compresseur.

3 PHASE SCROLL

COMPRESSOR UNITS UNITÉ DE COMPRESSEUR

SCROLL 3-PHASE

CAUTION/ATTENTION

CAUTION/ATTENTION

Use only copper conductors

IRU¿HOGLQVWDOOHGZLULQJ8QLW

terminals are not designed to

accept other types of

conductors.

Utilisez uniquement des

conducteurs en cuivre pour le

câblage. Bornes de l’unité ne

sont pas conçus pour

accepter d’autres types de

conducteurs.

Disconnect power supply

(ies) before servicing. Refer

VHUYLFLQJWRTXDOL¿HGVHUYLFH

personnel. Electric shock

hazard. May result in injury

or death!

Unit to be serviced by

TXDOL¿HGSHUVRQQHORQO\

Refrigerant system under

pressure. Relieve pressure

before using torch. Recover

refrigerant and store or

dispose of properly.

Debrancher avant d’entre-

prendre le dépannage de

l’appareil. Consulter un

UpSDUDWHXUTXDOL¿HSRXUOH

dépannage. Risque de choc

électrique. Résiltat de mai

dans dommages ou la mort!

Conifer la maintenance à

XQWHFKQLFLHQTXDOL¿H/H

V\VWpPHIULJRUL¿TXHVRXV

pression. Décomprimer avant

G¶H[SRVHUjODÀDPPH

Récuperer le frigorigene et

le stocker ou le détrulre

correctement.

WARNING/AVERTISSEMENT

CAUTION/ATTENTION

R

R

www.climacoolcorp.com

16

Wiring Diagram-Voltage/Phase Monitor

17

R

R

www.climacoolcorp.com

As with any water system, it is important that the system

be clean. The pipe work installer must remove weld scale,

rust and contamination during pipe work fabrication.

ƪ

ƪ

are compatible with 316 stainless steel prior to making

connections to the ClimaCool chiller. There are certain

necessary components that should always be installed in

the chilled water system. (See Figures 21 and 22 on page 19 -

ƤƤ

modules). All water piping must be installed in accordance

with applicable codes and standards.

Temperature Sensor and Wells

ClimaCool provides two (2) temperature sensors and

wells with each two pipe chiller system and four (4) with

simultaneous heating & cooling four pipe chiller systems

ƤCoolLogic Control System. They must

Ƥdzdz

away from the bank and before the strainer on the chilled

water inlet and chilled water outlet (See Water Piping

ƤȂȌǤNote: Sensors must be fully

inserted into the well to obtain proper readings. Use a

slender, blunt instrument to gently push the sensor to the

bottom of the sensor well.

ơ

ƪ

ǡƤ

26, are not exceeded. To prevent operation of the chiller

ƥƪǡ

ơƪ

the chilled water circuit. Place downstream of the strainer

on the outlet of a straight pipe, as close to the module

as possible. Do not put in an elbow on the outlet. When

ơǡ

sure to bleed any air from the tubing before tightening.

ȋƤȂȌǤ

Pressure Taps

The installing contractor must provide access ports for

ơƪ

sensors and pressure gauges for the chilled water system.

A 1/4” pressure tap is required on the inlet and the outlet

of the chilled water system for a total of four (4) taps

with each two (2) pipe chiller system and six (6) with each

simultaneous heating and cooling four pipe chiller system.

ơƪ

and the pressure gauge it will require two (2) 1/2” taps.

ȋƤȂȌǤ

Water Isolation Valves

It is recommended to provide bank water isolation valves for

proper isolation and maintenance of the chiller, pump and

ȋƤȂȌǤ

Strainers – Minimum 60 Mesh Screen Required

ClimaCool chillers utilize brazed plate heat exchangers

which are extremely sensitive to debris. Therefore, it is

mandatory that all chilled water systems include a strainer

ƤǤ

The strainer must be installed as shown in the Water Piping

Ƥ

when the chiller is operating. ClimaCool’s warranty does

not cover and does not apply to products which have

defects or damages due to freezing of the water supply,

an inadequate or interrupted water supply, corrosives or

abrasives in the water supply, or improper or inadequate

ƤǤ

Chiller/Heater System Water Header Bypass

A bypass is required for any load cooling, cooling only and

load cooling and load heating, simutaneous heating and

cooling heat pump with variable pumping. The chiller bank

bypass must be piped in such a way that the temperature

ơƪ

ƪǤȋƤȂȌǤ

The purpose of the chiller/heater system bypass is to

prevent deadheading of the pumps when all of the internal

unit valves go closed as well as allow temperature and

ơƪǤ

bypass should be sized for an absolute minimum of one

ǯƪǤȋ

ƪȌǤ

Ƥǡ

cooling, however, this limits the number of modules

remaining for that duty. Also, with a module acting as a

bypass increased wear of heat exchangers may be caused

ƪǤ

Water Piping

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

No.10

2" 90°

Elbow

No.50 Reducer

6 x 2

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

No.10

2" 90° No.50

Reducer

6 x 2

Module

Header

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

SIDE VIEW

6"

Groo ved Coupling

6"

Groo ved Coupling

2"

Grooved

Coupling

Hose Kit

2"

Grooved

Coupling

2" Belimo

Ball Valve &

Actuator

Figure 18 - Reverse Return

R

R

www.climacoolcorp.com

18

No. 25 Grooved Br anch

6 x 6 x 2

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

END VIEW

Hose Kit

2" Belimo

Ball Valve &

Actuator

2"

Grooved

Coupling

No. 25 Grooved Br anch

6 x 6 x 2 Module

Header

6"

Groov ed Coupling

No. 29 Reducing Tee

w/Thd. Branch

6 x 6 x 2

Module

Header

6"

Grooved Coupling

SIDE VIEW

2" Belimo

Ball Valve &

Actuator

Hose Kit

2"

Grooved

Coupling

Figure 19 - Direct Return

Water Piping

Load Side System Bypass (Air Handlers, Fan

Coils, etc.)

A load system bypass is required for preventing pump

ǡƪ

ƪȀǤ

Examples of an acceptable load side system bypass are:

• Utilize a quantity of 3-way control valves on the largest

loads farthest from the chiller/heater system.

• Field piping with a control valve to provide a bypass

across the larger system loads when their 2-way valves

go closed.

Please refer to Figure 20 for a typical load bypass valve

arrangement. The load side system bypass should be sized

for an absolute minimum of one module’s worth of design

ƪǤȋƪ

rates). A minimum of (6) six gallons per nominal system ton

are also required to maintain proper system thermal inertia.

This is to avoid short cycling of compressors in the chiller/

heater system as well as prevent nuisance alarms.

LOAD 1

FROM CHILLER BANK

TO CHILLER BANK

LOAD ϮLOAD 3 LOAD X

Figure 20 - Typical Load Bypass Valve Arrangement

TYPICAL CHILLED AND HOT WATER

LOAD SIDE BYPASS VALVES

SIZE EQUIVALENT TO ONE MODULE

WORTH OF FLOW

FROM CHILLER BANK

TO CHILLER BANK

ơǡ

reverse return (Figure 18) and direct return (Figure 19).

The bypass kits must be installed on each water source loop

and controls are integrated with the CoolLogic software.

Installation location can be found on page 19 – Water

ƤǤ

ƤǤ

The design piping must accommodate one module’s worth

ƪǡ

ơƪƪ

ǤȋƤȂȌǤThe

ƤȀ

controlled by others. There are system communication

ǡƪ

the use of ClimaCool sensors and controls for control

ƤƤǤ

ơ

ƪȀ

heating water systems.

This manual suits for next models

3

Table of contents

Other ClimaCool Chiller manuals

Popular Chiller manuals by other brands

Carrier

Carrier PC211 Start-up, operation and maintenance instructions

Advanced Thermoelectric

Advanced Thermoelectric ElectraCOOL L-A 550 user manual

TICA

TICA MINI VRF CHR Series Installation & operation manual

ATC

ATC R Series Installation, operation & service manual

Polar Refrigeration

Polar Refrigeration CB507 instruction manual

CIAT

CIAT POWERCIAT2 LXC instruction manual