ClimateMaster Tranquility TAC026BM17S Guide

Cased Coil for

Tranquility Split Series

Installation, Operation &

Maintenance Instructions

97B0100N01

Rev.: August 21, 2018

Tranquility Aluminum Tube Cased Coil (TAC)

Table of Contents

Model Nomenclature 3

General Information 4

Safety/Inspection 5

Specications 6

Dimensions 7

Installation 8 - 14

Maintenance 14

Warranty 15

RevisionHistory 16

This page was intentionally left blank.

3

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

climatemaster.com

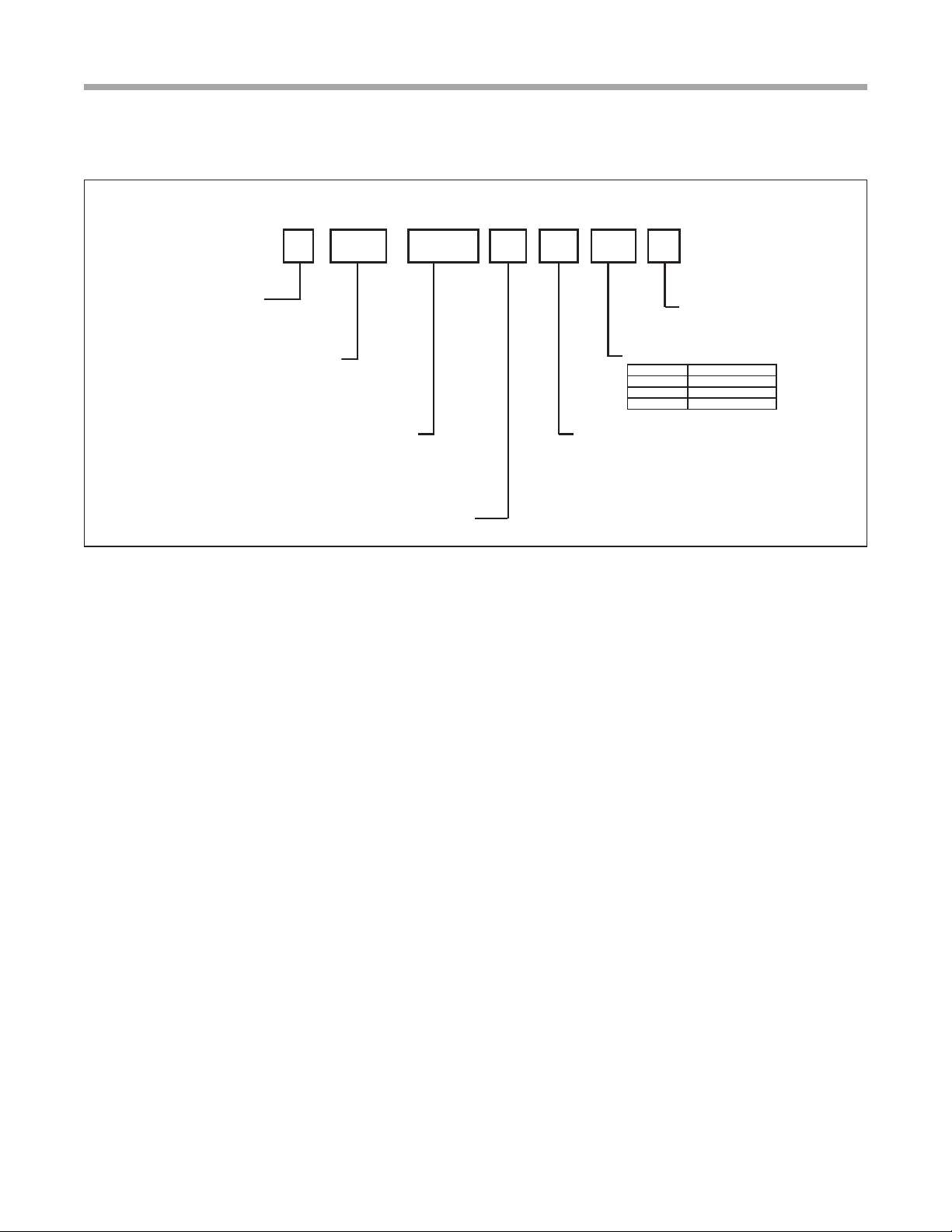

Model Nomenclature

ACT B026

2 31 4 5 6 7

T= TRANQUILITYHFC-410A

MODELTYPE

AC = CASED COIL

CONFIGURATION

026

NOMINALCAPACITY

038

049

REVISION LEVEL

064

M

8

COILOPTIONS

M = MULTI-POSITION CASED COIL

S

11

FUTURE USE

21

9 10

COILWIDTH

Width, Inches Nominal Capacity

17 26

21 26, 38, 49

24 38, 49, 64

B= CURRENT REVISION

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

4Geothermal Heating and Cooling

CASED COIL DESCRIPTION

ClimateMaster Tranquility Cased Coils are designed for

use with ClimateMaster indoor/outdoor split units and are

available for vertical upow or downow, and horizontal left

or horizontal right airow.

• Constructed of aluminum ns bonded to internally

grooved aluminum tubing.

• Coils are tested at the factory with an extensive

refrigerant leak check.

•Coils have sweat refrigerant connections.

•Ideally suited for new installations or add on air

conditioning.

•Feature two sets of 3/4” FPT condensate drain

connections for ease of connection.

• Coils are AHRI certied for system application with

ClimateMaster indoor and outdoor split units.

• Condensate drain pan is constructed of high grade, heat

resistant, corrosion free thermal-set material.

• Bi-Directional airow eliminates the need to switch any

internal components from horizontal left to right.

• Unique drain pan design maximizes application exibility

and condensate removal. � WARNING! �

WARNING! These instructions are intended as

an aid to qualied licensed service personnel for

proper installation, adjustment and operation of

this unit. Read these instructions thoroughly before

attempting installation or operation. Failure to follow

these instructions may result in improper installation,

adjustment, service or maintenance possibly resulting in

property damage, personal injury or death.

General Information

� CAUTION! �

� CAUTION! �

Inspection

Upon receipt of the equipment, carefully check the shipment

against the bill of lading. Make sure all units have been

received. Inspect the packaging of each unit, and inspect each

unit for damage. Insure that the carrier makes proper notation

of any shortages or damage on all copies of the freight bill and

completes a common carrier inspection report. Concealed

damage not discovered during unloading must be reported

to the carrier within 15 days of receipt of shipment. If not led

within 15 days, the freight company can deny the claim without

recourse. Note: It is the responsibility of the purchaser to le

all necessary claims with the carrier. Notify your equipment

supplier of all damage within fteen (15) days of shipment.

Storage

Equipment should be stored in its original packaging in a

clean, dry area. Store units in an upright position at all times.

Stack units a maximum of 3 units high.

Unit Protection

Cover units on the job site with either the original packaging

or an equivalent protective covering. Cap the open ends of

pipes stored on the job site. In areas where painting, plastering,

and/or spraying has not been completed, all due precautions

must be taken to avoid physical damage to the units and

contamination by foreign material. Physical damage and

contamination may prevent proper start-up and may result in

costly equipment clean-up.

Examine all pipes, ttings, and valves before installing any of

the system components. Remove any dirt or debris found in

or on these components.

Pre-Installation

Installation, Operation, and Maintenance instructions

are provided with each unit. Horizontal equipment is

designed for installation above false ceiling or in a ceiling

plenum. Other unit congurations are typically installed

in a mechanical room. The installation site chosen should

include adequate service clearance around the unit. Before

unit start-up, read all manuals and become familiar with the

unit and its operation. Thoroughly check the system before

operation.

Prepare units for installation as follows:

1. Compare the data on the unit nameplate with ordering

and shipping information to verify that the correct unit

has been shipped.

2. Keep the cabinet covered with the original packaging

until installation is complete and all plastering, painting,

etc. is nished.

3. Verify refrigerant tubing is free of kinks or dents and that

it does not touch other unit components.

CAUTION! CUT HAZARD - Failure to follow this caution

may result in personal injury. Sheet metal parts may have

sharp edges or burrs. Use care and wear appropriate

protective clothing, safety glasses and gloves when

handling parts and servicing.

CAUTION! DO NOT store or install units in corrosive

environments or in locations subject to temperature or

humidity extremes (e.g., attics, garages, rooftops, etc.).

Corrosive conditions and high temperature or humidity

can signicantly reduce performance, reliability, and

service life.

5

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

climatemaster.com

Safety

� WARNING! �

� CAUTION! �

CAUTION! It is recommended that an auxiliary secondary

drain pan be installed under units containing evaporator

coils that are located in any area of a structure where

damage to the building or building contents may occur as a

result of an overow of the coil drain pan or a stoppage in

the primary condensate drain piping.

The installation of water source heat pump units and all

associated components, parts and accessories which make

up the installation shall be in accordance with the regulations

of ALL authorities having jurisdiction and MUST conform to

all applicable codes. It is the responsibility of the installing

contractor to determine and comply with ALL applicable

codes and regulations.

Replacement Parts

Any replacement part must be the same as or an approved

alternate to the original part supplied. The manufacturer will

not be responsible for replacement parts not designed to

physically t or operate within the design parameters the

original parts were selected for. When ordering replacement

parts, it is necessary to order by part number and include

the complete model number and serial number from the coil

rating plate. (Parts are available through the local distributor.)

� WARNING! �

� WARNING! �

� CAUTION! �

CAUTION! To avoid equipment damage, DO NOT use

these units as a source of heating or cooling during the

construction process. The mechanical components and

lters can quickly become clogged with construction dirt

and debris, which may cause system damage and void

product warranty.

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal prociency requirements.

WARNING! The EarthPure® Application and Service

Manual should be read and understood before attempting

to service refrigerant circuits with HFC-410A.

Safety

Warnings, cautions and notices appear throughout this

manual. Read these items carefully before attempting any

installation, service, or troubleshooting of the equipment.

DANGER: Indicates an immediate hazardous situation, which

if not avoided will result in death or serious injury. DANGER

labels on unit access panels must be observed.

WARNING: Indicates a potentially hazardous situation, which

if not avoided could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice, which if not avoided could result in minor or

moderate injury or product or property damage.

NOTICE: Notication of installation, operation or maintenance

information, which is important, but which is not hazard-

related.

WARNING! PROPOSITION 65: This appliance contains

berglass insulation. Respirable particles of berglass

are known to the State of California to cause cancer.

All manufacturer products meet current Federal OSHA

Guidelines for safety. California Proposition 65 warnings

are required for certain products, which are not covered

by the OSHA standards. California’s Proposition 65

requires warnings for products sold in California that

contain or produce any of over 600 listed chemicals

known to the State of California to cause cancer or birth

defects such as berglass insulation, lead in brass,

and combustion products from natural gas. All “new

equipment” shipped for sale in California will have

labels stating that the product contains and/or produces

Proposition 65 chemicals. Although we have not changed

our processes, having the same label on all our products

facilitates manufacturing and shipping. We cannot always

know “when, or if” products will be sold in the California

market. You may receive inquiries from customers about

chemicals found in, or produced by, some of our heating

and air-conditioning equipment, or found in natural gas

used with some of our products. Listed below are those

chemicals and substances commonly associated with

similar equipment in our industry and other manufacturers.

• GlassWool (Fiberglass) Insulation

• Carbon Monoxide (CO).

• Formaldehyde

• Benzene

More details are available at the websites for OSHA

(Occupational Safety and Health Administration), at www.

osha.gov and the State of California’s OEHHA (Ofce

of Environmental Health Hazard Assessment), at www.

oehha.org. Consumer education is important since the

chemicals and substances on the list are found in our

daily lives. Most consumers are aware that products

present safety and health risks, when improperly used,

handled and maintained.

� WARNING! �

WARNING! This product can expose you to chemicals

including Carbon Black, which is known to the State of

California to cause cancer and Methanol, which is known

to the State of California to cause birth defects or other

reproductive harm. For more information go to

www.P65Warnings.ca.gov

The following warning complies with State of California law,

Proposition 65.

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

6Geothermal Heating and Cooling

Specifications

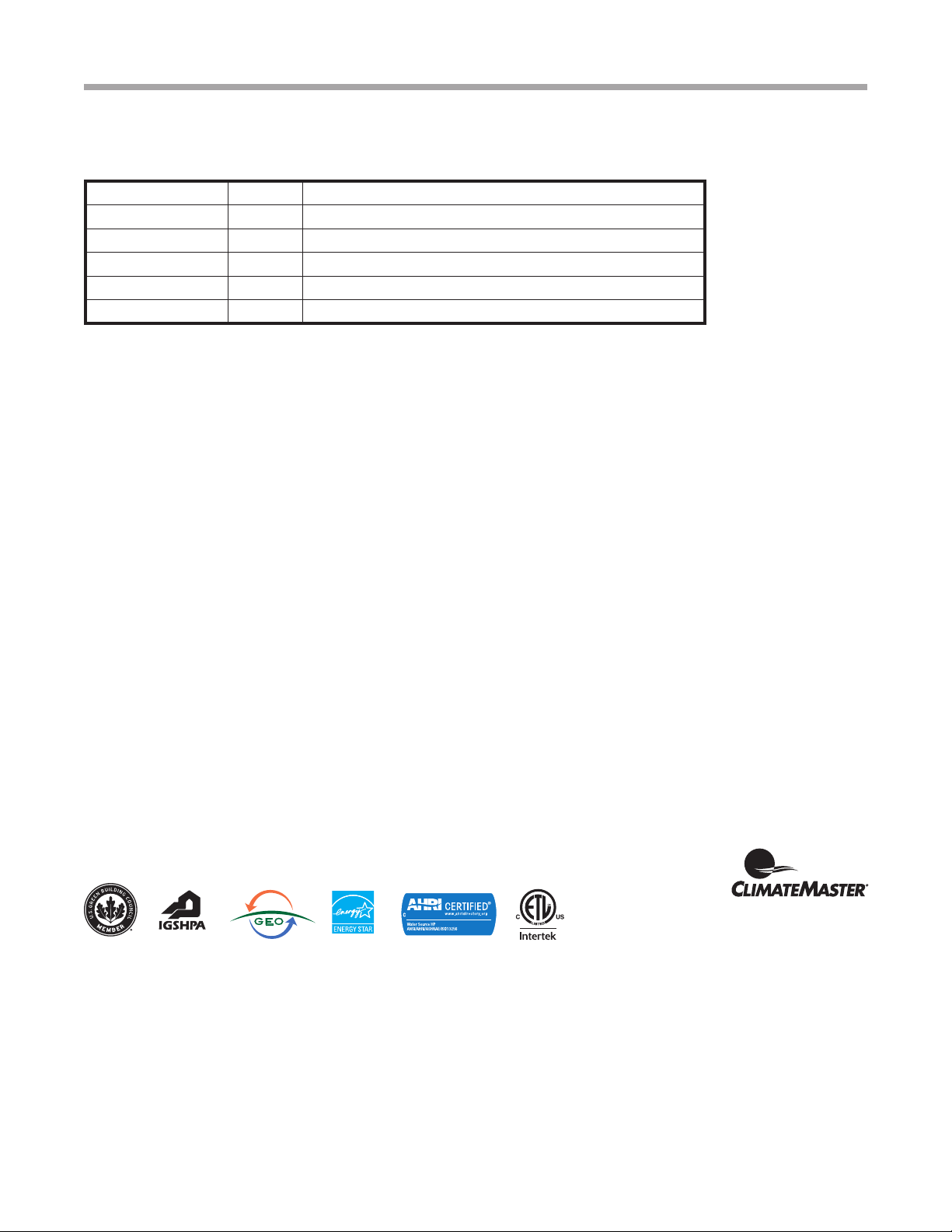

Table 1: Coil Specications/Airow Pressure Drop

Wet Coil Static Pressure Drop (Inches W.C.) - Coil Only

Coil Model

Face

Area

Ft2

(m2)

Case

Width

(cm)

600

CFM

700

CFM

800

CFM

900

CFM

1000

CFM

1100

CFM

1200

CFM

1300

CFM

1400

CFM

1500

CFM

1600

CFM

1700

CFM

1800

CFM

1900

CFM

TAC026BM17S 4.56

(0.42)

17.5

(44.5) 0.120 0.157 0.199 0.246

TAC026BM21S 5.70

(0.53)

21

(53.3)

0.113 0.145 0.181 0.222

TAC038BM21S 8.55

(0.79) 0.062 0.086 0.112 0.140 0.170 0.202 0.236 - - - - - - -

TAC038BM24S 8.55

(0.79) 0.062 0.086 0.112 0.140 0.170 0.202 0.202 0.272 0.309 - - - - -

TAC049BM21S 8.55

(0.79) 0.062 0.086 0.112 0.140 0.170 0.202 0.202 0.272 0.309 0.349 0.391 0.434 0.480 0.527

TAC049BM24S 8.55

(0.79) 24.5

(62.2)

0.062 0.086 0.112 0.140 0.170 0.202 0.202 0.272 0.309 0.349 0.391 0.434 0.480 -

TAC064BM24S 9.98

(0.93) 0.036 0.050 0.065 0.081 0.098 0.117 0.137 0.158 0.180 0.203 0.228 0.254 0.281 -

NOTE: Represents Coil-Only Airow Ratings

7

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

climatemaster.com

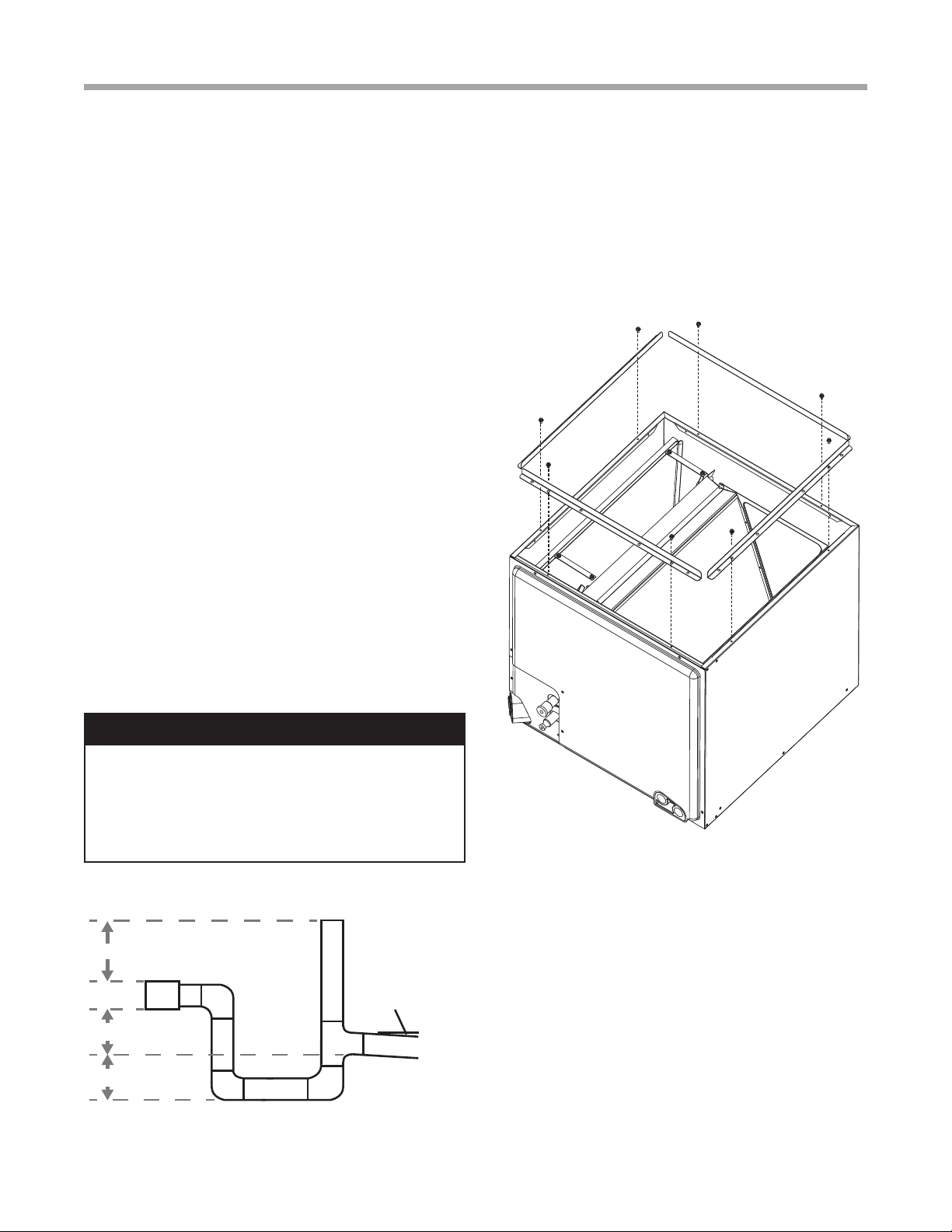

Table 2: Coil Dimensions and Weights

Dimensions

Figure 1: Dimensions

Model 026BM17 026BM21 038BM21 038BM24 049BM21 049BM24 064BM24

Connections - Sweat

Liquid I.D. - in 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Suction I.D. - in 3/4 3/4 7/8 7/8 7/8 7/8 7/8

Cased Coil Dimensions

A - Width - in [cm] 17 1/2 [44.5] 21 [53.3] 21[53.3] 24 1/2 [62.2] 21 [53.3] 24 1/2 [62.2] 24 1/2 [62.2]

B - Coil Height - in [cm] 14 1/2 [36.8] 17 1/2 [44.5] 25 7/8 [65.7] 25 3/8 [64.5] 25 7/8 [65.7] 25 3/8 [64.5] 30 [76.2]

C- Height - in [cm] 20 [50.8] 20 [50.8] 28 [71.1] 32 [81.3] 28 [71.1] 32 [81.3] 32 [81.3]

Weight

Coil Weight lbs. [kg] 43 [20] 49 [22] 71 [32] 83 [38] 71 [32] 83 [38] 100 [45]

Shipping Weight lbs. [kg] 48 [22] 54 [24] 78 [35] 93 [42] 78 [35] 93 [42] 110 [50]

PRIMARY DRAIN

(VERTICAL

AND HORIZONTAL)

PRIMARY DRA NI

SUCTION LINE

LIQUID LINE

SECONDARY DRAIN NOTE: FLANGES ARE PROVIDED

FOR FIELD INSTALLATION

SECONDARY DRAIN

3/4" [19.1 mm] FPT

(HORIZONTAL)

Coil

Model

Number

Connections Cased Coil Dimensions Weight

Sweat (In. ) [mm] (In. ) [mm]

A B C

Coil Weight

(lbs. ) [Kg. ]

Shipping Weight

(lbs. ) [Kg. ]

Liquid I. D. Suction I. D.

2417 3/8 [9.53] 3/4 [19.05] 171⁄2[445] 177⁄8[454] 20 [508] 52 [24] 57 [26]

2421 3/8 [9.53] 3/4 [19.05] 21 [533] 171⁄2[445] 20 [508] 54 [24] 60 [27]

3624 3/8 [9.53] 7/8 [22.23] 241⁄2[622] 301⁄4[768] 32 [813] 108 [49] 118 [54]

4824 3/8 [9.53] 7/8 [22.23] 241⁄2[622] 301⁄4[768] 32 [813] 108 [49] 118 [54]

6024 3/8 [9.53] 7/8 [22.23] 241⁄2[622] 301⁄4[768] 32 [813] 108 [49] 118 [54]

DIMENSIONS AND WEIGHTS DATA

A MINUS ONE INCH

1/2"

CASING TOP AND BOTTOM OPENINGS

ARE THE SAME DIMENSIONS.

197/8”

7/16” [1.1 cm]

11/4” [3.2]

113/16”

53/8”

[13.7 cm]

21/4”

17/16”

515/16”41/8”

2111/16”

FRONT VIEW

SIDE VIEW

PLENUM WIDTH

[4.6 cm]

[5.7 cm]

[3.7 cm]

[15.1 cm][10.5 cm]

[55.1 cm]

[1.3 cm]

[50.5 cm]

[2.5 cm]

3/4" [19.1 mm] FPT

3/4" [19.1 mm] FPT

3/4" [19.1 mm] FPT

(VERTICAL)

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

8Geothermal Heating and Cooling

Installation

The Tranquility Cased Coils are designed for upow, horizon-

tal, and downow applications. The coils have a dry nitrogen

holding charge and are equipped with brazing stub refriger-

ant connections for easy installation.

The installer should read the installation manual supplied

with the compressor section for refrigerant line set sizing,

connection procedure, and other important information per-

taining to the system installation.

The installer should:

1. Make sure that the air delivery of the furnace is adequate

enough to handle the recommended CFM and allow for

pressure drop across the air coil, lter, and duct work.

2. Where precise forming of refrigerant lines is required, a

copper tubing bender is recommended for small diameter

tubing. One should avoid sharp bends and contact of the

refrigerant lines with metal surfaces.

3. Refrigerant lines should be protected where they pass

through the raw edges of holes.

4. Coil must be level or slightly pitched toward drain for

proper condensate drainage.

5. Seal the openings into the cabinet to reduce risk of con-

densate blow o from the coil.

The installer should:

1. Disconnect all electrical power to the furnace.

2. For the install of an cased coil, it might be necessary to

fabricate a plate to adapt the coil’s cabinet to the furnace

or air handler air discharge opening.

3. Install the cabinet and level or slightly pitch it as needed to

allow proper condensate drainage.

4. Seal the enclosure as required minimizing air leakage.

5. Connect the refrigerant lines as outlined in the Refrigerant

Lines section.

Cased Coil Installation

� WARNING! �

WARNING! Electric furnaces may be connected to

more than one supply circuit.

9

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

climatemaster.com

Applications

Tranquility Cased coils can be applied in upow, downow,

horizontal right and horizontal left applications without

modications. For horizontal applications, installation of an

auxiliary/secondary drain pan is required. For coils that are

two sizes larger than the furnace, for example, a 21” [53.3

cm] wide coil on a 14” [35.6 cm] furnace, a tapered adaptor

with a minimum height of 6” [15.2 cm] is required to evenly

distribute airow. See Figure 3. For coils that are one size

larger than the furnace; for example a 21” [53.3 cm] wide coil

on a 171⁄2” [44.5 cm] furnace, seal the gap between the two

units with sheet metal. See gure 4.

� CAUTION! �

CAUTION! For horizontal applications, the horizontal

drain pan must be located under the indoor coil. Failure

to place the pan under the coil can result in property

damage.

FIGURE 3

COIL INSTALLATION OPTIONS

HORIZONTAL RIGHT

UPFLOW

HORIZONTAL LEFT

AIRFLOW

AIRFLOW AIRFLOW

DOWNFLOW

AIRFLOW

PRESSURE

SENSITIVE

GASKET

IMPORTANT: Coil must be installed on the

supply airflow side of a gas or oil furnace.

Installation

Figure 2: Coil Installation Options

Coil

Model

Furnace Width [cm]

Oil* Gas

TAC-026 21 [53.3]

17 1⁄2 [44.5]

14 [35.6]

TAC-026 21 [53.3]

21 [53.3]

17 1⁄2 [44.5]

TAC-038

24 1⁄2 [62.2]

24 1⁄2 [62.2]

TAC-049

TAC-064 21 [53.3]

Table 3: Coil Application

*Due to the proximity of the drain pan to the high

temperature oil furnace drum, horizontal left application is

NOT permitted on oil furnaces.

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

10 Geothermal Heating and Cooling

Installation

FIGURE 4

INSTALLATION OF COIL MATCHED WITH A FURNACE TWO SIZES SMALLER

6" [15.2 cm]

MINIMUM

UPFLOW OR HORIZONTAL

LEFT APPLICATION

DOWNFLOW OR

HORIZONTAL

RIGHT APPLICATION

FIGURE 5

INSTALLATION OF COIL MATCHED WITH

A FURNACE OF SMALLER SIZE

When a cooling coil is matched with a gas fur-

nace of one smaller size, always center coil

over the furnace.

IMPORTANT: Seal the gap between the two

units with appropriate sheet metal parts.

Figure 3: Installation of coil matched with a furnace two sizes smaller

Figure 4: Installation of coil matched with a furnace of smaller size

FIGURE 4

INSTALLATION OF COIL MATCHED WITH A FURNACE TWO SIZES SMALLER

6" [15.2 cm]

MINIMUM

UPFLOW OR HORIZONTAL

LEFT APPLICATION

DOWNFLOW OR

HORIZONTAL

RIGHT APPLICATION

FIGURE 5

INSTALLATION OF COIL MATCHED WITH

A FURNACE OF SMALLER SIZE

When a cooling coil is matched with a gas fur-

nace of one smaller size, always center coil

over the furnace.

IMPORTANT: Seal the gap between the two

units with appropriate sheet metal parts.

Indicates airow

Indicates airow

Field fabricated

tapered adaptor

11

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

climatemaster.com

� CAUTION! �

CAUTION! Installation of a factory supplied liquid line

bi-directional lter drier is required. Never install a suction

line lter in the liquid line.

� CAUTION! �

See compressor section IOM for refrigerant charge

information.

Line Set Installation

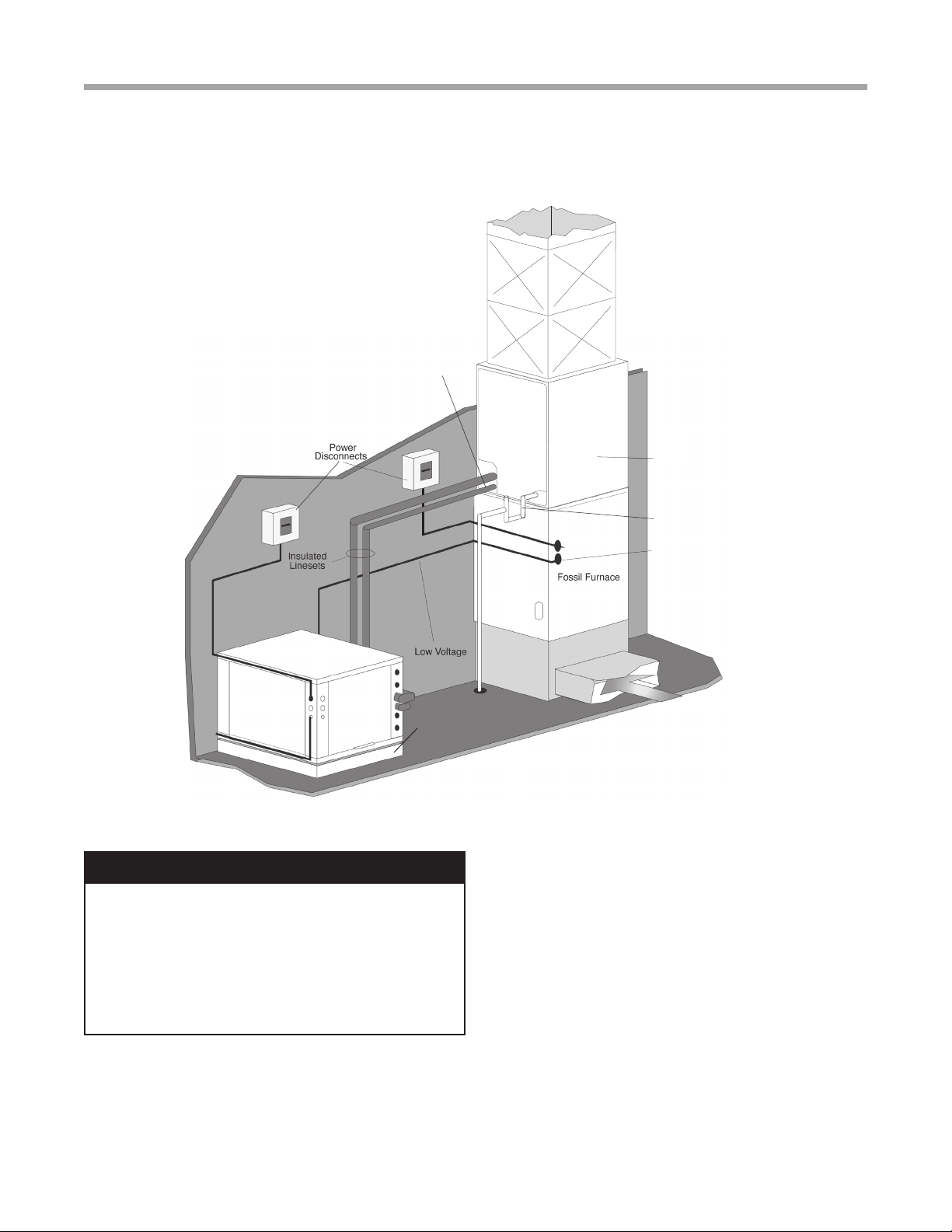

Figure 9 illustrates a typical installation of an air handler or

cased coil matched to an indoor compressor section. Lineset

lengths should be kept to a minimum and should always be

installed with care to avoid kinking. Line sets are limited to 60

feet [18 meters] in length (one way). Line sets over 60 feet [18

meters] void the equipment warranty. If the line set is kinked or

distorted, and it cannot be formed back into its original shape,

the damaged portion of the line should be replaced. A restricted

line set will eect the performance of the system.

ClimateMaster Split units are shipped with a lter drier (loose)

inside the cabinet that must be installed in the liquid line at the

line set.

All brazing should be performed using nitrogen circulating

at 2-3 psi [13.8-20.7 kPa] to prevent oxidation inside the

tubing. All linesets should be insulated with a minimum

of 1/2” [13mm] thick closed cell insulation. All insulation

tubing should be sealed using a UV resistant paint or

covering to prevent deterioration from sunlight.

When passing refrigerant lines through a wall, seal

opening with silicon-based caulk. Avoid direct contact

with water pipes, duct work, oor joists, wall studs,

oors or other structural components that could transmit

compressor vibration. Do not suspend refrigerant tubing

from joists with rigid straps. Do not attach line set to the

wall. When necessary, use hanger straps with isolation

sleeves to minimize transmission of line set vibration to

the structure.

Installing the Lineset at the Compressor Section

Braze the line set to the service valve stubs as shown in Figure

5. Nitrogen should be circulated through the system at 2-3

psi [13.8-20.7 kPa] to prevent oxidation contamination. Use a

low silver phos-copper braze alloy on all brazed connections.

Compressor section is shipped with a factory charge.

Therefore, service valves should not be opened until the

line set has been leak tested, purged and evacuated.

Installation

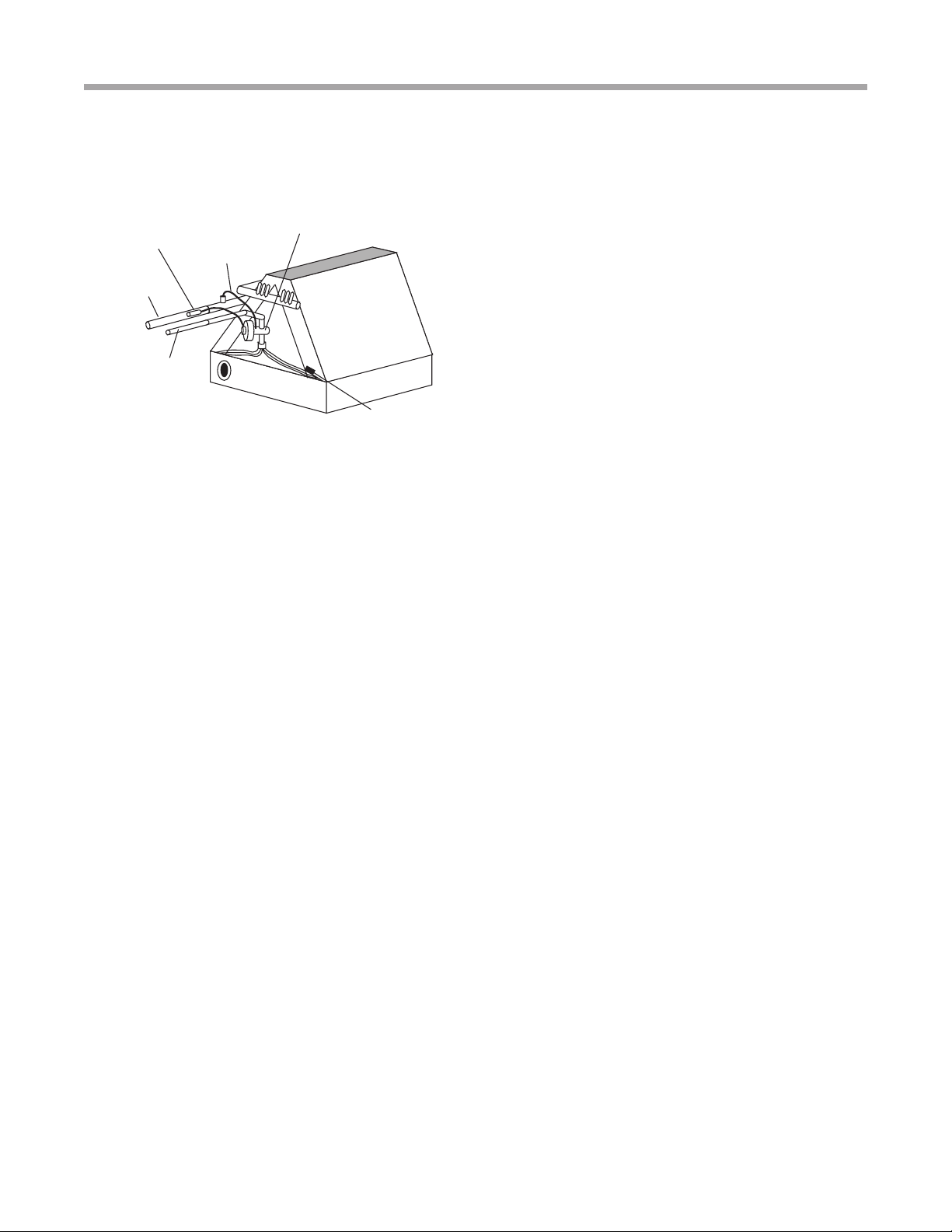

Installing the Indoor Coil and Lineset

Figure 6 shows the installation of the lineset and TXV to a

typical indoor coil. An indoor coil or air handler (fan coil) with a

TXV is required. Fasten the copper line set to the coil. Nitrogen

should be circulated through the system at 2-3 psi [13.8-20.7

kPa] to prevent oxidation inside the refrigerant tubing. Use a

low silver phos-copper braze alloy on all brazed connections.

Service ports for

gauges

CCW

CCW

service valves

Replace Caps after adjusting

service valves

Fully Insulated

Liquid Line

Fully Insulated

Vapor Line Nitrogen Braze

Figure 5: Braze Instructions

CAUTION! HFC-410A systems operate at higher

pressures than R-22 systems. Be certain that service

equipment (gauges, tools, etc.) is rated for HFC-410A.

Some R-22 service equipment may not be acceptable.

Fully Insulated

Vapor Line

Fully Insulated

Liquid Line

Nitrogen Braze

TES Compression Section

TEP Compression Section

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

12 Geothermal Heating and Cooling

Figure 6: Air Coil Connection

Add-On Heat Pump Applications

The indoor coil should be located on the supply side of

the furnace to avoid condensation damage to the furnace

heat exchanger for add-on heat pump applications. A high

temperature limit switch should be installed as shown

in Figure 9 just upstream of the coil to de-energize the

compressor any time the furnace is energized to avoid

blowing hot air directly into the coil, elevating refrigerant

pressures during operation. The heat pump will trip out on

high pressure lockout without some method of disengaging

the compressor during furnace operation. Alternatively, some

thermostats with “dual fuel” mode will automatically de-

energize the compressor when second stage (backup) heat

is required.

Air Coil

To obtain maximum performance of a newly manufactured

air coil it should be cleaned before start-up. A 10% solution

of dishwasher detergent and water is recommended for both

sides of the coil. A thorough water rinse should follow.

*An LT2 (low temperature air coil protection) sensor is

available for eld installation. Order sensor kit number

S17S0031N12.

Sensing Bulb

IMPORTANT: DO NOT perform any brazing with the TXV

bulb attached to any line. After brazing operations have been

completed, clamp the TXV bulb securely on the suction line

at the 10 to 2 o’clock position with the strap provided in the

parts bag. Insulate the TXV sensing bulb and suction line

with the provided pressure sensitive insulation and secure

with provided wire ties.

IMPORTANT: TXV sensing bulb should be located on a

horizontal section of copper suction line, just outside of

coil box. The copper sensing bulb must never be placed

on any aluminum tube as this will result in galvanic

corrosion and eventual failure of the aluminum tube.

Installation

Evacuation

LEAK TESTING -

The refrigeration line set must be pressurized

and checked for leaks before evacuating and charging the

unit. To pressurize the line set, attach refrigerant gauges to

the service ports and add an inert gas (nitrogen or dry carbon

dioxide) until pressure reaches 60-90 psig [413-620 kPa]. Never

use oxygen or acetylene to pressure test. Use a good quality

bubble solution to detect leaks on all connections made in the

eld. Check the service valve ports and stem for leaks. If a leak

is found, repair it and repeat the above steps. For safety reasons

do not pressurize system above 150 psig [1034 kPa]. System is

now ready for evacuation and charging.

Condensate Drain Tubing

Consult local codes or ordinances for specic requirements.

IMPORTANT: When making drain tting connections to the

drain pan, use a thin layer of Teon paste, silicone or Teon

tape and install hand tight.

IMPORTANT: When making drain tting connections to drain

pan, do not overtighten. Overtightening ttings can split pipe

connections on the drain pan.

•Install drain lines so they do not block service access

to front of the unit. Minimum clearance of 24 inches [61

cm] is recommended for lter, coil or blower removal and

service access.

• Make sure unit is level or pitched slightly toward primary

drain connection so that water will drain completely from

the pan. (See Figure 7.)

• Do not reduce drain line size less than connection size

provided on condensate drain pan.

• All drain lines must be pitched downward away from the

unit a minimum of 1/8” per foot [11 mm per m] of line to

ensure proper drainage.

• Do not connect condensate drain line to a closed or

open sewer pipe. Run condensate to an open drain or

outdoors.

• The drain line should be insulated where necessary to

prevent sweating and damage due to condensate forming

on the outside surface of the line.

TXV w/Internal

Check Valve

Suction Line

Liquid Line

Bulb (Must be

Installed and

Insulated)

Equalizer

Line

*LT2

Low Temperature

Air Coil Safety

(Optional)

13

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

climatemaster.com

Installation

• Make provisions for disconnecting and cleaning of the

primary drain line should it become necessary. Install

condensate trap at each unit with the top of the trap

positioned below the unit condensate drain connection

as shown in Figure 7. Design the depth of the trap

(water-seal) based upon the amount of ESP capability

of the blower (where 2 inches [51mm] of ESP capability

requires 2 inches [51mm] of trap depth). As a general

rule, 1-1/2 inch [38mm] trap depth is the minimum.

• Always vent the condensate line when dirt or air

can collect in the line or a long horizontal drain line

is required. Also vent when large units are working

against higher external static pressure than other units

connected to the same condensate main since this may

cause poor drainage for all units on the line. WHEN A

VENT IS INSTALLED IN THE DRAIN LINE, IT MUST

BE LOCATED AFTER THE TRAP IN THE DIRECTION

OF THE CONDENSATE FLOW.

• Auxiliary drain line should be run to a place where it will

be noticeable if it becomes operational. Occupant should

be warned that a problem exists if water should begin

running from the auxiliary drain line.

• Plug the unused drain connection with the plugs

provided in the parts bag, using a thin layer of Teon

paste, silicone or Teon tape to form a water tight seal.

• Test condensate drain pan and drain line after installation

is complete. Pour water into drain pan, enough to ll

drain trap and line. Check to make sure drain pan is

draining completely, no leaks are found in drain line

ttings, and water is draining from the termination of the

primary drain line.

Charging the System

See Compressor Section IOM for charging information.

� CAUTION! �

CAUTION! It is recommended that an auxiliary/secondary

drain pan be installed under units containing evaporator

coils that are located in any area of a structure where

damage to the building or building contents may occur as

a result of an overow of the coil drain pan or a stoppage

in the primary condensate drain piping.

FIGURE 7

FIELD-INSTALLED DUCT FLANGES

Figure 7: Condensate drain trap/vent

Figure 8: Field-installed duct anges

Duct Flanges

Field-installed duct anges (4 pieces) are shipped with units.

Install duct anges as needed on top or bottom of the coil

casing. (See Figure 8.)

2”

1.5”

1.5”

1/8” Per

Foot

UNIT MUST BE LEVEL OR SLIGHTLY

PITCHED TOWARD DRAIN CONNECTION

[5 cm]

[3.8 cm]

[3.8 cm]

[11mm per m]

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

14 Geothermal Heating and Cooling

Figure 9: Typical Split/Add-on Coil Fossil Fuel Furnace Installation

TAC

Cased Coil

Low Voltage

Compressor Section

PVC Condensate

with vented trap

Air pad or Extruded

polystyrene

Air Temperature

Limit Switch

Installation

� WARNING! �

WARNING! These instructions are intended as

an aid to qualied licensed service personnel for

proper installation, adjustment and operation of

this unit. Read these instructions thoroughly before

attempting installation or operation. Failure to follow

these instructions may result in improper installation,

adjustment, service or maintenance possibly resulting in

property damage, personal injury or death.

For continuing high performance and to minimize possible

equipment failure, it is essential that annual maintenance be

performed on this equipment. Consult your local dealer

as to the availability of a maintenance contract.

Air Filter

Check the system lter every ninety days or as often as found

to be necessary and if obstructed, clean or replace at once.

IMPORTANT: Do not operate the system without a lter in

place.

Indoor Coil - Drain Pipe - Drain Line

Inspect the indoor coil once each year for cleanliness and

clean as necessary. In some cases, it may be necessary to

remove the lter and check the return side of the coil with

a mirror and ashlight.

IMPORTANT: Do not use caustic household drain cleaners

or bleach in the condensate pan or near the indoor coil.

Drain cleaners will quickly damage the indoor coil.

MAINTENANCE

15

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

climatemaster.com

Warranty

CLIMATE MASTER, INC.

LIMITED EXPRESS WARRANTY AND LIMITATION OF LIABILITY AND

REMEDIES FOR RESIDENTIAL CLASS PRODUCTS WITH LABOR ALLOWANCE

This Limited Express Warranty And Limitation Of Liability And Remedies Affects Your Legal Rights And Should Be Read Carefully In Its Entirety.

Subject to the terms and conditions below, Climate Master, Inc. (“CM”) extends a limited warranty (“Limited Warranty”) for Residential Class heating and cooling equipment manufactured or sold by CM (“Products”), that was purchased on or after May 1, 2010 (this would generally include

CM Units with serial numbers beginning with “N118” and higher), and installed in a one or two family residential dwelling, for personal, household or family purposes in the United States of America or Canada, (“Application”), to be free from defects and workmanship under normal use and

maintenance. If you are unsure if this Limited Warranty applies to a Product you have purchased, contact CM at the phone number or address reected below.

This Limited Warranty DOES NOT cover commercial applications of the Products. Commercial applications include any application other than installation in a one or two family residential dwelling for personal, household or family purposes. Refer to ClimateMaster Commercial Limited Express

Warranty for details. Full copies are available for download at ClimateMaster.com .

This Limited Warranty provides a complete statement of CM’s responsibilities to purchasers of the Products. No oral or written statement made by CM, any person or entity associated with CM or by any person or entity claiming to be associated with CM, including but not limited to statements

made in sales literature, catalogs, or agreements to purchase or install the Products, is intended to provide an express or implied warranty of any kind and does not form a part of the basis of the bargain. Further, no such statement shall operate to extend, alter or modify the scope or terms of this

Limited Warranty.

EXCEPT AS SPECIFICALLY SET FORTH HEREIN, THERE IS NO EXPRESS WARRANTY AS TO ANY OF CM’S PRODUCTS. CM MAKES NO WARRANTY AGAINST LATENT DEFECTS, OF MERCHANTABILITY OF THE PRODUCTS OR OF THE PRODUCTS

FOR ANY PARTICULAR PURPOSE.

TERM: This Limited Warranty shall commence on the earliest to occur of the following dates: (i) proof of date of rst occupancy; (ii) proof of date of start-up of the Product by a qualied and trained HVAC contractor; or (iii) six (6) months from the shipment date of the Product from CM if items

(i) or (ii) are not available (“Warranty Inception Date”). The Limited Warranty shall extend as follows:

Costs of Repair or Replacement of Covered Product Parts

(1) Ten (10) years from the Warranty Inception date for air conditioning, heating and/or heat pump units built or sold by CM (“CM Units”);

(2) Ten (10) years from the Warranty Inception Date for thermostats, auxiliary electric heaters, water storage tanks, and geothermal pumping modules built or sold by CM, when installed with CM Units;

(3) One (1) year from the date of shipment from CM for any other accessories or parts built or sold by CM, when installed with CM Units; and

(4) Ninety (90) days from the date of shipment from CM for all repair or replacement parts that are not supplied under this warranty.

Costs of Labor to Install Repaired or Replaced Covered Product Parts

(1) Five (5) years from the Warranty Inception Date for CM Units;

(2) Five years from the Warranty Inception Date for thermostats, auxiliary electric heaters, water storage tanks, and geothermal pumping modules built or sold by CM, when installed with CM Units

This Limited Warranty does not cover labor costs for installation of other accessories or parts built or sold by CM or any repaired or replacement parts that are not supplied under this Limited Warranty.

WHO IS COVERED: This Limited Warranty is provided only to the original owner of the one or two family residential dwelling in which the Products are rst installed. This Limited Warranty is not transferrable. CM reserves the right to request any documentation necessary in its sole discretion

to determine the date of purchase and occupancy of the residential dwelling or the date of installation and start-up of the Product(s). For the avoidance of any doubt, this Limited Warranty shall not extend to, and shall provide no remedies whatsoever for, any distributor or installer of the Products.

CLAIM PROCESS: To make a claim under this warranty, the Product or parts must be returned to CM in Oklahoma City, Oklahoma, freight prepaid, no later than ninety (90) days after the date of the failure of the part. If CM determines the Product or part to be defective and covered by this

Limited Warranty, CM will either repair or replace the Product or part and send it to a CM-recognized distributor, dealer or service organization, F.O.B. CM, Oklahoma City, Oklahoma, freight prepaid. The Limited Warranty on any Product or part repaired or replaced under this Limited Warranty

extends only through the original warranty period.

WHAT IS COVERED: Subject to the Term, this Limited Express Warranty covers the: (i) the cost of repair or replacement of any covered Product or Product parts; and (ii) the cost of labor incurred by CM authorized service personnel in connection with the installation of a repaired or replaced

covered Product or Product part.

If a Product part is not available, CM will, at its option, provide a free suitable substitute part or provide a credit in the amount of the then factory selling price for a new suitable substitute part to be used by the claimant towards the retail purchase price of a new CM product. All labor costs are

subject and limited to amounts specically set forth in the then existing labor allowance\ schedule provided by CM’s Warranty Department. Actual labor costs are not covered by this Limited Warranty to the extent they: (i) exceed the amount allowed under the allowance schedule; (ii) are not

specically provided for in the allowance schedule; (iii) are not performed by CM authorized service personnel; (iv) are incurred in connection installation of a part not covered by this Limited Warranty; or (v) are incurred outside the Term.

WHAT IS NOT COVERED: This Limited Warranty does not cover and does not apply to: (1) air lters, fuses, refrigerant, uids, oil; (2) Products relocated after initial installation; (3) any portion or component of any system that is not supplied by CM, regardless of the cause of the failure of

such portion or component; (4) Products on which the unit identication tags or labels, or rating labels, have been removed or defaced; (5) Products on which payment to CM, or to the owner’s seller or installing contractor, is in default; (6) Products which have not been installed and maintained by

a qualied and trained HVAC contractor; (7) Products installed in violation of applicable building codes or regulations including but not limited to wiring or voltage conditions; (8) Products subjected to accident, misuse, negligence, abuse, re, ood, freezing, lightning, unauthorized alteration,

misapplication, contaminated or corrosive air or liquid supply, operation at abnormal air or liquid temperatures or ow rates, or opening of the refrigerant circuit by unqualied personnel; (9) mold, fungus or bacteria damages; (10) corrosion or abrasion of the Product; (11) products supplied by

others; (12) Products that have been operated in a manner contrary to CM’s printed instructions; (13) Products which have insufcient performance as a result of improper system design, sizing or the improper application, installation, or use of CM’s products; (14) electricity or fuel costs, or any

increases or unrealized savings in same, for any reason whatsoever; or (15) operating any water storage tanks when they are empty or partially empty (i.e. dry ring), at temperatures exceeding the maximum setting of the operating or high limit controls, at pressures greater than those shown on the

rating label, with non-potable water, with alterations or attachments (including energy savings devises) not specically authorized in writing by CM, or without the free circulation of water. CM may request written documentation showing compliance with the above limitations.

In connection with repair or replacement of covered Product parts, CM is not responsible for: (1) the costs of any uids, refrigerant or system components supplied by others, or associated labor to repair or replace the same, which is incurred as a result of repair or replacement of a covered Product

part; (2) the costs of labor, refrigerant, materials or service incurred in diagnosis and removal of a covered Product part subject to repair or replacement under this Limited Warranty; (3) shipping costs incurred in sending a claimed defective part from the installation site to CM; (4) shipping costs to

return a claimed defective part from CM to the installation site if the part is not covered by this Limited Warranty; (5) removal or disposal costs associated with the repair or replacement of covered Product Parts; or (6) the costs of normal maintenance.

OTHER WARRANTY LIMITATION: This Limited Warranty is given in lieu of all other warranties express or implied, in law or in fact. If, notwithstanding the disclaimers contained herein, it is determined that other warranties apply, any such warranty, including without limitation any express

warranties or any implied warranties of tness for particular purpose and merchantability, shall be limited in time to the Term of this Limited Warranty

LIMITATION OF REMEDIES: In the event of a breach of the Limited Warranty, a claimant’s remedies will be limited to repair or replacement of a part or unit, or to furnish a new or rebuilt part or unit in exchange for the part or unit which has failed. If after written notice to CM’s factory

in Oklahoma City, Oklahoma of each defect, malfunction or other failure, and a reasonable number of attempts by CM to correct the defect, malfunction or other failure, the remedy fails of its essential purpose, CM shall refund the purchase price paid to CM in exchange for the return of the

sold good(s). Said refund shall be the maximum liability of CM. THIS REMEDY IS THE SOLE AND EXCLUSIVE REMEDY OF THE BUYER OR THEIR PURCHASER AGAINST CM FOR ANY ACTION FOR BREACH OF CONTRACT, BREACH OF ANY WARRANTY, PATENT

INFRINGEMENT, OR FOR CM’S NEGLIGENCE OR IN STRICT LIABILITY. NO ACTION ARISING OUT OF ANY CLAIMED BREACH OF THIS LIMITED WARRANTY MAY BE BROUGHT MORE THAN ONE (1) YEAR AFTER THE CAUSE OF ACTION HAS ARISEN.

LIMITATION OF LIABILITY: CM shall have no liability for any damages if CM’s performance is delayed for any reason or is prevented to any extent by any event such as, but not limited to: any war, civil unrest, government restrictions or restraints, strikes, or work stoppages, re, ood,

accident, shortages of transportation, fuel, material, or labor, acts of God or any other reason beyond the sole control of CM.

CM EXPRESSLY DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL, INCIDENTAL, SPECIAL AND/OR PUNITIVE DAMAGES BASED ON ANY THEORY IN CONTRACT, BREACH OF ANY EXPRESS OR IMPLIED WARRANTY, PATENT

INFRINGEMENT, OR IN TORT, WHETHER FOR CM’s NEGLIGENCE OR AS STRICT LIABILITY AND REGARDLESS OF WHETHER CM IS ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

OBTAINING WARRANTY PERFORMANCE: Normally, the dealer or service organization who installed the products will provide warranty performance for the owner. Should the installer be unavailable, contact any CM recognized distributor, dealer or service organization. If assistance is

required in obtaining warranty performance, write or call:

Climate Master, Inc. • Customer Service • 7300 SW 44th Street • Oklahoma City, Oklahoma 73179 • (405) 745-6000 • e-service@climatemaster.com

NOTE: Some states or Canadian provinces do not allow the exclusion or limitation of implied warranties or the limitation of incidental or consequential damages for certain products supplied to consumers, or the limitation of liability for personal injury, so the above limitations and exclusions

may be limited in their application to you. When the implied warranties are not allowed to be excluded in their entirety, they will be limited to the duration of the applicable written warranty. This warranty gives you specic legal rights, which may vary depending on local law. IF ANY PRODUCT

TO WHICH THIS LIMITED WARRANTY APPLIES IS DETERMINED TO BE A “CONSUMER PRODUCT” UNDER THE MAGNUSON-MOSS WARRANTY ACT (15 U.S.C.A. §2301, ET SEQ.) OR OTHER APPLICABLE LAW, THE FOREGOING DISCLAIMER OF IMPLIED

WARRANTIES SHALL NOT APPLY TO YOU, AND ALL IMPLIED WARRANTIES ON THIS PRODUCT, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR THE PARTICULAR PURPOSE, SHALL APPLY FOR THE SAME TERM SET FORTH ABOVE

(ONE YEAR) AS PROVIDED UNDER APPLICABLE LAW. The portions of this Limited Warranty and limitation of liability shall be considered fully severable, and all portions which are not disallowed by applicable law shall remain in full force and effect.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state and from Canadian province to Canadian province. Refer to your local laws for your specic rights under this Limited Warranty.

Please refer to the CM Installation, Operation and Maintenance Manual for operating and maintenance instructions.

Rev.: 3/20

Part No.: RP851

Tranquility Aluminum Tube Cased Coil (TAC)

Rev.: August 21, 2018

16 Geothermal Heating and Cooling

Revision History

97B0100N01

ClimateMaster works continually to improve its products. As a result, the design and specications of each product at the time for order may be

changed without notice and may not be as described herein. Please contact ClimateMaster’s Customer Service Department at 1-405-745-6000

for specic information on the current design and specications. Statements and other information contained herein are not express warranties

and do not form the basis of any bargain between the parties, but are merely ClimateMaster’s opinion or commendation of its products.

© ClimateMaster, Inc. 2010

*97B0100N01*

7300 S.W. 44th Street

Oklahoma City, OK 73179

Phone: 405-745-6000

Fax: 405-745-6058

climatemaster.com

Date Page # Description

August 21, 2018 4 Added warning

November 5, 2015 All Updated to Aluminum Tube

April 23, 2012 3, 7 TAC 026-B Dimensions Corrected

July 6, 2011 3 Decoder Updated

April 22, 2010 All First Published

This manual suits for next models

6

Table of contents

Other ClimateMaster Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Webasto

Webasto Frigo Top 25 DS Instructions for use

Daikin

Daikin Split Sensira R32 Service manual

Samsung

Samsung AM***FN*D series user manual

Mitsubishi Electric

Mitsubishi Electric Mr. Slim PUZ-M200YKA2.UK Service manual

Panasonic

Panasonic CU-E9GFE-2 operating instructions

Airwell

Airwell AW-CFM012-N11 Service manual