TECHNICAL MANUAL

CVM 3000

C 5030 CV/04-99 GB

1

Summary

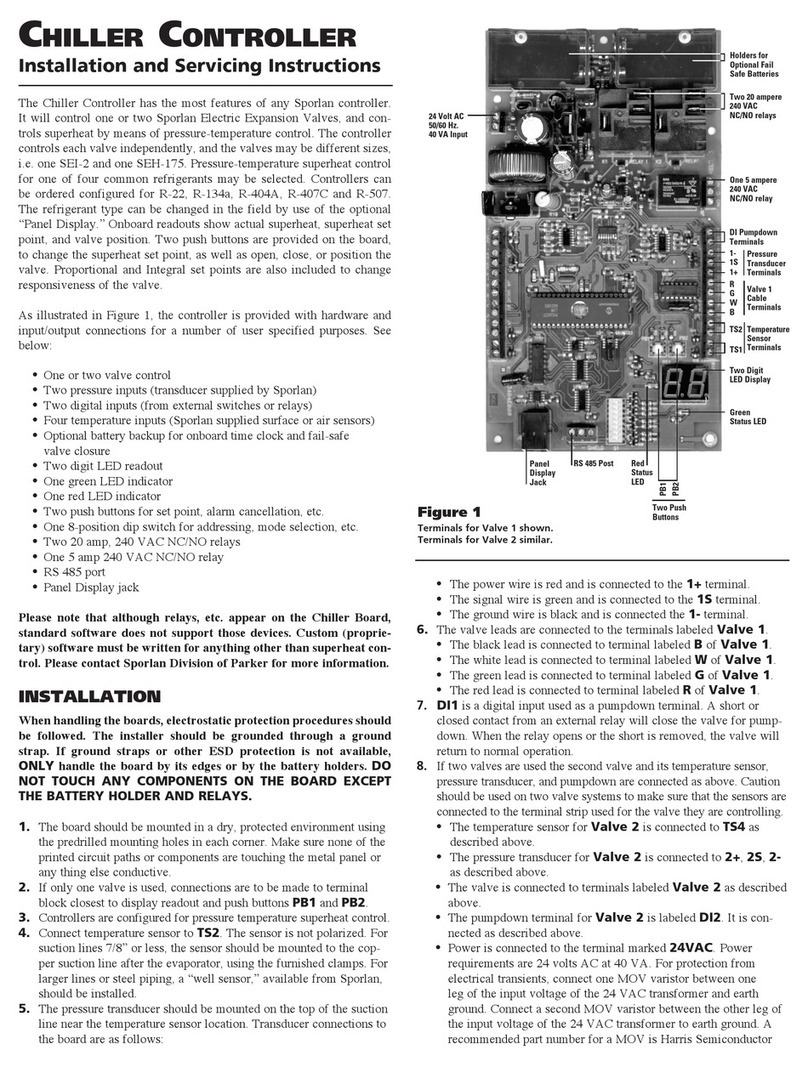

1 CONNECTIONS..............................................................................................................................8

1.1 TEMPERATURE PROBES.............................................................................................................8

1.2 PRESSURE PROBES.......................................................................................................................9

1.3 LOW VOLTAGE DIGITAL INPUTS............................................................................................10

1.4 LIVE DIGITAL INPUTS..............................................................................................................11

1.5 RELAY OUTPUTS......................................................................................................................12

2 VOLTAGE/FREQUENCY INPUT ...............................................................................................13

3 POWER SUPPLY..........................................................................................................................14

4 SERIAL CONNECTIONS............................................................................................................14

5 DESCRIPTION OF USER INTERFACE....................................................................................17

5.1 UNIT STARTUP..........................................................................................................................17

5.2 UNIT SHUTDOWN.....................................................................................................................17

5.3 ENABLING A COMPRESSOR......................................................................................................17

5.4 DISABLING A COMPRESSOR.....................................................................................................18

5.5 MEANING OF COMPRESSOR STATUS LED'S (A2)..................................................................18

5.6 READING THE OPERATINGCONDITIONS..............................................................................19

5.7 TEMPERATURE DISPLAY.........................................................................................................20

5.7.1 Version C (Chiller)................................................................................................................20

5.7.2 Versions R/N/Q Chiller with recovery; Heat pumps; Multipurpose units .............................20

5.7.3 Version FC (Chiller with free-cooling)..................................................................................21

5.8 OPERATING MODE SELECTION..............................................................................................22

5.8.1 Version R...............................................................................................................................22

5.8.2 Version N...............................................................................................................................22

5.8.3 Version FC.............................................................................................................................22

5.8.4 Version Q...............................................................................................................................23

5.9 SIGNALS......................................................................................................................................23

5.10 ALARMS.................................................................................................................................24

5.10.1 Circuit and/or compressor alarms......................................................................................24

5.10.2 General alarms....................................................................................................................25

5.11 FLASHING LED'S....................................................................................................................26

6 ALARM SIGNALS........................................................................................................................27

7 REGULATION................................................................................................................................30

7.1 CHILLED WATER REGULATION.............................................................................................30

7.1.1 Default set point settings........................................................................................................31

7.2 HOT WATER REGULATION.....................................................................................................32

7.2.1 Default set point settings........................................................................................................33

7.3 FREE-COOLING REGULATION (ONLY FC VERSION):............................................................34

7.3.1 Default set point settings........................................................................................................34