C0240102-01-10-GB

9

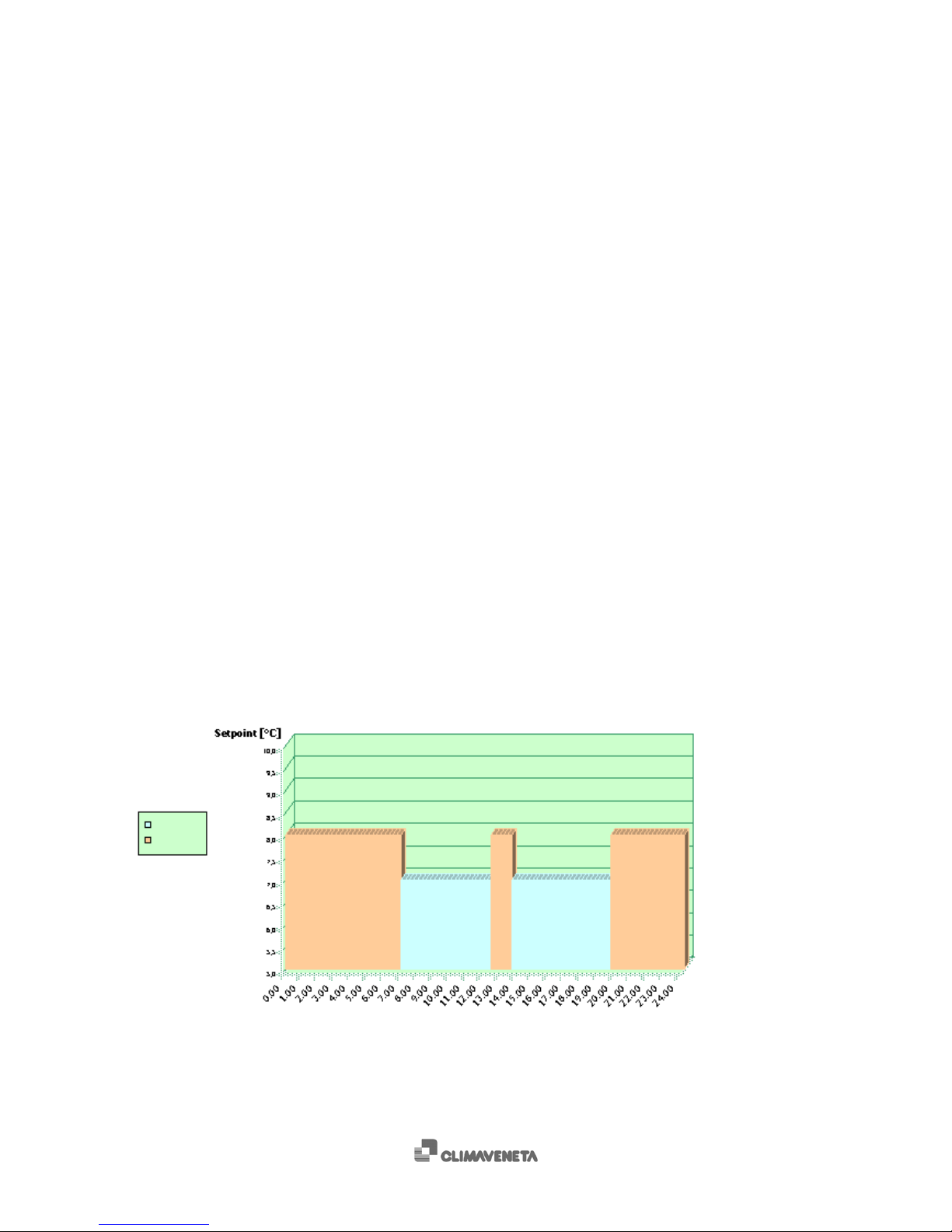

For W3000 and W3000 compact (if the clock board is fitted)

Make sure that the “Clock board not installed” is not displayed in the “clock menu”.

Check that the “Time bands enabled” parameter in the “user menu” is set to “Yes”.

SWITCHING ON: Set the required switching on time in the “clock menu”. The unit switches on

when the set time is reached. The “On from time bands” message appears in the main mask

to show that the unit has been switched on. N.B.: The unit does not switch on if it is set to

“Off from keypad” or “Off from digital input”.

SWITCHING OFF:set the required switching off time in the “clock menu”. The unit switches

off when the set time is reached. The “Off from time bands” message appears in the main

mask to show that the unit has been switched off.

Using the supervision protocol:

Only if the serial board is fitted.

Check that the “Supervisor enable” and “On/Off enable from supervisor” parameters in the “user

menu” are set to “Yes”.

Proceed as follows:

SWITCHING ON: Send the switching on command from the protocol. The “On from

supervisor” message appears in the main mask to show that the unit has been switched on.

N.B.: The unit does not switch on if it is set to “Off from keypad” or “Off from digital input”.

SWITCHING OFF:Send the switching off command from the protocol. The “Off from

supervisor” message appears in the main mask to show that the unit has been switched off.

1.4 Setting the operating mode

Caution: Do not switch from chiller to heat pump unless the inlet temperature is above 15°C.

Do not switch from heat pump to chiller unless the inlet water temperature is below 30°C.

There are various ways of setting the operating mode of the unit.

The set operating mode may be any one of the following, as long as they are compatible with the unit:

Operating mode Description

Chiller Chiller

chiller+rec Chiller plus recovery

heatpump Heat pump

summer ch Chiller in summer mode

summer ch+rec Chiller plus recovery in summer mode

summer rec Recovery in summer mode

recovery Recovery only

summer auto Automatic in summer mode

winter hp Heat pump in winter mode

winter rec Recovery in winter mode

winter auto Automatic in winter mode

auto Automatic

N.B.: in water-cooled chillers with water-side reversal the following operating modes are not yet

available: chiller+rec, summer ch+rec, auto, summer auto, winter auto.

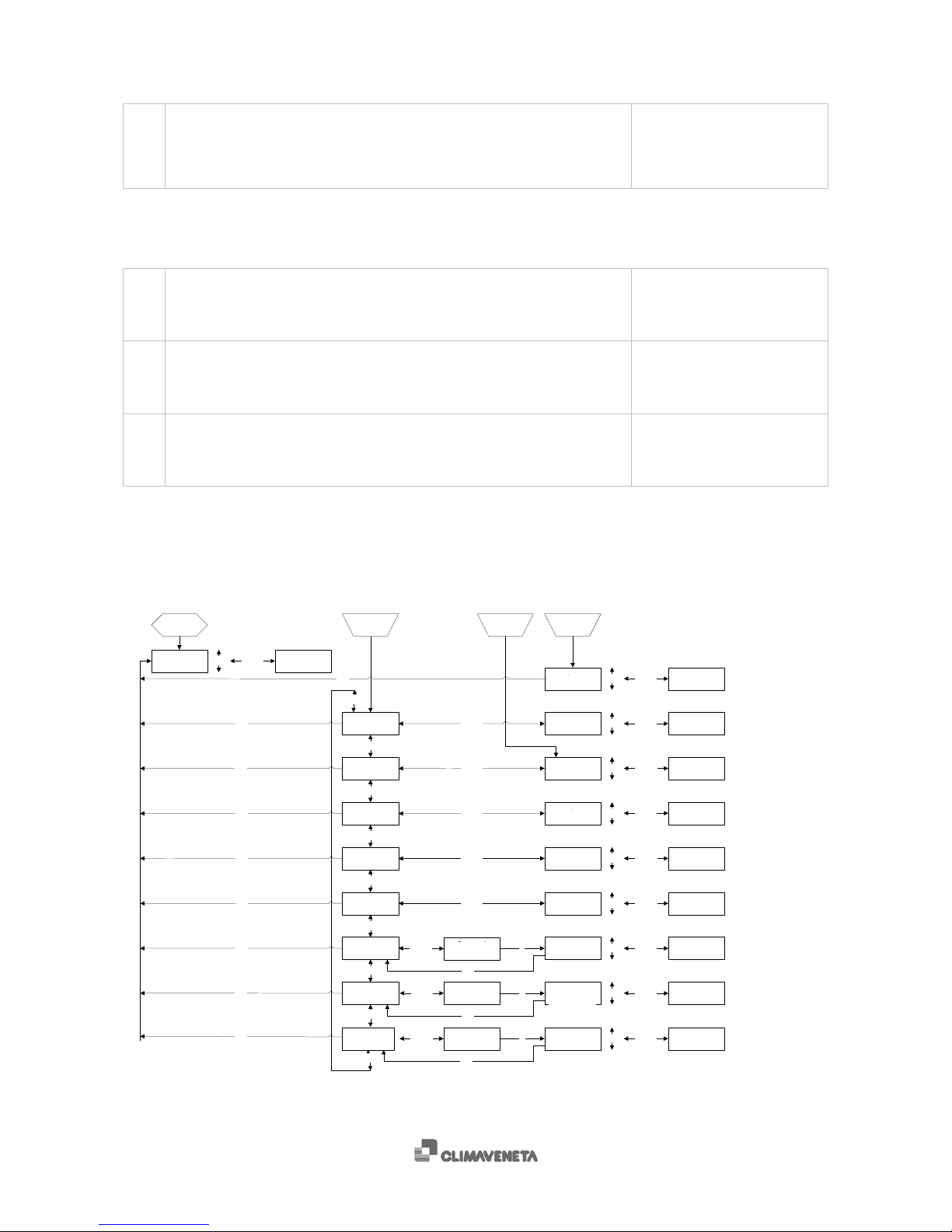

The following procedures have a priority: in the event of conflicts between opposing settings the following

priorities apply:

- highest priority: change through parameter

change through digital inputs

- lowest priority: change through protocol

Using the parameter: