Clinton 6000 Series User manual

THE

V

MANUAL NO. 137.780

REFER TO BACK OF PAGE FOR WARRANTY REGISTRATION.

IlUlPORTAN

CARE AFTER OPERATION IN SATT WATER

ATT ENGINE PARIS THAT CONTACT THE V/ATER HAVE BEEN CHEM.

ICATI.Y TREATED TO RETARD SAI,T WATER CORROSION. HOWEVER,

YOU SHOUI.D TAKE SOME SPECIAT PRECAUTION ATTER RUNNING

YOUR ENGINE IN SATT WATER.

I. ATWAYS IITT IHE ENGINE OUT OF THE WATER WHEN NOT IN

USE.

2. WHEN REAoVtNG MoToRFRoMBoAT BE suRE ro KEEP MoroR

HEAD VER'ICAI, AII.OWING WAIER TO DRAIN FROM TOWER

cotuA N.

3. FTUSH TOWER UNIT OUT WITH FRESH WATER OR PREFERABI.Y

RUN OUTBOARD MOTOR IN FRESH WATER IANK.

.. WASH ENGINE DOWN WITH FRESH WATER AND PERIODICAI.TY

APPTY AN AUTOMOTIVE TYPE WAX TO PROTECT THE fINISH.

5. PERIODICATTY REAAOVE PROPETIER AND TUBRICATE PROPETTER

SHAFT.

K-900 0 r_?=1

OATBOARD

(lWl{ERS MA]IUAT

AilD

PARTS IIST

r0R

9.0 H.p.

Monutactured by

GLINTON ENGINES

CORPO,RATION

OUTBOARD DIVISION

P. O. t30t

,nAOUOKtrA, IOWA 52060

Form No. OB-241'9 Made ln U.S.A.

IMPORTANT

Owner's Responsibility qnd Operoting Sofety Check list

BE SURE TO READ AND DO THE FOLLOWING BEFORE OPERATING YOUR OUTBOARD MOTOR

l. lnclude a life vest for each passenger in boat, as required by U.S. Coast Guard, approved type

1,2 or 3 Personal Flotation Device. lf your boat is I6 feet or longer, you are also required to

carry a Iype 4 throwable Personal Flotation Device. You are responsible for the safety of your

passengers.

2. Close fuel shut-off valve before placing motor in tilt position on transom to prevent fuel leak-

age from carburetor.

3. Before slorting, moke sure your molor is securely mounied lo boot. Tighten clomp stud hon-

dles securely by hond. A motor sofety choin is ovo iloble ol your neoresl Outboord Deoler.

1. Be sure to hove on odequole supply of fuel on boot. Use o good grode of regulor leoded goso-

line or o oulomotive type non-leoded gosoline is permissoble. Do not fill gos lonk wilh motor

running or neor ony flome.

5. To prevent possible injury from the rotating propeller, do not attempt to remove motor from

water and do not place hand near moving propeller, or allow swimming near moving propeller

until unit has come to a complete stop.

6. Be sure to have pliers, screwdriver, spare spark plugs, wrench, shear pins and cotter pins in

boat whenever leaving shore.

7. ln case of an emergency, the engine can be stop,ped by placing the choke knob in full choke

position.

8. Open vent screw on filler cap at remote tank and fuel shut-off valve before attempting to start

motor.

9. Wipe remote fuel tank connector clean before connecting connector to outboard motor.

.l0. Squeeze primer bulb on fuel line of the remote fuel tank until it becomes firm.

I I . Read break-in instructions before running your new outboard motor.

12. To assure supreme safety and compliance with the law, you should acquaint yourself with

boating laws of the U.S. Coast Guard and with the laws of your state and locality.

v

.l

DESCRI

tNTRODUCTIOl{

You have now invested in an Air Cooled Outboard Motor

which has been engineered and built to the highest of quality

standards. Many hours of enjoyment are before you in boating

pleasure.

Read this Owner's Guide thoroughly before operating the

' motor. The instructions are concise and complete in operation

, and recommendations to assure best in care and performance'

\ ' As you read the instructions, keep in mind that maximum per-

' formance and service depend on the owner or operator. May

\ u we suggest that you practice tire step by step instructiotls to

be certain you are familiar with each operation.

Periodic servicing will .be required. It is recommended

that you consult a Clinton Service Gnter when service is re'

quired. 2 CYCLE FUEL IIIXTURE INSTRUCTIONS

Use a good grade of regular gasoline. Do not use non-lead-

ed gasoline. The use of premium gasolines will shorten spark

plug life. In a clean container thoroughly mix3,ourices( 50to 1

fuel mix) of a High Quality Outboard I\totor Oil (or its equi'

valent) of SAE 30 or 40 viscosity to one gallon of gasoline. Do

not use D.M. or D.S. rated oils. For best results strain mired

\'r" fuel through a fine screened funnel when filling gasoline tank.

BBEAK.IN PERIOD

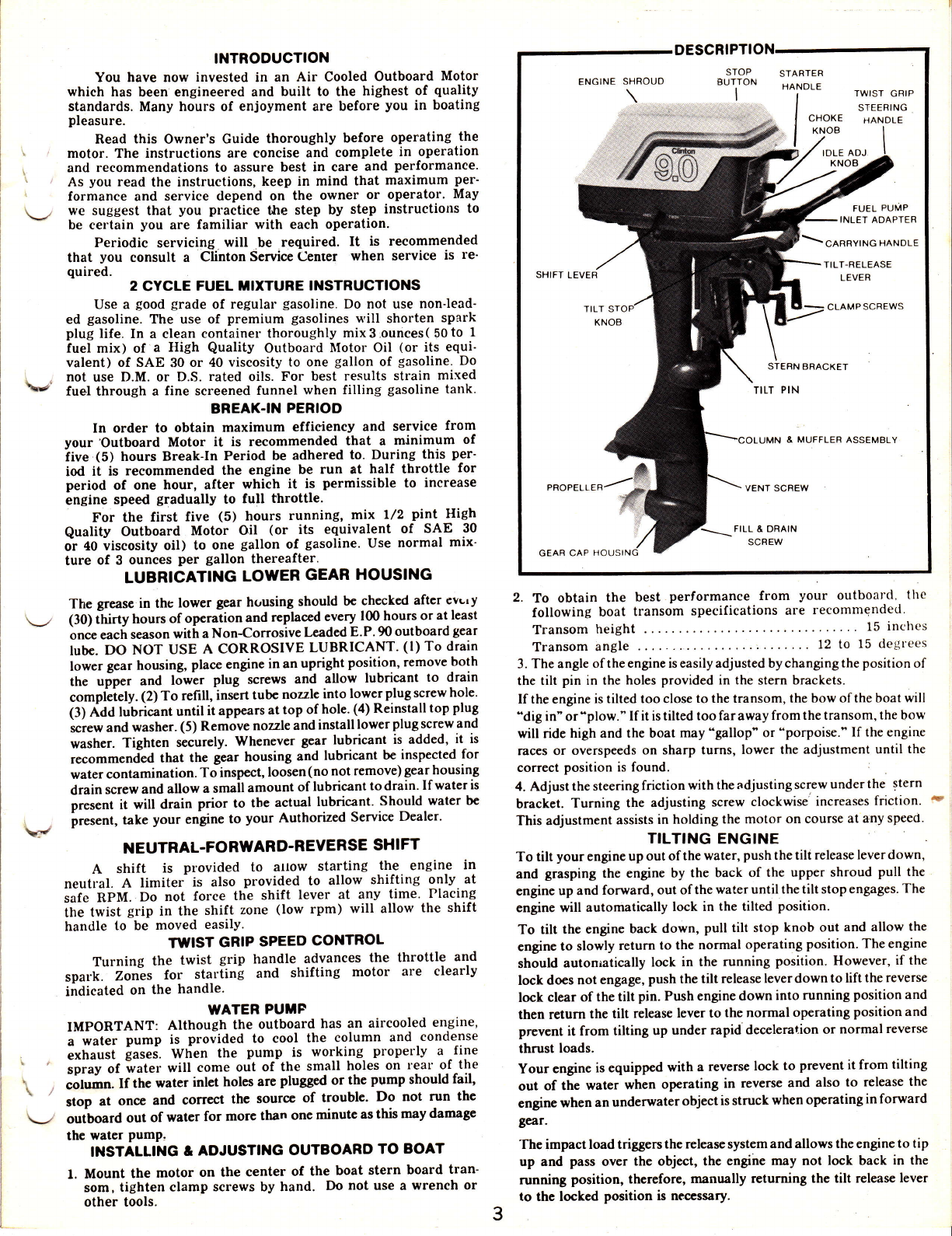

ENGINE SHROUD STOP

BUTTON

I

STABTER

HANDLE TWIST GRIP

STEERING

CHOKE HANDLE

KNOB I

JOB I

,o,-, oo, I

FUEL PUMP

INLET ADAPTER

\clnnvtruc Hnruole

SHIFT LEVEH

PROPELLER

GEAR CAP

TILT-RELEASE

LEVER

CLAMP SCREWS

E MUFFLER ASSEMBLY

In order to obtain maximum efficiency and service from

your'Outboard Motor it is recommended that a minimum of

iive (5) hours Break-In Period be adhered to. During this per'

iod it is recommended the engine be run at half throttle for

period of one hour, after which it is permissible to increase

engine speed gradually to full throttle.

For the first five (5) hours running, mix l/2 pint High

Quality Outboard Motor Oil (or its equivalent of SAE 30

o-r 40 viscosity oil) to one gallon of gasoline. Use normal mix'

ture of 3 ounces per gallon thereafter.

LUBRICATING LOWER GEAR HOUSING

The grease in thc lower gear housing should bc chccked after evLry

(30) thirty hours of opcration and replaced every l(X) hours or at least

on"" """h season witl a Non-Corrosive Leaded E.P. 90 outboard gear

lube. DO NOT USE A CORROSM LUBRICANT' (l) To drain

lower gear housing, place engine in an upright position' remove both

the ulper and lJwer plug screws and allow lubricant to drain

compleiely. (2) To refill, insert tubc nozzlc into lowcr plug screw hole'

(3) Add lubricant until it appears at top of hole.(4) Reinstall top plug

screw and washer. (5) Remove nozzle and install lower plug screw and

washer. Tighten securely. Whenever gear lubricant is added, it is

,."o--"n["d that the gear housing and lubricant be inspected for

water contamination. To inspect, loosen (no not remove) gear housing

drain screw and allow a smail amount of lubricant to drain. If water is

present it will drain prior to the actual lubricant' Should water be

present, take your engine to your Authorized Service Dealer'

NEUTRAL.FORWARD.REVERSE SHIFT

A shift is provided to attow starting the engine in

neutral. A limitei is also provided to allow shifting only at

sit" Rpttt. Do not force the shift lever at any time' Placing

itre twist grip in the shift zone (low rpm) will allow the shift

handle to be moved easilY.

TWIST GRIP SPEED CONTROL

Turning the twist grip handle advances the throttle and

.or.f.- Zon""s for starting and shifting motor are clearly

indicated on the handle.

WATER PUMF

IMPORTANT: Although the outboard has an aircooled engine,

i water pump is provided to cool the column and condense

extraust lasei. Wt,en the pump is working properly a -fine

ipriv of ivater will come out of the small holes on rear of the

;;ffi". If the water inlct holes are plugged or the pump should fail,

stop at onoe and correct the source of trouble' Do not run the

outboard out of watcr for morc than one minutc as this may damage

the water PumP.

INSTALLTNG & ADJUSTTNG OUTBOARD TO EOAT

l. Mount the motor on the center of the boat stern board tran-

som, tighten clamp screws by hand. Do not use a wrench or

other tools.

2. To obtain the best performance from your outboard, the

following boat transom speci(ications are recommended

VENT SCBEW

,\,?/

Transom height 15 inches

Transom angle . . . ' l2 to 15 degt'ees

3. Thc angle of the engine is easily adjusted by changing the position of

the tilt pin in the holes provided in the stern brackets.

If the engine is tilted too close to the transom, the bow of the boat will

'dig in" or 'plow." If it is tilted too far away from the transom, the bow

will ride high and the boat may'gallop" or'porpoise." If the engine

races or overspeeds on sharp turns, lower the adjustment until the

i

correct position is found.

4. Adjust the steering friction with the adjusting screw unde r the stern

bracket. Turning the adjusting screw clockwise' increases friction. t

This adjustment assists in holding the motor on course at any speed.

TILTING ENGlNE

To tilt your engine up out of the wate r, push the tilt release lever down,

and grasping the engine by the back of the upper shroud pull the

engine up and forward, out of the water until the tilt stop engages. The

engine will automatically lock in the tilted position.

To tilt the engine back down, pull tilt stop knob out and allow the

engine to slowly return to the normal op€rating position. The engine

should autonratically lock in the running position. However, if the

lock does not engage, push the tilt release lever down to lift the reverse

lock clear of the tilt pin. Push engine down into running position and

then return the tilt release lever to the normal operating position and

prevcnt it from tilting up under rapid deceleralion or normal reverse

thrust loads.

Your engine is equipped with a reverse lock to prevent it from tilting

out of the water when operating in reverse and also to release the

engine when an underwater object is struck when operating in forward

gear.

The impact load triggers thc release system and allows the engine to tip

up and pass over the object, the engine may not lock back in the

running position, thcrefore, manually returning the tilt releasc lever

to the locked position is ne.ccssary.

3

STARTING PROCEDURE

l. lnsert fuel coupling into fuel pump inlet adapter located above

front carrying handle.

2. Open air vent on tank. Since fuel is supplied to the carb-

uretor by means of the fuel pump, it is necessary to prime

the fuel system. The primer is located between the r.emote

tank and the fuel pump. To operate primer pump, squeeze

by hand. Upon squeezing the primer, fuel is forced into

the fuel line and carburetor. When sufficient {uel is in

the system, it becomes more difficult to squeeze the primer

This is your signal that sufficient fuel is in the system.

3. Turn throttle control twist grip to slow position.

4. Move shift handle to neutral position.

5. Turn throttle control twist grip toward high speed until

it stops. (START POSITION)

6. Pull choke knob to full "Choke" position.

7. IMPORTANT: Pull starter handle slowly until you feel

starter engage, then pull rapid motion and allow thl starter

cord to retract slowly.

6. When engine starts push choke knob in about hal{way

and.-leave in this position until engine warms up sufficient-

ly. Then push choke all the way in.

9. When ready to go.forward, turn twist grip to slow posi-

tion and pull shift lever forward.

IiITMEMBER: Do not accelerate engine to full speed until

completing "Break-In" period.

STOPPING PROCEDURE

To stop outboard turn twist grip throttle to slow position

and push stop button located on front panel. Tighten air vent

on fuel tank if outboard is not going to be run for a period

of time.

FLOODING

Flooding is usually caused by over choking the outboard.

If flooding occurs see that the choke is in "Run" position and

that the throttle twist grip is at START. Continue to pull the

starter handle until the outboard starts. It may be necessary

to remove spark plug and dry the electrodes.

CARBURETOR

Throttle Shaft

Stop Screw

Choke Knob

(C) Idle

Adjustment

Screw -'

Set Screw Idle Adjustment

:' Knob

(A) Power Adjustment

Screw

CARBUBETOR ADJUSTTENT

The carburetor is adjusted at the factory. It should not

be necessary to readjust it until the engine is well broken in

at which time you may want to adiust. To do this or to verify

the original adjustment pnoceed as follows: Remove shroud'

l. Turn (A) power adjustment screw clockwise until closed.

Do Not Force. Then open counter+lockwise at least 2 turns.

CAREURETOR ADJUSTMENT CONTTNUED

2. Turn (C) idle adjustment screw clockwise until closed. Do Not

Forcc. Then op€n countef-clockwise I turn from closed position.

lf idle needle must be set beyond the range of the idle knob follow

these instructions. To close idle adjustment screw first loosen

screw located on idle shafi with a 5164' allen wrench, tl '

turn idle adjustment knob clockwise. After carburet. I

adjusted retighten set screw at horizontal position as shown. i

Loosen idle adjustment knob and placc poinier at number \-/

position and re-tighten.

3. Start engine. Allow a short period of time for engine to

warm up.

4. To adjust carburetor power adjustment screw (A) move

speed control lever to fast position and turn (A) power'

adjustment screw clockwise until engine speed dlops off.

Then turn counter-clockwise l,/4 turn. If needle is open loo

far, engine exhaust will be heavy and speed will drop off.

5. To adjust (C) idle adjustment screw, move speed cont-ol

lever to slow position. Adjust (B) throttle shaft stop s I

to keep engine operating at low speed. CAUTION: MVr

MUM ADJUSTMENT r/4 TURN AT A TIME. Stop screw

(B) sets minimum speed. Turn (C) idle adjustment sclew

clockwise very slowly and continue closing as long as engine

sound improves and speed increases. In some cases idle

needle may need to be opened counter-clockwise to secure

desired results. Throttle shaft stop screw (B) will usually

require a change to set minimum speed as desired. Nolmal

idle speed is 800 to 900 revolutions per minute.

6. Check engine acceleration from slow to fast operation. It

may be necessary to open (C) idle adjustment screw

counter-clockwise 1/8 turn to secure best acceleration from

slow to fast speeds.

7. Should engine backfire or pop when throttle control is

moved to slow position, the idle mixture is too lean. To

correct this turn the (C) idle adjustment screw cou'

clockwise until backfiring or popping is eliminated rx-;l

throttle control is moved to slow position.

PROPELLER SHEAR PIN

The soft safety pin shears off when an obstruction is

struck at,high speed, thus protecting the gears and shafts from

damage. When shear pin is broken the engine will continue

to run, however, the propeller will not be rotating. To repair

shut off motor and remove propeller cotter pin and nut. Slip

off propeller and replace with new shear pin. Extra shear pins

and cotter pin are located under shroud on powerhead.

SOLID STATE IGNITION SYSTEM

(A) The solid state ignition system consists of the following compononF

parts: Flywheel, Ignition Module, Spark Plug, and S. . ;

Advance Assembly.

(B) Inspect the following if engine fails or is hard to start. ( I ) Spark plug

as often as necessary. Be sure spark plug gap setting is .025. (2)

Gasoline fuel supply air vent screw on filler cap at fuel tank should

be open. (3) Carburetor bcing starved of fuel.

(C) The correct spark plug for this motor is Champion J I 3Y or

equivalent.

(D) To test ignition system for spark remove high tension wire from

spark plug and hold about I / E' from any metal part of motor and

pull starter cord. If a spark bridges thc gap the ignition system is in

good operating condition. If no spark, have the ignition system

checkcd at a Authorizcd Servicc Ccntcr.

STORAGE \ /

To store your outboard drain all water from lowel /

umn and drain gas line and carburetor. Place motor c 's

side, remove spark plug and pour about l,/4 cup of oiL.-,/o

spark plug hole. Pull starter rope sever'al times to rotate the

crankshaft then replace spark plug. Fill gear housing with

grease as directed. Store in upright position. When starting a

new season always use fresh gasoline. Last. year's gasoline

may have vArnish deposits that will plug the carburetor jetg

thus requiring a carburetor overhaul.

(B)

4

\#'

Although interior surfaces of your outboard motor are designed

to resist corrosion, there still is a possibility of mechanical

build-up of salt and silt deposits. This can be eliminated only

by ftushing with fresh water. To materially increase the life

of all expoged parts and decorative finishes, follow these steps:

1. Always tilt your motor out of water when not in use.

2. Never leave the lower unit in salt water overnight.

3. Run outboard motor in fresh water tank for approximately

5 minutes to flush out salt deposits and to avoid possible

corrosion (see illustration),

4. l{ash engine down with fresh water and periodically apply

an automotive type wax to protect the finish.

5. Lubricate propeller shaft occasionally with a waterproof

type of lubricant (Lithium Grease), thus enabling the pro-

peller to be removed easily.

6. It is a good practice when operating in salt water to inspect

your motor daily and to apply a light coating of grease to

any part or area that shows evidence of corrosion or rust.

7. Always remove motor from boat vertically, allowing water

to drain from column before tilting the motor.

-XEEP WATER LEVEL APPROXIMATELY

I s rilcxrs FRoM ToP

I

OVERFLOW

DRAIN

?"x4"

MOUNTING BOARO

\*

CAUTION

Do not run your outboard motor out of water be-

cause it will damage the cooling system and engine'

To check out your motor at home, or flush it after

salt water use, obtain a S5-gallon drum with top

removed. fit it with a mounting board for your

motor, and fiII the drum to within 9" of top with

fresh water to serve as a test tank fol running your

motor. Make sure propeller is turning, but do not

exceed idle speed position. Do not readjust the

carburetor while running your motor in this type

of test tank. Run motor in a well ventilated area

or outside.

/"""i/* I i/si$

*"*/i'"lSlsliFr TROUBTE SHOOTING CHECK LIST

x x Remote Fuel Tank Not Connected - where opplicoble

xxFuel Tank Empty

xxXXFuel Line Kinked or Pinched

xxxFuel Filters Dirty or Clogged

xxXXVent Screw Gasket Obstructing Air Flow - Fuel Tonk

xXxVent Screw on Fuel Tank Cap Closed - Fuel Tonk

xxXx Air Leak in Engine

xx x Air Leak ln Fuel System

x x XxCarburetor Passages Clogged or Dirty

xxxx x lncorrect Fuel-Oil Mixture

xxxxxCarburetor Out of Adjustment

xEngine Flooded

xxx x xWrong Type Spark Plug

xxxXxDefective or Fouled Spark Plug

xDefective Magneto

xSpark Does Not Jump Spark Plug Gap

xEngine Out of Time

xxxxxWeak or Defective lgnition Transformer

xSpark Plug Lead Wire Not Secured

xxFrayed or Cracked Lead Wire !nsulation

xxDisconnected, Grounded or Loose Wiring in Electrical System

xPropeller Bound by Foreign Objects (Fishing Line, Weeds, Etc.)

xxWater Pump and Coolinq System Failure

5

f

POWERHTAD PARIS LISI

a-'-'-89

E

e__1 18

I

)

2r ' ,/ *^ s -\rE| -l

*/-ttt e5- (g 68\({2- ^ 6-11-_/_ |

o, --9,r"----r12

N r'o)) i (

2t

123 {) ._ O 5p*--;jz i;<

r -t- t r'a{ / 25

tr?-'^7ffi'1,'ffiffi

m+ mi *'?l],,'-\el' ,[T

tT.l -l t*I1_l a-

-*'d

76 rbr ,[o

$--5

,r{ I

POWTRHEAD PARIS TISI

Ref .

!6-

t1

48

2 19- 186-500 AINER-Dos Starter

REIAINER-Bear

RE'IAINER-Wrist Pin

BRACKET-Spare Pin PI

258-1t27

CONNECTOR-Elbow -Thrott1e Control Arm

OVER-Float Bowl

CRANKSHAFT 4-Adaptor to Shilt Linriter

DEFLECTOR-Cvlinder Head BRACKET-Shortins Wire

FLOAT & LEVER ASS'Y SCREW-Choke & Throttle Valve

l2]:r!-!l!-:!IS3l4

SCREW-Head

258-8?3-500 SCREW-Induction Bracket

-Brns. Plate to B

-Brns. Plate to Block

6- 614-500 SCREW-Idle Adi- Ass'

181-5-500 SCREW-Connectins Rod

SCREW-Recoil

L-Bearing Plate

HEAD-Cylinder

ASS'Y-Recoil

232-t37 SPARK PLUG-J13Y

-Starter Pawl

159-210

136- 147

SPRING-Carb- Float

268-36-500 MAGNETO ASS'Y

NUT-Shoulder Screw

WASHER-Thrrttle Arm

NUT-Carb. to Ind. Bracket

2 15-578-500

1

2

\J

\r

order By part Number, Not Reference Number. spEctFlcATloNs

BORE AND STROKE 2-5/8 x l-7/8

DISPLACEMENT (Cu. rn.) ------- --- 10.14

CARBTRETOR ---------- Float

CRANKSHAFT---------- Forged

BEARINGS (Engine) --------Needle and BaII

BEARINGS (Gear HousinC)---- ----Needle

GEAR RATIO ------ --- L3-22

PROPELLB TYPE --------- Shear Pin - Semi Weedless

PROPELLER, DIA. & PITCH -- 6-3/4x6-3/8

IDLE SPEED -.--- 9OO R. P. M"

OPMATION RANGE --. 4OOO . 5OOO R. P. M.

z PEAK HORSEPOM, --------At 6000 R" P.M. Sea Level

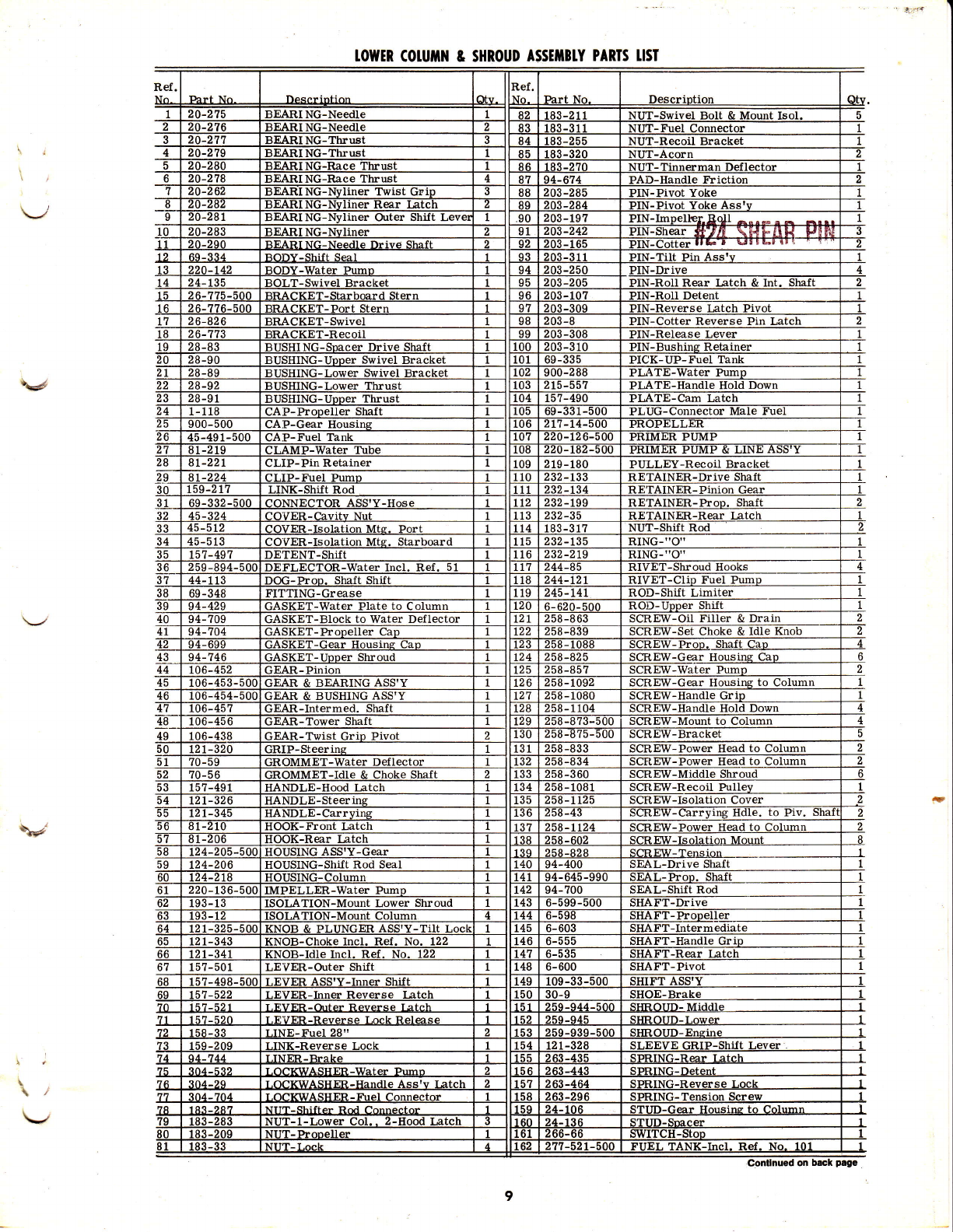

TOTIIER COLUIIN & SHROUD ASSETIBIY PARIS TISI

50

I127

i/

130

I 168

[/ 156 -rr8

v{--,,

113-$-

. __-.c

tr7

<-d>

- --'

I

\#

\./'

\

1OWM COUIII]I & SHROUD ASSIITB]Y PARIS TISI

IP-Pin Retainer

GASKET-BIoCk to Water Deflector SCREW-OiI Filler & Drain

SCREW-Water

LEVffi,-Outer Shift

9

towtR CotUftlH & sHRoUD ASSt[lBtY

Descr ir)t r ()n

TUtsE-Water

WASHm-Filler Hole

WASHER-Gear Housing to Column

ETAI NER-''X''

EW-Carrving Handle to PivASHffi.-Friction Notc

PARTS I.I5T

NOTE: ORDER BY PART NO., NOT REFERENCE NO.

MR. SALESI\{AN OR MR. DEALER: Please fill out this warranty form to insure

that your customer will receive warranty

service if needed.

Street Address or R. F. D. No. County

CLIN.T0N ENGINES C0RP0RATI0N o MAQU0KETA, l0WA

wa.E3.E3. ^rtfY

THERE ARE NO WARRANTIES WHICH EXTENO BEYOND THE PRODUCT OESCRIPTION EXCEPTING ONLY THAT

EAEij pnooucl soLD HEREUNoER ls wARRANTEo AS FoLLows:

ONE YEAR LIMITED WARRANTY

FOR ONE YEAR FROM PURCHASE, qLrNl'9Ir_E!-Gr!ErS COBeOR^TIq{, rvlL.L-REPLACE FOR THE ORIGINAL

FU'Cc-iiA-sent, FireE or CnancE, ANY PART qBroABls,-Equryg_uf-ory qx-AMlNArloN BY ANY FA6T6RY

icJiiijHiieD'senvrce eccouNr., oR By FAcroRy, AI M^auq[ETA-, !o_w.! To BE DEFEcrlvE lN MATER-

iir-f iji i^ionrua_Nsrrip on BoTH, ALL 1RANIPqtTATION CHARGES ON PARTS SUBMITTED FOR REPLACE-

i',iiNi iJr'ioER rxii wnRRaurY MUST FE BoRNE BY PURcHASER

ixene ts No orHER ExPREss wARRANTY.

il,iFAiEd wnnnANTIes, INCLUoING THOSE OF MERCHANTABILITY ANO FITNESS FOR A PARTICULAR PUR.

ij.iisE. [ne LIMITED To oNE YEAR FRoM PURCHASE AND TO THE EXTENT PERMITTED BY LAW ANY AND

iil_rr.irpIleo WARRANTIES ARE EXCLUDED. THIS IS THE EXCLUSIVE REMEDY ANO LIABILITY FOR CON-

SEQUENTIAL DAMAGES UNDER ANY AND ALL IVARRANTIES ARE EXCLUDED TO THE EXTENT EXCLUSION

IS PERMITTED BY LAW.

Outboard - Warranty Period One Year

C LII,ITON ENGINES CORPORATION

Maquoketa, Iowa

WARRANTY PROCEDIJRE

Outboard Model No. (Copy No. from Outboard name plate) Outboard Serial No.

Date Purchased

MR. CUSTOMER:

Purchased From

Should warranty service be required, present this completed

warranty form to your Authorized Clinton Service Account

along with outboard.

City State

This manual suits for next models

1