7

CAUTION! –Lowering the propeller into the water or shifting into forward at a high engine

rpm may cause a standing operator or passenger to lose balance or be ejected from the

boat. ALWAYS ALLOW THE ENGINE TO COME TO IDLE OR SHIFT INTO NEUTRAL

BEFORE LOWERING THE PROPELLER INTO THE WATER!

NOTE: AFTER YOUR FIRST TEST RUN ON THE WATER IT IS NECESSARY TO

REMOVE THE DRAIN PLUG (SHOWN ON PAGE 10) AT THE REAR OF THE DRIVE

HOUSING TO CHECK FOR WATER LEAKING IN. THIS BOX MUST RUN

COMPLETELY DRY. IF WATER COMES OUT OF THE DRAIN PLUG THE COVER

PLATES MUST BE REMOVED AND RE-SEALED WITH A GOOD GRADE SILICONE.

PERFORM THIS CHECK ANY TIME THE COVERS ARE REMOVED AND REPLACED.

Low Speed Operation

As described before, let the engine warm up for a few minutes. Holding the handle

carefully, remove the handle rope and get a feel for the balance of the engine.

For the first time operating your new Surface Drive engine, turn the trim adjustment knob

counterclockwise until the prop and cavitation plate can befully submerged while the boat

is floating at rest. Under normal conditions the trim can be adjusted for high speed

performance and does not need to be changed while idling or getting back up on plane.

Steer the engine slowly to avoid getting water into or overturning the boat. The

Go-Devil Surface Drive engine is better suited for wider bottomed boats (48” or wider).

Use extreme caution- even while idling -when making sharp turns on narrow boats.

To turn the boat around in a tight situation, allow the boat to nearly come to a complete

stop. While the engine is idling and in neutral, turn the engine all the way to one side and

shift into forward. Most boats will turn in their own length when this is done.

TIP! - Turning left at low speed requires less reach due to the handle being on the left

side of the engine. When reversing direction from rest or idle speed, set up to turn left

whenever possible. This will become instinctive with time.

High Speed Operation

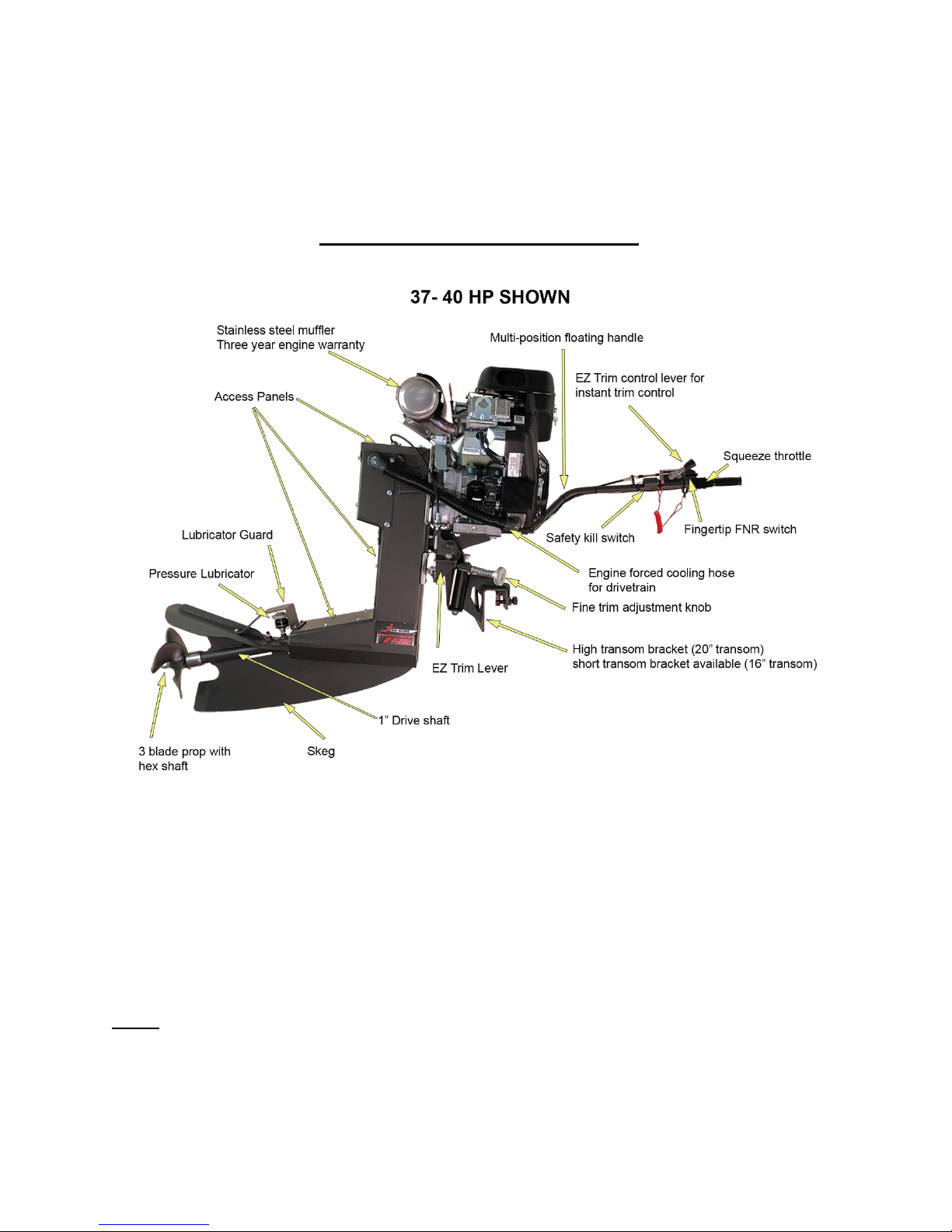

As its name implies, the Go-Devil “Surface Drive”, uses a surface piercing propeller. The

surface propeller is designed to be run primarily with a fraction of each blade breaking the

surface of the water with each revolution. To get maximum performance from the engine,

propeller depth can be fine tuned using the manual trim.

The manual trim mechanism is a standard feature on all SD models. The trim is simply

a bottom stop on the tilt axis of the engine which allows the engine to tilt upward freely

when an underwater obstacle is struck.