CMNA DLCLRB Series User manual

Specifications subject to change without notice.

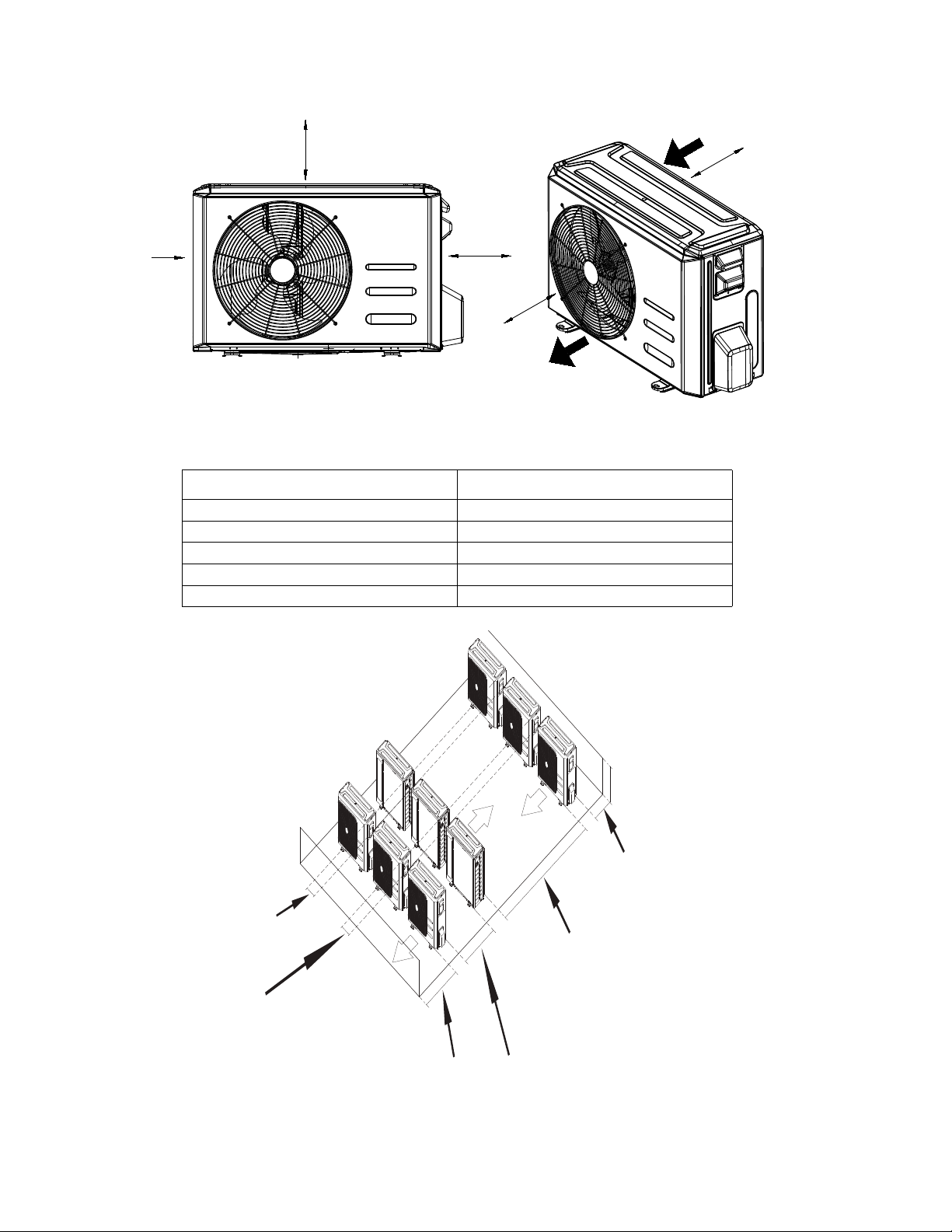

Fig. 1 —Size 36K

Fig. 2 —Size 48K

NOTES: Read the entire instruction manual before starting the

installation.

Images are for illustration purposes only. Actual

models may differ slightly.

TABLE OF CONTENTS

Page

SAFETY CONSIDERATIONS........................................................2

INTRODUCTION ............................................................................3

ACCESSORIES................................................................................3

DIMENSIONS..................................................................................4

CLEARANCES ................................................................................6

INSTALLATION REQUIREMENTS .............................................7

INSTALLATION .............................................................................7

Step 1 - Check Equipment ................................................................7

Step 2 - Mount Unit ..........................................................................7

Step 3 - Condensate Drain Installation .............................................8

Step 4 - Refrigerant Piping ...............................................................9

Step 5 - Evacuate Coil And Tubing System .....................................12

Step 6 - Electrical Connections.........................................................13

WIRING ...........................................................................................13

ELECTRICAL DATA......................................................................14

CONNECTION DIAGRAMS ..........................................................14

START-UP .......................................................................................15

CARE AND MAINTENANCE........................................................15

OUTDOOR UNIT DIAGNOSTIC GUIDES ...................................15

DUCTLESS START-UP CHECKLIST ...........................................16

DLCLRB

INSTALLATION INSTRUCTIONS

Outdoor Unit Single Zone Ductless System - Sizes 36 to 48

2 Specifications subject to change without notice. 32801100001

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air- conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start- up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as coil cleaning. All other operations should be performed by

trained service personnel only.

When working on the equipment, observe the precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes.Wear safety glasses and work gloves. Keep

a quenching cloth and a fire extinguisher nearby when brazing.

Use care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and National Electrical Code (NEC) for

special requirements. Recognize safety information.

This is the safety- alert symbol . When you see this symbol on

the unit and in instructions or manuals, be alert to the potential for

personal injury. Understand these signal words: DANGER,

WARNING, and CAUTION. These words are used with the

safety- alert symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death. WA R N I N G

signifies hazards which could result in personal injury or death.

CAUTION is used to identify unsafe practices which may result in

minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or

death.

Before installing, modifying, or servicing system, main electrical

disconnect switch must be in the OFF position. There may be

more than 1 disconnect switch. Lock out and tag switch with a

suitable warning label.

WA R N I N G

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing oxy-

gen for leak testing or operating refrig-

erant compressors. Pressurized

mixtures of air or gases containing oxy-

gen can lead to an explosion.

WA R N I N G

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe in the

ground. If any section of pipe is buried, there must be a 6 in. (152

mm) vertical rise to the valve connections on the outdoor units. If

more than the recommended length is buried, refrigerant may

migrate to the cooler buried section during extended periods of

system shutdown. This causes refrigerant slugging and could

possibly damage the compressor at start-up.

CAUTION

32801100001 Specifications subject to change without notice. 3

INTRODUCTION

The Horizontal Discharge Outdoor units are R-410A

condensing units designed with application flexibility in mind.

These units have a max total piping length up to 213 ft (65 m)

and a maximum piping lift of up to 98 ft (30m).

The inverter driven compressor is designed to run at various

input power frequencies (Hz) which controls the compressor’s

motor speed.

ACCESSORIES

The system is shipped with the following accessories. Use all

of the installation parts and accessories to install the system.

Improper installation may result in water leakage, electrical

shock and fire, or cause the equipment to fail. Keep the

installation manual in a safe place and do not discard any other

accessories until the installation work has been completed.

Table 1 —Accessories Fig. 3 —Parts List

NOTE:

- If the outdoor unit is higher than the indoor unit, prevent rain

from flowing into the indoor unit along the connection pipe by

making a downward arc in the connection pipe before it enters

the wall to the indoor unit. This ensures that rain drips from the

connection pipe before it enters the wall.

- Piping and the interconnecting wiring are field supplied.

- The illustration above is only a sketch. Different models may be

slightly different.

Table 2 lists the units covered in this manual.

Table 2 — Unit Sizes

PART

NO. PART NAME QTY.

1 Outdoor unit 1

-Literature package including installation instructions

and warranty 1

-Grommet to secure the outdoor unit (helps with

vibration prevention during unit operation) 4

-DrainJoint 1

-DrainHose 1

SYSTEM TONS KBTUH VOLTAGE -

PHASE OUTDOOR MODEL

3 36,000 208/230 - 1 DLCLRBH36AAK

4 48,000 208/230 - 1 DLCLRBH48AAK

Ŷ2XWGRRU

4 Specifications subject to change without notice. 32801100001

DIMENSIONS

Table 3 — Dimensions

Fig. 4 —Size 36K

UNIT SIZE 36K 48K

Height in (mm) 31.89 (810) 52.48 (1333)

Width in (mm) 37.24 (946) 37.48 (952)

Depth in (mm) 16.14 (410) 16.34 (415)

Operating Weight lbs (kg) 155.42 (70.5) 219.14 (99.4)

Shipping Weight lbs (kg) 166.23 (75.4) 249.12 (113)

Shipping Height in (mm) 34.45 (885) 34.45 (885)

Shipping Width in (mm) 42.91 (1090) 42.91 (1090)

Shipping Depth in (mm) 19.69 (500) 19.69 (500)

32801100001 Specifications subject to change without notice. 5

DIMENSIONS (CONT.)

Size 48K

Fig. 5 —Size 48K

6 Specifications subject to change without notice. 32801100001

CLEARANCES

Fig. 6 — Outdoor Unit Clearances

Table 4 — Outdoor Unit Clearance Dimensions

Fig. 7 —Clearances for multiple units

DB

AE

C

Air inlet

Air outlet

UNIT MINIMUM VALUE

IN. (MM)

A 24 (610)

B 24 (610)

C 24 (610)

D 4 (101)

E 4 (101)

59in (150cm)

or more when

facing each other

Blowing into the air-inlet of other

condenser shall be avoided.

24in (60cm)

or more

59in (150cm)

or more on a

multiple parallel

unit arrangement

24in (61cm) or more on a single parallel unit arrangement

19in (48cm) or more on

a multiple parallel unit

arrangement 4in (10cm)

or more on a single

parallel unit arrangement

9.8in (25cm) or more for proper airflow

24in (61cm) or more is recommended

for service

9.8in (25cm) or more for

proper airflow 24in (61cm)

or more is

recommended

for service

32801100001 Specifications subject to change without notice. 7

INSTALLATION REQUIREMENTS

• A location which is convenient to installation and not exposed to

strong winds.

• A location which can bear the weight of the outdoor unit and

where the outdoor unit can be mounted in a level position.

• A location which provides appropriate clearances (see Fig. 6).

• Do not install the indoor or outdoor units in a location with special

environmental conditions. For those applications, contact your

Sales representative.

• Allow sufficient space for airflow and service of the unit. See Fig.

6 — on page 7 for the required minimum distances between the

unit or walls.

NOTE: DO NOT install the indoor or outdoor units in a location with

special environmental conditions. For those applications, contact your

Ductless representative.

INSTALLATION

Step 1 - Check Equipment

Unpack the unit and move to the final location. Remove the carton,

taking care not to damage the unit. Inspect the equipment for damage

prior to installation. File a claim with the shipping company if the

shipment is damaged or incomplete.

Locate the unit rating plate which contains the proper installation

information. Check the rating plate to ensure the unit matches the job

specifications.

Step 2 - Mount Unit

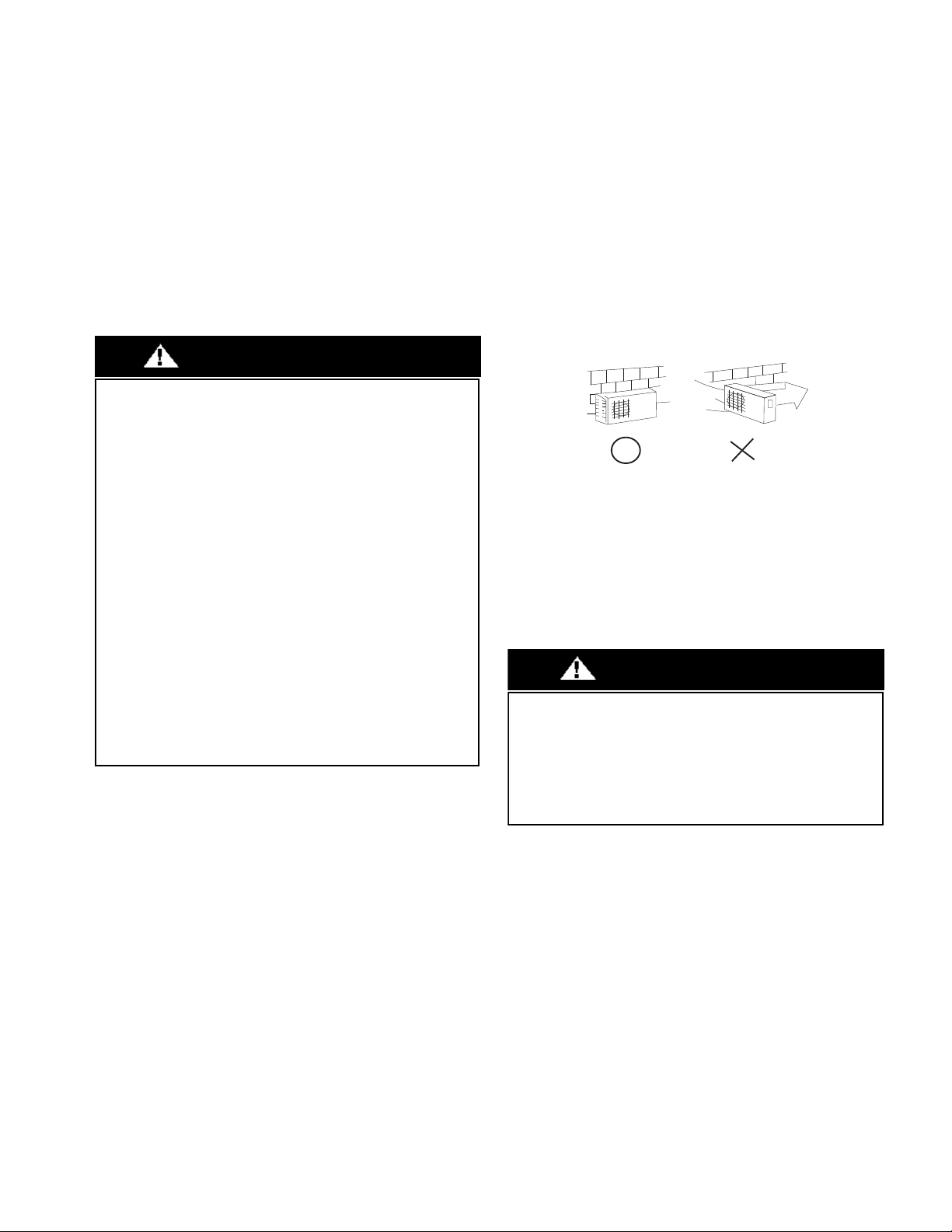

1. Select the installation location of the outdoor unit following the

installation requirements. To prevent high wind exposure, install the

outdoor unit with the air inlet side facing the wall (see fig 8).

Fig. 8 — High Wind Installation

2. Use a rigid base to support the unit in a level position. If conditions

or local codes require the unit be attached to a pad, tie down bolts

should be used and fastened through knockouts provided in unit

base pan. Refer to unit mounting pattern in Fig. 3 to determine base

pan size and knockout hole location. For hurricane tie downs,

contact distributor for details and PE (Professional Engineer)

Certification, if required. For extreme outdoor conditions

applications refer to the 'Cold Climate Application Guideline

Ductless’.

PRODUCT INSTALLATION

• Installation must be performed by an authorized dealer or

specialist. A defective installation can cause water leakage,

electrical shock, or fire.

• The installation must be performed according to the installation

instructions. Improper installation can cause water leakage,

electrical shock, or fire. (In North America, installation must be

performed in accordance with the requirements of NEC or CEC

by authorized personnel only.)

• Contact an authorized service technician for repair or

maintenance of this unit. This appliance must be installed in

accordance with local codes.

• Only use the included accessories, parts, and specified parts for

installation. Using non-standard parts can cause water leakage,

electrical shock, fire, or unit failure.

• Install drainage piping according to the instructions in this

manual. Improper drainage may cause water damage to your

home and property.

•DO NOT install the unit in a location that may be exposed to

combustible gas leaks. If combustible gas accumulates around

the unit, it may cause a fire.

•DO NOT turn on the power until all work has been completed.

• When moving or relocating the system, consult experienced

service technicians for the disconnection and re-installation of

the unit.

WA R N I N G

Strong

wind

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

In regions with snowfall and cold temperatures, avoid installing

the outdoor unit in areas where it can be covered by snow.

Blocking the air intake may result in reduced airflow,

significantly reduced performance and damage to the equipment.

CAUTION

8 Specifications subject to change without notice. 32801100001

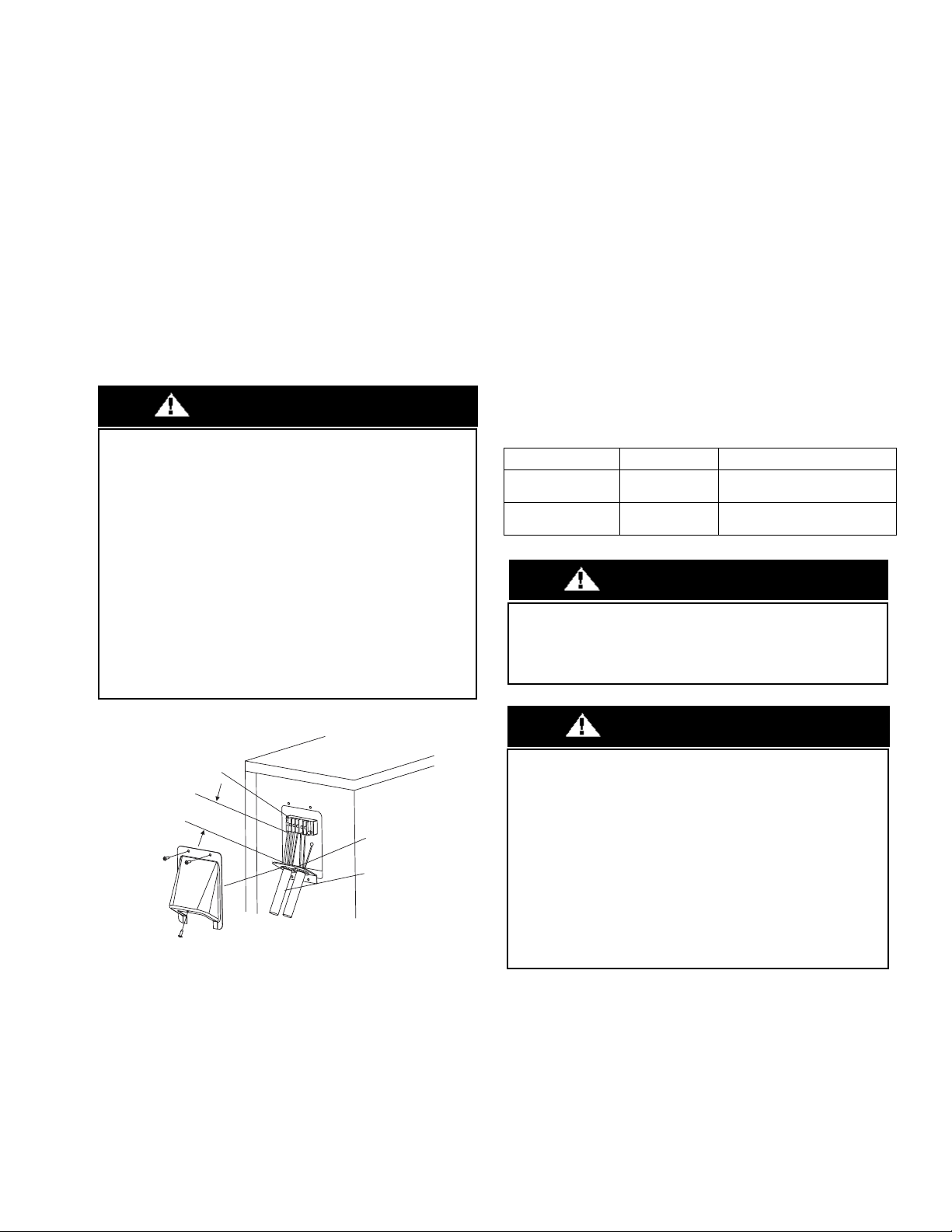

Step 3 - Condensate Drain Installation

Install drains must meet local sanitation codes.

Install the outdoor unit drain joint

Fit the seal into the drain joint, then insert the drain joint into the base

pan hole of the outdoor unit. Rotate 90° to securely assemble them.

Connect the drain joint with an extension drain hose to avoid

condensate from draining off the outdoor unit during the heating

mode.

Fig. 9 —Drain Joint

NOTE: Images are for illustration purposes only.

NOTE: Basepan built-in with multiple holes for proper

draining during defrost. For applications where it is

required to seal these holes, and re-direct the

condensate drain, rubber plugs are available through

RCD.

Table 5 — Base Pan Base Rubber Plugs

Seal Base pan hole

Drain joint

Seal

Base pan Drain

joint

OUTDOOR UNIT

MODEL NUMBER

PER UNIT

BASE PAN BASE

RUBBER PLUGS RCD

PART NUMBER

QUANTITY

DLCLRBH36AAK 12600801A00117 5

DLCLRBH48AAK 12600801A00118 5

EQUIPMENT DAMAGE HAZARD

In cold climates, ensure the drain hose is as vertical as possible to

ensure swift water drainage. If water drains too slowly, it can freeze

in the hose and flood the unit.

CAUTION

32801100001 Specifications subject to change without notice. 9

Step 4 - Refrigerant Piping

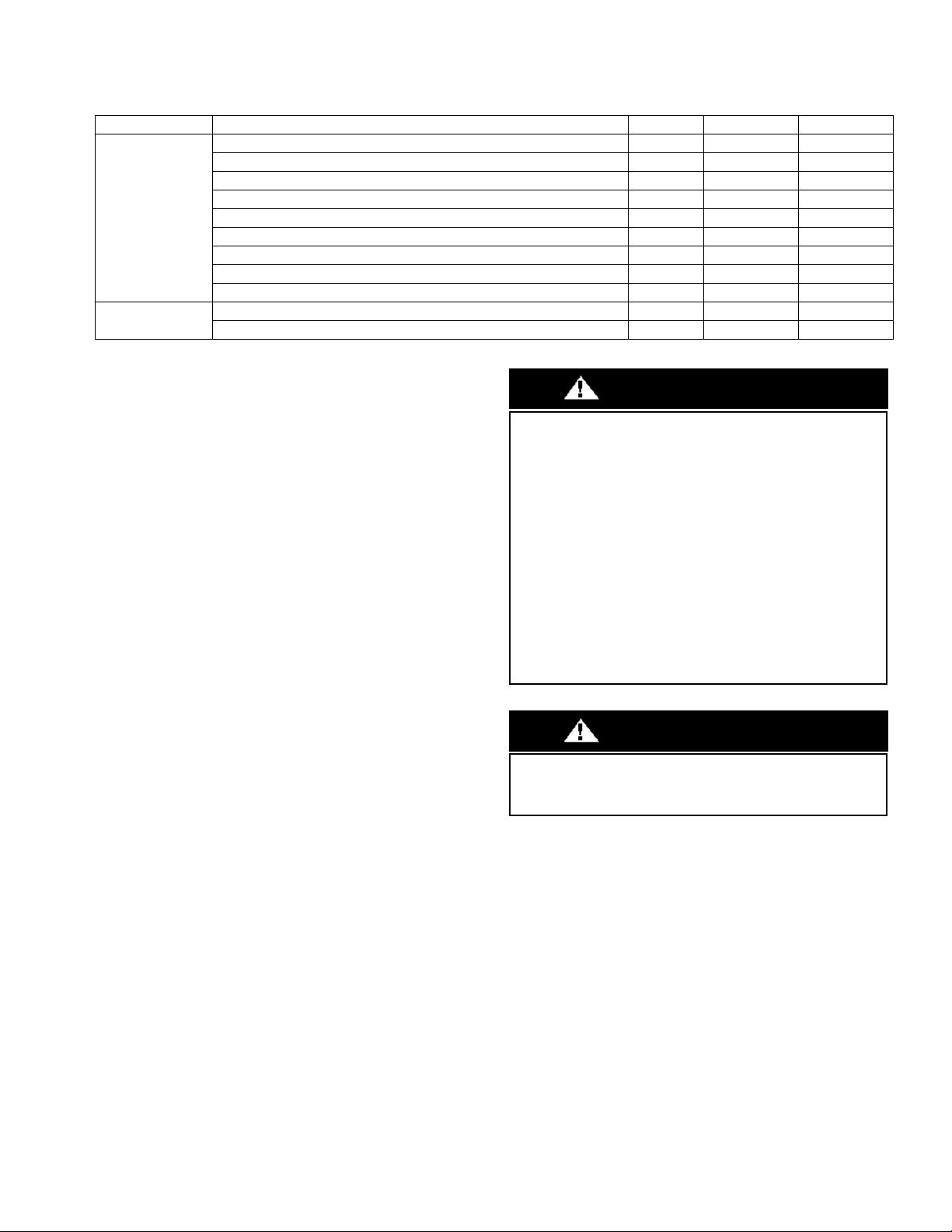

Table 6 — Piping and Refrigerant Information

IMPORTANT: Both refrigerant lines must be insulated

separately. Use refrigeration grade tubing ONLY. No other

type of tubing may be used. Use of other types of tubing

will void the manufacturer's warranty.

• All outdoor units have an electronic expansion valve to manage the

refrigerant flow of the fan coil connected.

• The minimum refrigerant line length between the indoor and

outdoor unit is 10 ft. (3m).

• When paired with Ductless indoor units, size the line sets based on

the connection size of the indoor unit unless specified.

• Do not open the service valves or remove the protective caps from

the tubing ends until all connections are made.

• Bend the tubing with bending tools to avoid kinks and flat spots.

• Keep the tubing free of dirt, sand, moisture, and other

contaminants to avoid damaging the refrigerant system.

• Avoid sags in the suction line to prevent the formation of oil traps.

• Insulate each tube with a minimum 3/8-in. (10 mm) wall thermal

pipe insulation. Inserting the tubing into the insulation before

making the connections will save time and improve installation

quality.

SYSTEM SIZE 36K 48K

Piping

Min. Piping Length ft (m) 10 (3) 10 (3)

Standard Piping Length ft (m) 25 (7.5) 25 (7.5)

Max. outdoor - indoor height difference (OU higher than IU) ft (m) 98 (30) 98 (30)

Max. outdoor - indoor height difference (IU higher than OU) ft (m) 98 (30) 98 (30)

Max. Piping length with no additional refrigerant charge ft (m) 25 (7.5) 25 (7.5)

Max. Piping Length ft (m) 213 (65) 213 (65)

Additional refrigerant charge (between Standard - Max piping length) Oz/ ft (g/m) 0.32 (30) 0.32 (30)

Gas Pipe (size - connection type) in (mm) 5/8 (16) 5/8 (16)

Liquid Pipe (size- connection type) in (mm) 3/8 (9.52) 3/8 (9.52)

Refrigerant Refrigerant Type - - R410A R410A

Charge Amount Lbs (kg) 7.05 (3.2) 9.92 (4.5)

All field piping must be completed by a licensed technician and

must comply with the local and national regulations.

When the system is installed in a small room, measures must be

taken to prevent the refrigerant concentration in the room from

exceeding the safety limit in the event of refrigerant leakage. If the

refrigerant leaks and its concentration exceeds its proper limit,

hazards due to lack of oxygen may result.

When installing the refrigeration system, ensure that air, dust,

moisture or foreign substances do not enter the refrigerant circuit.

Contamination in the system may cause poor operating capacity,

high pressure in the refrigeration cycle, explosion or injury.

Ventilate the area immediately if there is refrigerant leakage

during the installation.

Leaked refrigerant gas is hazardous. Ensure there is no refrigerant

leakage after completing the installation work.

WA R N I N G

DO NOT install the connecting pipe until both the indoor and

outdoor units have been installed.

Insulate both the gas and liquid piping to prevent condensation.

CAUTION

10 Specifications subject to change without notice. 32801100001

Use the following steps to connect the refrigerant piping:

1. Run the interconnecting piping from the outdoor unit to the indoor

unit.

2. Connect the refrigerant piping and drain line outside the indoor

unit. Complete the pipe insulation at the flare connection then

fasten the piping and wiring to the wall as required. Completely seal

the hole in the wall.

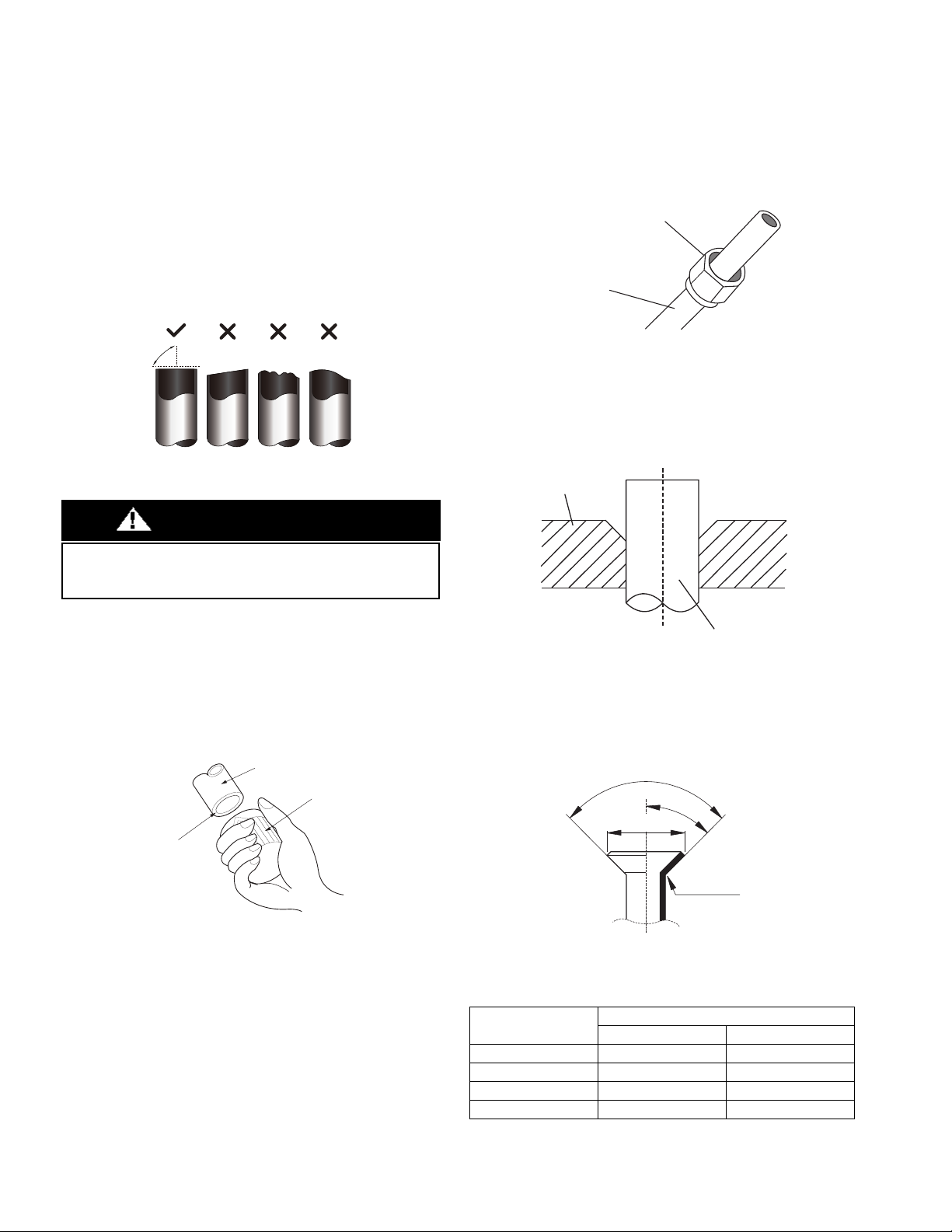

3. Cut tubing to the correct length.

When preparing refrigerant pipes, take extra care to cut and

flare them properly. This ensures efficient operation and

minimizes the need for future maintenance.

a. Measure the distance between the indoor and outdoor units.

b. Using a pipe cutter, cut the pipe a little longer than the

measured distance.

c. Make sure the pipe is cut at a perfect 90° angle.

Fig. 10 — Pipe Cutting

4. Remove Burrs

Burrs can affect the air-tight seal of the refrigerant piping connection.

Therefore, they must be completely removed. To remove:

a. Hold the pipe at a downward angle to prevent burrs from

falling into the pipe.

b. Using a reamer or deburring tool, remove all burrs from the

cut section of the pipe.

Fig. 11 — Deburring Tool

5. Flare Pipe Ends

Proper flaring is essential to achieving an airtight seal.

a. After removing the burrs from the cut pipe, seal the ends with

PVC tape to prevent foreign materials from entering the pipe.

b. Sheath the pipe with insulating material.

c. Place factory flare nut on pipe facing the proper direction.

Make sure they are facing the right direction. Once the ends are

flared, it is impossible to put them on or change their direction.

Fig. 12 — Copper pipe and flare nut

d. Remove the PVC tape from ends of pipe when ready to perform

the flaring work.

e. Clamp the flare block on the end of the pipe. The end of the

pipe must extend beyond the flare form.

Fig. 13 — Flare Block

f. Place the flaring tool onto the form.

g. Turn the handle of the flaring tool clockwise until the pipe is fully

flared. Flare the pipe in accordance with the dimensions in Table 7.

Fig. 14 — Flare Shape

Table 7 — Flare Nut Spacing

h. Remove the flaring tool and flare block, then inspect the end

of the pipe for cracks and even flaring.

Oblique Rough

Warped

90°

DO NOT DEFORM PIPE WHILE CUTTING

Be extra careful not to damage, dent, or deform the pipe while

cutting. This will drastically reduce the heating efficiency of the unit.

CAUTION

Pipe

Reamer

Point down

OUTER DIAMETER

IN (MM)

A” IN (MM)

MAX. MIN.

Ø 1/4” (6.35) 0.05 (1.3) 0.03 (0.7)

Ø 3/8” (9.52) 0.06 (1.6) 0.04 (1.0)

Ø 1/2” (12.7) 0.07 (1.8) 0.04 (1.0)

Ø 5/8” (15.88) 0.09 (2.2) 0.08 (2.0)

Flare nut

Copper pipe

Flare block

Pipe

R0.4~0.8

45qr2

90 q

r4

A

32801100001 Specifications subject to change without notice. 11

6. Connect the Pipes

Connect the copper pipes to the indoor unit first, then connect

the pipes to the outdoor unit. Connect the low-pressure pipe

first, then connect the high pressure pipe.

a. When connecting the flare nuts, apply a thin coat of

refrigeration oil to the flared ends of the pipes.

b. Align the center of the two pipes that you will connect.

Fig. 15 — Align the center of the two pipes

c. Tighten the flare nut as much as possible by hand.

d. Using a wrench, grip the nut on the unit tubing.

e. While firmly gripping the nut, use a torque wrench to

tighten the flare nut according to the torque values listed in

Table 8.

Table 8 — Tightening Torque

NOTE: Use both a backup wrench and a torque wrench when

connecting or disconnecting pipes to or from the unit.

Fig. 16 — Torque wrench with backup wrench

All tubing bends should be performed with a properly sized tubing

bender to prevent kinking or damaging the tubing.

f. After connecting the copper pipes to the indoor unit, wrap

the power cable, signal cable and the piping together with

binding tape.

NOTE: While bundling these items together, DO NOT intertwine or

cross the signal cable with any other wiring.

g. Thread this lineset through the wall and connect it to the

outdoor unit.

h. Insulate all piping, including the outdoor unit valves.

NOTE: DO NOT open the service valves until pressure test is

complete.

7. Pressure Test Piping

NOTE: Use refrigeration gauges that are pressure rated for

R410a refrigerant.

a. Attach low side gauge hose to the 5/16” Schrader valve on

the outdoor unit service valve.

b. Attach the charging hose to the regulator on the dry nitrogen

tank.

c. Preset the nitrogen regulator to 550 psi.

d. Slowly pressurize the line set until the low side gauge reads

500 psi. Do not exceed 550 psi.

e. Close all the valves on the nitrogen tank and gauges.

f. Allow the pressure test to stand for a minimum of 30

minutes.

g. If the pressure holds, release the nitrogen and proceed with

See “Step 5 - Evacuate Coil And Tubing System” on

page 12..

h. If the pressure goes down in the 30 minute delay, leak check

the tubing and flare fittings to identify the source of the

leak. Return to Step C, above.

BRASS FLARE SIZE

(IN”)

RECOMMENDED SEATING

TORQUE FOR BRASS

FLARE NUTS

N-M

Ø1/4 8-10 Ft. - Lbs. 10.8 to 13.6

Ø3/8 15-18 Ft. - Lbs 20.3 to 24.4

Ø1/2 28-32 Ft. - Lbs 38.0 to 43.4

Ø5/8 38-42 Ft. - Lbs 51.5 to 56.9

Ø3/4 50-55 Ft. - Lbs. 68.0 to 74.6

Pipe

Indoor unit tubing Flare nut

Wrap insulation around the piping. Direct contact with the bare

piping may result in burns or frostbite. Ensure the pipe is properly

connected. Over tightening may damage the bell mouth and under

tightening may lead to leakage.

CAUTION

Only use Dry Nitrogen to pressure test refrigerant systems. Use of

other gases can result in injury, property damage or death.

CAUTION

12 Specifications subject to change without notice. 32801100001

Step 5 - Evacuate Coil And Tubing System

Refrigerant tubes and the indoor coil should be evacuated using the

recommended 500 microns deep vacuum method. The alternate triple

evacuation method may be used if the procedure outlined below is

followed.

NOTE: Always break a vacuum with dry nitrogen.

Using Vacuum Pump

1. Completely tighten flare nuts A, B, C, D. Connect the manifold

gage charge hose to a charge port of the low side service valve (see

Fig. 17).

2. Connect the charge hose to vacuum pump.

3. Fully open the low side of manifold gage (see Fig. 18).

4. Start the vacuum pump.

5. Evacuate using either the deep vacuum or triple evacuation method.

6. After evacuation is complete, fully close the low side of manifold

gage and stop the vacuum pump operation.

7. The factory charge contained in the outdoor unit is good for up to

25 ft. (8 m) of line length. For refrigerant lines longer than 25 ft. (8

m), add refrigerant, up to the allowable length.

8. Disconnect the charge hose from the charge connection of the low

side service valve.

9. Fully open service valves B and A.

10. Securely tighten the service valve caps.

Fig. 17 — Service Valve

Fig. 18 — Manifold

Evacuation

Evacuation of the system will remove air or nitrogen (non-condensables)

as well as moisture. A proper vacuum will assure a tight, dry system

before charging with refrigerant. The two methods used to evacuate a

system are the deep vacuum method and the triple vacuum method.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of pulling

a vacuum of 500 microns and a vacuum gauge capable of accurately

measuring this vacuum depth. The deep vacuum method is the most

positive way of assuring a system is free of air and moisture (see

Figure 19).

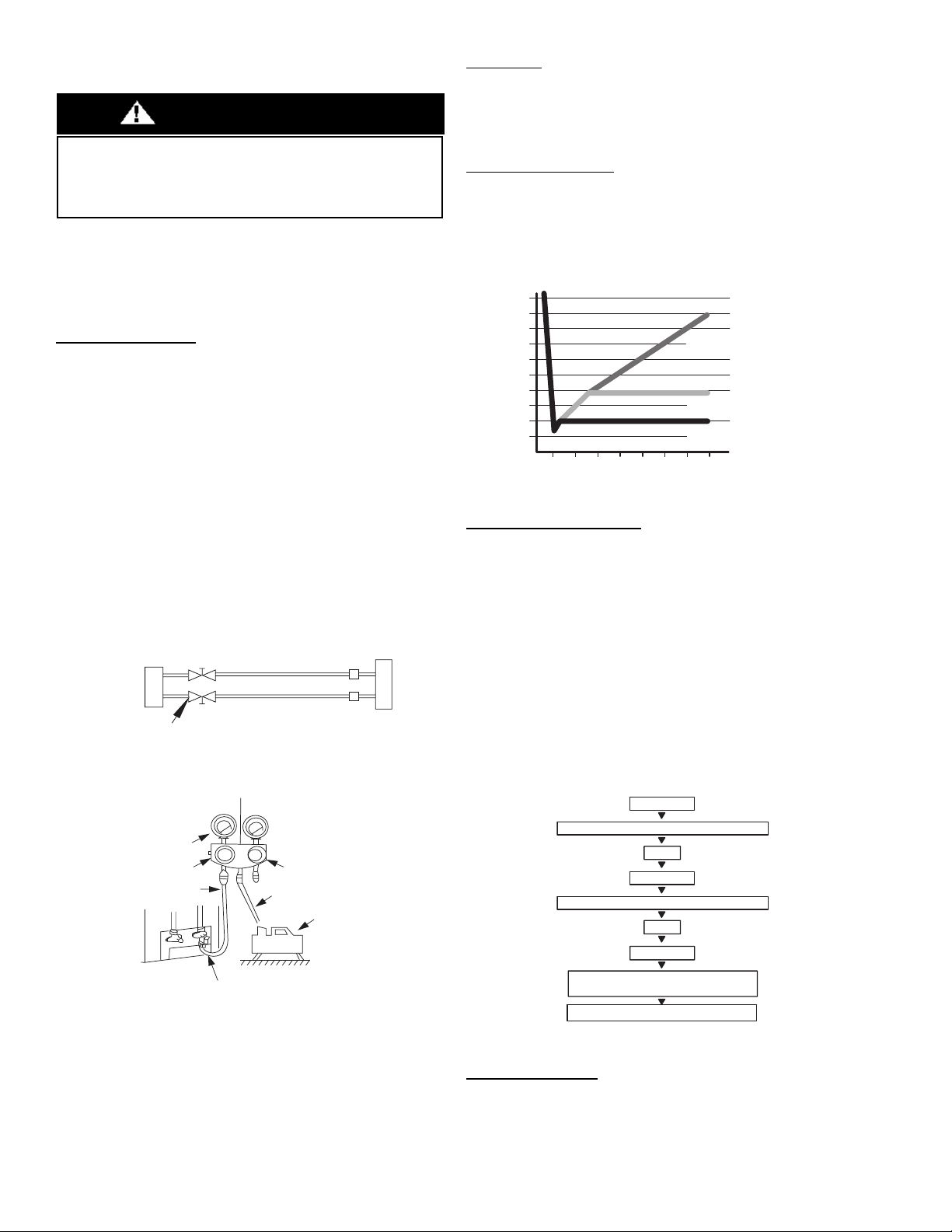

Fig. 19 — Deep Vacuum Graph

Triple Evacuation Method

The triple evacuation method should be used when vacuum pump

is not capable of pumping down to 500 microns and system does not

contain any liquid water. Refer to Fig. 20 and proceed as follows:

1. Attach refrigeration gauges and evacuate system down to 28 in. of

mercury and allow pump to continue operating for an additional 15

minutes.

2. Close service valves and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system and flow

nitrogen until system pressure is 2 psig.

4. Close service valve and allow system to stand for 1 hour. During

this time, dry nitrogen will be able to diffuse throughout the system

absorbing moisture.

5. Repeat this procedure as indicated in Fig. 20. System will then be

free of any contaminants and water vapor.

Fig. 20 — Triple Evacuation Method

Final Tubing Check

Check to be certain factory tubing on both the indoor and outdoor unit

has not shifted during shipment. Ensure tubes are not rubbing against

each other or any sheet metal. Pay close attention to the feeder tubes,

making sure wire ties on feeder tubes are secure and tight.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Never use the system compressor as a vacuum pump.

CAUTION

Outdoor Unit Indoor UnitRefrigerant

Service Valve

Low Side

High Side

A

B

C

D

500 microns

Low side valve

High side valve

Charge hose

Charge hose

Vacuum

pump

Low side valve

500

MINUTES

01234567

1000

1500

LEAK IN

SYSTEM

SYSTEM TIGHT

EVACUATE MOISTURE

TIGHT DRY SYSTEM

2000

MICRONS

2500

3000

3500

4000

4500

5000

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

RELEASE CHARGE INTO SYSTEM

BREAK VACUUM WITH DRY NITROGEN

EVACUATE

WAIT

32801100001 Specifications subject to change without notice. 13

Step 6 - Electrical Connections

Install All Power and Interconnecting Wiring to

Outdoor Units

1. Mount the outdoor power disconnect.

2. Run the power wiring from the main box to disconnect per NEC

and local codes.

3. Remove the field wiring cover from the unit by loosening the

screws.

4. Remove the caps on the conduit panel.

5. Connect the conduit to conduit panel (see Fig.21).

6. Properly connect both the power supply and control lines to the

terminal block per the connection diagram for the appropriate unit

capacity and voltage.

7. Ground the unit in accordance with NEC and local electrical codes.

8. Use the lock nuts to secure the conduit.

9. Reinstall the field wiring cover.

Fig. 21 —Field Wiring

WIRING

All wires must be sized per NEC (National Electrical Code) or CEC

(Canadian Electrical Code) and local codes. Use Electrical Data table MCA

(minimum circuit amps) and MOCP (maximum over current protection) to

correctly size the wires and the disconnect fuse or breakers respectively.

SIZES 36-48 RECOMMENDED CONNECTION METHOD

FOR POWER AND COMMUNICATION WIRING

Power and Communication Wiring: The main power is supplied to

the outdoor unit. The field supplied power wiring from the outdoor

unit to the indoor unit consists of three (3) wires and provides the

power for the indoor unit. Two wires are high voltage AC power and

one is a ground wire. To minimize voltage drop, the factory

recommended wire size is 14/2 stranded with a ground.

Communication Wiring: A separate shielded stranded copper

conductor only, with a 600 volt rating and double insulated copper

wire, must be used as the communication wire from the outdoor unit

to the indoor unit.

Please use a separate shielded 16GA stranded control wire.

Table 9 — Wiring Sizes 36-48

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Be sure to comply with local codes while running wire from

indoor unit to outdoor unit.

Every wire must be connected firmly. Loose wiring may cause the

terminal to overheat or result in unit malfunction. A fire hazard

may also exist. Therefore, ensure all wiring is tightly connected.

No wire should be allowed to touch the refrigerant tubing,

compressor or any moving parts.

Disconnecting means must be provided and shall be located within

sight and readily accessible from the air conditioner.

Connecting cable with the conduit shall be routed through hole in

the conduit panel.

CAUTION

Over 1.57" (40mm)

Terminal Block

Conduit

panel

Conduit

Outdoor unit

CABLE CABLE SIZE REMARKS

Power

Connection Cable 14AWG 2 wire + Ground 1Φ208/230 V

Communication

Cable 16AWG 2 wire stranded shielded

control wire

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation. Wires should be sized based on NEDC and

local codes.

WARNING

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation. Be sure to comply with local codes while

running wire from the indoor unit to the outdoor unit. Every wire

must be connected firmly. Loose wiring may cause the terminal to

overheat or result in unit malfunction. A fire hazard may also exist.

Ensure all wiring is tightly connected.

No wire should touch the refrigerant tubing, compressor or any

moving parts. Disconnecting means must be provided and shall be

located within sight and readily accessible from the air conditioner.

Connecting cable with conduit shall be routed through the hole in

the conduit panel.

CAUTION

14 Specifications subject to change without notice. 32801100001

ELECTRICAL DATA

Table 10 — Electrical Data

*Permissible limits of the voltage range at which the unit will operate satisfactorily.

LEGEND

FLA - Full Load Amps

MCA - Minimum Circuit Amps

MOCP - Maximum Over-Current Protection

RLA - Rated Load Amps

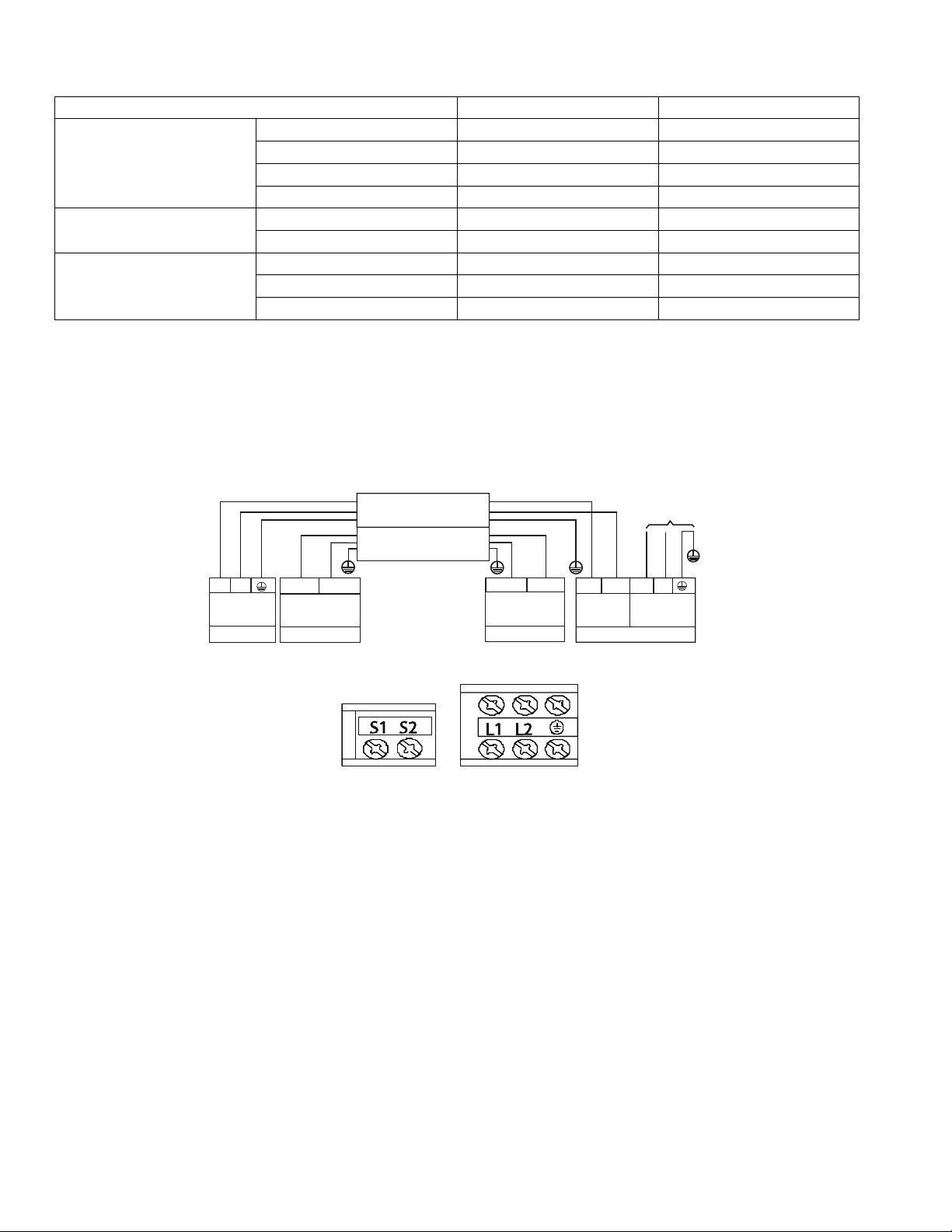

CONNECTION DIAGRAMS

Fig. 22 — Connection Diagram sizes 36-48

Fig. 23 — Control and Power Terminals on Indoor Unit sizes 36-48

NOTES:

1. Do not use the thermostat wire for any connection between indoor and outdoor units.

2. All connections between indoor and outdoor units must be as shown in Figure 22. The connections are sensitive to polarity and will result in a

fault code.

OUTDOOR UNIT SIZE 36K 48K

Power Supply

208/230 - 1 - 60 208/230 - 1 - 60

Max – Min* Oper. Voltage 253 - 187 253 - 187

MCA 30 36.5

MOCP 45 50

Compressor Volts- PH- Hz 208/230 - 1 - 60 208/230 - 1 - 60

RLA 23.5 28

Outdoor Fan Motor

FLA 0.6 1.17

Rated HP 0.16 0.11

Output 120 85

208-230-1-60

L1 L2

FIELD POWER SUPPLY

Indoor Unit

Power Supply

Low voltage

Nonpolar RS-485

communication

208-230-1-60

Nonpolar RS-485

Low voltage

communication

Outdoor Unit

208-230-1-60

Power Supply

SHIELDED WIRE CONNECTING

OUTDOOR TO INDOOR

To Indoor Unit

Power Supply

S1 S2

L1

(1)L1 (2)L2

L2

P(S1)

GND

Q(S2)

CONNECTING CABLE

OUTDOOR TO INDOOR

32801100001 Specifications subject to change without notice. 15

START-UP

Test Operation

Perform a test operation after completing a gas leak and electrical safety check. See the indoor unit installation instructions and owner's manual

for additional start up information.

System Checks

1. Conceal the tubing where possible.

2. Make sure that the drain tube slopes downward along its entire length.

3. Ensure all tubing and connections are properly insulated.

4. Fasten the tubes to the outside wall, when possible.

5. Seal the hole through which the cables and tubing pass.

Outdoor Unit

Are there unusual noises or vibrations during operation?

Explain the Following Item to the Customer (with the aid of the Owner's Manual):

• Explain unit care and maintenance.

IMPORTANT: Present the installation instructions to the customer.

CARE AND MAINTENANCE

To help ensure high performance and minimize possible equipment failure, periodic maintenance must be performed on this equipment.

Maintenance frequency may vary depending upon geographic areas.

OUTDOOR UNIT DIAGNOSTIC GUIDES

For ease of service, the systems are equipped with a diagnostic code display LEDs on both the indoor and outdoor units. The outdoor diagnostic

is displayed on the outdoor unit microprocessor board.

There may be a few error codes displayed in the indoor unit that might relate to the outdoor unit's problems. If possible, always check the

diagnostic codes displayed on the indoor unit first.

The diagnostic codes displayed on the outdoor units are listed on Table 11.

Table 11 — Unit Diagnostic Guides

For additional diagnostic information, refer to the service manual.

DISPLAY LED STATUS

E1 Communication malfunction between indoor and outdoor units.

F0 Protection of over - current

F1 Open circuit or short circuit of outdoor ambient temperature sensor T4

F2 Open circuit or short circuit of condenser coil temperature sensor T3

F3 Open circuit or short circuit of Compressor discharge temperature sensor T5

F4 Outdoor unit EEPROM error

F5 Outdoor fan speed has been out of control

P0 IPM malfunction

P1 Over voltage or over low voltage protection

P2 High temperature protection of compressor top

P3 Outdoor low temperature protection

P4 Inverter compressor drive error

P7 Outdoor IGBT temperature sensor error

J0 High temperature protection of indoor coil in heating

J1 Outdoor temperature protection of outdoor coil in cooling

J2 Discharge temperature protection

J3 Protection of active PFC module

J4 Communication error between control board and IPM board

J5 High - pressure switch protection

J6 Low - pressure switch protection

J8 AC voltage protection

16 Specifications subject to change without notice. 32801100001

Installation Data

Site Address:_______________________________________________________________________________________________________

City:________________________________________________________ State:___________ Zip Code:__________________

Installing Contractor:______________________________________________________ Contractor Contact #: ( ) _____-___________

Job Name:_______________________________________________________________ Start-up Date:_____________________________

Distributor:_______________________________________________________________

System Details

Wiring Electrical

Wire Size and Type Used? AWG:__________ TYPE:_________

Are there any breaks, splices, wire nuts or butt connectors between the outdoor unit and the indoor door unit? YES:______ NO:______

Was the wiring from the outdoor unit port to the correct indoor unit verified? YES:______ NO:______

REMARKS:_______________________________________________________________________________________________________

__________________________________________________________________________________________________________________

Voltage Check

Wiring: Single zone ___________

UNITS MODEL NO. SERIAL NO. CONTROLLER

OUTDOOR UNIT

INDOOR UNIT A

Outdoor Unit

Disconnect

1(L1):GND

Outdoor Unit

Terminal Block

1(L1):GND NOTES:__________________________________

_________________________________________

_________________________________________

_________________________________________

_________________________________________

2(L2):GND 2(L2):GND

1(L1):L2(2) 1(L1):2(L2)

Indoor Unit

Voltage Check

@ Outdoor Unit

1(L1):GND

Indoor Unit

Voltage Check

@ Indoor Unit

1(L1):GND NOTES:__________________________________

_________________________________________

_________________________________________

_________________________________________

_________________________________________

2(L2):GND 2(L2):GND

1(L1):2(L2) 1(L1):2(L2)

2(L2):3(S) 2(L2):3(S)

DUCTLESS START-UP CHECKLIST

32801100001 Specifications subject to change without notice. 17

Ductless Start-Up Checklist (CONT)

Piping

Leak Check:

System held 500 psig (max. 550psi) for a minimum of 30 minutes using dry nitrogen. YES:______ NO:______

Evacuation Method:

•Was the Triple Evacuation Method used as outlined in the installation manual? YES:______ NO:______

• Was the Deep Vacuum Method used as outlined in the installation manual? YES:______ NO:_______

• Did the System Hold 500 microns for 1 hour? YES:______ NO:_______

• Does the line set match the diameter of the evaporator connections? YES:______ NO:_______

Single Zone Piping:

Has the liquid pipe length been measured and the additional charge calculated? Size:___________ Length:_________ Charge:____________

Performance Check

Error Codes

Were there any error codes present at start-up? YES:______ NO:______

Comments:

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

NOTES:

PORT LIQUID SIZE SUCTION SIZE LENGTH CHARGE NOTES:____________________________________

___________________________________________

___________________________________________

A

For 1:1 Single Zone Systems: Adjust the set-point to create an operational call for the desired testing operation. Allow the system to run for a

minimum of 10 min. and record the following details:

(Operational data recorded on applicable heads with the wireless remote controller’s Point Check function)

UNIT

SET-POINT

MODE T1 T2 T3 T4 Tb Tp Th LA/Lr

A

Indoor Unit Error Code: Notes:

Outdoor Unit Error Code:

Wall Controller:

24V Interface:

Copyright 2020 CMNA

3300 Riverwood Parkway Atlanta GA 30339 32801100001

This manual suits for next models

2

Table of contents

Other CMNA Air Conditioner manuals