Impco Mobile Symphony SPM20 User manual

email: customerservice@impcollc.com, Website: www.impcollc.com

Owner’s Manual

Manual de Operación

PRECAUCIO

´N

LEA Y CONSERVE ESTE MANUAL

Lea todas las instrucciones cuidadosamente antes

de montar y operar esta unidad. Este manual fue

diseñado para proveerle importante información

necesaria para instalar, operar, mantener y detectar

problemas en su enfriador. La falla en seguir estas

instrucciones puede dañar y/o afectar la operación

del enfriador y anular la garantía.

U.S. Models:

SPM20, SPM30, SPM45

CAUTION

SAVE AND READ THESE

IMPORTANT INSTRUCTIONS

Read all instructions carefully before setting up and

operating this unit. This manual was designed to pro-

vide you with important information needed to setup,

operate, maintain, and trouble-shoot your cooler.

Failure to follow these instructions may damage

and/or impair its operation and void the warranty.

1

WARNINGS AND SAFETY RULES

!

INTRODUCTION

Evaporative cooling works on the principle of heat absorption

by moisture evaporation. Simply put, heat is removed from the

air as water evaporates. You feel this principle in action when

you step out of a swimming pool or shower; you feel immedi-

ately cooler as water evaporates from the surface of your skin.

Your evaporative cooler works on the same principle. Hot out-

side air is pulled through water-saturated pads, where the air is

cooled by evaporation and then discharged from the cooler.

WARNING…

To r duc th risk of l ctric shock, fir or injury:

• Read instructions and labels carefully.

• Always unplug the electric cord to your cooler before

you work on the cooler.

• Your cooler will run on 120 Volt AC, 60 Hz (cycle)

current only.

• Plug into three-prong grounded GFCI protected

electrical receptacle only.

• Do not operate if plug or cord are damaged in any way.

• Do not step on or roll over power cord with heavy or

sharp objects.

• Do not operate unit unless all panels are securely in

place.

• Remove the plug from the electrical receptacle by

pulling on the plug and not the cord.

• Test the GFCI receptacle or breaker monthly to ensure

it is functioning properly.

• Do not operate near open containers of flammable

liquids or gases.

• Never wash your cooler cabinet with a garden hose;

water may harm the motor and pump.

• If the unit is damaged or it malfunctions, do not contin-

ue to operate it. Refer to the warranty or troubleshooting

section at www.impcollc.com

Oth r Symphony Units

Hi Cool

R28RTE

2

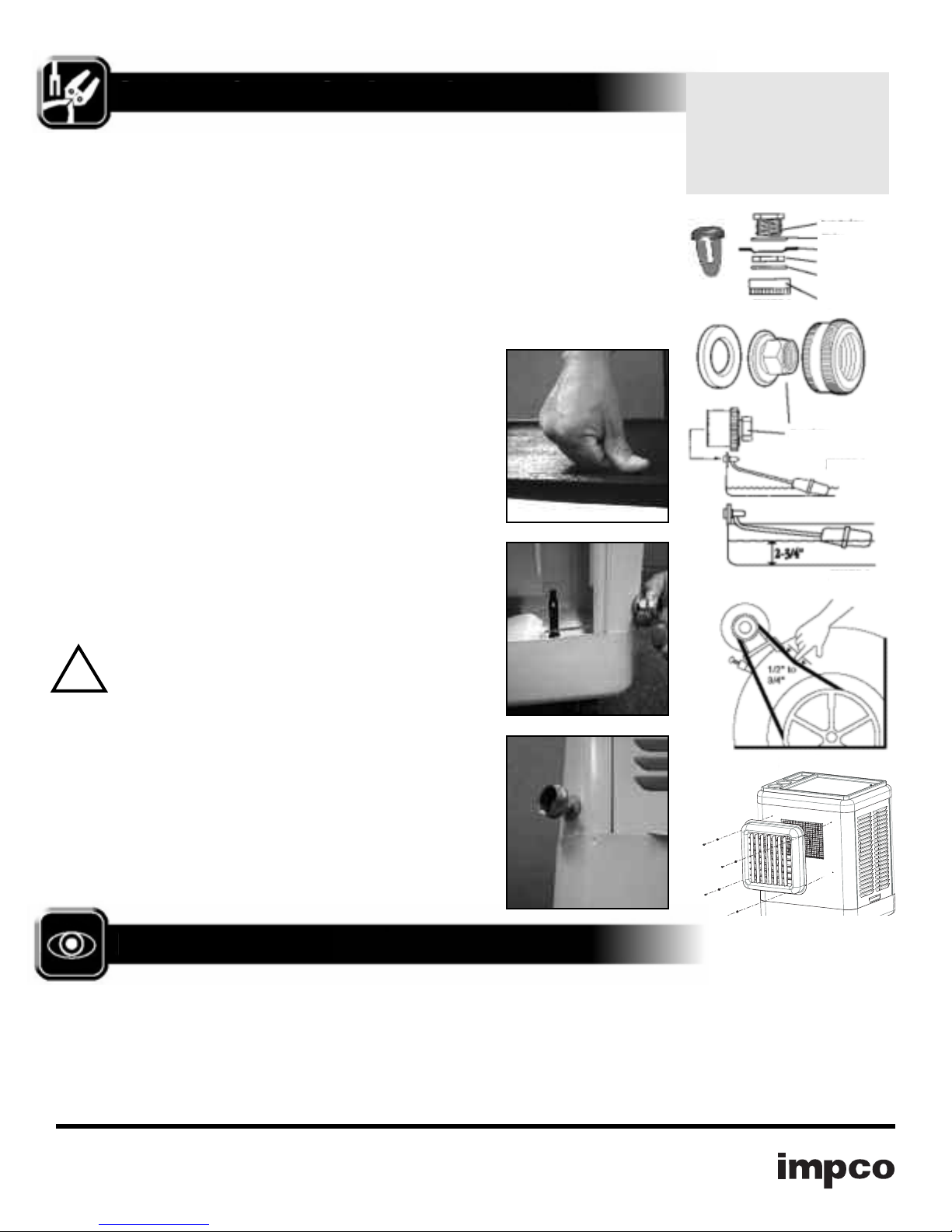

Unpacking th Mobil Symphony.

The unit is shipped with the casters

(wheels), grille and the top tray inside the cabinet.

Grill Installation.

Before attempting to use your new Mobile Symphony

cooler you must complete the grille installation.

Attaching th plastic tray.

Remove the side pad frames from the cooler

by lifting them up and out of the cooler cabinet. Locate the parts bag in the

cooler and attach the tray top using the push rivets provided. (Picture 1)

Installing th cast rs.

Some models ship with the wheels already

attached to the cabinet bottom. If wheels are not attached then locate the

wheels inside of the cooler and attach them to the cabinet bottom using the

bolts included.

Installing th grill .

Refer to the installation instructions in the grille bag.

Installing th drain bushing and standpip .

Refer to Figure 2 and

install the drain bushing and standpipe through the hole provided in the bottom of

the cooler.

Installing th float valv and adapt r.

Refer to Figure 3 and attach the

float to the side leg of the cooler using the hole provided. The garden hose

adapter attaches to the brass inlet fitting on the float valve. (Picture 2). Verify

that the hose washers are properly in place. Position the pump snug to blower

housing to prevent contact with the pads.

Conn cting to Wat r

.

Move the cooler to an area where it can be filled

with water and drained. The cooler should be located on level ground.

Connect to a water supply using a commercial grade garden hose (supplied by

customer) connected to the adapter on the float valve and turn on the water.

Verify water tight connections by visually examining both the float / hose con-

nection and the drain plug. (Picture 2)

CAUTION: Wat r inl t pr ssur should b limit d to a

maximum of 105 PSI or an inlin pr ssur r gulator

should b install d.

Adjusting th wat r l v l.

Refer to Figure 3 and set the water height as

shown by adjusting the float.

Conn cting to a Pow r Supply.

Plug the grounded plug directly into a

120 Volt AC 60 Hz grounded GFCI protected electrical power sup

ply.

Note:

Improper voltage will burn out the motor and pump windings and will void the

warranty.

LOCATION

ASSEMBLY INSTRUCTIONS

TOOLS REQUIRED

• 3/

˝

Open End Wrench

•3/

˝

Box End Wrench

• 6

˝

Adjustable Wrench

• 7/16

˝

Box End Wrench

• #2 Phillips Screwdriver

Picture 1

Picture 2

Picture 3

Figure 2

Figure 3

Figure 4

Figure 4

Always make sure the unit is operated on a level surface. When

using indoors, the best location for it is near a partially opened

window or door where hot outdoor air can be drawn into the

unit. This cooler is portable, but use caution when rolling the

unit to avoid splashing and spilling of water. Cool air can best

be directed through the space by using a partly opened window

or door, ideally one that is situated on the opposite side of the

space from the cooler. This allows the cooled air to be moved

through the space and exhausted back outdoors which is

critical to proper performance of the cooler.

!

Figure 5

Push Rivet

Hose Adapter

Drain Bushing

Washer

Cooler Bottom

Lock Nut

Washer Inside

Cap

Cap

3

USE & OPERATION

CLEANING & MAINTENANCE

!

P riodic Drying of Pads. For best results allow pads to

dry after each operation by turning off the pump 15 minutes

before turning off the fan blower motor.

P riodic Draining of Sump. The entire water sump

should be drained at least once weekly to reduce mineral build-

up. The failure to regularly drain the entire water sump will

greatly increase the mineral deposits and reduces the expected

life of the cooling pads. This could result in early replacement

of the pads at the owner’s expense. Use a damp cloth and wipe

off any mineral deposits that appear outside or inside the unit

at least once per week of use.

Lubrication. The pump and blower motors do not require

lubrication. For belt driven blower wheel models only, the

blower shaft bearings need periodic lubrication. The oil cups

on the blower shaft bearings should be filled with a good grade

SAE20W or 30W oil when necessary. Under normal use, oiling

is required every three months of operation. DO NOT OVER OIL.

Cl aning Wat r Pump. (Pictures 5 and 6) Disassemble

and clean the water pump as follows.

• Disconnect power supply to the cooler.

• Access the pump by lifting the pad frames up and out of

the cooler. Remove pump from cooler.

• To prevent breakage, carefully release the four snap-out

tabs and lift impeller base plate from the pump body.

(Picture 5)

• Use a mild detergent solution and wash all deposits from

the inside around the impeller and impeller base plate.

• Spin the impeller to dislodge any foreign material.

(Picture 6) Rinse and reinstall impeller base plate.

• Reinstall pump into the cooler.

CAUTION

Do not allow th pump to fall ov r and

b com subm rg d in th wat r. Wat r

will damag th pump motor.

1. Turn on the water supply to the cooler. The hose concection

to the float valve provides an automatic method of refilling

the water supply as water evaporates.

2. For best results, turn the pump on a few minutes before

turning on the blower fan. This allows the cooling pads to

pre-wet for best efficiency.

3. When cooling is not required you can operate the unit as a

fan by turning on the blower fan only and leaving the pump

turned off.

4. The water can be adjusted by tightening or loosening the

clamp that pinches the water supply tube. Adjust the water

flow clamp so that adequate water is supplied to the pads

without excess water splashing out of the trough during

normal operation.

CAUTION

Do not op rat th unit with pads or

grill r mov d.

CAUTION

Unplug th l ctrical cord to th cool r

b for att mpting to work on or s rvic

th cool r.

!

!

Picture 5

Picture

4

Electrical wiring on your unit is not required as the unit has

been wired at the factory. For your future reference, the wiring

diagram in Figure 7 shows rocker switches, two-speed motor,

capacitor and pump.

The cooling pads should be replaced with fresh aspen fiber

at least once a year, at the beginning of each cooling season.

The need to change pads varies with locality and how much

dust, alkali and other foreign matter accumulates in pads. If

cooling efficiency is impaired, it may be desirable to change

pads several times during a cooling season.

Replacement Instructions:

To remove pad assemblies from the unit, lift up, pull out and

then down. Lay the metal side down on a flat surface and

remove the pad retainers. The aspen filters can now be removed.

Rinse off pad assembly, then install new aspen filter and retainer.

Replacement filter pads are available at your cooler dealer.

ELECTRICAL

COOLING PAD REPLACEMENT

GREEN (GROUND WIRE)

GREEN (GROUND WIRE)

GREEN (GROUND WIRE)

GREEN (GROUND WIRE)

NEUTRAL (WHITE WIRE)

HOT (BLACK WIRE)

HOT HIGH SPEED (BLACK WIRE)

HOT LOW SPEED (RED WIRE)

NEUTRAL (WHITE WIRE)

NEUTRAL (WHITE WIRE)

MOTOR

WIRE NUT

PLUG

PUMP

PUMP SWITCH

GROUND SCREWS (ISOLATED CORD GROUND)

WIRING DIAGRAM

MOTOR SWITCH

HOT (BLACK WIRE)

Dimensions (in) Water Capacity Shipping

Weight

ABCD

22 19 23.6 29 4.5 Gallons 65 lb

SPECIFICATIONS AND DIMENSIONS

Motor Frequency Volts Current

1/8 HP 60 Hz 120 V~ 3.6 A

Picture 7 Picture 8 Picture 9 Picture 10

Figure 7

6

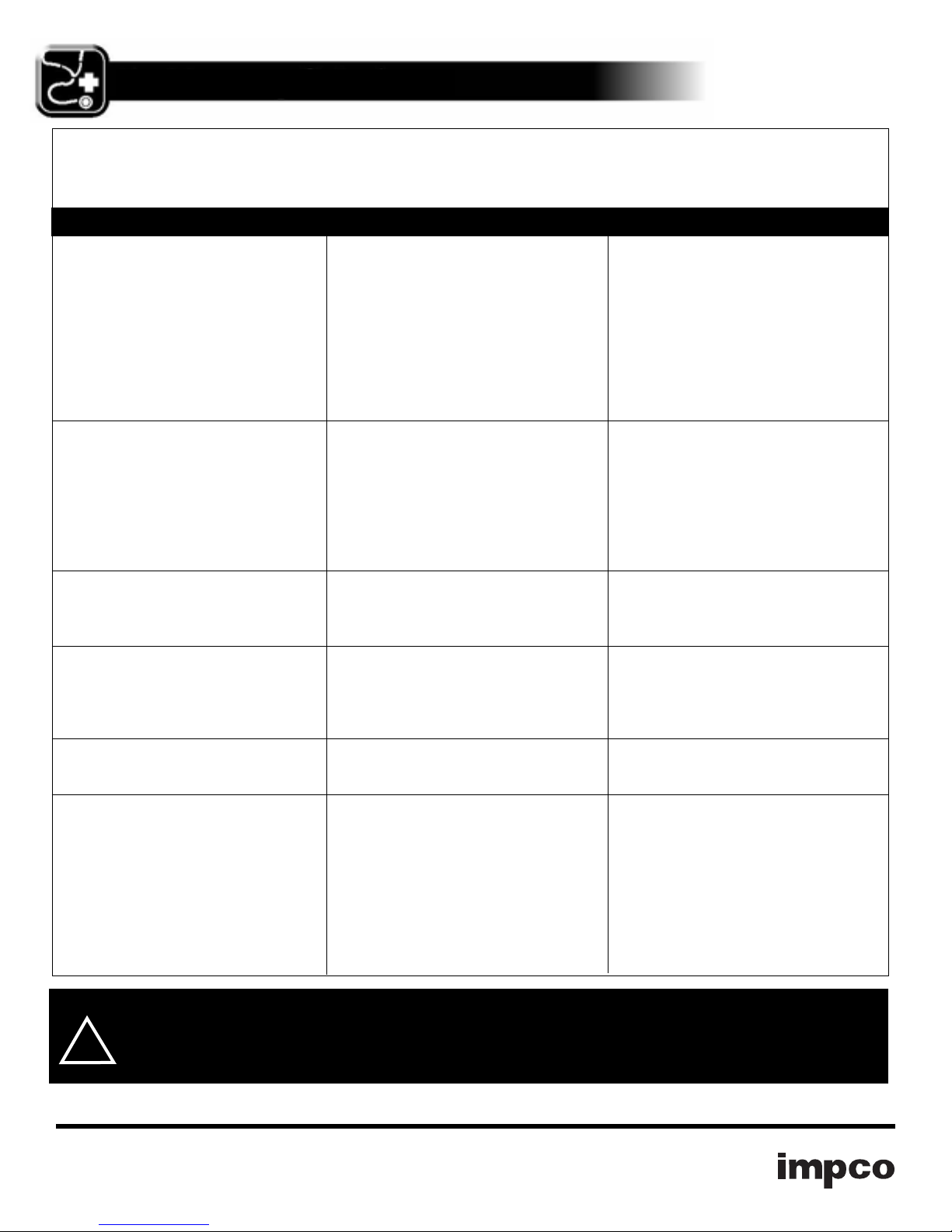

The following troubleshooting guide is intended to address the most common symptoms and is by no means exhaustive. If

symptoms persist, call a qualified service provider. Only a certified electrician should complete electrical work.Turn off all power

to the cooler before attempting to troubleshoot any of the following symptoms.

SYMPTOM POSSIBLE CAUSES REMEDY

Unit fails to start or d liv r air 1. No electrical power to unit 1. Check power

A. Fuse blown A. Replace fuse*

B. Circuit breaker tripped B. Reset breaker*

C. GFCI tripped C. Reset GFCI*

D. Cord(s) unplugged or damaged D. Plug in cord(s) or replace if damaged

*If condition persists, call an electrician

2. Motor overheated (thermally protected) 2. Try to restart after cool down

3. Motor frozen 3. Replace motor

4. Motor able to free spin 4. Replace capacitor

Unit starts but air d liv ry is inad quat 1. Insufficient air exhaust 1. Open windows or doors

2. Insufficient water – pad not wet 2. Check water distribution system

A. Cooling pads clogged A. Clean or replace pads

B. Dry streaks on pads B. Check water level

C. Large dry spots on pads C. Make sure cooler is level

D. Pump not working D. Clean or replace pump

E. Loose water connections E. Check for leaks and correct

Wat r draining from cool r 1. Float arm improperly adjusted 1. Adjust float to proper level

2. Seat in float valve leaking 2. Replace float valve

3. Drain bushing not tight 3. Tighten fitting

Musty or unpl asant odor 1. Stale or stagnant water in sump 1. Drain, flush and clean sump

2. Pads mildewed or clogged 2. Replace pads

3. Pads not completely wet before 3. Turn on pump before starting fan

cooler is turned on

Knocking, shaking or rattling sounds 1. Loose parts 1. Check and tighten where needed

2. Blower wheel loose or rubbing 2. Inspect and adjust, or replace

Wat r dropl ts in th discharg d air str am 1. Too much water delivered to the 1. Make sure pads are properly positioned

cooling pads in the pad frames and that the unit is level.

If necessary, reduce the flow of water to

the pads by tightening the screw on the

hose restrictor clamp found on the pump

discharge hose.

2. Outdoor humidity level is too high 2. Use cooler as a fan only (turn pump off)

or it is raining or discontinue use of cooler until outdoor

humidity level drops.

TROUBLESHOOTING

NOTE

Do not us cool r cl an rs, cool r tr atm nts, or oth r additiv s in this vaporativ cool r. Th us

of any of th s products will void your warranty and may impair th lif of your vaporativ cool r.

!

WARRANTY

1-YEAR LIMITED WARRANTY

Impco, Phoenix, Arizona, extends this limited warranty to the

original purchaser of a Mobile Symphony Evaporative Cooler

operated under normal conditions within the continental United

States.

I. One Year Coverage applies to all components and

accessories furnished by Impco. At our option, we

will exchange or repair any part which fails due to

non-conformance of material or workmanship during

the first year from the date of initial purchase.

II. What this warranty do s not cov r:

a. This warranty does not cover any failure or damage

resulting from unauthorized modification or service;

or from the use of products or replacement parts

other than those from Impco; including, but not limit-

ed to, motors and pumps.

b. This warranty does not cover any damage or

malfunction unless caused by a non-conformance

in material or workmanship. Damage or malfunction

which is not covered by this warranty includes, but is

not limited to, water damage to the motor, abuse,

misuse, alteration, improper installation / maintenance

/ operation, and transportation damage.

c. Mineral accumulations, dirt, and dust on the pad are

not defects and are excluded from this warranty. Refer

to the Owners’ Manual section for maintenance instruc-

tions to help minimize these conditions.

d. This warranty does not cover the cost of a service call

at the site of installation to diagnose cause of trouble,

the cost of labor to install the part, or mileage

allowance to or from the site. Impco does not

pay freight or postage on any exchange.

e. This specific warranty does not cover evaporative

coolers installed and operated outside the continental

United States.

III. Do not us cool r cl an rs, cool r tr atm nts, or oth r

additiv s in this vaporativ cool r. Th us of any of

th s products will void your warranty and may impair

th lif of your vaporativ cool r.

IV. To obtain service under this warranty, contact the dealer

where you purchased your evaporative cooler. As a final

step, if you cannot locate your dealer, contact Customer

Service, the model number and serial number of your

evaporative cooler, date of installation, and a description

of your problem.

Impco

Tel: 602-2 1-7 16

www.impcollc.com

This warranty is the only warranty extended by Impco to su-

ppliers and/or purchasers of this evaporative cooler. Impco dis-

claims all other warranties, express or implied, that arise by the

operation of the law, except that implied

warranties of merchantability or fitness for a particular purpose

are limited to the duration of the warranty period. Impco shall

not be liable for any incidental or consequential damage which

may have resulted from any alleged breach or warranty.

Some states do not allow limitations on how long an implied

warranty lasts or the exclusion or limitation of incidental or

consequential damages, so the limitations or exclusions stated

above may not apply to you.

This warranty gives you specific legal rights and you may have

other rights, which vary from state to state.

Since Impco, follows a policy of continuous product improve-

ment; it reserves the right to change design and

specification without prior notice or liability.

For information on the entire family of Symphony cooling

solutions, visit us online at www.impcollc.com.

7

This manual suits for next models

8

Table of contents

Popular Air Conditioner manuals by other brands

Panasonic

Panasonic CS-WU12VKYF Series operating instructions

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Daikin

Daikin Split Sensira R32 Service manual

Kaden

Kaden KCS Series manual

Mitsubishi Electric

Mitsubishi Electric MSZ-DM25VA operating instructions

Cooler Master

Cooler Master Silent Pro Gold 450W user manual

Panasonic

Panasonic CS-YS9TKV operating instructions

Convair

Convair ClimateMaster CM12RW instruction manual

Frigidaire

Frigidaire FAA074S7A12 Use & care manual

Hisense

Hisense APC09 Use and Installation Instructions

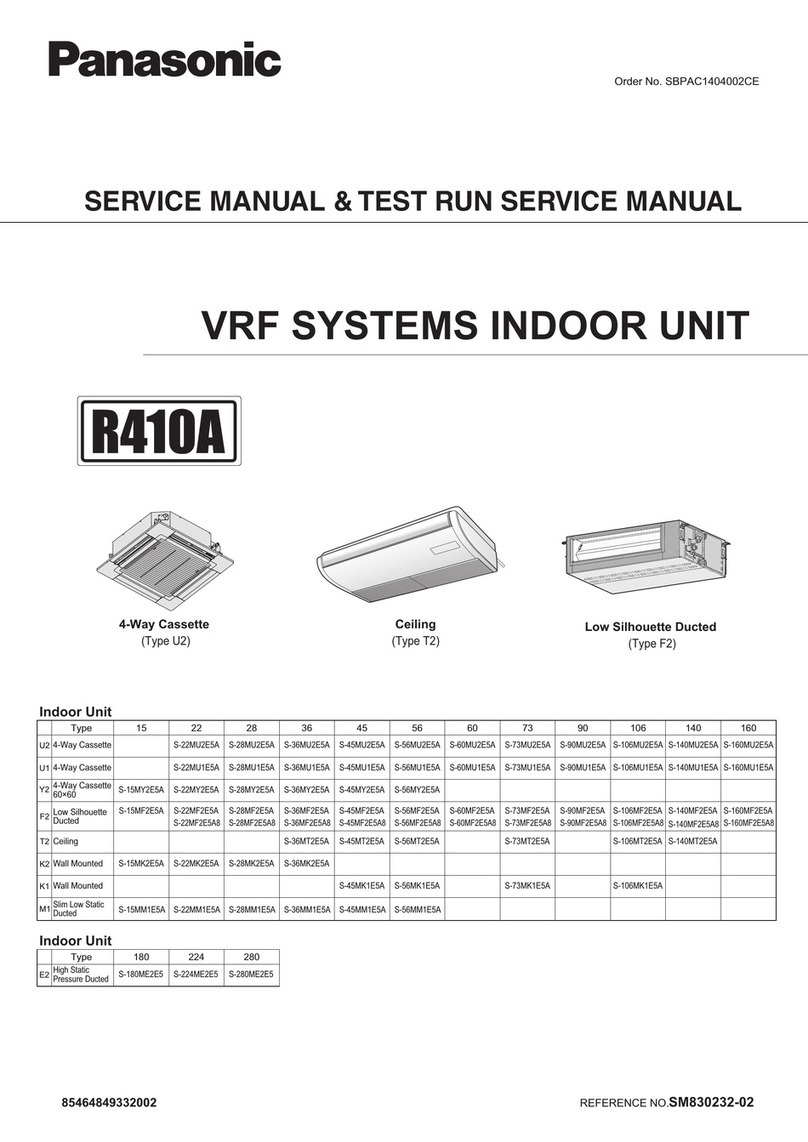

Panasonic

Panasonic S-22MF2E5A8 Service Manual & Test Run Service Manual

Samsung

Samsung AJ TNTDKH Series user manual