CNPV CNPV-PS-M-S0010-IEC User manual

IEC INSTALLATION INSTRUCTION AND

MAINTENANCE MANUAL

FOR CRYSTALLINE SOLAR PV MODULE

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 1 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

1. INTRODUCTION

This installation instruction manual provides information about CNPV Crystalline Solar Photovoltaic Modules.

CNPV Dongying Solar Power Company Limited has a history of successful innovation within the Solar Industry.

The company was founded in 2006 and has made significant investments in research and development, creating over

10 patents during the company’ history.

The company has several fully integrated product lines including ingots, casting, wafers, Cells and Modules of Mono

and Poly crystalline, and those products are also exported to overseas markets. With an experienced international

management team and a strong reputation for innovation, CNPV is one of the leaders in China’s Solar Energy Sector

and provides the highest quality SPV Modules in a range of sizes designed to meet the requirements of the most

demanding energy and power users worldwide.

2. POWER MODULE

CNPV Solar Photovoltaic Modules consist of a series of electrically interconnected crystalline silicon solar cells,

which are permanently encapsulated between a low iron toughened glass superstrate and substrate. The entire

laminate is secured within an anodized aluminum frame for structural strength; ease of installation and to protect the

cells from the most severe environmental conditions.

3. APPLICATIONS

CNPV SPV Modules are a highly reliable, virtually maintenance-free direct current (DC) power source, designed to

operate most efficiently in sunlight. CNPV series Modules are ideal to power remote homes, recreational vehicles,

water pumps, telecommunication systems and many other applications either with or without the use of storage

batteries.

4. PERMIT

Before installing your system, contact local authorities to determine the necessary permit, installation and inspection

requirements.

5. CLIMATE CONDITION

Install the CNPV Solar Photovoltaic Crystalline series Modules in the following conditions:

Ambient temperature: -20°C to +40°C.

Operating temperature: -40°C to +85°C.

Storage temperature: -40°C to +40°C,

Humidity: below 85RH%

Wind pressure: below 50.12lb / ft2(2400Pa).

Snow Load Pressure: below 112.76lb / ft2(5400Pa).

Corrosion resistance: Except for heavy corrosive salt area and sulfurous area.

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 2 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

6. SITE SELECTION

In most applications, CNPV SPV Modules should be installed in a location where they will receive maximum

sunlight throughout the year. In the Northern Hemisphere, the Module should typically face south, and in the

Southern Hemisphere, the Modules should typically face north. Modules facing 30 degrees away from true South (or

North) will lose approximately 10 to 15 per cent of their power output. If the Module faces 60 degrees away from

true South (or North), the power loss will be 20 to 30 per cent.

When choosing a site, avoid trees, buildings or obstructions, which could cast shadows on the solar photovoltaic

Modules especially during the winter months when the arc of the sun is lowest over the horizon. Shading causes loss

of output, even though the factory fitted bypass diodes of the SPV Module will minimize any such loss.

Do not install the SPV Module near naked flame or flammable materials.

Do not install the SPV Module in a location where it would be immersed in water or continually exposed to water

from a sprinkler or fountain etc.

7. MODULE TILT ANGLE

CNPV SPV Modules connected in series should be installed at same orientation and angle. Different orientation or

angle may cause loss of output power due to difference of amount of sunlight exposed to the Module.

CNPV SPV Modules produce the most power when they are pointed directly at the sun. For installations where the

SPV Modules are attached to a permanent structure, the SPV Modules should be tilted for optimum winter

performance. As a rule, if the system power production is adequate in winter, it will be satisfactory during the rest of

the year. The Module tilt angle is measured between the solar Modules and the ground (Figure 1). Optimal tilting of

SPV Module is almost the same as the latitude of installation location.

SUNLIGHT

TILT ANGLE

MODULE

H

O

RIZ

O

NTAL

Figure 1 SPV Module Tilt Angle

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 3 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

8. MOUNTING AND NOTES

Systems should be installed by qualified personnel only. It involves electricity, and can be dangerous if the personnel

are not familiar with the appropriate safety procedures.

The Module frame is made of anodized aluminum, and therefore corrosion can occur if the Module is subject to a

salt water environment with contact to a rack of another type of metal (Electrolysis Corrosion). If required, PVC or

stainless steel washers can be placed between the SPV Module frame and support structure to prevent this type of

corrosion. Module support structures that are to be used to support SPV Modules at correct tilt angles should be wind

and snow load rated for use by the appropriate local and civil codes prior to installation.

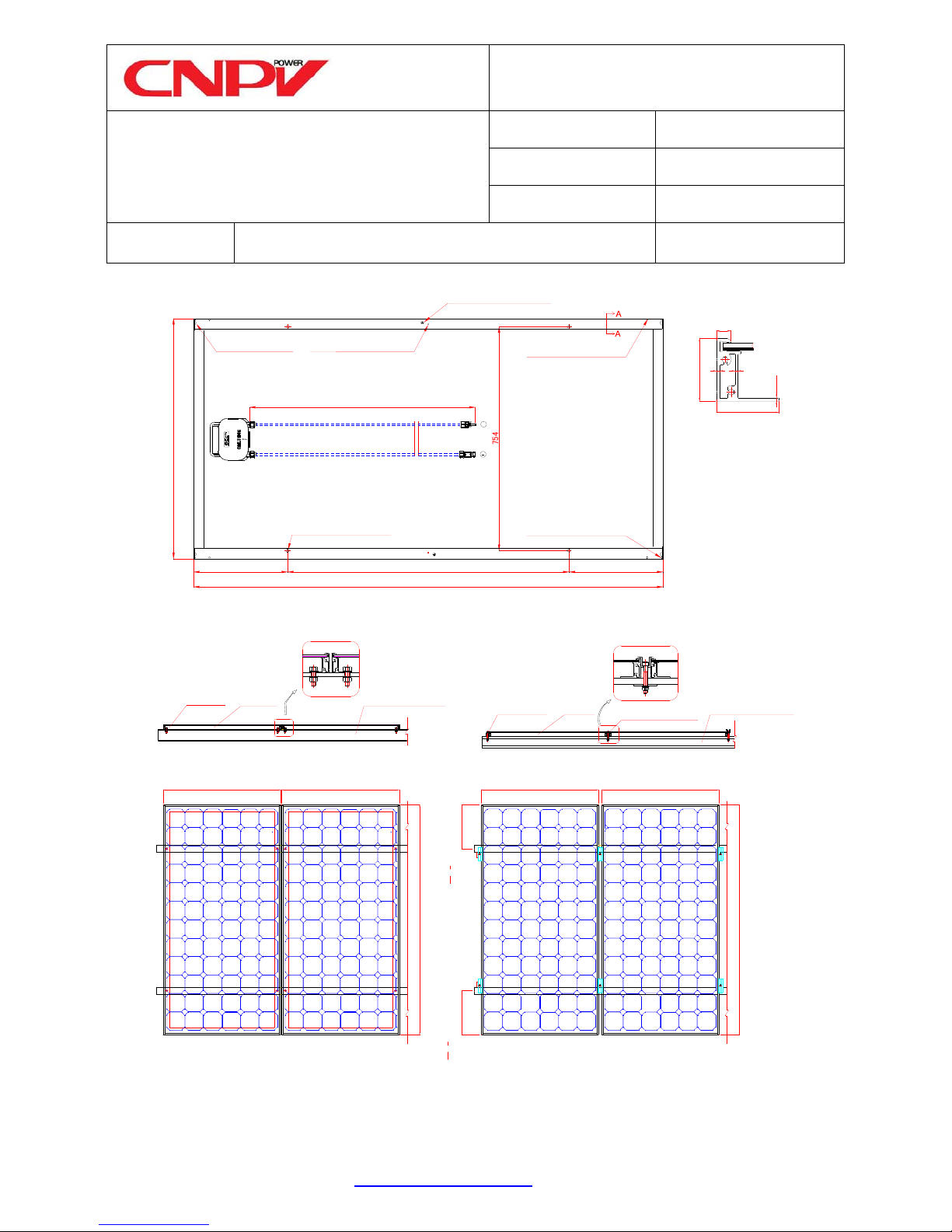

CNPV SPV Modules can be mounted as following method:

Figure 2 Mounting Method a and b

a) Using corrosion-proof screws (M8) on the existing installing holes (see drawing 1, 3, 5 & 7) in the Module

frame. The frame of each Module has 4 or 8 mounting holes (12mm×9mm) used to secure the Modules to

supporting structure. The Module frame must be attached to a supporting rack using M8 stainless steel hardware

together with spring washers and flat washers in four places symmetrical on the SPV Module. See method a of

figure 2. The applied torque is about 8 Newton-meters.

b) Using suitable Module clamps on the Module frame, see method b of figure 2. The module frame must be

attached to supporting rack using M8 stainless steel hardware together with corrosion-proof clips in four places

on the SPV module. See drawing 10, 12, 14 & 16, with clamping clip, for positioning of clamping clips. The

applied torque is about 8 Newton-meters. See figure 3 if clamping mounting is on short frames of the module.

Width

1/4W1/4W

Length

c) Insertion System

Method a: Using corrosion-proof

screws on existing Installation Method b. Using suitable module

clamps on the module frame

Using Short sides for module clamping. W

means module width, and 1/4W means

permissible clamping range.

Figure 3. Mounting on short frames.

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 4 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

NOTES:

(1) The Module clamps must not come into contact with the front glass and must not deform the frame. Avoid

shadowing effects from the Module clamps and the insertion systems. It is not permitted to modify the Module frame

under any circumstances. Recommended distance between 2 Solar Modules is 5mm considering linear thermal

expansion of the Module frames.

(2) Clearance between the Module frame and mounting surface may be required to prevent the junction box from

touching the surface, and to circulate cooling air around the back of the Module.

(3) The Modules are not designed for integral mounting as part of a roof or wall. The mounting design may have an

impact on the fire resistance. If the Modules are to be installed on the roof or wall of a building, the fire resistance of

roof covering or wall should be rated for the application. Here the standoff method or the rack method is

recommended. The Modules are supported parallel to surface of the building wall or roof. Clearance between the

Module frames and surface of the wall or roof is required to prevent wiring damage and to allow air to circulate

behind the Module. The recommended stand-off height is 115mm. Any slope less than 5in/ft (127mm/305mm)

required to maintain a fire class rating. Do not mount SPV Module in such way that the drain holes of SPV Module

are intended to block up.

(4) Do not step on the Module, although SPV Modules are quite rugged, the glass can be broken (and the Module

will no longer work properly) if it is dropped or hit by tools or other objects.

9. GROUNDING

All Module frames and mounting racks must be properly grounded in accordance with the local regulations. Proper

grounding is achieved by connecting the Module frame(s) and structural members contiguously one to another using

a suitable grounding conductor. The grounding conductor or strap may be copper, copper alloy, or other material

acceptable for use as an electrical conductor per local regulations. The grounding conductor must then make a

connection to earth using a suitable earth ground electrode.

Attach a separate conductor to one of the

4mm diameter grounding holes marked

' ' on the Module frame with a screw

and nut that incorporates an external tooth

washer. This is to ensure positive electrical

contact with the frame.

The rack must also be grounded unless they are mechanically connected by nuts and bolts to the grounded SPV

Modules. The array frame shall be grounded in accordance with local regulations.

Figure 4 Schematic drawing

for SPV Module grounding

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 5 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

10. BYPASS DIODES AND BLOCKING DIODES

Partial shading of an individual Module can cause a reverse voltage across the shaded SPV Module. Current is then

forced through the shaded area by the other Modules.

When a bypass diode is wired in parallel with the series string, the forced current will flow through the diode and

bypass the shaded SPV Module, thereby minimizing Module heating and array current losses.

In system utilizing a battery, blocking diodes are typically placed between the battery and the SPV Module output to

prevent battery discharge at night.

Diodes that are used as blocking diodes must: Have a Rated Average Forward Current [IF(AV)] above maximum

system current at highest Module operating temperature. Have a Rated Repetitive Peak Reverse Voltage [VRRM]

above maximum system voltage at lowest Module operating temperature.

11. WARNING AND NOTES

The SPV Modules generate electricity when exposed to light. Array of many Modules can cause lethal electrical

shock and burn hazards. Only authorized and trained personnel should have access to these Modules. To reduce the

risk of electrical shock or burns, modules maybe covered with an opaque material during installation to avoid

electrical shocks or burns. Do not touch live terminals with bare hands. Use insulated tools for electrical connections.

Use appropriate methods to mount SPV Modules. Fall of Modules from high place will cause death, injury or

damage.

The SPV Module has a pair of male and female waterproof connectors. For a series electrical connection, connect

positive (+) connector of first SPV Module to negative (-) connector of the following Module.

Do not short the positive and the negative. Do not disconnect under load. Be sure connectors have no gap between

the insulators. In case there is a gap, a fire and/or an electrical shock may occur.

NOTES:

(1) Artificially concentrated sunlight shall not be directed on the SPV Module. The rated electrical characteristics are

within 10 percent of measured values under standard test conditions (Irradiance of 1000W/m2, AM 1.5 spectrum, and

cell temperature of 25°C).

(2) Under normal conditions, a solar photovoltaic Module is likely to experience conditions that produce more

current and/or voltage than reported at standard test conditions. Accordingly the value of Isc and Voc marked on this

Module should be multiplied by a factor of 1.25 when determining component voltage ratings, conductor current

ratings, fuse sizes, and sizes of controls connected to the SPV output.

(3) Details for wiring in accordance with the local regulations.

(4) If you install modules in parallel electrically, each module (or series string of modules so connected) shall be

provided with the maximum series fuse as specified.

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 6 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

12. MODULE WIRING

Each Module has two #12 AWG type standard 90°C sunlight resistant output cables each terminated with plug & ply

connectors. This cable is suitable for applications where wiring is exposed to the direct rays of the Sun. We

recommend that all wiring and electrical connections comply with local regulations.

For field connections, use the minimum No. #12 AWG copper wires insulated for a minimum of 90°C and sunlight

resistant as well. The minimum and maximum outer cable diameters of the cable are 5 to 7mm. Refer to table 1 for

the maximum electrical rating of series fuse.

13. TYPE OF PRODUCT APPLICATION

“The modules are qualified for application class A: Hazardous voltage (IEC61730: higher than 50V DC; EN61730:

higher than 120V), hazardous power applications (higher than 240W) where general contract access is anticipated

(Modules qualified for safety through EN IEC61730-1 and EN IEC61730-2 within this application class are

considered to meet the requirements for Safety class II)”

14. MAINTENANCE

Under most weather conditions, normal rainfall is sufficient to keep the SPV Module glass surface clean. If dirt

build-up becomes excessive, clean the glass only with a soft cloth using mild detergent and water. USE CAUTION

WHEN CLEANING THE BACK SURFACE OF THE MODULE TO AVOID PENETRATING THE SUBSTRATE

MATERIALS. SPV Modules that are mounted flat (0° tilt angle) should be cleaned more often, as they will not ''self

clean'' as effectively as Modules mounted at a 15° tilt or greater. Once a year, check the tightness of terminal screws

and the general condition of the wiring. Also, check to be sure that mounting hardware is tight. Loose connections

will result in damage for array. Changed SPV Module must be the same kind and type. Do not touch live parts of

cables and connectors. Use appropriate safety equipment (insulated tools, insulating gloves, etc.), when touching

them.

Cover the front surface of the SPV Module by an opaque or other material when repairing. The SPV Modules when

exposed to sunlight generate high voltage and are dangerous.

15. SPECIFICATIONS:

See Table1

Notes

1. Standard Test Condition(STC) of Irradiance of 1000W/m²,AM1.5 Solar Spectrum & 25ºC cell temperature

2. Nominal Operating Cell Temperature (NOCT): 45±2ºC

3. The tolerance of Voltage and Current within ±10%

4. Temperature coefficient of Current is 0.05%/ºK

5. Temperature coefficient of Voltage is -0.30%/°K

6. See SPV Module drawing for mounting and grounding holes locations. The drawing for CNPV-xxxxM and

CNPV-xxxxB(Black module) is identical.

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 7 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

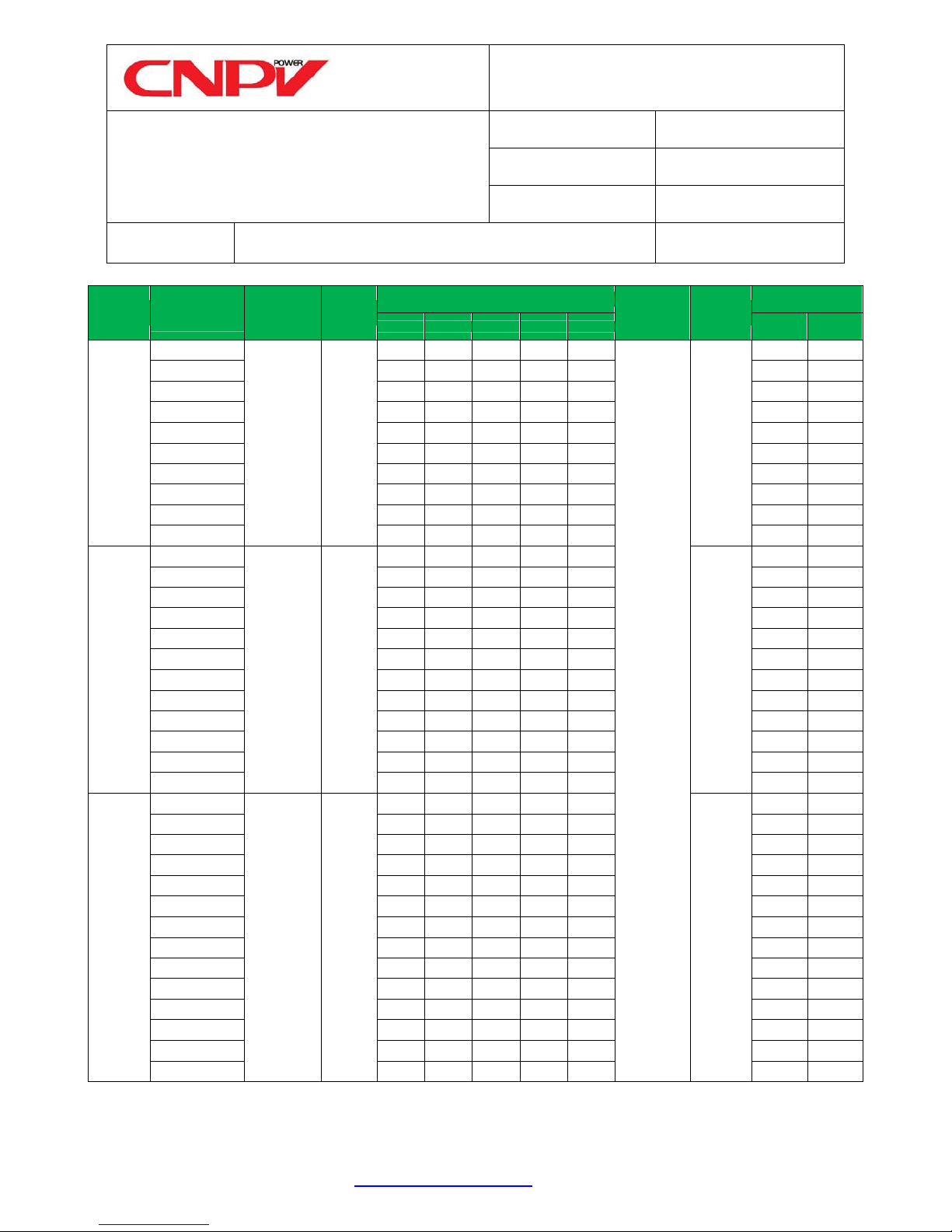

Table 1: Electrical and Mechanical Specifications.

Module

Series Model Dimensions

(mm) Weight

(kg)

Electrical Performance @ STC Max-System

Voltage (VDC) Max-Series

Fuse (A)

Recommended Max.

Module Number

Pmax(Wp) VPm(V) IPm(A) VOC(V) ISC(A) In Series In Parallel

72pcs 125×125mm

SPV Module

(Mono-Crystalline Silicon )

CNPV-160M

1581×809×35 15

160 34.5 4.65 43.0 5.15

IEC61215/IEC61730:1000VDC

10

17 2

CNPV-165M 165 35.2 4.70 43.4 5.20 17 2

CNPV-170M 170 35.8 4.75 43.8 5.25 17 2

CNPV-175M 175 36.6 4.80 44.2 5.30 17 2

CNPV-180M 180 37.2 4.85 44.6 5.35 17 2

CNPV-185M 185 37.8 4.90 45.0 5.40 17 2

CNPV-190M 190 37.8 5.05 45.1 5.55 17 2

CNPV-195M 195 37.9 5.15 45.2 5.60 17 2

CNPV-200M 200 38.0 5.25 45.3 5.65 17 2

CNPV-205M 205 38.1 5.38 45.4 5.70 17 2

CNPV-210M 210 38.2 5.50 45.6 5.80 17 2

72pcs 125×125mm

SPV Module-Black

(Mono-Crystalline Silicon )

CNPV-160MB 160 34.5 4.65 43.0 5.15 17 2

CNPV-165MB 165 35.2 4.70 43.4 5.20 17 2

CNPV-170MB 170 35.8 4.75 43.8 5.25 17 2

CNPV-175MB 175 36.6 4.80 44.2 5.30 17 2

CNPV-180MB 180 37.2 4.85 44.6 5.35 17 2

CNPV-185MB 185 37.8 4.90 45.0 5.40 17 2

CNPV-190MB 190 37.8 5.05 45.1 5.55 17 2

CNPV-195MB 195 37.9 5.15 45.2 5.60 17 2

CNPV-200MB 200 38.0 5.25 45.3 5.65 17 2

CNPV-205MB 205 38.1 5.38 45.4 5.70 17 2

CNPV-210MB 210 38.2 5.50 45.6 5.80 17 2

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 8 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

Module

Series Model Dimensions

(mm) Weight

(kg)

Electrical Performance @ STC Max-System

Voltage

(VDC)

Max-Series

Fuse (A)

Recommended Max.

Module Number

Pmax(Wp) VPm(V) IPm(A) VOC(V) ISC(A) In Series In Parallel

54pcs 156×156mm

SPV Module

(Mono-Crystalline Silicon)\

CNPV-190M-54

1482×992×35 18

190 26.6 7.15 32.6 7.90

IEC61215/IEC61730:1000VDC

20

23 3

CNPV-195M-54 195 26.9 7.25 32.8 8.00 23 3

CNPV-200M-54 200 27.0 7.40 33.0 8.10 23 3

CNPV-205M-54 205 27.2 7.55 33.2 8.20 23 3

CNPV-210M-54 210 27.4 7.65 33.4 8.30 23 3

CNPV-215M-54 215 27.6 7.80 33.6 8.40 23 3

CNPV-220M-54 220 27.7 7.95 33.7 8.50 23 3

CNPV-225M-54 225 27.8 8.10 33.8 8.60 23 3

CNPV-230M-54 230 28.0 8.20 33.9 8.70 23 3

CNPV-235M-54 235 28.3 8.30 34.0 8.80 23 3

CNPV-240M-54 240 28.7 8.35 34.1 8.85 23 3

60pcs 156×156mm

SPV Module

(Mono-Crystalline Silicon)

CNPV-220M

1650×992×35 20

220 29.7 7.40 36.8 8.00

20

21 3

CNPV-225M 225 30.0 7.50 37.0 8.10 21 3

CNPV-230M 230 30.3 7.60 37.2 8.20 21 3

CNPV-235M 235 30.7 7.65 37.5 8.30 21 3

CNPV-240M 240 30.8 7.80 37.6 8.40 21 3

CNPV-245M 245 30.9 7.93 37.7 8.50 21 3

CNPV-250M 250 31.0 8.05 37.8 8.60 21 3

CNPV-255M 255 31.3 8.15 37.9 8.70 21 3

CNPV-260M 260 31.5 8.25 38.0 8.80 21 3

CNPV-265M 265 31.7 8.35 38.1 8.90 21 3

72pcs 156×156mm

SPV Module

(Mono-Crystalline Silicon)

CNPV-255M

1965×992×40 24

250 35.9 7.10 43.2 7.70

20

17 3

CNPV-260M 260 36.1 7.20 43.4 7.80 17 3

CNPV-265M 265 36.3 7.30 43.6 7.90 17 3

CNPV-270M 270 36.5 7.40 43.8 8.00 17 3

CNPV-275M 275 36.7 7.50 44.0 8.10 17 3

CNPV-280M 280 36.9 7.60 44.2 8.20 17 3

CNPV-285M 285 37.0 7.70 44.4 8.30 17 3

CNPV-290M 290 37.2 7.80 44.6 8.40 17 3

CNPV-295M 295 37.3 7.90 44.8 8.50 17 3

CNPV-300M 300 37.5 8.00 45.0 8.60 17 3

CNPV-305M 305 37.7 8.10 45.1 8.70 17 3

CNPV-310M 310 37.9 8.18 45.2 8.80 17 3

CNPV-315M 315 38.1 8.25 45.3 8.90 17 3

CNPV-320M 320 38.3 8.35 45.4 8.95 17 3

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 9 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

Module

Series Model Dimensions

(mm) Weight

(kg)

Electrical Performance @ STC Max-System

Voltage

(VDC)

Max-Series

Fuse (A)

Recommended Max.

Module Number

Pmax(Wp) VPm(V) IPm(A) VOC(V) ISC(A) In Series In Parallel

54pcs 156×156mm

SPV Module-Black

(Mono-Crystalline Silicon)\

CNPV-190MB-54

1482×992×35 18

190 26.6 7.15 32.6 7.90

IEC61215/IEC61730:1000VDC

20

23 3

CNPV-195MB-54 195 26.9 7.25 32.8 8.00 23 3

CNPV-200MB-54 200 27.0 7.40 33.0 8.10 23 3

CNPV-205MB-54 205 27.2 7.55 33.2 8.20 23 3

CNPV-210MB-54 210 27.4 7.65 33.4 8.30 23 3

CNPV-215MB-54 215 27.6 7.80 33.6 8.40 23 3

CNPV-220MB-54 220 27.7 7.95 33.7 8.50 23 3

CNPV-225MB-54 225 27.8 8.10 33.8 8.60 23 3

CNPV-230MB-54 230 28.0 8.20 33.9 8.70 23 3

CNPV-235MB-54 235 28.3 8.30 34.0 8.80 23 3

CNPV-240MB-54 240 28.7 8.35 34.1 8.85 23 3

60pcs 156×156mm

SPV Module-Black

(Mono-Crystalline Silicon)

CNPV-220MB

1650×992×35 20

220 29.7 7.40 36.8 8.00

20

21 3

CNPV-225MB 225 30.0 7.50 37.0 8.10 21 3

CNPV-230MB 230 30.3 7.60 37.2 8.20 21 3

CNPV-235MB 235 30.7 7.65 37.5 8.30 21 3

CNPV-240MB 240 30.8 7.80 37.6 8.40 21 3

CNPV-245MB 245 30.9 7.93 37.7 8.50 21 3

CNPV-250MB 250 31.0 8.05 37.8 8.60 21 3

CNPV-255MB 255 31.3 8.15 37.9 8.70 21 3

CNPV-260MB 260 31.5 8.25 38.0 8.80 21 3

CNPV-265MB 265 31.7 8.35 38.1 8.90 21 3

72pcs 156×156mm

SPV Module-Black

(Mono-Crystalline Silicon)

CNPV-255MB

1965×992×40 24

250 35.9 7.10 43.2 7.70

20

17 3

CNPV-260MB 260 36.1 7.20 43.4 7.80 17 3

CNPV-265MB 265 36.3 7.30 43.6 7.90 17 3

CNPV-270MB 270 36.5 7.40 43.8 8.00 17 3

CNPV-275MB 275 36.7 7.50 44.0 8.10 17 3

CNPV-280MB 280 36.9 7.60 44.2 8.20 17 3

CNPV-285MB 285 37.0 7.70 44.4 8.30 17 3

CNPV-290MB 290 37.2 7.80 44.6 8.40 17 3

CNPV-295MB 295 37.3 7.90 44.8 8.50 17 3

CNPV-300MB 300 37.5 8.00 45.0 8.60 17 3

CNPV-305MB 305 37.7 8.10 45.1 8.70 17 3

CNPV-310MB 310 37.9 8.18 45.2 8.80 17 3

CNPV-315MB 315 38.1 8.25 45.3 8.90 17 3

CNPV-320MB 320 38.3 8.35 45.4 8.95 17 3

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 10 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

Module

Series Model Dimensions

(mm) Weight

(kg)

Electrical Performance @ STC Max-System

Voltage

(VDC)

Max-Series

Fuse (A)

Recommended Max.

Module Number

Pmax(Wp) VPm(V) IPm(A) VOC(V) ISC(A) In Series In Parallel

54pcs 156×156mm

SPV Module

(Poly-Crystalline Silicon)

CNPV-190P-54

1482×992×35 18

190 26.2 7.25 32.7 7.95

IEC61215/IEC61730:1000VDC

20

23 3

CNPV-195P-54 195 26.5 7.35 32.9 8.05 23 3

CNPV-200P-54 200 26.7 7.5 33.1 8.15 23 3

CNPV-205P-54 205 26.9 7.63 33.3 8.25 23 3

CNPV-210P-54 210 27.1 7.75 33.5 8.35 23 3

CNPV-215P-54 215 27.4 7.85 33.7 8.40 23 3

CNPV-220P-54 220 27.7 7.95 33.9 8.45 23 3

CNPV-225P-54 225 28.1 8.00 34.1 8.50 23 3

CNPV-230P-54 230 28.4 8.10 34.3 8.55 23 3

CNPV-235P-54 235 28.6 8.20 34.5 8.65 23 3

60pcs 156×156mm

SPV Module

(Poly-Crystalline Silicon)

CNPV-210P

1650×992×35 20

210 29.2 7.20 36.4 7.80

20

21 3

CNPV-215P 215 29.5 7.30 36.6 7.90 21 3

CNPV-220P 220 29.8 7.40 36.8 8.00 21 3

CNPV-225P 225 30.1 7.50 37.0 8.10 21 3

CNPV-230P 230 30.3 7.60 37.2 8.20 21 3

CNPV-235P 235 30.5 7.70 37.3 8.30 21 3

CNPV-240P 240 30.8 7.80 37.4 8.40 21 3

CNPV-245P 245 31.0 7.90 37.5 8.50 21 3

CNPV-250P 250 31.2 8.00 37.6 8.55 21 3

CNPV-255P 255 31.3 8.15 37.7 8.60 21 3

CNPV-260P 260 31.5 8.25 37.8 8.65 21 3

CNPV-265P 265 31.7 8.35 37.9 8.70 21 3

72pcs156×156mm

SPV Module

(Poly-Crystalline Silicon)

CNPV-250P

1965×992×40 24

250 35.8 7.00 43.4 7.60

20

17 3

CNPV-255P 255 36.0 7.10 43.6 7.70 17 3

CNPV-260P 260 36.2 7.20 43.8 7.80 17 3

CNPV-265P 265 36.4 7.30 44.0 7.90 17 3

CNPV-270P 270 36.6 7.40 44.2 8.00 17 3

CNPV-275P 275 36.7 7.50 44.4 8.10 17 3

CNPV-280P 280 36.9 7.60 44.6 8.20 17 3

CNPV-285P 285 37.0 7.70 44.8 8.30 17 3

CNPV-290P 290 37.2 7.80 45.0 8.40 17 3

CNPV-295P 295 37.4 7.90 45.1 8.45 17 3

CNPV-300P 300 37.6 8.00 45.2 8.50 17 3

CNPV-305P 305 37.7 8.10 45.3 8.55 17 3

CNPV-310P 310 38.0 8.15 45.4 8.60 17 3

CNPV-315P 315 38.2 8.25 45.5 8.65 17 3

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 11 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

Module

Series Model Dimensions

(mm) Weight

(kg)

Electrical Performance @ STC Max-System

Voltage

(VDC)

Max-Series

Fuse (A)

Recommended Max.

Module Number

Pmax(Wp) VPm(V) IPm(A) VOC(V) ISC(A) In Series In Parallel

54pcs 156×156mm

SPV Module-Black

(Poly-Crystalline Silicon)

CNPV-190PB-54

1482×992×35 18

190 26.2 7.25 32.7 7.95

IEC61215/IEC61730:1000VDC

20

23 3

CNPV-195PB-54 195 26.5 7.35 32.9 8.05 23 3

CNPV-200PB-54 200 26.7 7.50 33.1 8.15 23 3

CNPV-205PB-54 205 26.9 7.63 33.3 8.25 23 3

CNPV-210PB-54 210 27.1 7.75 33.5 8.35 23 3

CNPV-215PB-54 215 27.4 7.85 33.7 8.40 23 3

CNPV-220PB-54 220 27.7 7.95 33.9 8.45 23 3

CNPV-225PB-54 225 28.1 8.00 34.1 8.50 23 3

CNPV-230PB-54 230 28.4 8.10 34.3 8.55 23 3

CNPV-235PB-54 235 28.6 8.20 34.5 8.65 23 3

60pcs 156×156mm

SPV Module-Black

(Poly-Crystalline Silicon)

CNPV-210PB

1650×992×35 20

210 29.2 7.20 36.4 7.80

20

21 3

CNPV-215PB 215 29.5 7.30 36.6 7.90 21 3

CNPV-220PB 220 29.8 7.40 36.8 8.00 21 3

CNPV-225PB 225 30.1 7.50 37.0 8.10 21 3

CNPV-230PB 230 30.3 7.60 37.2 8.20 21 3

CNPV-235PB 235 30.5 7.70 37.3 8.30 21 3

CNPV-240PB 240 30.8 7.80 37.4 8.40 21 3

CNPV-245PB 245 31.0 7.90 37.5 8.50 21 3

CNPV-250PB 250 31.2 8.00 37.6 8.55 21 3

CNPV-255PB 255 31.3 8.15 37.7 8.60 21 3

CNPV-260PB 260 31.5 8.25 37.8 8.65 21 3

CNPV-265PB 265 31.7 8.35 37.9 8.70 21 3

72pcs156×156mm

SPV Module-Black

(Poly-Crystalline Silicon)

CNPV-250PB

1965×992×40 24

250 35.8 7.00 43.4 7.60

20

17 3

CNPV-255PB 255 36.0 7.10 43.6 7.70 17 3

CNPV-260PB 260 36.2 7.20 43.8 7.80 17 3

CNPV-265PB 265 36.4 7.30 44.0 7.90 17 3

CNPV-270PB 270 36.6 7.40 44.2 8.00 17 3

CNPV-275PB 275 36.7 7.50 44.4 8.10 17 3

CNPV-280PB 280 36.9 7.60 44.6 8.20 17 3

CNPV-285PB 285 37.0 7.70 44.8 8.30 17 3

CNPV-290PB 290 37.2 7.80 45.0 8.40 17 3

CNPV-295PB 295 37.4 7.90 45.1 8.45 17 3

CNPV-300PB 300 37.6 8.00 45.2 8.50 17 3

CNPV-305PB 305 37.7 8.10 45.3 8.55 17 3

CNPV-310PB 310 38.0 8.15 45.4 8.60 17 3

CNPV-315PB 315 38.2 8.25 45.5 8.65 17 3

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 12 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

4-

Φ

9

×

12

INSTALLING HOLE

1581±2

948

7

5

4

4-

Φ

12 DRAIN HOLE

2-

Φ

4

GROUNDING HOLE

GROUNDING MARKING

809±2

4-

Φ

4

×

6 DRAIN HOLE

4-

Φ

4

×

4 DRAIN HOLE

316.5 316.5

Section A-A

(

magnified

)

8

1.9

35

35

900(Typical)

+

1.8 1.5

Drawing 1 Back View of 6×12-125mm- 72cell SPV Module

1

20

~

1

4

Module Length

1

20

~

1

4

Module Length

809

1581

809

Module Middle Clip

End Clip Support Rack

809

1581

809

Module Support Rack

M8 Screw

Mounting Drawing (with clamping clips)

Mounting Drawing (with screws)

Drawing 2 Mounting Drawing for 6×12-125×125mm 72cell SPV Module (with screws and clamping clips on long frames)

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 13 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

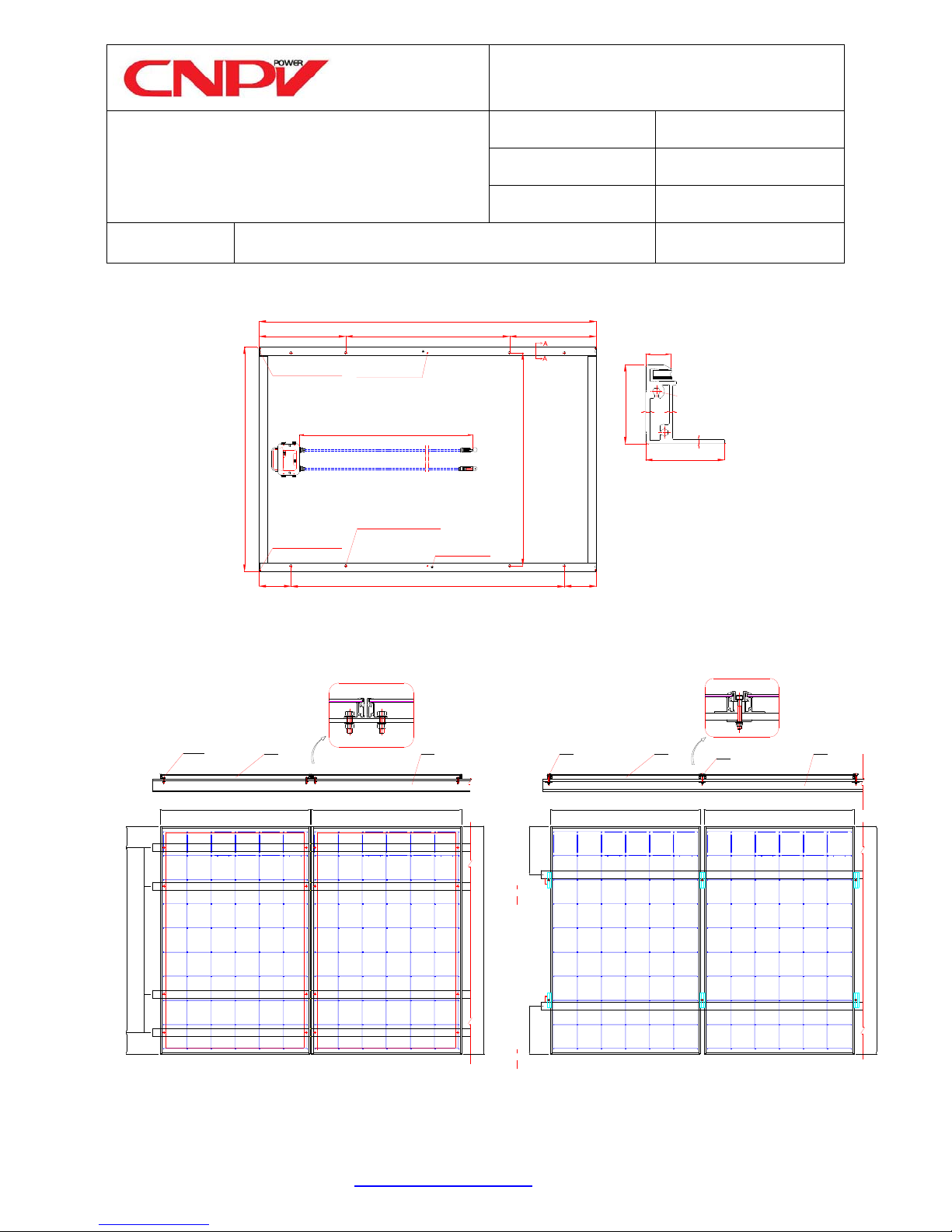

35

1.8

1.9

11

1.5

35

1000VDCIP65

+

TUV CE

1202

4-Φ12 DRAIN HOLE

8-Φ9×12 INSTALLING HOLE

2-Φ4 GROUNDING HOLE

992±2

702(For normal installation)

1200(Typical)

GROUNDING MARKING

942

4-Φ4.5×4 DRAIN HOLE

140 140

1482±2

390390

(For High wind and snow load, these two

installation holes should also be used.)

Section A-A

(magnified)

Drawing 3 Back View of 6×9-156×156mm 54cell SPV Module

1

20~1

4 Module Length

1

20~1

4 Module Length

992

1482

992

Moudle Middle Clip

End Clip Support Rack

Mounting Drawing (with clamping clips)

702

992

1482

992

Moudle Support Rack

Mounting Drawing (with screws)

Screw M8

1202

250 250

140 140

Drawing 4 Mounting Drawing for 6×9-156×156mm 54cell SPV Module (with screws and clamping clips on long frames)

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 14 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

1.9

+

35

35

1.8 1.5

990

4-Φ12 DRAIN HOLE

8-Φ9×12 INSTALLING HOLE

2-Φ4 GROUNDING HOLE

992±2

Section A-A

(magnified)

941

4-Φ4.5×4 DRAIN HOLE

330 330

1200(Typical)

1650±2

11

GROUNDING MARKING

Drawing 5 Back View of 6×10-156×156mm 60cell SPV Module

1

20

~

1

4

Module Length

1

20

~

1

4

Module Length

992

1650

992

Moudle Middle Clip

End Clip Support Rack

Mounting Drawing (with clamping clips)

330990330

992

1650

992

Moudle Support Rack

Mounting Drawing (with screws)

Screw M8

Drawing 6 Mounting Drawing for 6×10-156×156mm 60cell SPV Module (with screws and clamping clips on long frames)

TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.: CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE: July 2012

AUTHOR(S): Bypina Veerraju Chaudary, Yang Xiaowu Page 15 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail: marketing@cnpv-power.com Tel: +86-546-7795555, Fax: +86-546-7795777

+

1965±2

1177

941

4-R2.25×4 DRAIN HOLE

2-Φ4 GROUNDING HOLES

4-?9×12 INSTALLING HOLE

GROUNDING MARKING

4-R6 DRAIN HOLE

Section A-A

(

magnified

)

11

394 394

35

40

2.0

992±2

1200(Typical)

1.8 1.5

Drawing 7 Back View of 6×12-156×156mm 72cell SPV Module

1

20

~

1

4

Module Length

1

20

~

1

4

Module Length

992

1965

992

Module Middle Clip

End Clip Support Rack

Mounting Drawing (with clamping clips)

3941177394

992

1965

992

Module Support Rack

Mounting Drawing (with screws)

Screw M8

Drawing 8 Mounting Drawing for 6×12-156×56mm 72cell SPV Module (with screws and clamping clips on long frames)

Table of contents

Popular Solar Panel manuals by other brands

Euro-Line Solar

Euro-Line Solar ApolloFLEX Mono instructions

flamco

flamco Falx F1219 Installation and operating instructions

ultron

ultron REALPOWER SP-22E instruction manual

Sapphire Solar

Sapphire Solar SS270-280P/60A installation manual

CORAB

CORAB PI-068P installation manual

Qcells

Qcells Q.MAXX-G5 Series Installation and operation manual