7

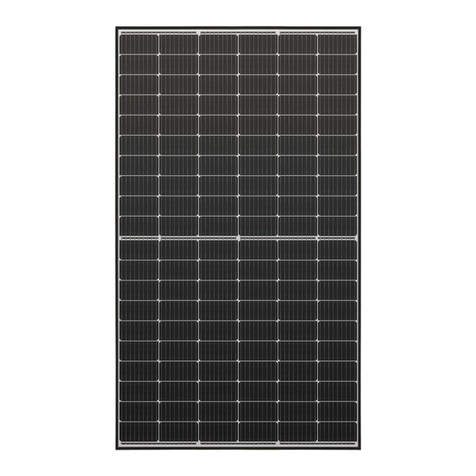

Correct handling of AR glass modules

The nano-porous coating on the glass surfaces of the solar

module reduces reection losses. Compared to uncoated

glass, a deviation of the irradiation angle from the vertical

can result in an angle-dependent transmission of up to 2

% more power. To maintain this effect and to avoid visual

impairments, we urgently recommend observing the follo-

wing instructions:

+Handle the modules with care due to the coated glass.

+Handle the modules with care when unpacking

and mounting. We recommend only touching

the surfaces with clean gloves because the

special reective properties make light soiling

easier to detect. Especially grease and oil are

visible even in small quantities and can inuence the

transmission.

+We advise against attaching stickers or labels

to the coated surface. Depending on the material used,

this can result in very ne residues

that are dicult to remove.

+In rare cases, there may be visible white residues of

the coating uid and colour variations

in the edge area (≤ 5 mm). These are fully functional

modules and there is no reduction in

quality.

+ If it is necessary to clean the modules due to

heavy soiling, we recommend the following

procedure:

+ Clean the modules when they have cooled down

(e.g. during the morning hours)

+ For moderate to strong residues, we recommend

cleaning with lukewarm, de-mineralised water and

clean, lint-free cotton cloths, microbre cloths or

paper towels

+ For particularly heavy and stubborn soiling, we

recommend detergents containing surfactants

+ Avoid cleaning with strong acids, alkaline solutions,

petrol-based cleaners, steam and hot cleaners, clea

ners with silicone oils, uorides or waxes,

polishes, alkaline cleaners and cleaners with scou-

ring agents and high-pressure cleaners.

+

This so-called anti-reective coating is subject to

coating tolerances, making the colour image of the

individual module different; this is most noticeable

in diffuse light.

Conrmation can be made that the anti-reective

coating may result in increased power yields and is

not a negative quality feature.

The phenomenon of optical differences should get

better after the rst few years of yield due to clima-

tic conditions, meaning that the system can be

operated in combination with these modules

without any reservations .

Technical Explanation of the cell production

process used in the manufacture of solar

modules

+The cells we use in the production of our panels are

classied as ‚A-Grade‘ cells without exception. Howe-

ver, the cell sorting process is undertaken both manu-

ally and mechanically. This can already lead to hetero-

geneous cell colours, which become visible through a

black backing lm.

+The cells used are both 166mm x 83mm and 182mm

x 91mm Mono Perc P-Type Halfcut cells or TOPCon N-

Type Halfcut cells. These module cells were subjected

to a coating thickness tolerance, this process can also

result in differences in colour.

+The cells were also treated with plasma-enhanced

chemical vapour deposition (PECVD) during the pro-

duction process. This separation process guarantees

improvements in eciency. However, it can also result

in differences in colour within the blue colour family.

Consequently, module cells may be light blue to grey

colour.

Independent of these processes, Solar Fabrik modules are

tested again by an independent test laboratory. Here, the

electro luminescence shows the desired quality characte-

ristics. This guarantees worry-fee operation.

Solar module mounting instructions

Mono S5 / Mono S4 / Mono S3 / Mono S2 / M Serie / P Serie