Co2meter RAD-0012 User manual

Oxygen Monitor Operating Manual

Model: RAD-00

12

Remote Oxygen

Enrichment

Safety System

1. Product Description

Thank you for selecting the RAD-0012 Remote Oxygen Enrichment Safety

System. This monitor is designed to detect oxygen enhancement in enclosed

spaces and to warn occupants of high oxygen levels. High concentrations of

oxygen (O2) in confined spaces are dangerous and may lead to health

problems ranging from headaches and fatigue to asphyxiation and death. This

monitor has both audible and visual alarms which activate when the O2

concentration is higher than the pre-set alarm levels. Detection of high levels of

O2 will also activate relays that can be used for a fan or air-handling system to

ventilate the confined space and improve O2concentration in the area.

The RAD-0012 O2 Monitor is cost-effective and has many features including:

1. Separate SEU (Main Sensor Unit) and RDU (Remote Display Unit) allow you to

see warning before entering an enclosedarea. Up to 3 RDUs can be used.

2. Large digital LCD display clearly indicates the ambient O2concentration.

3. Relay outputs tocontrol ventilation devices.

4. Audible and visual alarm indications at three separate alarm levels. Ability to

add strobes for additional indication.

5. Automatic barometric pressure compensation for high altitude use.

2. Package Contents & Description

The RAD-0012package comprises the following parts:

SEU (Main Sensor Unit), RDU (Remote Display Unit),Power Supply (Pre-Wired),

CAT 5 Communication Cable (1 piece), Relay Cables (3 pieces),

Wall Plug Safety Strap (1 piece), Warning Signs, User Manual (1 piece)

Mounting Brackets (2 pieces), Screws (13 pieces), Wall Anchors (12 pieces)

Cable Clips (10 pieces), International PowerAdaptor (3 pieces)

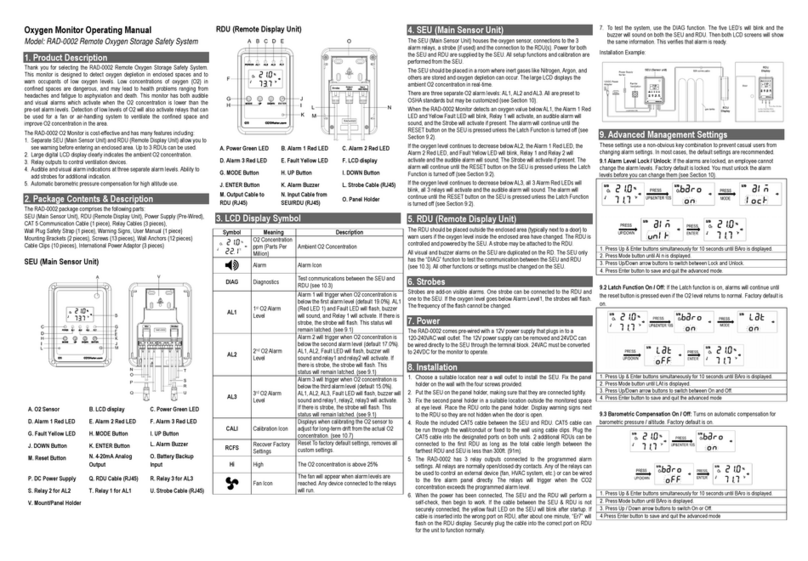

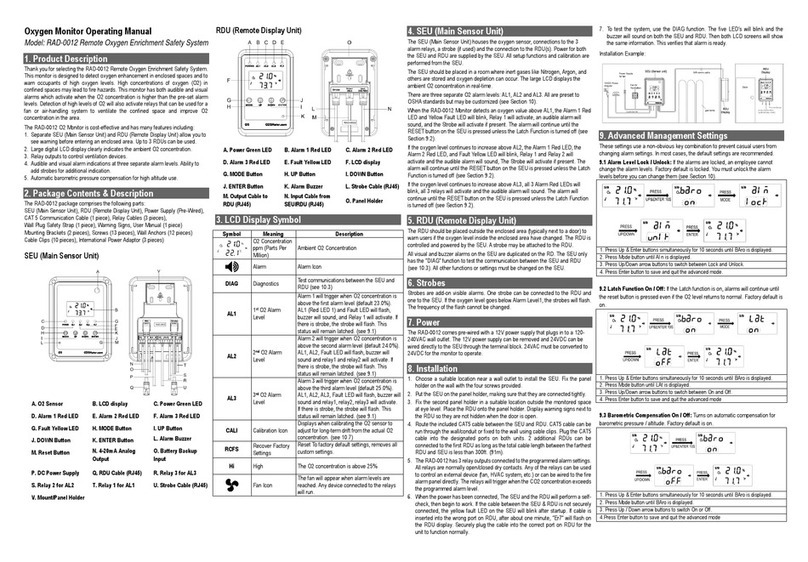

SEU (Main Sensor Unit)

A. O2 Sensor B. LCD display C. Power Green LED

D. Alarm 1 Red LED E. Alarm 2 Red LED F. Alarm 3 Red LED

G. Fault Yellow LED H. MODE Button I. UP Button

J. DOWN Button K. ENTER Button

L. Alarm Buzzer

M. Reset Button

N. 4-20mA Analog

Output

O. Battery Backup

Input

P. DC Power SupplyQ. RDU Cable (RJ45) R. Relay 3 for AL3

S. Relay 2 for AL2 T. Relay 1 for AL1 U. Strobe Cable (RJ45)

V. Mount/Panel Holder

RDU (Remote Display Unit)

A. Power Green LED B. Alarm 1 Red LED C. Alarm 2 Red LED

D. Alarm 3 Red LED E. Fault Yellow LED F. LCD display

G. MODE Button H. UP Button I. DOWN Button

J. ENTER Button K. Alarm Buzzer L. Strobe Cable (RJ45)

M. Output Cable to

RDU (RJ45)

N. Input Cable from

SEU/RDU (RJ45)

O. Panel Holder

3. LCD Display Symbol

Symbol

Meaning

Description

O2 Concentration

ppm (PartsPer

Million)

Ambient O2Concentration

Alarm Alarm Icon

DIAG Diagnostics Testcommunications between the SEU and

RDU (see10.3)

AL1 1st O2Alarm

Level

Alarm 1will trigger when O2 concentration is

below the first alarm level (default 23.0%).AL1

(Red LED 1) and Fault LED will flash, buzzer

will sound,and Relay 1 will activate. Ifthere is

strobe,the strobe will flash.This status will

remain latched. (see 10.4)

AL2 2nd O2Alarm

Level

Alarm 2will trigger when O2 concentration is

below the second alarmlevel (default 24.0%).

AL1,AL2,Fault LEDwill flash, buzzer will

sound and relay1 and relay2 will activate. If

there isstrobe,the strobe will flash.This

status will remain latched.(see10.5)

AL3 3rd O2Alarm

Level

Alarm 3 will trigger when O2 concentration is

below the third alarm level (default 25.0%).

AL1,AL2, AL3, Fault LED will flash, buzzer will

sound and relay1, relay2, relay3 will activate.

If there is strobe,the strobe will flash.This

status will remain latched.(see10.6)

CALI Calibration Icon

Displays when calibrating the O2sensor to

adjust for long-term drift from the actual O2

concentration. (see 10.7)

RCFS

Recover Factory

Settings

ResetTo factory default settings, removes all

custom settings.

Hi High The O2 concentration is above 25%

Fan Icon

The fan will appear when alarm levels are

reached. Any device connected to the relays

will run.

4. SEU (Main Sensor Unit)

The SEU (Main Sensor Unit) houses the oxygen sensor, connections to the 3

alarm relays, a strobe (if used) andthe connection to the RDU(s). Power for both

the SEU and RDU are supplied by the SEU.All setup functions and calibration are

performedfromthe SEU.

The SEU should be placed in aroom where inert gaseslike Nitrogen,Argon,and

others are stored and oxygen depletioncan occur. The large LCD displays the

ambient O2 concentration in real-time.

There are three separate O2 alarm levels:AL1,AL2 and AL3.All are preset to

OSHAstandards but may be customized (see Section 10).

When the RAD-0012Monitor detects an oxygen value aboveAL1, theAlarm 1 Red

LED andYellow Fault LED will blink, Relay 1 will activate,an audible alarm will

sound, and theStrobewill activate if present.The alarm will continue until the

RESETbutton on the SEU is pressed unless the Latch Function is turned off (see

Section 9.2).

If the oxygen level continues to increase aboveAL2,the Alarm 1 Red LED, the

Alarm 2 Red LED, and Fault Yellow LED will blink, Relay 1 and Relay 2 will

activate and the audible alarm will sound, The Strobe will activate if present. The

alarm will continue until the RESET button on the SEU is pressed unless the Latch

Function is turned off (see Section 9.2).

If the oxygen level continues to increase aboveAL3,all 3Alarm Red LEDswill

blink, all 3 relays will activate and the audible alarm will sound.The alarm will

continue until the RESETbutton on the SEU is pressed unless the Latch Function

isturned off (seeSection 9.2).

5. RDU (Remote Display Unit)

The RDU should be placed outside the enclosed area (typically next to a door) to

warn users if the oxygen level inside the enclosed area have changed. The RDU is

controlledand powered bythe SEU.Astrobe may be attached to theRDU.

All visual and buzzer alarms on the SEU are duplicated on the RD. The SEU only

has the “DIAG” function to test the communication between the SEU and RDU

(see 10.3).All other functions or settings must be changed on the SEU.

6. Strobes

Strobes are add-on visible alarms. One strobe can be connected to the RDU and

one to the SEU. If the oxygen level goes below Alarm Level1, the strobes will flash.

The frequency of the flash cannot be changed.

7. Power

The RAD-0012 comes pre-wired with a 12V power supply that plugsin to a

120-240VAC wall outlet.The 12V power supply can be removed and 24VDC can

be wired directly to the SEU through the terminal block. 24VAC must be converted

to 24VDC for the monitor to operate.

8. Installation

1. Choose a suitable location near a wall outlet to install the SEU. Fix the panel

holder on the wall with the four screws provided.

2. Put the SEU on the panel holder, making surethat they are connected tightly.

3. Fix the second panel holder in a suitable location outside the monitored space

at eye level. Place the RDU onto the panel holder. Display warning signs next

to the RDU so they are not hidden when the door is open.

4.

5.

Route the included CAT5 cable between the SEU and RDU. CAT5 cable can

be run through the wall/conduit or fixed to the wall using cable clips.Plug the

CAT5 cable into the designated ports on both units.2 additional RDUs can be

connected tothe first RDU as long as the total cable length between the

farthest RDU andSEU is less than 300ft. (91m).

The RAD-0012 has 3 relay outputs connected to the programmed alarm

settings. All relays are normally open/closed dry contacts. Any of the relays can

be used to control an external device (fan, HVAC system, etc.) or can be wired

to the fire alarm panel directly. The relays will trigger when the CO2

concentration exceeds the programmed alarm level.

6. When the power has been connected, The SEU and the RDU will perform a

self-check, then begin to work. If the cable between the SEU & RDU is not

securely connected, the yellow fault LED on the SEU will blink after startup. If

cable is inserted into the wrong port on RDU, after about one minute, “Er7” will

flash on the RDU display. Securely plug the cable into the correct port on RDU

for the unit to function normally.

7. To test the system, use the DIAG function. The five LED’s will blink and the

buzzer will sound on both the SEU and RDU. Then both LCD screens will show

the same information. This verifies that alarm is ready.

Installation Example:

9.Advanced Management Settings

These settings use a non-obvious key combination to prevent casual users from

changing alarm settings. In most cases, the default settings are recommended.

9.1 Alarm Level Lock / Unlock:If the alarms are locked, an employee cannot

change the alarm levels. Factory default is locked. You must unlock the alarm

levels before you can change them (see Section 10).

1. Press Up& Enter buttons simultaneously for 10 seconds until BAro is displayed.

2. Press Mode button until Al n is displayed.

3. Press Up/Down arrow buttons to switch between Lock and Unlock.

4. Press Enter button to save and quit the advanced mode.

9.2 Latch Function On / Off:If the Latch function is on, alarms will continue until

the reset button is pressed even if the O2 level returns to normal. Factory default is

on.

1. Press Up & Enter buttons simultaneously for 10 seconds until BArois displayed.

2. Press Mode button until LAt is displayed.

3. Press Up/Down arrow buttons to switch between On and Off.

4. PressEnter button to save and quit the advanced mode

9.3 Barometric Compensation On / Off:Turns on automatic compensation for

barometric pressure / altitude. Factory default is on.

1. Press Up& Enter buttons simultaneously for 10 seconds until BArois displayed.

2. Press Mode button until BArois displayed.

3. Press Up / Down arrow buttons to switch On or Off.

4.Press Enter button to save and quit the advanced mode

10. Customizing the Settings

10.1 Select Temperature Units: Press the Up button to switch between ºF & ºC:

10.2 Select Barometric Units: Press the Down button to switch fromhPa to inHg

10.3 Diagnostic Test:Test the communication link between the SEU & RDU.

1. Press Mode until the “DIAG” icon flashes

2. Press Enter.The five LED’s will blink and the buzzer will sound on the SEU and

RDU simultaneously.

10.4 Set AL1 Alarm Level: (only ifAlarm level is unlocked- see 9.1)

1. Press Mode until the “O2” & “AL1” icons flash

2. Press Enter, the “AL1” icon shows on LCD. Default AL1 = 23.0%

3. Press Up/Down to go through AL1 levels: 21%, 21.5%, 22%, 22.5%, 23%,

23.5%, 24%, 24.5% and 25%

4.Press Enterto save or press Mode to exit without saving.

10.5 Set AL2 Alarm Level: (only ifAlarm level is unlocked- see 9.1)

1. Press Mode until the “O2” “AL2” icon flashes

2. Press Enter, the “AL2” icon shows on LCD. DefaultAL2 = 24.0%

3. Press Up/Down to go through AL2 levels: 21%, 21.5%, 22%, 22.5%, 23%,

23.5%, 24%, 24.5% and 25%

4. Press Enter to save or press Mode to exit without saving.

10.6 Set AL3 Alarm Level: (only if alarm level is unlocked - see 9.1)

1. Press Mode until the “O2” “AL3” icon flashes

2. Press Enter, the “AL3” icon shows on LCD. Default AL3 = 25.0%

3. Press Up/Down to go throughAL3 levels: 21%, 21.5%, 22%, 22.5%, 23%,

23.5%, 24%, 24.5% and 25%

4.Press Enterto save or press Mode to exit without saving.

Note:The 3 alarm levels cannot overlap.

10.7 Calibration:

Zero and Span Calibration should both be performed at least annually. They can

be performed onsite or the SEU can be returned forfactorycalibration. Check your

state or local code for calibration schedule requirements in your jurisdiction.

What you will need: a test gas cylinder of pure nitrogen (0% O2), a cylinder of 21%

oxygen, a regulator, tubing, and a small piece of masking tape to cover the buzzer

hole on the bottom right corner of the SEU. If you are calibrating in situ, first inform

occupants to ignore the alarms while calibration takes place.

Part 1: Zero Calibration:

1. Hold the tubing from the Nitrogen (0% O2) gas cylinder to the oxygen sensor

opening on the top right-hand corner of the SEU.

2.Open the gas regulator. Set the flow rate between0.15-0.50 liters per minute.

3. Wait until the O2 reading on the SEU settles consistently at or near 0% O2 on

the screen.All alarms will be triggered.

4. Press the Mode button 5 times.The “O2” and“CALI” icons will flash.

5. Press Enter to view the calibration settings. The words “O2” and “ZEro” will

begin flashing on the LCD.

6. Press Enter againto begin calibrating. “CALIBRATING” will begin flashing.

7.After approximately 3 minutes, the LCD will display either “PASS” or “FAIL”

8. If the LCD reads “FAIL”, repeat the steps again. If it displays “PASS”, press

Enter. The display should now show 0%

9. Remove the nitrogen gas.

10. Press theResetbutton at the bottom right-hand side of the SEU front cover.

Part 2: Span Calibration:

1. Hold the tubing from the 21% oxygen gas cylinder to the oxygen sensor

opening on the top right-hand corner of the SEU.

2.Open the gas regulator. Set the flow rate between0.15-0.50 liters per minute.

3. Wait until the O2 reading on the SEU settles consistently at or near 21% O2 on

the screen.

4. Press the Mode button 5 times.The“O2” and“CALI” icons will flash.

5. Press Enter to view the calibration settings. The words “O2” and “ZEro” will

begin flashing on the LCD.

6. Press the Up or Down arrow key tochange from“Zero” to “SPAn”.

7.Press Enter again to begin calibrating. “CALIBRATING” will begin flashing.

8.After approximately 3 minutes,the LCD will display either “PASS” or “FAIL”

9.If the LCD reads “FAIL”, repeat the steps again. If it displays “PASS”, press

Enter. The display should now show 21% O2.

10. Remove the oxygen gas.

11.Press theResetbuttonat the bottom right-hand side of the SEU front cover.

12. Remove tape over the alarm buzzer holes.

10.8 Recover Factory Settings:

If calibration or changing custom parameters has caused the RAD-0012 to behave

incorrectly, use the ReFactSet (Recover FactorySettings) function to return the

unit to its original condition at shipping.

1. Press Mode until the “ReFactSet” icon flashes.

2. Press Up/Down button to choose either “Yes” or “No”.

3. Press Enterto save orpress Mode to exit without saving.

11. Product Care

To insure you receive the maximum benefit from using this product, please

observe the follow guidelines.

1. Repair - Do not attempt to repair the product or modify the circuitry by yourself.

Please contact CO2Meterdirectlyif the product needs servicing, including the

replacement or calibration of sensor See section 15 for technical support

contact information.

2. Cleaning - Disconnect the power before cleaning. Use a damp cloth. Do not use

liquid cleaning agents such as benzene, thinner or aerosols, as these will

damage the device.

3. Maintenance – We recommend testing the communication between the SEU

and RDU under ‘DIAG” function. If these five LEDs blink and the buzzer of SEU

and RDU sound simultaneously, it indicates that SEU and RDU work normally.

12. Specifications

■ Oxygen & Temperature Sensor Specifications:

Oxygen Sensor Specifications

Measurement Range 0 - 25% display

Display Resolution 0.1%

Accuracy Better than 2%FS

Pressure

Dependence

Auto pressure compensation, built in barometer.

(500

‐1200 mbar

)

Response Time

O2: <2min by 90%

O2AL1 21%, 21.5%, 22%, 22.5%, 23%, 23.5% and 24%.

The default AL1 is 23.0%.

O2AL2 21.5%, 22%, 22.5%, 23%, 23.5%, 24% and 24.5%.

The default AL2 is 24.0%

O2AL3 22%, 22.5%, 23%, 23.5%, 24%, 24.5% and 25%.

The default AL3 is 25.0%.

SoundAlarm

80db@10cm

Warm-UpTime

< 60 seconds at 72°F (22°C)

Temperature Sensor Specifications:

Temperature Range

32°F to 122°F (0°C to 50°C)

Display Resolution

0.1°F (0.1°C)

Display Options

°F /°C

Accuracy

±2.7°F (±1.5°C) when O2concentration is above first

alarm level

Response Time

20-30 minutes (case must equalize with environment)

Operating Conditions:

Operating

Temperature

32°F to 122°F (0°C to 50°C)

Humidity Range

0 ~ 95% RH non-condensing

Storage Conditions:

StorageTemperature

-4°F to 140°F (-20°C to 60 °C)

■Power Supply

Power

Supply

DC

9~32VDC (12~32VDC recommended), 2A.

AC adapter

Input: 100~240 VAC,50/60Hz, 0.6A

Output: 12VDC, 2000mA.

Battery Voltage

6VDC (5.4V~7.0V),

recommended capacity is 12AH

■Relay Outputs

Relays 1-3

Peak currentfor each relay < 2A@ 30VDC or 250VAC

Relay configuration: SPDT

■Weight and Dimensions

SEU

Weight

1 lb.

Dimensions (LxWxD)

6.69 x 4.96 x 2.73 inches

RDU

Weight

0.4 lb.

Dimensions (LxWxD)

5.51 x 3.54 x 1.89 inches

13. Safety Notes

Warning: Your safety is very important to us. To ensure to use the product correctly

and safety, please read these warnings and the entire User Manual before using

the product. Otherwise, the protection provided by the equipment may be impaired.

These warnings provide important safety information and should be observed at all

times.

1. Please handle the device carefully; do not subject the product to impact or

shock. Otherwise, this may cause the accuracy drift.

2. Do not place the unit near a heat source. Heat can cause distortion of the unit,

which may result in an explosion or fire.

3. Do not touch the exposed electronic circuitry of the device under any

circumstances, as there is the dangerous of electric shocks.

4.Please take care of cable connection between SEU and RDU. Make sure the

cable from SEU is connected into the INPUT port of RDU.

5.Please ensure the external power supply is normally supplied to ventilation fan

while the relay is working. If there has no normally power supply to the fan, the

relay will not work, which may result in potential danger with lower O2

concentration in confined space.

14.Fault Codes &Troubleshooting Guide

This section includes a list of FrequentlyAsked Questions for problems you may

encounter with the RAD-0012O2 Monitor.

No

LCD

Fault

Icon

Description

(of the fault)

SEU

Indication

RDU

Indication Suggested Actions

1 Er3

The ambient

temperature has

exceeded the

temperature range

32°F to 122°F

(0°C to 50°C)

“Er3” flash,

Fault LED

blink

“Er3” flash,

Fault LED

blink

This error will

disappear when the

temperature returns to

the range between

32°F to 122°F (0°C

and 50°C)

2 Er5 EEPROM System

Problem

“Er5” flash,

Fault LED

blink

“Er5” flash,

Fault LED

blink

Power on again or

press reset button, if

the “Er5” always

appear, please contact

with the local dealer.

3 Er7 Internal Data

Transmission Error

“Er7” flash,

Fault LED

blink,

“Er7” flash,

Fault LED

Blink

Check the RJ45 plug is

connected into the

INPUT port of RDU, if

the “Er7” displays on

the RDU only.

Press reset button on

SEU or power on

again

15.Support & Warranty

Contact us: We’re here to help!

If the troubleshooting guide above doesn’t help you solving your problem or for

more information, please contact us using the information below.

Support@CO2Meter.com

(386) 256-4910 (M-F 9:00am–5:00pm EST)

www.CO2Meter.com

CO2Meter, Inc.

131 Business Center Drive

Ormond Beach, FL32174

Phone: 386-872-7665 | Fax: 866-422-2356

Email: Sales@CO2Meter.com

Ref. No.:122016

11-8-2020

Other Co2meter Monitor manuals