9P/N: 11817503 REV. AA June 2014

MONITOR

SPECIFICATIONS

The Pulse monitor records the following information:

MOTOR EVENT PARAMETERS

Motor direction is referenced as Up or Down� The Pulse monitor

can record up to two speed points� The speed points are referenced

as Slow and Fast�

The following are all the designated motor events that can be

recorded:

Motor Event Data Filters

Motor Up Slow (Normal Start), (Slow), (Up)

Motor Up Fast (Normal Start), (Fast), (Up)

Motor Down Slow (Normal Start), (Slow), (Down)

Motor Down Fast (Normal Start), (Fast), (Down)

Plug Event Excessive Plugging (Plug Event)

Motor Trip Up Thermal Shutdown (Motor Trip), (Up)

Motor Trip Up Fast Thermal Shutdown (Motor Trip), (Up)

Over Capacity Up (Over Capacity), (Up)

Over Capacity Up Fast (Over Capacity), (Up)

CURRENT MOTOR EVENTS

The Pulse monitor records all current motor events up to a maximum

of 5119 events� After 5119, each new motor event will record over

the oldest motor data beginning at memory count one�

HISTORY EVENTS

The Pulse monitor records the following motor events simultaneously

into the current and history motor event memory registers�

The motor events are plug event, motor trip and over capacity�

The history event register can store up to 64 occurrences before

recording over the oldest data located in memory count one�

CUMULATIVE RUN TIME

Every time the motor is energized, the Pulse monitor records how

long it runs and adds to the cumulative total run time� Maximum

time count is 1�9 million hours� Cumulative run time is updated

every 16 motor starts� Overall operating time cannot be reset

to zero� Cumulative Motor Starts - Pulse monitor keeps track

of overall starts of a motor� Maximum start count is 4�29 billion�

The cumulative memory location is updated every 16 motor

starts� Overall starts cannot be reset to zero�

MOTOR STARTS

A motor start is recognized by energization of either the slow or fast

motor winding for 300ms or more�

* Pulse monitor card revision 1�4�0 - counts a motor start

when either the slow or fast winding of the motor is energized�

No time constraints are in place for determining a motor start�

PLUG EVENT (EXCESSIVE PLUGGING)

A plug event is recorded when the directional contactor (node 0A

or 1A) is energized four times within any two second period of

operation� The plug event is recorded simultaneously into current

motor data and history data�

MOTOR TRIP EVENT

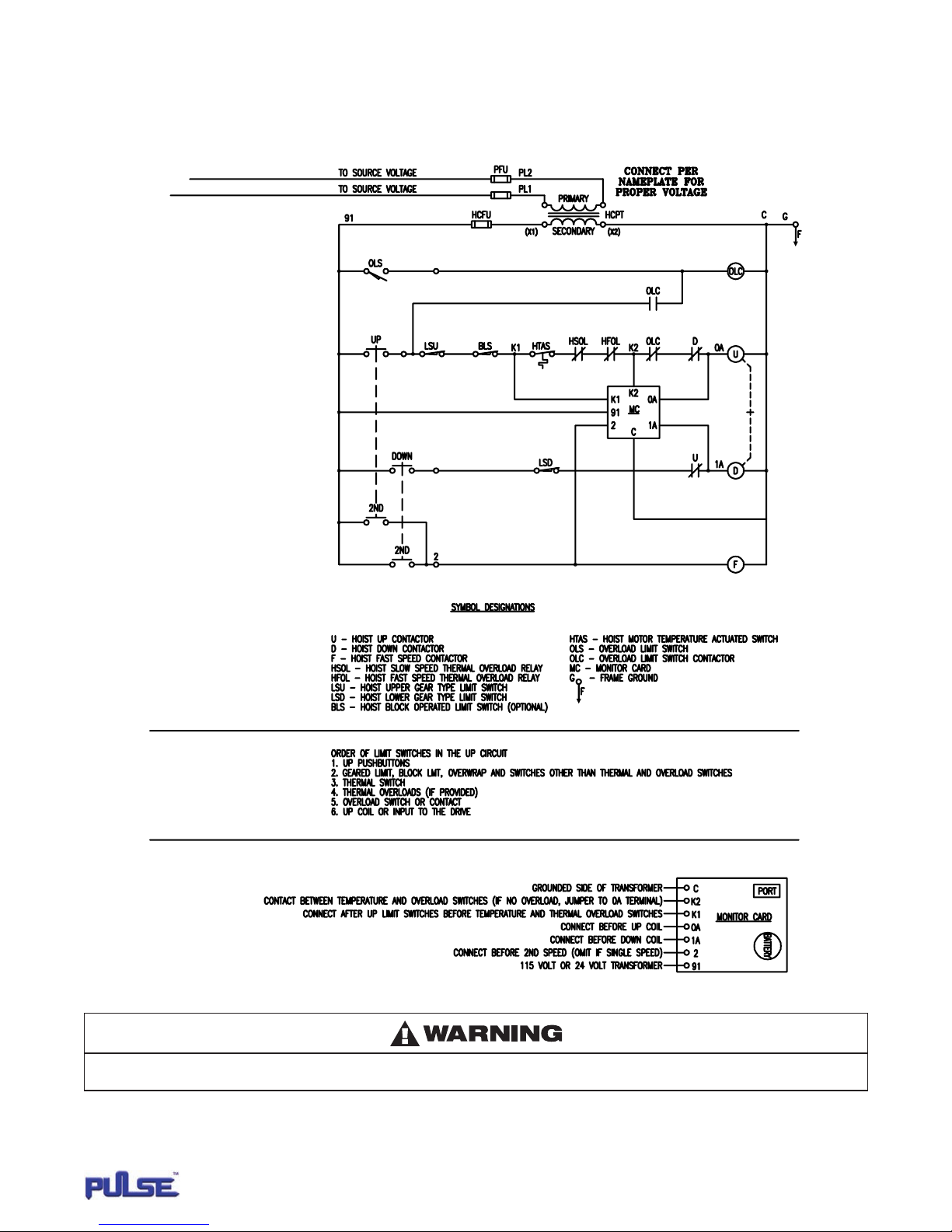

A motor trip event will be recorded when the monitor card terminal

K1 measures 115 volts* and terminal K2 is at 0 volts� If the event

occurs with all three terminals K1, K2 and 0A being at 0 volts

followed by numerous occurrences of terminal K1 sensing 115 volts*

and K2 remaining at 0 volts, only one event will be recorded�

OVER CAPACITY EVENT

An overcapacity trip will be recorded when the monitor card

terminals K1 and K2 measure 115 volts* and terminal 0A being at

0 volts� If the event occurs with all three terminals K1, K2 and 0A

being at 0 volts followed by numerous occurrences of terminal K1

and K2 sensing 115 volts* and 0A remaining at 0 Volts, only one

event will be recorded�

VOLTAGE

For every motor event, the voltage will be measured�**

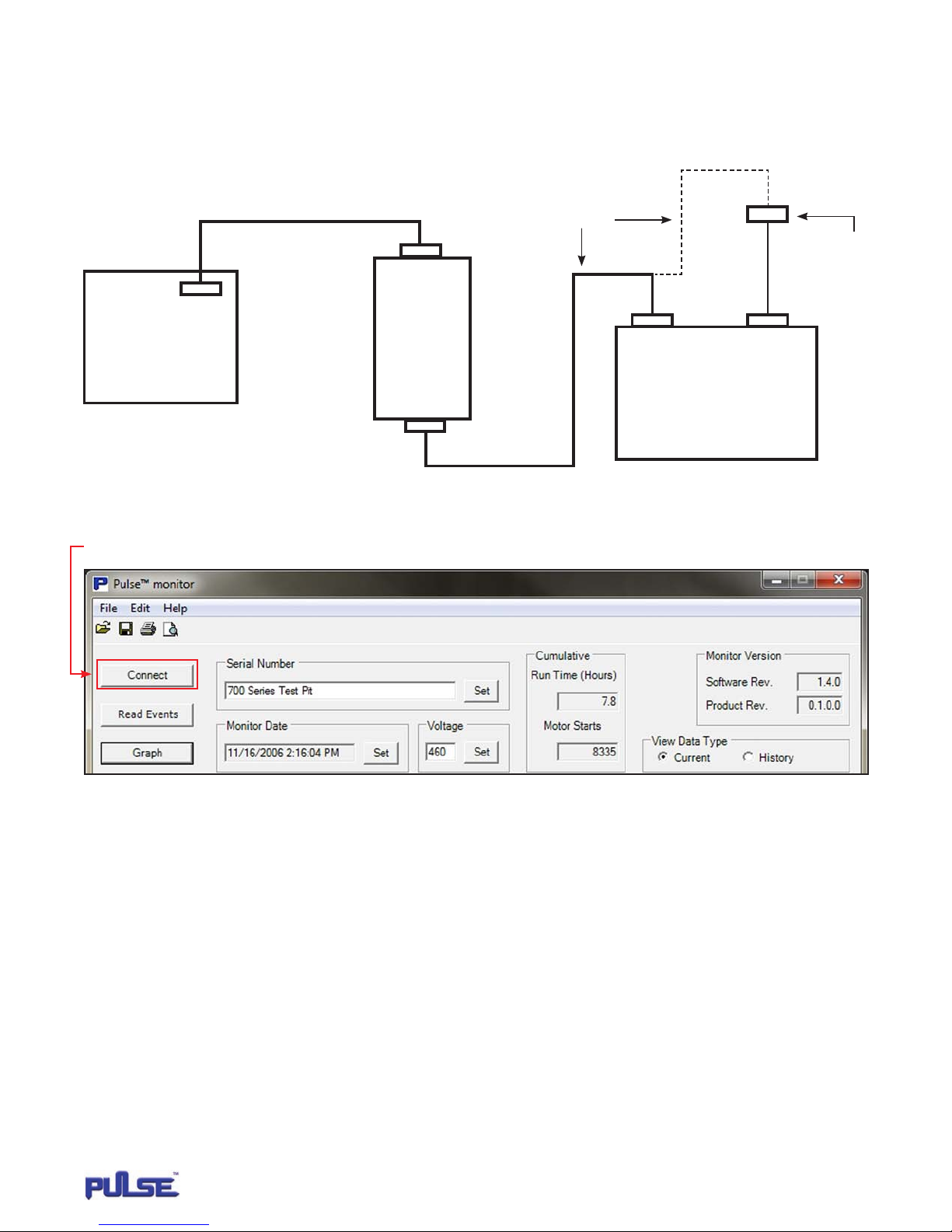

TIME / DATE STAMP

All motor events are recorded along with the time and date the motor

event occurred� The real time clock in the Pulse monitor card has a

default starting time of midnight, January 1, 1970� Once the Pulse

monitor software connects to the card, you can change the default

time to your computer's time by pressing the Set button�

* All cited voltages are nominal referenced to ground using the

115-volt monitor card� If using the 24-volt card, all non-zero

voltage references will be 24 volts�

** See Appendix 2 for discussion of accuracy�