INSTALLATION GUIDE FOR RX-4122

Copyright - refer to title page

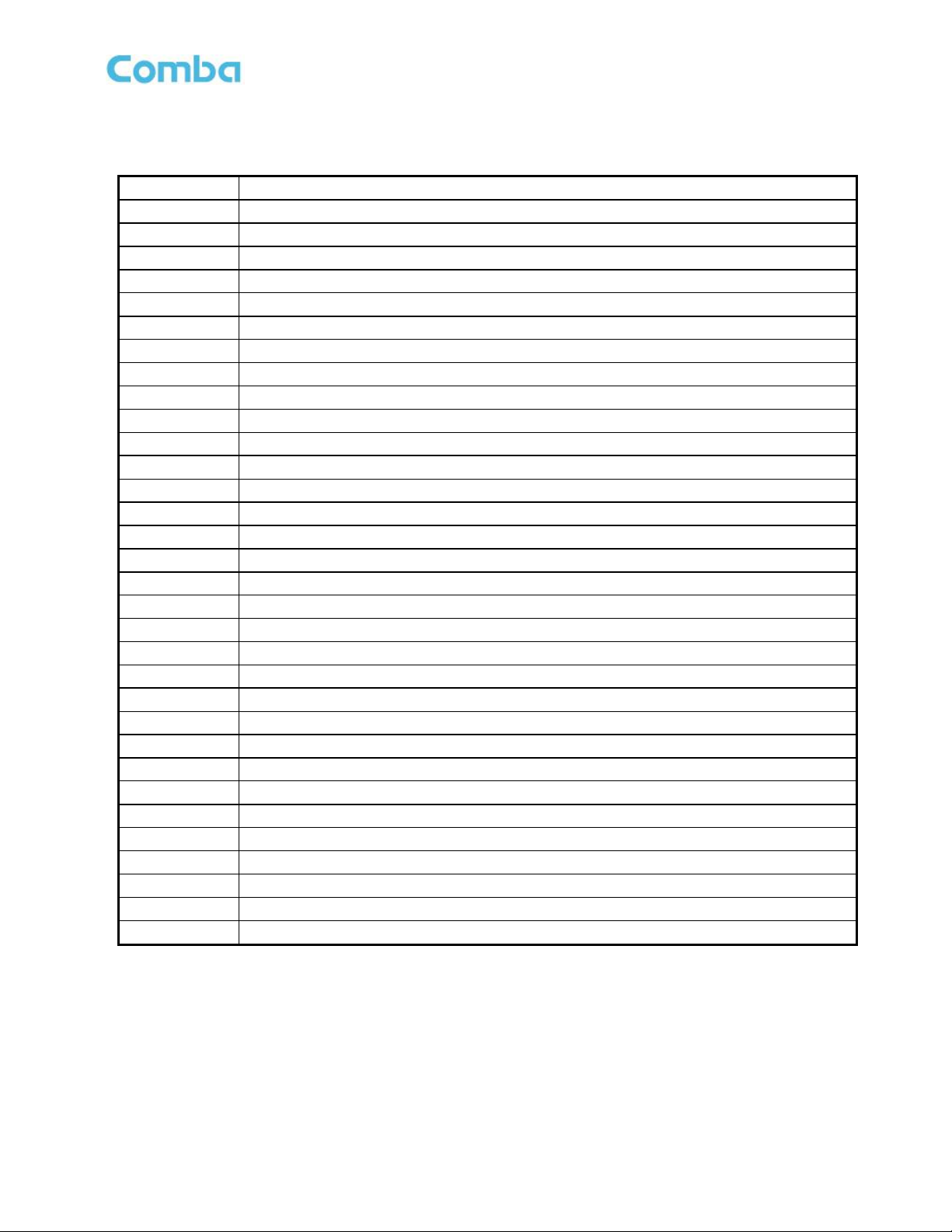

0.2 INDEX TO FIGURES AND TABLES

Figure 1: Front, Side and Bottom Views of the PS BDA Enclosure................................................................ 9

Figure 2: PS BDA Functional Block Diagram............................................................................................... 10

Figure 3: Layout of the PS BDA.................................................................................................................. 11

Figure 4: Mounting Rack Overview............................................................................................................. 16

Figure 5: PS BDA Wall Mounting................................................................................................................ 17

Figure 6: Equipment Connectors................................................................................................................. 18

Figure 7: Commissioning Procedure........................................................................................................... 24

Figure 8: Input IP Address .......................................................................................................................... 26

Figure 9: Input Domain Name..................................................................................................................... 26

Figure 10: Input User Name and Password................................................................................................. 26

Figure 11: Web GUI Main Screen............................................................................................................... 27

Figure 12: Overview Screen........................................................................................................................ 27

Figure 13: 400MHz Screen 1...................................................................................................................... 28

Figure 14: 400MHz Screen 2...................................................................................................................... 28

Figure 15: 400MHz Screen......................................................................................................................... 29

Figure 16: [Commissioning] Screen ............................................................................................................ 29

Figure 17: [Firmware] Screen –MCU Firmware Upgrade............................................................................ 30

Figure 18: [Firmware] Screen –Firmware Swap.......................................................................................... 30

Figure 19: [Firmware] Screen –Module Update.......................................................................................... 30

Figure 20: [Management] Screen................................................................................................................ 31

Figure 21: Management –Import & Export.................................................................................................. 32

Figure 22: Management –IP Setting........................................................................................................... 33

Figure 23: Management –Comm. Setting................................................................................................... 34

Figure 24: Management –Security............................................................................................................. 35

Figure 25: Modify Password........................................................................................................................ 36

Figure 26: Management –Device Reset..................................................................................................... 36

Figure 27: Management –Device Info ........................................................................................................ 37

Figure 28: Management –Isolation............................................................................................................. 37

Figure 29: Management –RF Setting ......................................................................................................... 38

Figure 30: Management –Alarm Setting..................................................................................................... 38

Figure 31: Management –Report ............................................................................................................... 39

Figure 32: Management –Alarm Log.......................................................................................................... 39

Figure 33: Management –Clear History Alarm............................................................................................ 40

Figure 34: Commissioning Procedure –Start.............................................................................................. 41

Figure 35: Commissioning Procedure –Site Info. Setting............................................................................ 41

Figure 36: Device Information Setting......................................................................................................... 42

Figure 37: Device Sub Band Setting-Class A.............................................................................................. 42

Figure 38: Channel parameters setting-Class A .......................................................................................... 43

Figure 39: Device sub-band setting-Class B................................................................................................ 44

Figure 40: Commissioning Procedure –Isolation Detection......................................................................... 44

Figure 41: Commissioning Procedure –Isolation Detection Confirm............................................................ 45

Figure 42: Commissioning Procedure –Isolation Detection Failed .............................................................. 45

Figure 43: Commissioning Procedure –Isolation Detection Finish............................................................... 46

Figure 44: Commissioning Procedure –Center Frequency Setting.............................................................. 46

Figure 45: Commissioning Procedure –Channel Number Setting ............................................................... 46

Figure 46: Commissioning Procedure –Finish............................................................................................ 47

Table 1: Equipment Connectors.................................................................................................................. 19

Table 2: LED Indicators .............................................................................................................................. 20

Table 3: Pin Definition of Dry Contact Cable ............................................................................................... 21

Table 4: Commissioning Task Explanation.................................................................................................. 25