2

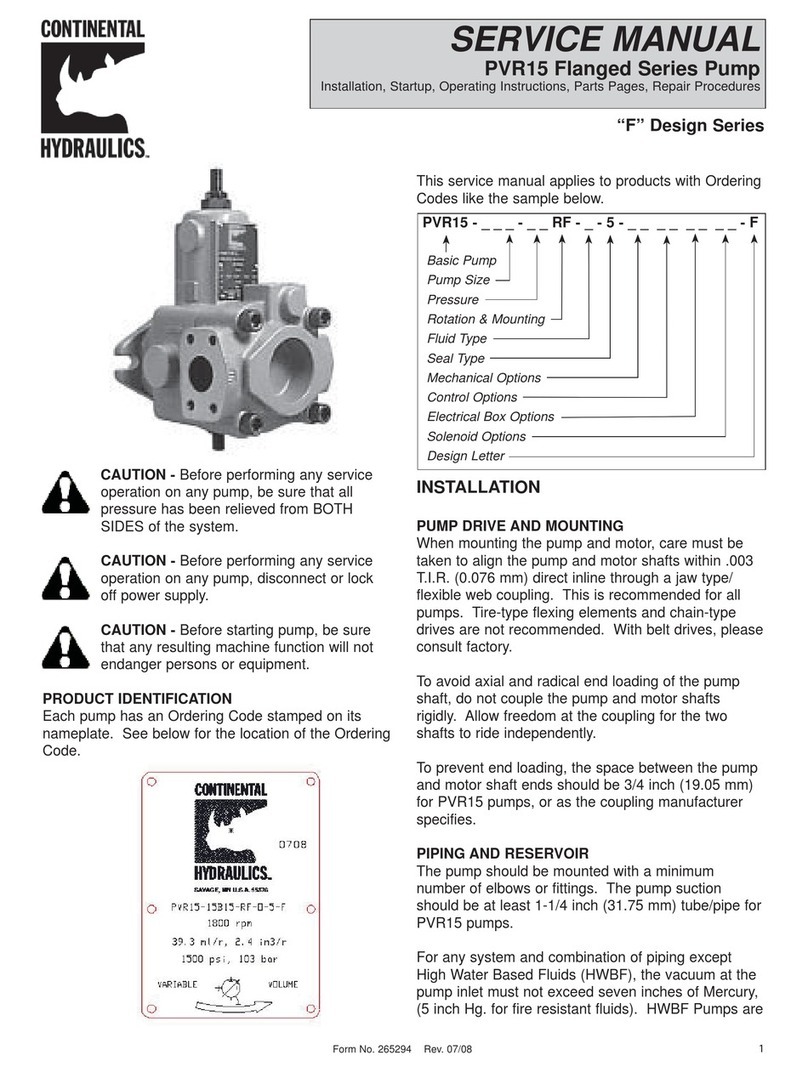

One indicator rides on the inside face of the pump

coupling. Measuring parallel offset alignment, as in

Figure 4, Proper alignment is achieved when neither

indicator varies more than 0.006 inch (0.152 MM) dur-

ing one complete shaft revolution.

CAUTION - THE COUPLING SELECTED

SHOULD PROVIDE A CLEARANCE FIT ON

THE PUMP AND MOTOR SHAFTS.

Never use couplings with interference or

sweat fits. Do not press jaw coupling hub together

tightly. Allow air gap between hub and insert to pre-

vent end thrust into pump rotor, which will damage

the pump. No external forces (other than rotational)

should be applied to the shaft.

INSTALLATION

Careful attention to the following installation require-

ments will assure satisfactory operation of your PVX

hydraulic pump. The pump should only be installed

by qualified personnel. Please read this bulletin care-

fully for detailed steps to install this equipment

1. REMOVE ALL PLASTIC PROTECTIVE CAP

PLUGS FROM COMPONENT BEFORE

INSTALLATION.

2. Prior to installation, pour a small amount of clean

hydraulic circuit fluid into the pump inlet port and

rotate the pump shaft by hand in the direction indi-

cated by the arrow cast into the pump body (all

PVX pumps rotate from thrust block to compensa-

tor). This insures lubrication at initial start-up.

3. Mount the pump and drive motor to a rigid base not

more than three feet above the fluid level.

4. Align the pump shaft to within 0.006 inches (0.152

mm) Full Indicator Movement (F.I.M.) of the motor

shaft, as in one of the two procedures outlined on

the cover page of this bulletin.

5. Carefully connect the inlet, outlet and case drain

plumbing to the pump. Do not force hard piping to

align with the pump ports. This may pull the pump

out of alignment with the motor.

The inlet line must be plumbed full size to within

three inches of the bottom of the reservoir.

PVX Models: Case flow on all PVX pumps exits

through the port located on the pump body. PVX

8/11/15 models also have an external shock clip-

per drain port located on the compensator that, if

used, must be plumbed. PVX 20 through PVX 75

models have internal shock clipper drains and no

additional plumbing is necessary.

Electric Motor Shaft

Dial Indicators

Figure 4

When installing the case drain plumbing, do not

install the flared portion of any fitting into the case

drain port. Using flared fittings in this manner will

block case drain flow causing shaft seal failure.

The case drain line must also be plumbed to within

three inches of the bottom of the reservoir. The

case drain and main system return lines must be

separated from the pump inlet line by a baffle. The

baffle causes all return flow to travel the length of

the reservoir before re-entering the pump. allowing

for heat dissipation and de-aeration.

6. Fill the reservoir with fluid

INITIAL START-UP

1. Rotate the shaft by hand, in the direction of the

cast in arrow, to insure freedom of rotation.

2. To prime the pump on initial start-up, it is impera-

tive to clear all air from the pumping chambers

first. To do this, open center valving should be

immediately down-stream of the pump outlet port,

which allows all flow (fluid and air) to pass directly

to tank upon start-up. If open center valving is not

included in your circuitry, position your valving to

move cylinders and/or motors in a no-load condi-

tion (75 to 150 psi, 5.2 to 10.3 bar) until the pump

has primed. This “no load” condition is not a pump

compensating pressure value, but is strictly the

result of system resistance.

Another way to clear air from the pumping cham-

bers and prime the pump is to incorporate an auto-

matic air bleed valve in the pump outlet port, or as

close to the outlet port as possible. This valve will

automatically open to allow air to exit to tank upon

start-up. Once all air contained in the pump has

been purged, the valve will automatically close.

3. All PVX Pumps incorporate a volume control.

Continental recommends not reducing the pump’s

output flow by more than 50 percent on start-up

(pump flow is reduced by turning the adjustment

screw clockwise). Once the pump is running, the

volume can be adjusted down to as low as 20 per-

cent of maximum volume at maximum RPM.

4. Jog the motor (no more than 10 revolutions if pos-

sible) and observe the direction of rotation. If the

pump shaft is not rotating in the direction as the

cast arrow on the pump body indicates, reverse

direction of rotation of the motor.

If rotation is correct, continue jogging the motor

until the pump has primed. You will notice a defi-

nite pump tone change and pressure gauge move-

ment when the pump begins to prime. Pressure

adjustments can be made after priming the pump.

5. Pressure adjustments must be made against a

blocked or dead-headed system (cylinders and/

or motors stalled or valving shut off). Increase

pressure by turning the pressure adjustment knob

clockwise. Decrease pressure by turning the pres-

sure adjustment knob counter-clockwise. Pump

pressure setting should be as low as possible, yet

high enough to insure satisfactory machine

performance.

CRITICAL SHAFT ALIGNMENT (Continued...)