ON CONSIGNMENT OF THE MACHINE................................................................................................................. 4

INTRODUCTORY COMMENT ............................................................................................................................. 4

TECHNICAL DESCRIPTION............................................................................................................................... 4

SYMBOLS USED ON THE MACHINE.................................................................................................................... 5

GENERAL SAFETY REGULATIONS...................................................................................................................... 6

MACHINE PREPARATION ................................................................................................................................ 7

HANDLING THE PACKED MACHINE

HOW TO UNPACK THE MACHINE

TYPE OF BATTERY

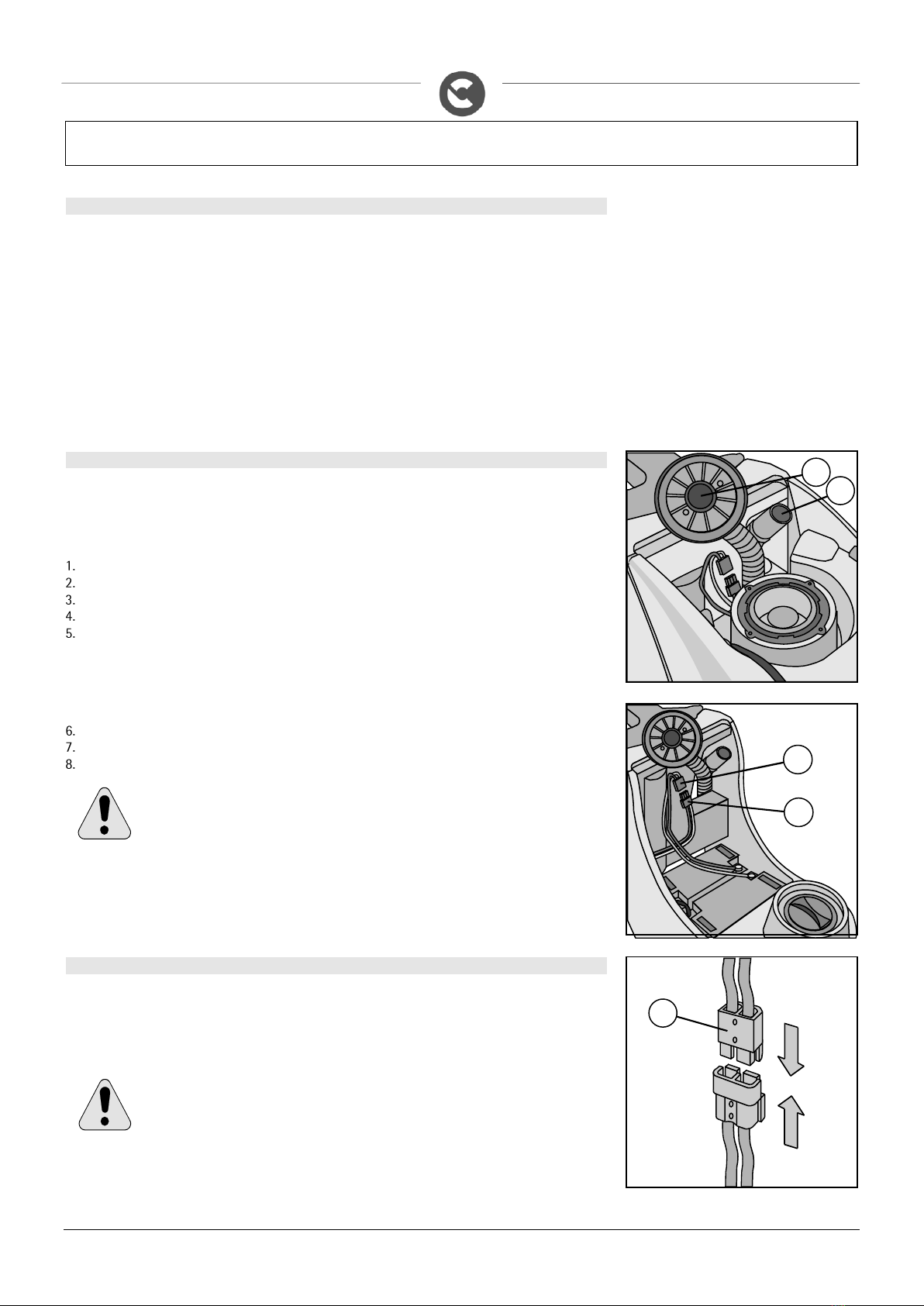

FITTING THE BATTERIES INTO THE MACHINE

CONNECTING THE BATTERY CHARGER

RECHARGING THE BATTERIES

BATTERY INDICATOR

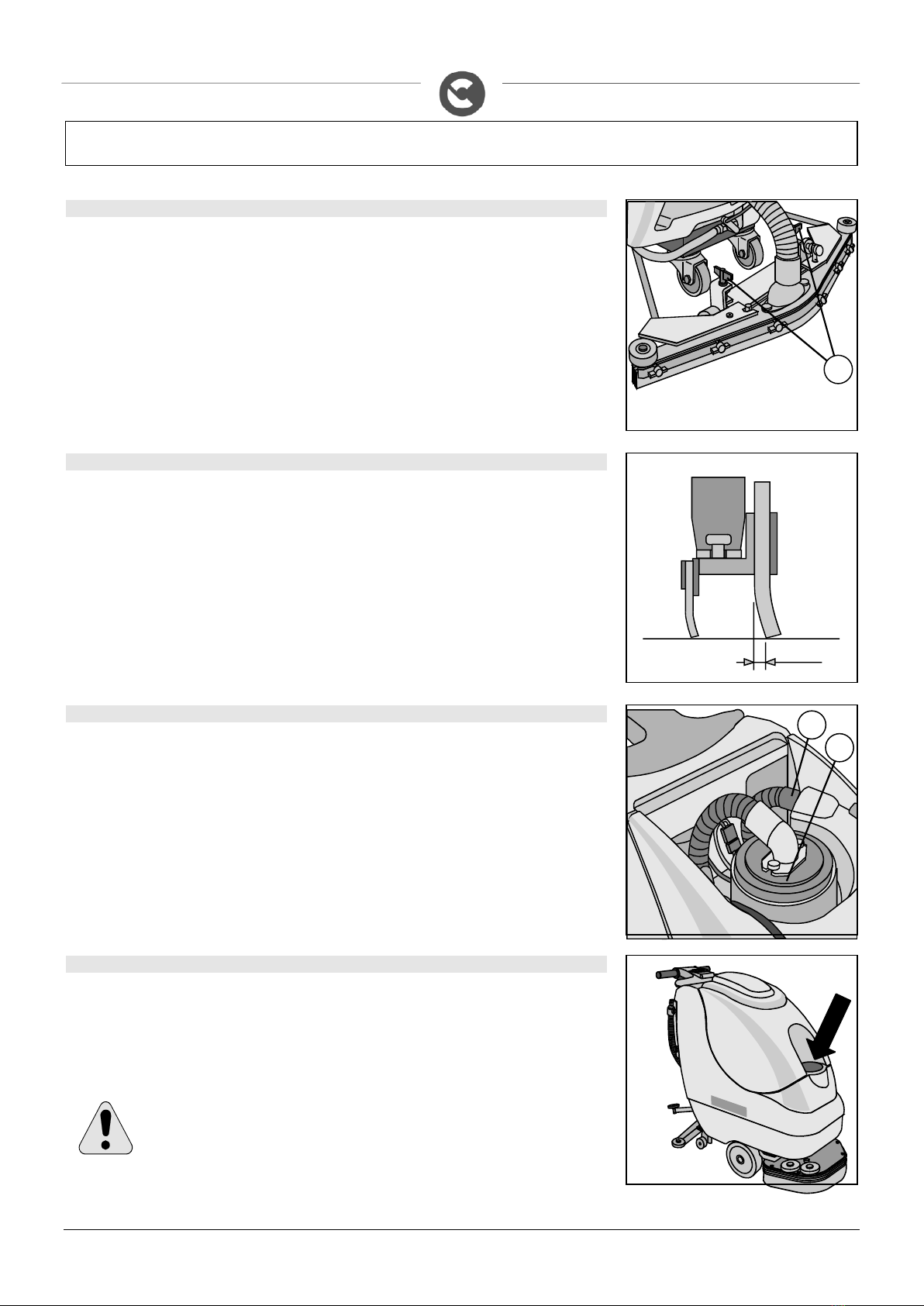

ASSEMBLING THE SQUEEGEE

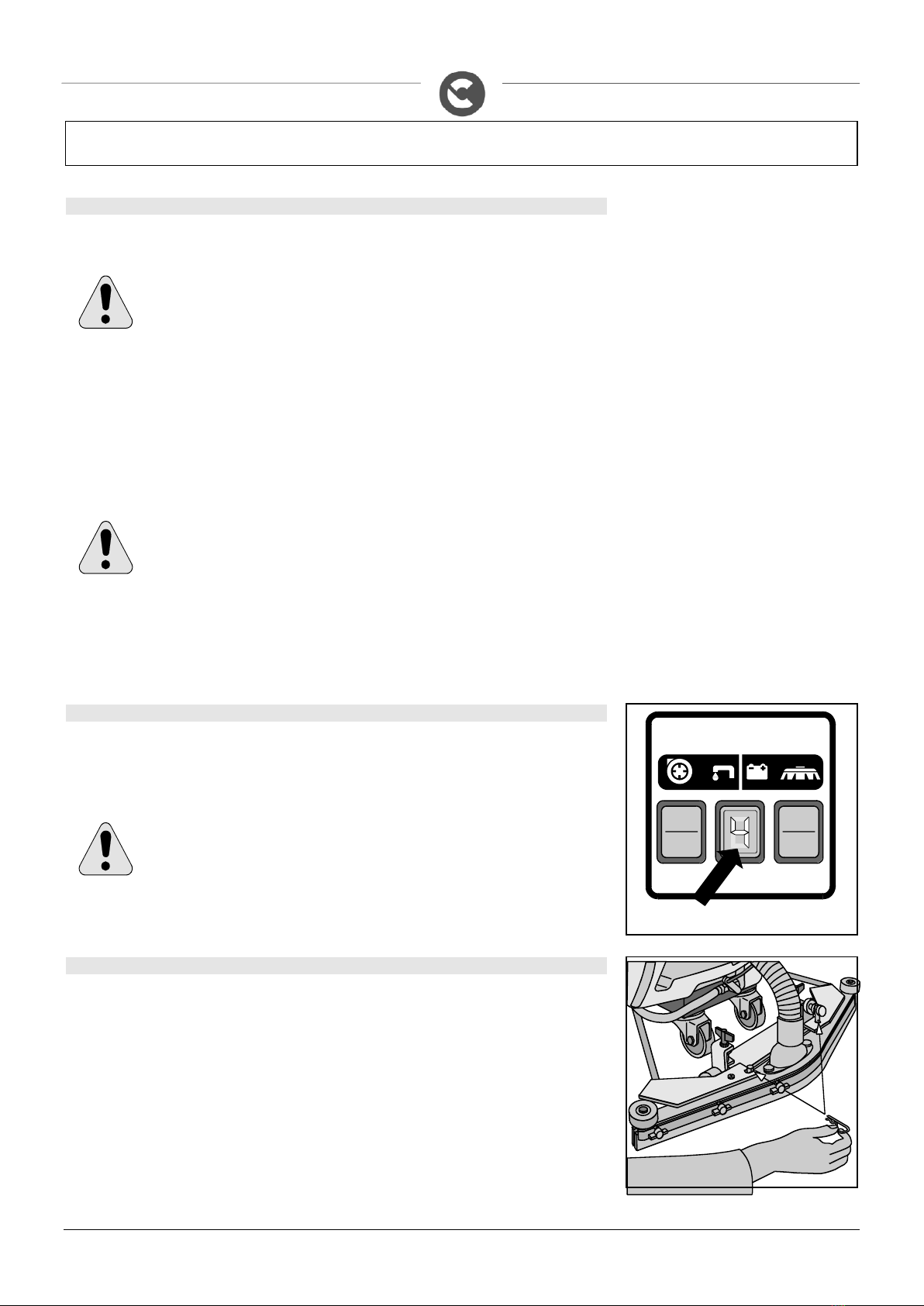

ADJUSTING THE SQUEEGEE HEIGHT

ADJUSTING THE SQUEEGEE INCLINATION

RECOVERY TANK

DETERGENT SOLUTION

ASSEMBLING THE SPLASH GUARD

ASSEMBLING THE BRUSHES ABILA 42-52

ASSEMBLING THE BRUSH ABILA 17-20

WORK...................................................................................................................................................... 13

PREPARING TO WORK

OVERFLOW DEVICE

AT THE END OF THE WORK............................................................................................................................ 15

DAILY MAINTENANCE .................................................................................................................................. 16

CLEANING THE RECOVERY TANK

CLEANING THE VACUUM FILTER

CLEANING THE SQUEEGEE

DISASSEMBLING THE BRUSHES ABILA 42 52

DISASSEMBLING THE BRUSH ABILA 17-20

CLEANING OF THE SOLUTION DISCHARGE FILTER

WEEKLY MAINTENANCE ............................................................................................................................... 18

CLEANING THE SQUEEGEE TUBE

CLEANING THE SOLUTION TANK

REPLACING THE SQUEEGEE RUBBERS

TROUBLESHOOTING .................................................................................................................................... 19

INSUFFICIENT WATER ON THE BRUSHES

THE MACHINE DOES NOT CLEAN WELL

THE SQUEEGEE DOES NOT DRY PERFECTLY

EXCESSIVE FOAM PRODUCTION

CHOOSING AND USING THE BRUSHES ............................................................................................................. 20

MACHINE DISPOSAL.................................................................................................................................... 21

EC DECLARATION OF CONFORMITY ................................................................................................................. 22

UKCA DECLARATION OF CONFORMITY ............................................................................................................. 24