4 June 13

1. Product information

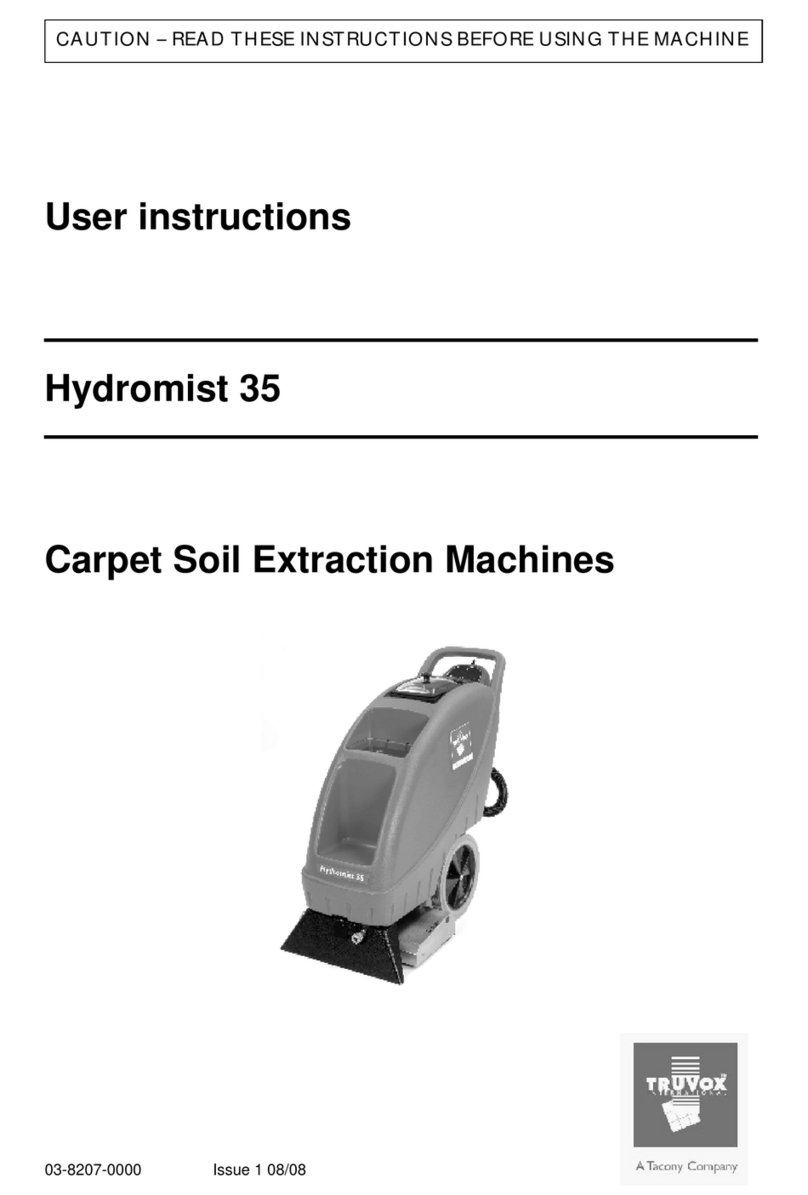

The Hydromist range of carpet soil extraction machines

are designed for the efficient cleaning of carpets and

upholstery. The machine is intended for commercial use,

for example in hotels, schools, hospitals, factories, shops,

offices, rental businesses and other than normal

housekeeping purposes.

The following instructions contain important information

about the machines and safety advice for the operator.

These instructions are valid for the following models:

HM13...,

Equipment must be operated, serviced and maintained in

accordance with the manufacturer’s instructions. If in

doubt contact the supplier of your machine.

1.1 Important safety advice

When using this machine, basic safety

precautions should be followed, including the

following:

•This machine must only be used for the manufacturer’s

approved application as described in this manual.

•Please note that the safety information described in the

manual supplements and does not replace standards in

force in the country in which the machine is used.

•WARNING - Only use accessories and spare parts

provided with the machine or those approved by the

manufacturer. The use of other spare parts or

accessories may impair the safety of the machine.

•CAUTION - This machine is for indoor use only and

should not be used or stored outdoors in wet conditions.

•All parts are to be positioned as indicated in the

instructions before using the machine.

•The machine must be unpacked and assembled in

accordance with these instructions before connecting to

the electrical supply.

•DO NOT use where hazardous dust is present.

•DO NOT use in an explosive atmosphere.

•DO NOT pick up or use near flammable fluids, dusts or

vapours.

•DO NOT use to clean up any burning or lighted

materials such as cigarettes, matches, ashes or other

combustible objects.

•DO NOT use the appliance to vacuum tiny particles like

cement or plaster dust as this will shorten life of the

motors.

•Take care when using a machine near the top of stairs

to avoid overbalancing.

•Only use the machine on firm level surfaces. DO NOT

use on a gradient or more than 2% slopes.

•DO NOT operate this machine on rough uneven

surfaces e.g. industrial concrete floors.

•DO NOT use on coarse concrete surfaces.

•DO NOT use outdoors e.g. on patios, decks or rough

surfaces.

•WARNING – Do not fill machines with water hotter than

50°C.

•DO NOT use diesel/petrol or corrosive detergents to

wash floors.

•DO NOT wash and vacuum corrosive, flammable and/

or explosive liquids, even if diluted.

•DO NOT put any object into openings. DO NOT use

with any opening blocked; keep free of dust, debris and

anything that may reduce airflow.

•DO NOT block air flow, blocking the suction in any way

(blocked filters, blocked hose) will decrease the

efficiency and will shorten the life of the motor.

•DO NOT cover machine when in use.

•DO NOT leave the machine connected to the electricity

supply when not in use; always remove the plug from

the socket outlet.

•DO NOT leave machine running unattended.

•Switch off the machine before removing the plug.

•This machine should always be connected to a fully

earthed power supply of the right voltage and frequency.

•The machine shall be disconnected from its power

source during its cleaning or maintenance and when

replacing parts or accessories, by removing the plug

from the socket-outlet.

•DO NOT use if it has been damaged, left outdoors or

dropped into water.

•DO NOT operate buttons or touch the mains plug with

wet hands as this may cause electric shock.

•WARNING - Keep the power supply cord clear of

moving parts (and/or rotating brushes). During operation

hazard may occur when running the machine over the

power supply cord.

•DO NOT operate the machine with a damaged supply

cord or plug, or after the machine malfunctions or is

damaged in any way. Contact an authorised Service

Agent for repair or adjustment.

•DO NOT pull or carry by the supply cord. DO NOT use

cord as a handle, close door on cord or pull cord around

sharp edges or corners.

•The plug of the power supply cord must be removed

from the socket-outlet before commencing cleaning of

the machine or undertaking maintenance operations.

•DO NOT kink or twist the power cord and keep cord

away from heated surfaces.

•When unplugging, pull the plug, not the supply cord.

•Never use excessive foaming or highly corrosive

cleaning solutions.

1.2 Guidelines for the operator

•This machine is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the machine by a

person responsible for their safety.