COUP’ECO Lamiers 700 Series Operating instructions

Issue September 2015

SERIES 700

TRANSLATION OF THE ORIGINAL

USER'S AND MAINTENANCE MANUAL

SERIAL No : 04.15.688

TYPE : 04.200.602

Saw Head Series 700 Issue September 2015 page 1

Dear User,

Thank you for your trust! We hope that your Saw Head will prove fully satisfactory.

Taking a few minutes to read these instructions will ensure that you can:

Get the most out of the performance of your Saw Head,

Preserve its service life,

Work in complete safety.

This manual comprises a description of how to use and maintain the Saw Head in the widest possible

configuration. Consequently, the basic Saw Head version and its accessories may vary. For more

information on the equipment levels available in the market place, please contact your nearest

dealer.

If you have any question, please don't hesitate to contact your dealer.

When your Saw Head was delivered, your dealer will have given you a start-up form. If your dealer

did not give you this document, please request it right away. This document will be necessary for any

work performed under the warranty.

The start-up form shows:

Whether the user's and maintenance manual comprising the CE declaration of conformity was

given to you.

Whether the spare parts manual was given to you.

Whether you were informed of the conditions of use and warned about the safety rules to be

complied with.

In cases where one of these requirements was neglected, it is up to you to contact your dealer right

away.

Saw Head Series 700 Issue September 2015 page 2

Contents

I - CE DECLARATION OF CONFORMITY Regarding self certified equipment .............................................................3

II - INTRODUCTION.........................................................................................................................................................4

2-1/ Characteristics and manual updates...................................................................................................................4

2-2/ Retaining the manual..........................................................................................................................................4

III - USING THE SAW HEAD FOR ITS DESIGNED PURPOSE ........................................................................................5

IV - SYMBOLS USED.......................................................................................................................................................6

4-1/ Meaning of the symbols found in this manual......................................................................................................6

4-2/ Meaning of the symbol affixed to the Saw Head..................................................................................................6

V - LOCATING THE RATING PLATE...............................................................................................................................7

VI - SAFETY INSTRUCTIONS..........................................................................................................................................8

6-1/ General safety instructions.................................................................................................................................8

6-2/ Checking the conformity of the cutter prior to starting, every time it is run............................................................8

6-3/ Prior inspection of the work area.........................................................................................................................8

6-4/ Characteristics of the ground that the carrier can operate on ..............................................................................8

6-5/ General operating instructions............................................................................................................................9

6-6/ Site safety instructions........................................................................................................................................9

6-7/ Maintenance instructions..................................................................................................................................10

6-8/ Warnings..........................................................................................................................................................11

VII - EQUIPMENT DESCRIPTION..................................................................................................................................12

7-1/ Names of the main components .......................................................................................................................12

7-2/ Technical characteristis....................................................................................................................................13

7-3/ Airborne noise..................................................................................................................................................15

VIII - COMPONENTS INCLUDED IN THE DELIVERY....................................................................................................16

IX - INSTALLING THE SAW HEAD AND THE CUTTING TOOLS..................................................................................17

9-1/ Handling the Saw Head....................................................................................................................................17

9-2/ Mounting the saw head on a carrier..................................................................................................................18

9-3/ Choosing the cutting tool..................................................................................................................................21

X - WORKING WITH THE CUTTING EQUIPMENT ........................................................................................................23

10-1/ Moving the carrier with the cutting equipment in place ....................................................................................23

10-2/ Marking off the work site.................................................................................................................................23

10-3/ Inspection of the work area.............................................................................................................................23

10-4/ Restate the safety instructions to the site personnel........................................................................................23

10-5/ Choosing the span on the supporting tube......................................................................................................23

10-6/ Starting the saw head.....................................................................................................................................23

10-7/ Working with the saw head.............................................................................................................................24

10-8/ Choosing the cutting tool rotation direction......................................................................................................24

10-9/ Choosing the forward speed when working.....................................................................................................25

10-10/ Driving recommendations.............................................................................................................................25

XI - UNDESIRABLE EVENTS ........................................................................................................................................26

11-1/ Trapping branches in the saw head: jamming.................................................................................................26

11-2/ Saw blade jamming in a thick branch..............................................................................................................26

XII - AT THE END OF THE WORK.................................................................................................................................27

12-1/ Unmounting the Saw Head.............................................................................................................................27

12-2/ Storing the Saw Head.....................................................................................................................................27

XIII - SERVICING AND ADJUSTMENTS........................................................................................................................28

13-1/ Greasing........................................................................................................................................................28

13-2/ Tightening of Class 8.8 screws.......................................................................................................................28

13-3/ Maintenance of the cutting parts.....................................................................................................................29

13-4/ Mounting and removing a blade or a flail plate................................................................................................33

13-5/ Tensioning the belts .......................................................................................................................................35

13-6/ Replacing the belts.........................................................................................................................................36

13-7/ Adjusting the pressure limiters........................................................................................................................37

13-8/ Adjusting the rotation speed of the blades/flail plate........................................................................................38

13-9/ Using the pulley puller ....................................................................................................................................38

13-10/ Adjusting the Saw Head span.......................................................................................................................39

13-11/ Adjusting the angle of the support tube.........................................................................................................39

13-12/ Faults and troubleshooting............................................................................................................................40

XIV - ELIMINATING WASTE..........................................................................................................................................41

XV - WARRANTY TERMS..............................................................................................................................................42

Saw Head Series 700 Issue September 2015 page 3

I - CE DECLARATION OF CONFORMITY Regarding self certified equipment

The declaration of conformity will be given on a separate document, when your equipment will be

delivered.

Saw Head Series 700 Issue September 2015 page 4

II - INTRODUCTION

This manual describes the conditions of use and maintenance. It is an integral part of the Saw Head.

It defines what the Saw Head was built for and comprises the information needed to guarantee

proper and safe use.

The Saw Head is intended for professional use and only specialist personnel may use it. Its use is

prohibited to minors, persons who have physical or mental health issues as well as persons who are

insufficiently informed and trained.

2-1/ Characteristics and manual updates

All of the technical support and the description provided in this manual is the exclusive property of

COUP’ECO that prohibits its reproduction, whether in full or in part, without their express written

authorisation and permission.

The contents of this manual may be subject to change at any time. COUP’ECO reserves the right to

make any changes that they see fit at any time, with a view to improving the Saw Head or for any

manufacturing or sales needs.

The illustrations and the technical data provided in this manual may not all correspond precisely to

your Saw Head. Conditions of use do however remain unchanged.

2-2/ Retaining the manual

This manual must be kept carefully in a suitable location to guarantee that it remains in good

condition. It must be easily accessible to anyone authorised to access it. The manual is an important

document that accompanies the Saw Head and all users are responsible for keeping it in good

condition. Always pass it on to the new owner in case of resale.

Saw Head Series 700 Issue September 2015 page 5

III - USING THE SAW HEAD FOR ITS DESIGNED PURPOSE

The Saw Head is designed for use in cutting branches, road broders, field borders, edges, access

paths, fruit trees, hedges...

It will cut all varieties of wood, hard or softwood, whether green or dry.

The branches of trees and hedges are cut cleanly, without shredding or crushing. This technique

limits any development of plant ailments and encourages healthy vegetation regrowth.

Only use cutting equipment (blades, blade disks) recommended by S.A. COUP’ECO.

The Saw Head fits onto the end of an articulated arm (bank mowers, excavators, telescopic lifters,

etc. that will henceforth be referred to as carrier vehicles), and the working area is adjusted using

hydraulic cylinders located on the arms.

Any other use is prohibited. The manufacturer declines any liability in case of damage resulting from

non compliant use. Always observe the maintenance and servicing measures set out in this manual.

The Saw Head user is responsible should an accident occur of if any damage is caused to third

parties or to property belonging to third parties.

Using the Saw Head for mowing or brush

cutting is absolutely prohibited.

Working with the Saw Head when travelling

in reverse is absolutely prohibited.

Saw Head Series 700 Issue September 2015 page 6

IV - SYMBOLS USED

4-1/ Meaning of the symbols found in this manual

The following symbols are used in this manual to draw attention to specific hazards.

4-2/ Meaning of the symbol affixed to the Saw Head

The following symbols are affixed to the Saw Head to warn of specific hazards.

Anchor point for

handling.

Cutting hazard!

The cutting blades are cutting tools.

Caution! When handling them and when cutting.

Wearing a worksite helmet, ear defenders and

protective goggles is required.

Rotary tools!

Objects and debris are likely to be projected.

Keep a safe distance around the saw head.

Wearing a worksite

helmet, ear defenders and

protective goggles is

required.

A worksite helmet must be

worn.

Protective footwear must

always be worn.

Protective gloves must

always be worn.

Prohibited. These

symbols show actions that

are prohibited.

Warning.

These symbols warn of

specific hazards.

Cutting hazard!

The blades are cutting tools.

Caution! When handling them and when cutting.

Saw Head Series 700 Issue September 2015 page 7

V - LOCATING THE RATING PLATE

Every Saw Head is marked with a rating plate that shows the main technical and identification data.

The rating plate is located in a location where it is easy to find and read.

The rating plate must never be removed nor used for other purposes. If the Saw Head is

damaged or discarded, always ensure that it is properly destroyed to avoid any possible misuse.

This plate displays the following information:

- Information on the manufacturer

- Designation

- Type

- Serial No.

- Year manufactured

- Weight

- Rotation speed for cutting components

- Max. operating pressure

Systematically record the data on the manufacturer's rating plate when making any request for

support and/or ordering spare parts.

Saw Head Series 700 Issue September 2015 page 8

VI - SAFETY INSTRUCTIONS

6-1/ General safety instructions

Following the measures introduced by articles R4323-55 and R4323-56 of the Labour Code,

operating this machine is strictly reserved for personnel who are trained and designated by

name.

6-2/ Checking the conformity of the cutter prior to starting, every time it is

run

Always check that the equipment is properly mounted on the carrier arm.

Always check the condition of the cutting tools and and sharpen or replace them as required.

Always check that the cover and protective casings are properly attached.

Always ensure that all safety symbols are present on the machine, are legible and clean and replace

them if necessary.

Always check the condition of hydraulic hoses and ensure that there are no leaks.

Always check that related components are greased.

6-3/ Prior inspection of the work area

Always inspect the work area to check for the possible presence of wire, metal posts, large stones,

bottles and other dangerous objects. Remove these objects before starting work. Also lift up broken

or damaged branches before starting work to prune branches.

Always note the presence of raised obstacles, particularly electrical cables: in this case, always

determine the category of cable, notify the driver, and check the instructions: (In France)

- For power lines of less than 50 kV, the minimum working distance to respect is 3 metres.

- For power lines of more than 50 kV, the minimum working distance to respect is 5 metres.

See local regulations in force.

6-4/ Characteristics of the ground that the carrier can operate on

The kind of ground that the carrier can operate on is of great importance as regards stability and

safety: wet ground, bare earth, grass, leaves, steel plates must all be taken into consideration

especially when working on ground that is sloping or inclined.

It is essential to pay attention to the maximum slopes

or inclines allowed as stated in the carrier instructions.

Failure to pay attention to these instructions may

cause the carrier to tip over.

Saw Head Series 700 Issue September 2015 page 9

6-5/ General operating instructions

Always keep third parties away from the machine during operations to mount or unmount the Saw

Head on the carrier. During these operations, define a safety perimeter of 10 metres around the

machine in case it should overturn.

Always keep people away from the machine during cutting operations and create a safety perimeter

of 100 metres around the machine in case branches fall or are ejected.

Place warning markings sign posting that tree cutting is in progress, in line with the applicable rules

for marking off hazardous worksites.

Always inform worksite staff of any safety areas to be complied with.

Always ensure that personnel dedicated to picking up fallen branches or other wear suitable

personal protective equipment and not remain within a 50 meter perimeter around the cutting tool and

100 metres in the direction that the blades are pointing in (both ahead and behind it).

Always ensure that people gathering branches and other objects respect and ensure that others

respect the safety perimeter.

Always keep the carrier stable when cutting.

Always stop the rotating blades before carrying out any manoeuvres not related to cutting: carrier

arm movements, reversing, positioning the saw head, etc.

Always call on someone on the ground to watch over movement, with the blades stopped, if the

operator's visibility is reduced.

Always adapt the machine's forward motion speed to the condition of the terrain that the carrier is

operating on.

Always fit the protective cover over the blades as soon as the work ends or as soon as the carrier

stops.

Always clean the cutting equipment at the end of each working day: remove branches, leaves and

any accumulation of sawdust.

Always fold the cutting equipment to the transport position after saw head shutdown and when

moving it away from the work area.

6-6/ Site safety instructions

When working with cutting equipment, there are projection hazards, a risk of falling branches or flying

debris, especially in front of and behind the saw head.

To avoid these risks, is it necessary to stop anyone from entering the safety zone, this being a circle

with radius of 100 metres around the carrier.

Pedestrians, cyclists, site personnel:

For site personnel, always wear personal protective equipment (helmet, gloves, glasses etc.),

the safety zone can be reduced to a 50 metre radius.

Excluding site personnel, it is necessary to ensure that no other people (pedestrians, cyclists

etc.) are within an area with a radius of 100 metres around the carrier.

If people enter the zone, the operator must stop

working momentarily to allow enough time for these

people to leave this zone.

Whenever reverse motion is required, always

stop saw head rotation.

Saw Head Series 700 Issue September 2015 page 10

Other vehicles :

Other vehicles passing through the safety zone is strictly prohibited while cutting is in

progress.

During the manoeuvre phases, please mark off a travel area located 1.50 metres away from

the outer edge of the wheels or the turret.

Homes alongside the site:

When homes are inside the safety zone, inform residents of cutting operations and, for their

safety, of the need to remain off balconies or terraces, to close windows and shutters and to not

leave the house in order to avoid any harm linked to potential flying debris.

6-7/ Maintenance instructions

Always position the carrier vehicle and cutting machine on flat, stable ground in an open

environment to carry out any maintenance operations.

Always wear personal protective equipment for maintenance operations: Gloves, safety shoes,

safety glasses.

Always cut the power from the carrier vehicle and activate the parking brake before carrying out any

work on the cutting equipment: Switch off the carrier's engine.

Always respect all general safety standards in addition to the recommendations given in this manual.

Always use a specialist technician to carry out any maintenance operations other than those

described in this manual.

Always keep the blades in good, sharp condition and properly set. Replace a blade as soon as you

see any cracking appear at the base of a saw tooth.

Always keep the blades in good, sharp condition. Replace the blade fixing nuts and bolts each time

that they are removed.

Always check that the nuts and bolts on the cutting equipment are securely screwed in before each

use.

Always be very careful to follow the procedures described in the manual dismounting and mounting

the cutting part (saw blade or cutting blades).

Always clean the cutting equipment fully at the end of each working day.

Always replace worn or defective parts with original COUP'ECO parts.

If the width of the road does not allow it, it is essential

for the operator to stop when meeting oncoming

traffic.

Saw Head Series 700 Issue September 2015 page 11

6-8/ Warnings

Never allow non-accredited or untrained people to use this cutting equipment.

Never use this cutting equipment or carrier vehicle under the influence of alcohol or drugs.

Never use the machine during strong winds: maximum: 40 km/h.

Never use the cutting equipment during a storm: risk of lightning.

Never use the cutting equipment at night, nor if light levels do not allow the operator to clearly see

the end of the cutting tool.

Never use the machine without setting out the site markings.

Never stand below the cutting component regardless of its height.

Never cut large branches using the saw head when the blades are not parallel to the direction of

carrier motion or to the cutting direction.

Never cut branches larger that the dimensions recommended in this manual (see "Technical

specifications" on page 13).

Never continue using the cutting equipment when a wire or similar wire objects have wound

themselves around a disk.

Never use knife cutters that no longer cut. These must always be replaced in pairs, to keep the

cutting discs balanced.

Never use a blade that no longer cuts.

Never overhang a traffic zone without having first stopped access.

Never travel along the road without having first installed the blade protection covers.

Never carry out maintenance operations not described in this manual.

Never use spare parts that do not originate from COUP’ECO.

Never use the cutting equipment as lifting equipment for people or objects.

Never use the Saw Head tip to push cut branches.

Never leave the circular saw blades rotating during manoeuvres with the carrier when not cutting

(changing road, reversing, changing carrier direction, etc.)

Saw Head Series 700 Issue September 2015 page 12

VII - EQUIPMENT DESCRIPTION

7-1/ Names of the main components

Cutting tool :

Flail plates or

Circular saw blade

Cover 02

Blade cover

Rear protective

casing

Support tube

Shoe

Hydraulic

motor

Cover 01

Motor dome

Motor cover

Saw Head Series 700 Issue September 2015 page 13

7-2/ Technical characteristis

Model

3700

4700

5700

Number of cutting tools

3

4

5

Dimensions and weight,

Weight (kg)

230

285

332

Overall length (mm)

A

1750

2250

2750

Overall width (mm)

B

750

750

750

Overall height (mm)

C

583

583

583

Cut length (mm)

Lc

1694

2191

2688

Position of center of gravity

(in relation to the underside and

the rear of the mounting tube)

X

290

293

294

Y

30

18

11

Z

609

882

1088

This mounting is possible for all models

Hydraulic motor,

vane motor

Type

Displacement (cm³)

31,5

43,9

Required flow rate (L/min)

60

85

Max. pressure (bar)

150

150

Blades’s max rotation speed (tr/min)

2000

Motor filtration (μm)

10

Max. pressure on the drain (bar)

2

Drive

Poly V belt with 12 grooves

Transmittable power (kW)

20.5

Cutting tool,

Saw blade

Flail plates

Diameter (mm)

700

Reinforced stamped disk

fitted with two flail cutting

blades that are sharpened

at an angle on both sides.

Number of teeth

80

Thickness (mm)

4

Cutting capacity, (mm)

Saw blade

Flail plates

Stopped (C1)

up to Ø200

Ø25

Moving forward (C2)

up to Ø120

It is essential that the flexible drain hose be connected directly to the

carrier's hydraulic fluid reservoir.

Saw Head Series 700 Issue September 2015 page 14

C1

C2

Saw Head Series 700 Issue September 2015 page 15

7-3/ Airborne noise

The airborne noise produced by the carrier + cutting equipment, with the saw head rotating, was

measured under the following conditions:

Carrier engine running at 1500 rpm so that the flow rate obtained is suitable for the saw head.

Saw head equipped with rotary saw blades

Carrier stopped on flat terrain

Windows and doors closed

* Measurement made in the cab, in the driving position: 84.5 dB

* Measurement made 10 metres from the carrier: 99 dB

This measurement was made with new blades and the saw head under no load. When the blades cut

branches they make less noise.

Nevertheless, everyone working near the machine (picking up branches), must wear ear

defenders

The values below are provided as an indication only.

They may vary depending on the make of the carrier and the engine speed needed to obtain the

necessary flow rate.

Saw Head Series 700 Issue September 2015 page 16

VIII - COMPONENTS INCLUDED IN THE DELIVERY

The saw head is delivered boxed, on a pallet. You should find the following components:

The saw head

This user's and maintenance manual

The certificate of conformity included in this manual

The start-up form which serves as the warranty slip

A set of tools:

A tightening wrench for fitting/removing the cutting tools

A locking stop

A complete pulley puller wrench

A 5mm Allen wrench

A 8mm Allen wrench

A straight M8 grease nipple

Two hex head M12x20 screws

Three hex head M14x50 screws

Saw Head Series 700 Issue September 2015 page 17

IX - INSTALLING THE SAW HEAD AND THE CUTTING TOOLS

9-1/ Handling the Saw Head

If the saw head needs to be completely removed from its carrier, then there are three lifting points for

moving it safely (see Figure below).

Use approved lifting equipment (straps, chains, hoist) taking care to abide

by their rules for use and with a lifting weight capacity that matches the

weight of the saw head (see "Technical characteristics" on page 13).

The saw head must be equipped with its blade casing during all handling

and moving operations.

Saw Head Series 700 Issue September 2015 page 18

If the saw head needs to be moved or mounted vertically, sling the saw head as described below

(see figure below).

9-2/ Mounting the saw head on a carrier

9-2-1/ Choosing the carrier arm

Before installing the saw head on the carrier vehicle arm, it is essential to ensure that the carrier arm

and the carrier vehicle are heavy enough and have sufficient capacity to bear the weight of the saw

head with the coupling parts and to guarantee their stability while working in complete safety.

The weight of the saw head alone is shown on the rating plate attached to the cover (see "Locating

the rating plate" page 7 and "Technical characteristics" page 13)

It is necessary to add the weight of the various mechanical coupling parts to reach the full weight on

the end of the carrier arm.

Saw Head Series 700 Issue September 2015 page 19

9-2-2/ Mechanical coupling

The saw head can be mounted on a variety of carrier types and models. To mechanically couple the

saw head with your carrier, we have developed a multitude of adaptations. Don't hesitate to ask your

dealer for advice.

Proceed as follows: (see photographs below)

Place the saw head on a stable horizontal surface (ground or pallet).

On the saw head, attach the two V-shaped tightening jaws (1) used for the mechanical

adaptation onto the supporting tube (2) using the bolts, washers and nuts provided.

Approach the carrier arm ready for coupling.

Attach the carrier side of the mechanical coupler (3) on to the carrier arm.

To unmount the saw head, follow the above instructions in reverse order.

1

2

3

1

2

3

Table of contents

Popular Saw manuals by other brands

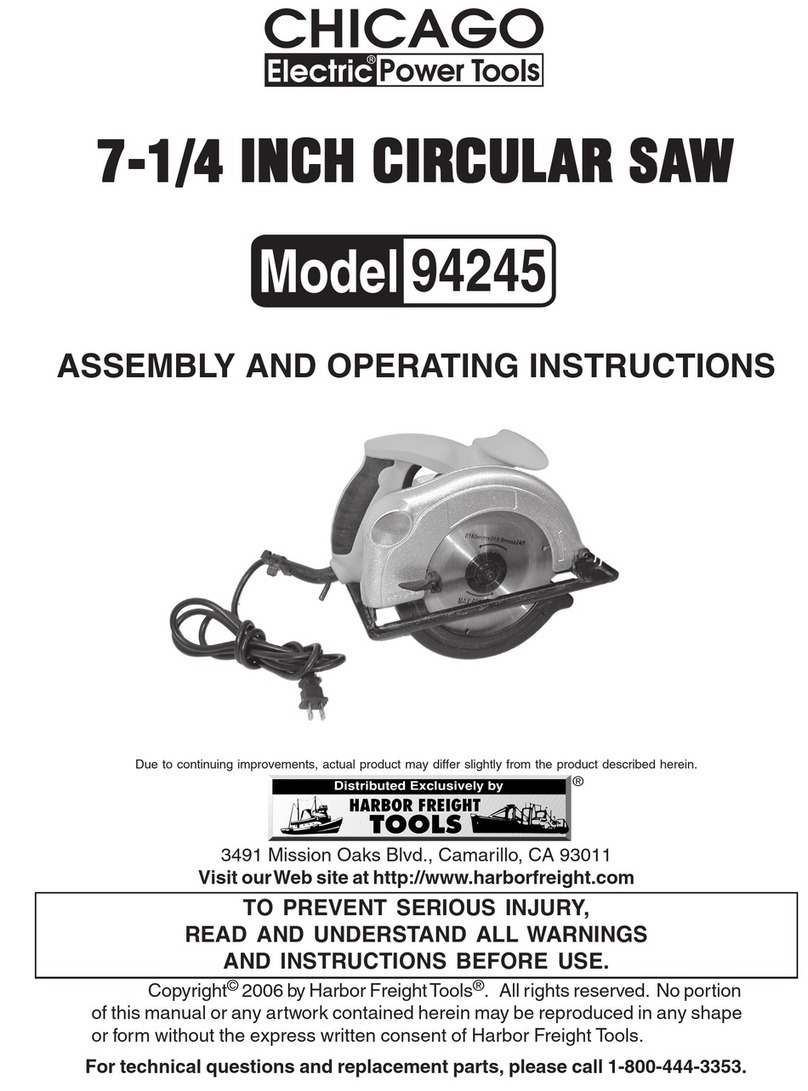

Chicago Electric

Chicago Electric 94245 Assembly and operating instructions

DeWalt

DeWalt DCS373 instruction manual

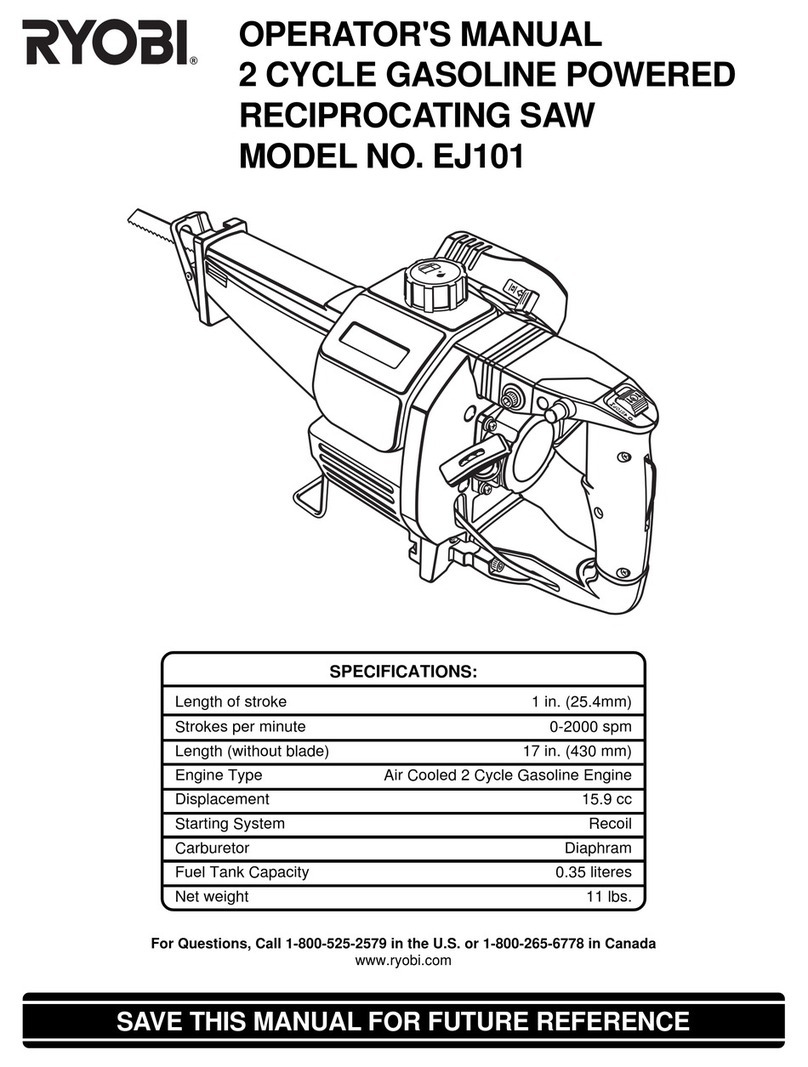

Ryobi

Ryobi ECO2335HG Original instructions

MULTIQUIP

MULTIQUIP SP113H18 Operation and parts manual

RIDGID

RIDGID MS1250LZ1 Operator's manual

Clarke

Clarke Woodworker CTS10PLM operating & maintenance manual