CPMG Magma M1 Owner's manual

Melter Applicator

Owner/Operator Manual

2601 Niagara Lane · Plymouth, MN 55447 · (763) 557-1982 · (877) 841-0848 · Fax (763) 557-1971

Part # 161607 Rev D 11/15/16

Magma M1 & M2

Table of Contents

Shipping Papers and Information .................................................. 3

Safety Notes .................................................................................... 4

Weights and Dimensions................................................................ 5

Controls and Their Functions......................................................6-9

Start Up ..................................................................................... 10-11

Automatic Temperature Control Setting...................................... 12

Loading Empty Tank ..................................................................... 13

Cleanout Procedure ...................................................................... 14

Maintenance ............................................................................. 15-16

Fluid and Components Specs ...................................................... 17

Heat Transfer Oil Specs ................................................................ 18

Material Tank Capacity.................................................................. 19

Trouble Shooting Guide................................................................ 20

Parts Section

Wiring Diagrams....................................................................... 22-27

Complete Wiring Diagram ........................................................ 22

Engine Wiring Harness............................................................. 23

Control Panel ....................................................................... 24-25

Main Wiring Diagram ................................................................ 26

Burner Wiring............................................................................ 27

Hydraulic Schematic ..................................................................... 28

Hydraulic Manifold Parts List ....................................................... 29

Isuzu Diesel Engine and Pump Parts List

(See supplement for compressor models)......................... 30-31

Plumbing System Parts List .................................................... 32-33

Material Pump Parts List.......................................................... 34-35

Electrical Components.................................................................. 36

Sealing Hose and Wand................................................................ 37

Sealing Tips ................................................................................... 38

Agitation System Parts List.......................................................... 39

Oil Burner Parts List ..................................................................... 40

Combustion Chamber Parts List and Tank Insulation ................ 41

Miscellaneous Parts................................................................. 42-43

Fuel and Hydraulic Tank Components......................................... 44

Spare Parts Kit............................................................................... 45

Compressor Option....................................................................... 46

3

Shipping Papers and Information

A packet containing IMPORTANT INFORMATION has been enclosed with your Melter.

This packet contains:

1) Operation Instructions

2) Parts List

3) Warranty Information

4) Manufacturer's Documents

a) Engine

b) Material Pump

c) Burner (Diesel only)

IMPORTANT: This manual contains the basic information required to operate, main-

tain and repair the CIMLINE Melter you have purchased. The use of this manual in-

sures accurate adjustments, operation and proper lubrication of your equipment.

Please keep it handy.

Any parts orders or service problems relating to CIMLINE equipment should be di-

rected to the CIMLINE Parts Department at either (763) 557-1982 or (800) 328-3874.

When ordering parts, please have the following information available.

Serial Number: ____________________________

Model Number: ____________________________

Engine Model (H.P.): ____________________________

Engine Manufacturer: ____________________________

Pump Number: ____________________________

Replacement Part Number(s):

4

PLEASE READ AND UNDERSTAND ENTIRE OPERATORS MANUAL BEFORE

PROCEEDING

WARNING: Protective clothing must be worn. Refer to ANSI Regulations:

1) Wear gloves with wristlets.

2) Wear long sleeve shirt with sleeves rolled down and cuffs buttoned.

3) Wear a face shield.

4) Load Melter from ground level.

5) Keep material door closed at all times except when adding material.

6) Never stand on any part of the machine.

7) Do not pull, twist, stretch or kink the material hose.

8) Do not operate without safety cover on hose.

9) Do not touch exhaust stacks or mufflers.

10) Wear heavy leather boots or shoes.

11) Wear long pants with no cuffs.

12) Verify brakes are engaging before towing (including brake-away switch)

WARNING: Do not over fill the melting tank. For best results, add only as much

material as required for the job or a maximum of 75% of tank capacity.

(M-1 - 113 gallons, M-2 - 168 gallons & M-4 - 308 gallons).

WARNING: On a new Melter applicator or a unit that has been idle for some time,

slowly raise the oil temperature to 250º F and hold there for approximately

20 to 30 minutes. This will help get rid of any condensation that may be in

the oil chamber.

WARNING: Never leave machine unattended while it is running.

Safety Notes

5

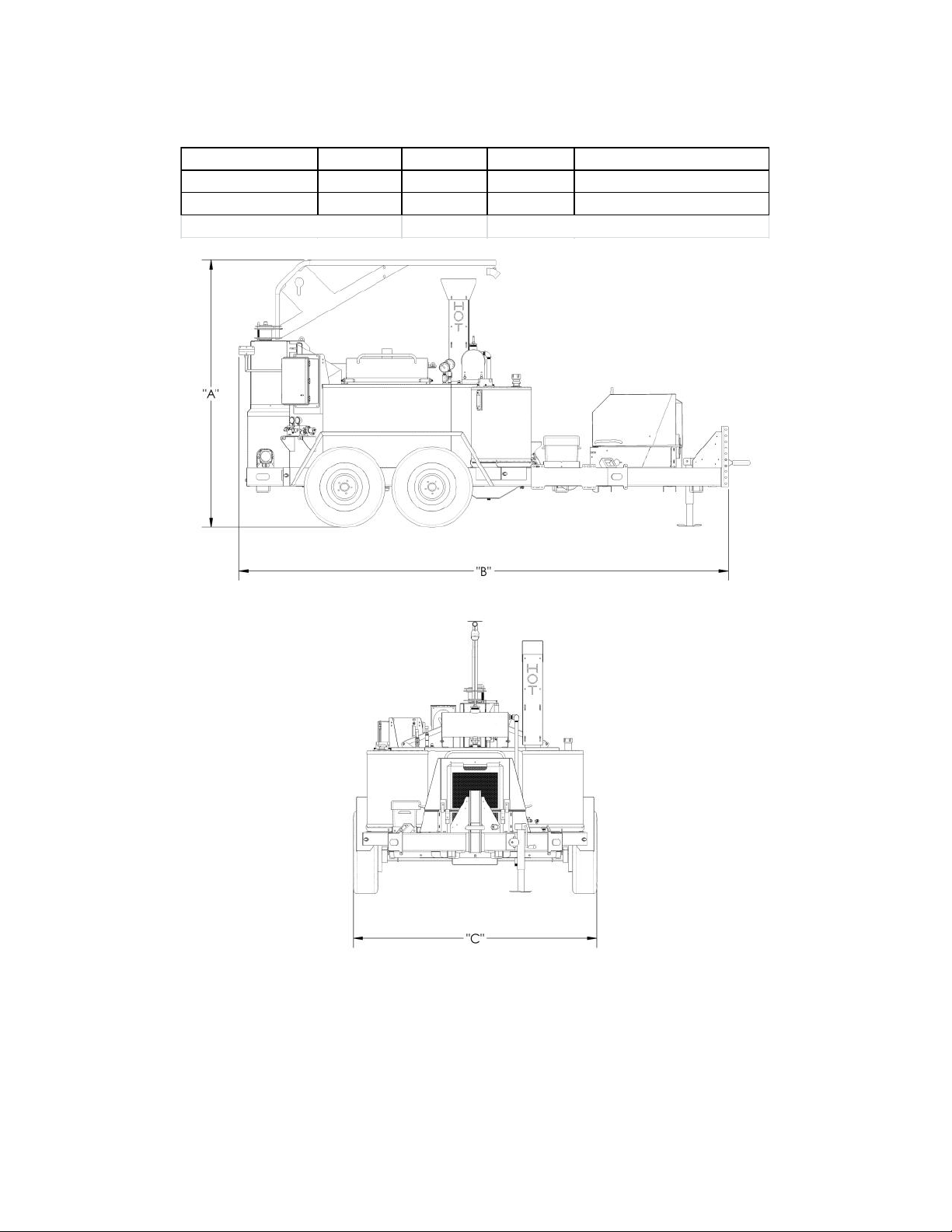

Model Number "A" in/cm "B" in/cm "C" in/cm Weight lbs/kg (empty)

M1 92/234 148/376 82/208 4000/1814

M2 90/229 164/417 81/206 4700/2132

Weights are without options

M2 shown

Weights and Dimensions

6

NOTE: This general outline will only familiarize you with the machine. Read through the en-

tire manual before putting this machine into operation.

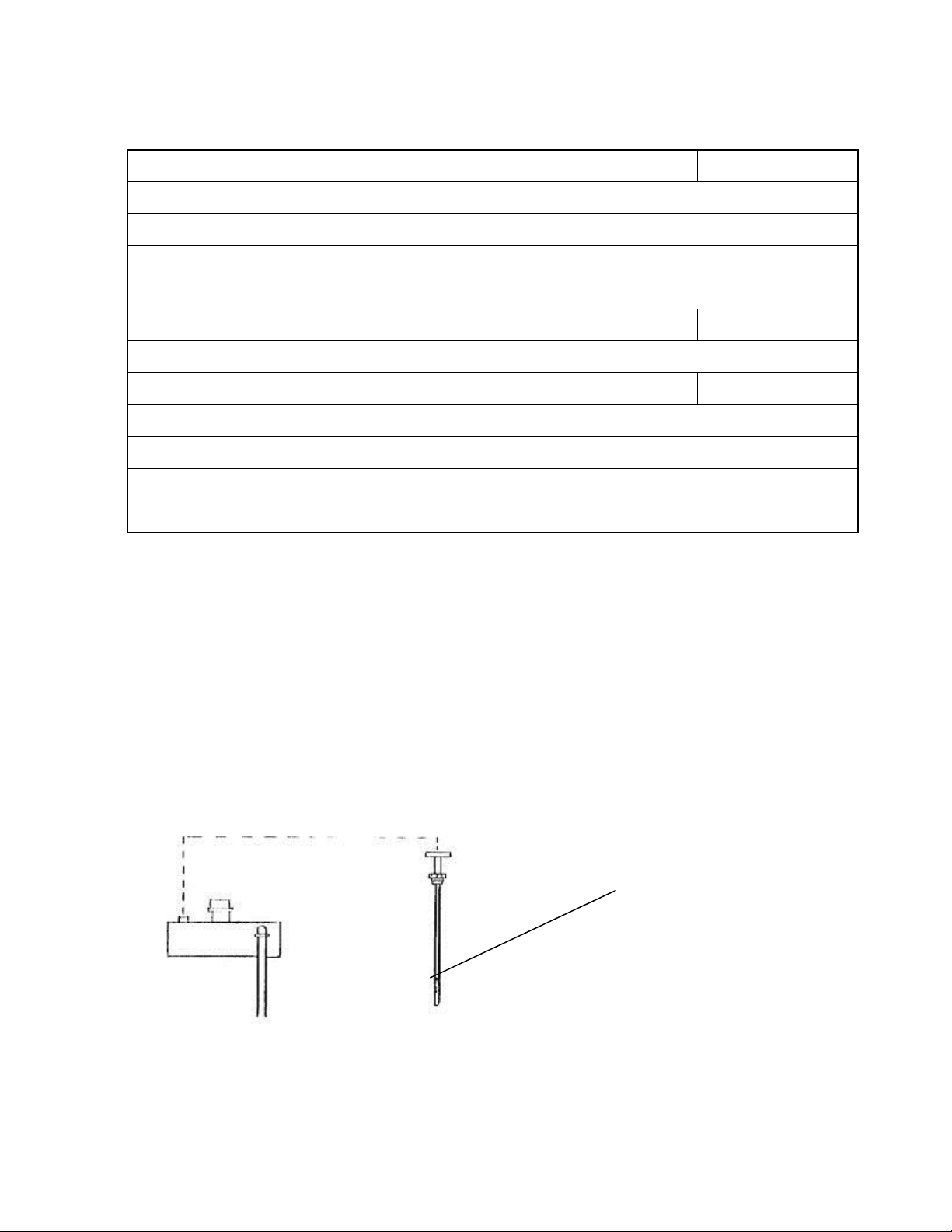

1) Access Port: The sealing wand is placed in here when not in use. This allows operator to

continue circulating material through the hose to prevent material from cooling and freezing

up.

2) Loading Door (1 on Model 150): Place the material on safety door to load the melting tank.

3) Oil Temperature Gauge: Monitors the heat transfer oil temperature.

4) Material Temperature Gauge (optional): This gauge shows the temperature of material in-

side the melting tank. This gauge is for reference before pumping starts. Once pumping be-

gins, material controller will be an exact reading of material passing through the system. (Not

shown)

5) Micropanel ignition Switch: Use the key to turn the engine on and off.

6) Pressure Gauge: This gauge measures the pressure required to turn the agitator and the

material pump.

7) Sealing Hose Valve: This valve stops the material recirculating back into the material tank

causing it to go out of the wand.

8) Control Panel: The main control panel is used to control the direction of the material pump

and agitator, and you can also monitor the temperature of the material and heat transfer oil.

Controls and Their Functions

7

Controls and Their Functions

8

NOTE: Typically it is best to run the M series Magma melter in the Auto control mode. See

page 10 for the start-up procedure. Occasionally you may want to manually override

the presets and control the Melter. Below is an explanation on what each switch in-

side the control box does.

1) Auto/Off/Manual Switch In Auto mode, power will be sent to the rotary switch on the front

cover. When the switch is Off, power is not being sent beyond this switch and the melter will

be unusable. When the Switch is in Manual mode, the four switches below will be energized

and the melter will be under the control of those switches.

2) Controller On/Off Switch: When this switch is on, the three controllers to the right will be

energized and they will be controlling the Diesel burner and the heated hose generator.

3) Material Pump Seal/Off/Clean-out Switch: When this switch is on “Seal”, the pump will be

rotating and material will either be pumping back to tank or to the hose. When the switch is

“Off”, the pump will not be rotating. When the switch is on “Clean-out”, the pump will be rotat-

ing in the reverse directing and will be sucking back any material in the plumbing or the hose.

4) Agitator CCW/Off/CW Switch: This switch controls the rotation of the agitator from counter-

clockwise or Clockwise. If the switch is in the center position, the agitator will not rotate.

5) Low Flow Switch: Occasionally, you will find that the material spits out the wand if the flow

control knob is set to 3 or lower. If this is happening, switch the Auto/Manual switch to Manual

and place the Low flow switch to the “For material flow Lower than 4”. This will make the ma-

terial pump only rotate when the wand trigger is pressed.

6) Pump LED (Green): This LED indicates that the material has reached the preset tempera-

ture and if the unit is running in the Auto mode, the Material pump will be pumping.

7) Agitator LED (Green): This LED indicates that the Heat Transfer Oil has reached the preset

temperature and if the unit is running in the Auto mode, the Agitator will be turning.

8) Heated Hose LED (Green): This LED indicates that the Heated Hose has reached the pre-

set temperature and is ready to use.

9) Diesel Burner LED (Yellow): This LED indicates that the Diesel Burner is on.

10) Heated Hose Fuse: This Slow-blow fuse is protecting the Heated Hose.

11) Heated Hose Generator LED (Yellow): This LED indicates that the Heated Hose Generator

is on.

Controls and Their Functions

9

Controls and Their Functions

1

2

3

4

5

6

7

8

9

10

11

10

1. SETUP:

A) Set Flow control to “9”

B) Set rotary switch to RUN.

2. START ENGINE:

A) Turn key on engine control to “1”

B) Heat glow plugs 3-5 seconds.

C) Turn key to “2”

D) Release when engine starts

Start up

11

3. WAND

When Pump and Agitator Green

Lights are on:

A) Unlock Boom

B) Place wand in port.

4. Ready for Work

When all 3 GREEN lights are on:

A) Set Flow to “0”

B) Pin Wand trigger and

set handle forward

C) Set Flow to

desired level

D) Start Sealing

Start up

12

Automatic Temperature Control Setting

The control system on your CIMLINE “M” series melter has been factory set to run the most

common types of materials. These Materials have an application temperature of 380 deg F.

With some materials, it may be needed to change the controller to achieve the appropriate appli-

cation temperature. To achieve this, open the control box and alter the material controller (top

controller) by following the directions below.

Decrease (DOWN)

Increase (UP)

(A)

1) Press the SET button.

2) SP1 is displayed.

3) Press the SET button.

4) Current Temperature is displayed.

5) Use the arrow buttons to change to the desired temperature.

6) Press the SET button.

7) Let the controller time out. Your controller will now be change and the updates will

be saved.

13

Loading Empty Tank

All material must be clean. Keep all foreign matter out of melting tank.

1) Open the material door (1) and place slab or biscuit (2) on the open door against the

holder (3).

2) Push door to the closed position. DO NOT DROP MATERIAL INTO THE MELTER

WITH DOOR OPEN.

1

2

3

14

Cleanout Procedure

1. SETUP:

A) Place wand in port.

B) Pin wand trigger and set handle forward.

C) Set rotary switch to Clean Out.

D) Set flow to “9”

Hose Clean-out:

Let pump run in reverse for 2 minutes.

Pump Clean-out:

Unpin wand trigger.

Continue running pump in reverse for 2 minutes.

Shut down:

Shut Engine off by turning key to “0”

Set rotary switch to Off.

Move Boom to travel position and lock.

Store wand

Contact material supplier for information on

how to flush out non-reheatable materials.

15

Maintenance

Engine: The operation and life of the engine depends on you and your operator. Do not start

engine until the engine precheck is complete. The engine precheck consists of checking the oil,

the fuel level, the hydraulic oil level and the air filter. The M-1/M-2 Melter Applicator has the op-

tion of (2) different engines. The Isuzu 22.8 H.P. and 40.3 diesel units. For more detailed infor-

mation please refer to the Engine Operator Maintenance Manual and Warranty provided with

your Melter applicator.

NOTE: When breaking in a new Melter, we recommend running the engine for one

hour with no load prior to actual use on the job.

Air cleaner: Due to the dusty conditions that can be created by road work, it is essential to

check the engine air cleaner element daily. Remove element and shake out the accumulated

dust and dirt. Wipe out dirt from inside cover and from housing. Check engine manual for

washing instructions. We recommend stocking replacement filters.

Fuel: Use of high quality detergent oil of API (American Petroleum Institute) service class CC

or CD grade. Select the viscosity based on the air temperature at the time of operation. Check

your engine manual for other recommendations.

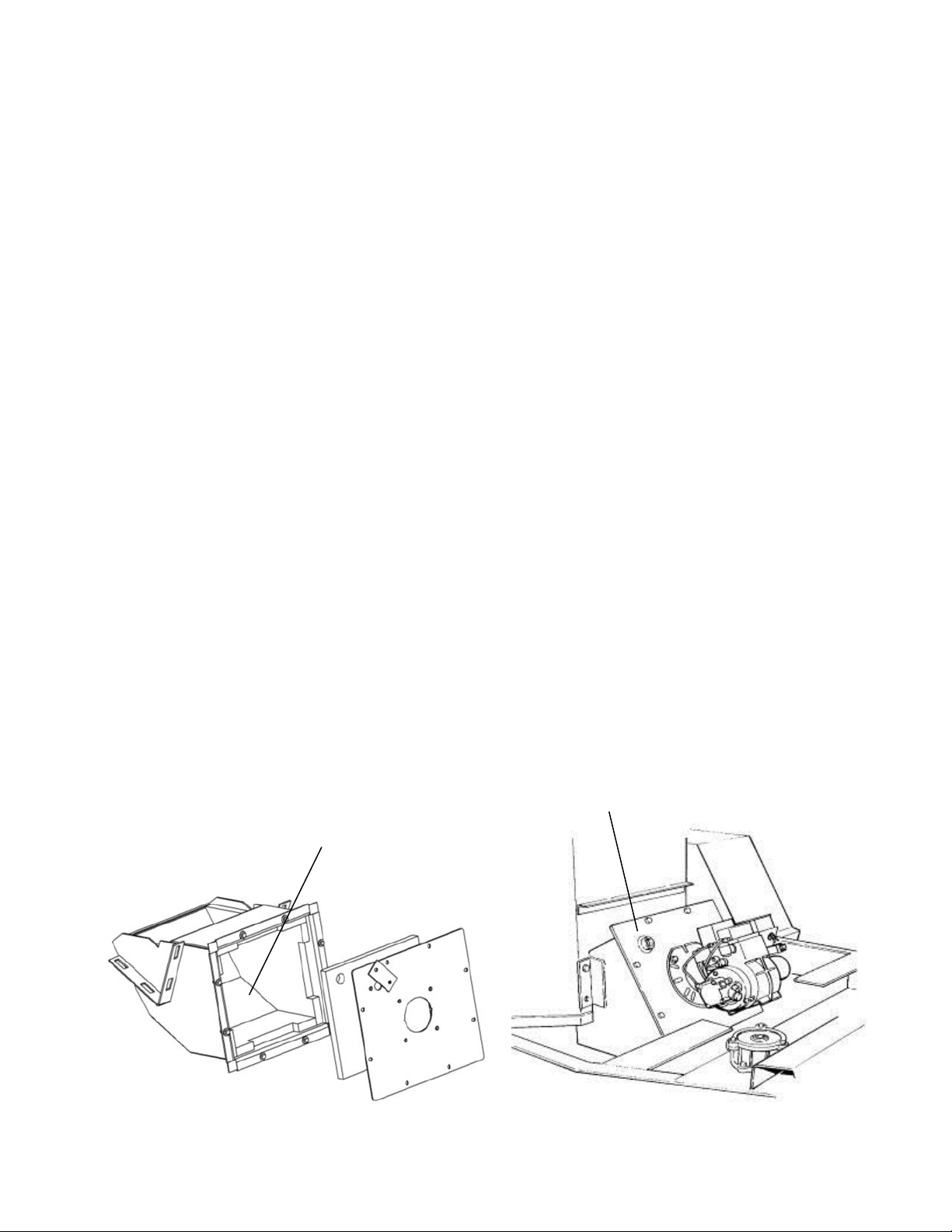

Burner: There are several items that need to be inspected periodically on the burners. These

items include the burner nozzle, electrode and head position, chamber lining (see below) and

the electric eye. Please refer to the burner manual on how to perform each of these operations

in this manual..

After each 200 hours of operation, the chamber lining should be inspected. Remove (8) burner

mount securing bolts (A) and pull out burner and mount. Inspect lining (B) for excessive crack-

ing. Lining cracks are acceptable as long as they are not large enough to allow flame to contact

the combustion chamber walls.

(A)

(B)

16

Maintenance

Maintenance Operation Daily 25 Hrs 100

Hrs 200

Hrs 1000

Hrs Yearly

Check fuel level (add if low) X

Check engine and heat transfer oil (add if low) X

Check hydraulic oil (add if low) X

Check engine air cleaner X

Inspect pre-cleaner X

Cleanout material system X

Inspect sealing hose and cover X

Inspect sealing hose connection X

Drain condensation from air compressor option X

Blow oil cooler on the air compressor option X

Inspect and clean cooling system (Diesel units only X

Inspect material pump packing (adjust if leaking is excessive) X

Check oil level on air compressor option X

Service air cleaner element X

Inspect spark plugs and breaker pts. (Propane units only) X

Inspect burner motor brushes (replace if worn out X

Inspect burner nozzle, electrode & head pos. (adjust if nec.) X

Change engine oil and oil filter X

Grease agitator bearing block (load adapter) X

Inspect fuel filter (replace if dirty) X

Inspect Diesel burner electric eye (clean if dirty) X

Grease wheel bearings X

Inspect chamber lining (replace if excessive cracking) X

Change oil on compressor option X

Change air inlet filter on compressor option X

Inspect starting motor X

Replace hydraulic oil X

Replace hydraulic return filter X

Replace hydraulic suction strainer X

Replace burner nozzle X

Change heat transfer oil X

Change Diesel fuel filter X

Flush radiator and replace fluid (Diesel units only) X

Replace separator on air compressor X

17

Fluid and Components Specifications

WARNING: Only the oil specified or equal may be used in this system. (Always check

your local and state regulations before disposal).

NOTE: A dipstick (A) is provided for checking oil level when cold.

This is a petroleum based product. We recommend that you do not mix oil brands. Mixing any

oils (Engine oil, transmission fluid, etc.) adversely affects each manufacturers formula.

COLD OIL LEVEL

M1 M2

Hydraulic Reserve Capacity 30 Gallons

Hydraulic Oil Type Conoco MV32 or equiv

Diesel Fuel Capacity 30 Gallons

Diesel Fuel Type ASTM D975 No.2

Heat Transfer Oil Capacity 21 Gal. 26 Gal.

Heat Transfer Oil Type See Specs. On next page.

Agitation Drive Relief Setting 1100 800

Material Pump Drive Relief Setting 800

Material Pump Displacement .11 Gal/Rev

Material Pump Maximum Output Pres-

sure 125 PSI

18

Heat Transfer Oil Specifications

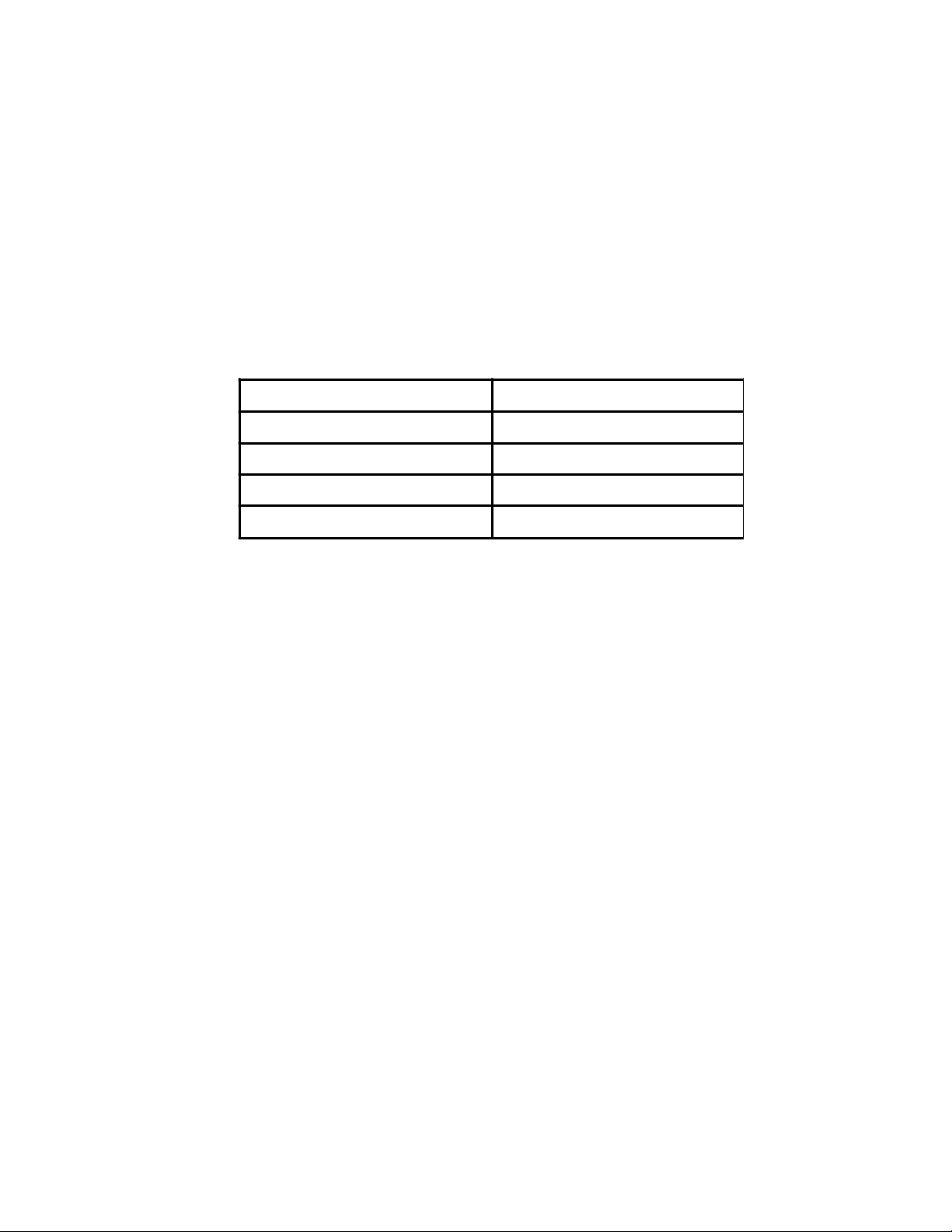

ISO Grade 68 Heat transfer Oil Specification

There are many different types of Heat Transfer Oils on the international marketplace. It is criti-

cal that you use the proper oil to prevent poor performance, oil flashing, or auto-ignition. To

conform to most government bids and to supply a readily available product, CIMLINE typically

uses brands manufactured by Conoco or Phillips 66 that meet the ISO Grade 68 Heat Transfer

Oil specifications listed. To insure maximum safety and performance, we recommend you pur-

chase your oil through CIMLINE.

ISO VG# 68

Pour Point - F 10º F (12º C)

Flash Point - F 485º F (252º C)

Lbs/Gallon 7.27

Viscosity CsT @ 40C 62

IMPORTANT NOTICE!!

The ISO Grade is just a viscosity index (ability to flow/thickness). An ISO Grade 68 oil can be

an engine oil, hydraulic oil, etc. The manufacturer uses different additives to make the oil con-

form to different applications. YOU MUST CLARIFY with the supplier that the oil is to be used

in a heat transfer system to avoid any potential problems. Oil is also available from CIMLINE in

5 and 30 Gallon containers for ship-out.

NOTE: CIMLINE Melter/Applicators include and expansion tank that cools the oil that is ex-

posed to the outside air. When the oil heats up and expands, it flows into the expansion tank.

The tank is cooler since it is not oil jacketed and is surrounded by outside airflow. The only ex-

posure the hot oil has to the atmosphere is through a 3/4" vent/overflow pipe. This is done so

the oil in the tank can run higher than the flash point. Only the lower temperature oil fumes are

exposed to the atmosphere.

FLASH POINT - Test in which an open container of oil is heated until an open flame will flash

when passed over the fumes.

FIRE POINT - Same test as the flash point except the oil is heated until the gasses will start a

fire.

AUTO IGNITION POINT - The point at which fumes will burst into flame when exposed to air.

19

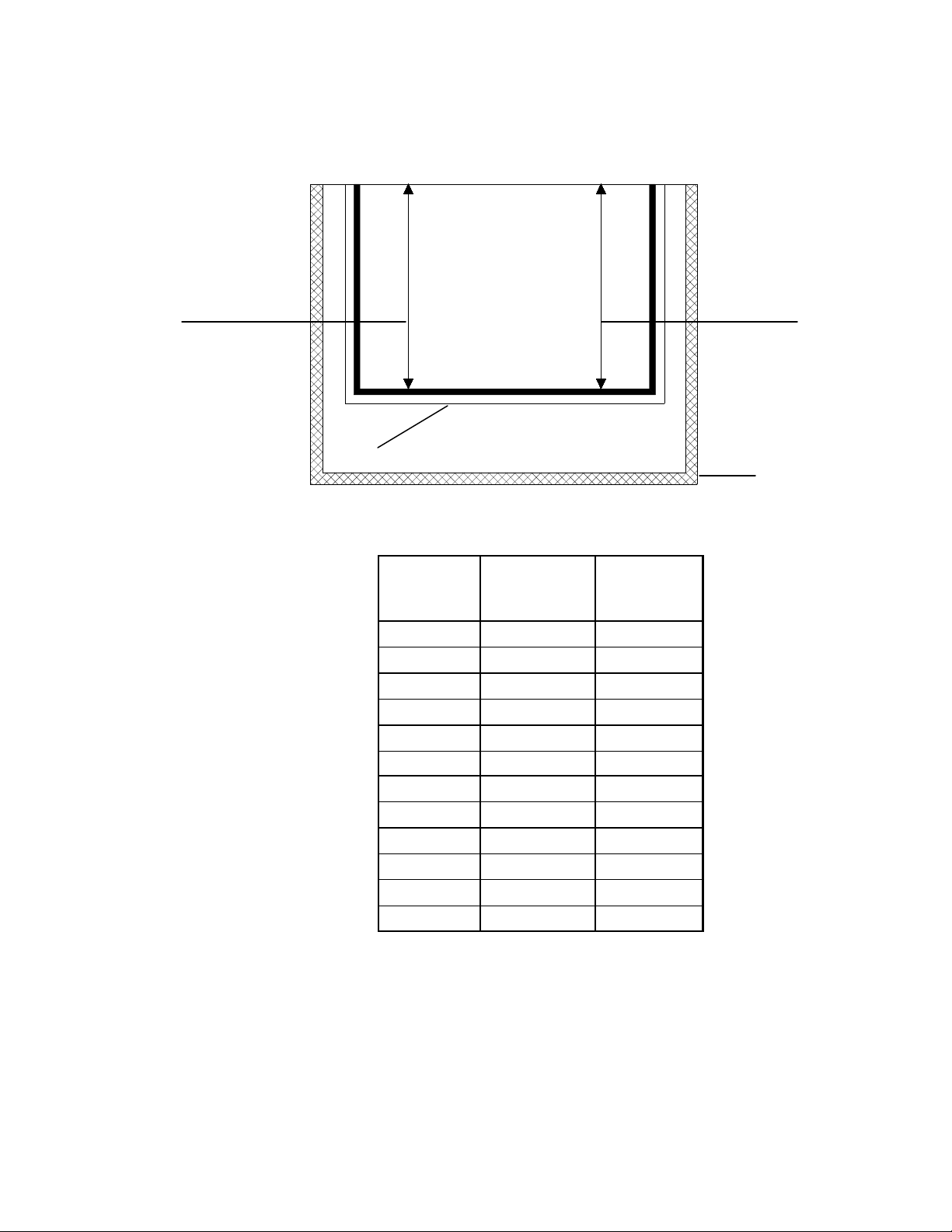

Material Tank Capacity

MATERIAL CAPACITY

(Tank cutaway)

Gallons of material is found by first dividing the tank volume by 231 (# of cubic inches

per gallon of liquid), and then multiplying that number by the number of inches of mate-

rial in the tank. For example, 1052 divided by 231 = 4.55. 4.55 x 2" of material = 9.11.

* Volume of tank in cubic inches for each inch of material.

MATERIAL VAT

M2

9.37 GALLONS

PER INCH

INSULATION

AIR

OIL

M1

6.8 GALLONS PER INCH

Material

Depth

M1

1570 Cubic

Inches

M2

2165 Cubic

Inches

2" 13.6 18.74

4" 27.18 37.48

6" 40.78 56.22

8" 54.37 76.96

10" 67.96 93.7

12" 81.56 112.44

14" 95.15 131.18

16" 108.74 149.92

18" 122.34 168.66

20" 135.93 187.4

22" 149.52 204.14

24" 224.88

20

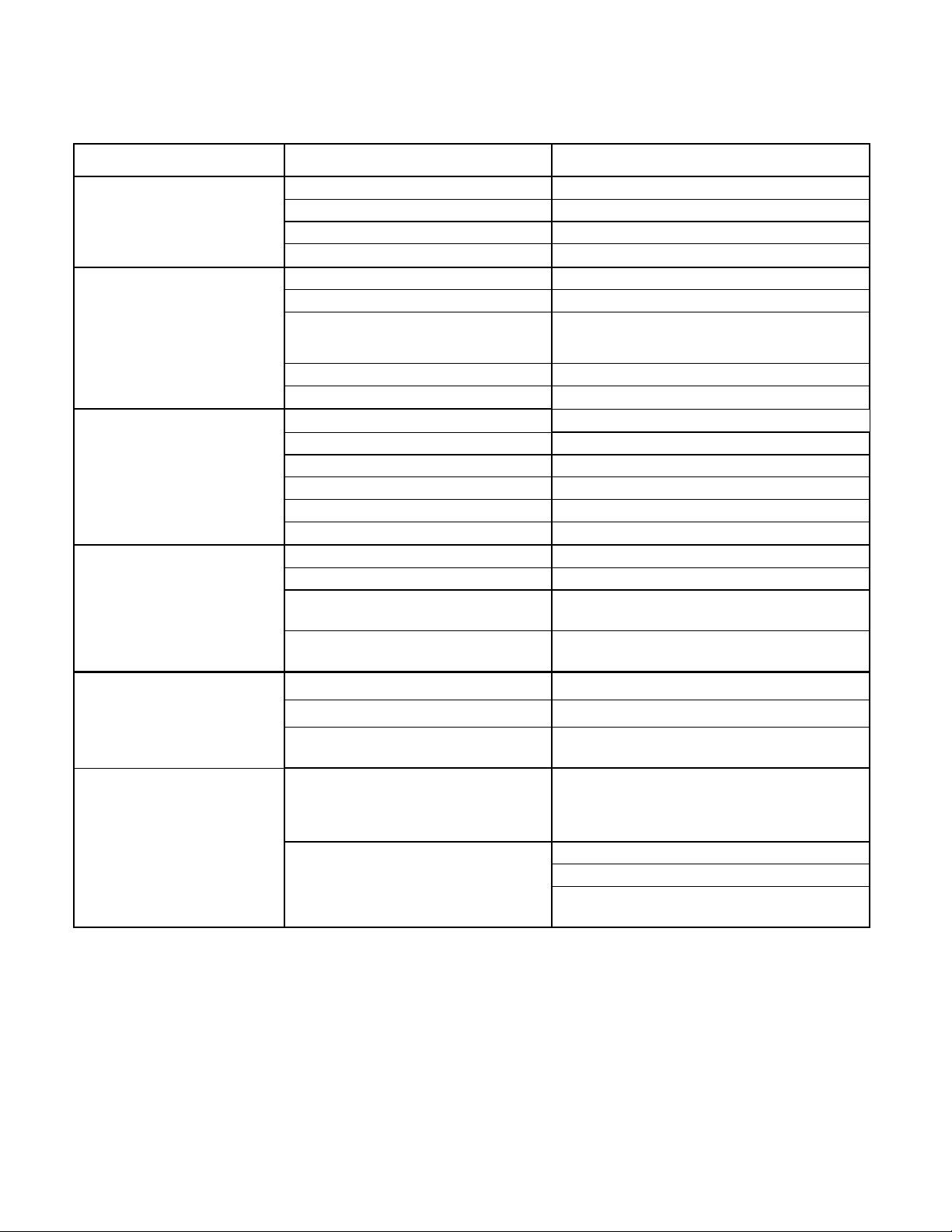

Trouble Shooting Guide

Problem Cause Solution

Burner will not ignite

Fuse burned out. Check fuse

Burner relay inoperative. Check for 12VDC at relay.

Primary control fuse. Check fuse

Thermocouple(s) inoperative Replace thermocouple(s)

Agitator will not rotate

Fuse burned out. Check fuse

Sealant material not hot enough. Allow material to heat longer

Too many biscuits added at one

time. Continue heat up and reverse agitation

to break biscuits free.

Low hydraulic oil level. Check oil Level

Worn agitator motor. Replace Motor

Material pump will not ro-

tate

Fuse burned out. Check fuse

Sealant material not hot enough. Allow material to heat longer

Too much material left in lines Heat plumbing and valve to melt material

Low hydraulic level Check oil level

Foreign object lodged in line Remove foreign object

Pump damaged Repair or replace pump

Material pump rotates but

does not pump material

Pump worn or damaged Repair or replace pump

Pump rotating in wrong direction Reverse pump switch

Pump inlet line plugged

Check matl tank grid and lines for ob-

struction

Too much material left in lines Heat plumbing and valve to melt material

Material heat up time slow

Burner orifice clogged Remove orifice and clean

Heat transfer oil is worn out Check oil level. Replace if necessary

Too much old material on tank Clean material tank

Material recirculates but

will not flow through seal-

ing wand.

Sealing hose valve not completely

closing or worn out Realign valve or replace

Actuator not turning valve

Check Fuse

Check trigger switch

Broken or disconnected wire in the elec-

This manual suits for next models

1

Table of contents

Other CPMG Melting Machine manuals