This manual contains DANGER, WARNING, CAUTION, and NOTE callouts

which must be followed to reduce the possibility of personal injury, damage to

the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol, CAUTION indicates a potentially

hazardous situation which, if not avoided, may result in property damage.

Note: Contains additional information important to a procedure.

2.1 Laws Pertaining to Spark Arrestors

Notice: State Health Safety Codes and Public Resources Codes specify that in certain

locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental

discharge of sparks or flames from the engine exhaust. Spark arresters are

qualified and rated by the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult the engine distributor

or the local Health and Safety Administrator.

2.2 Operating Safety

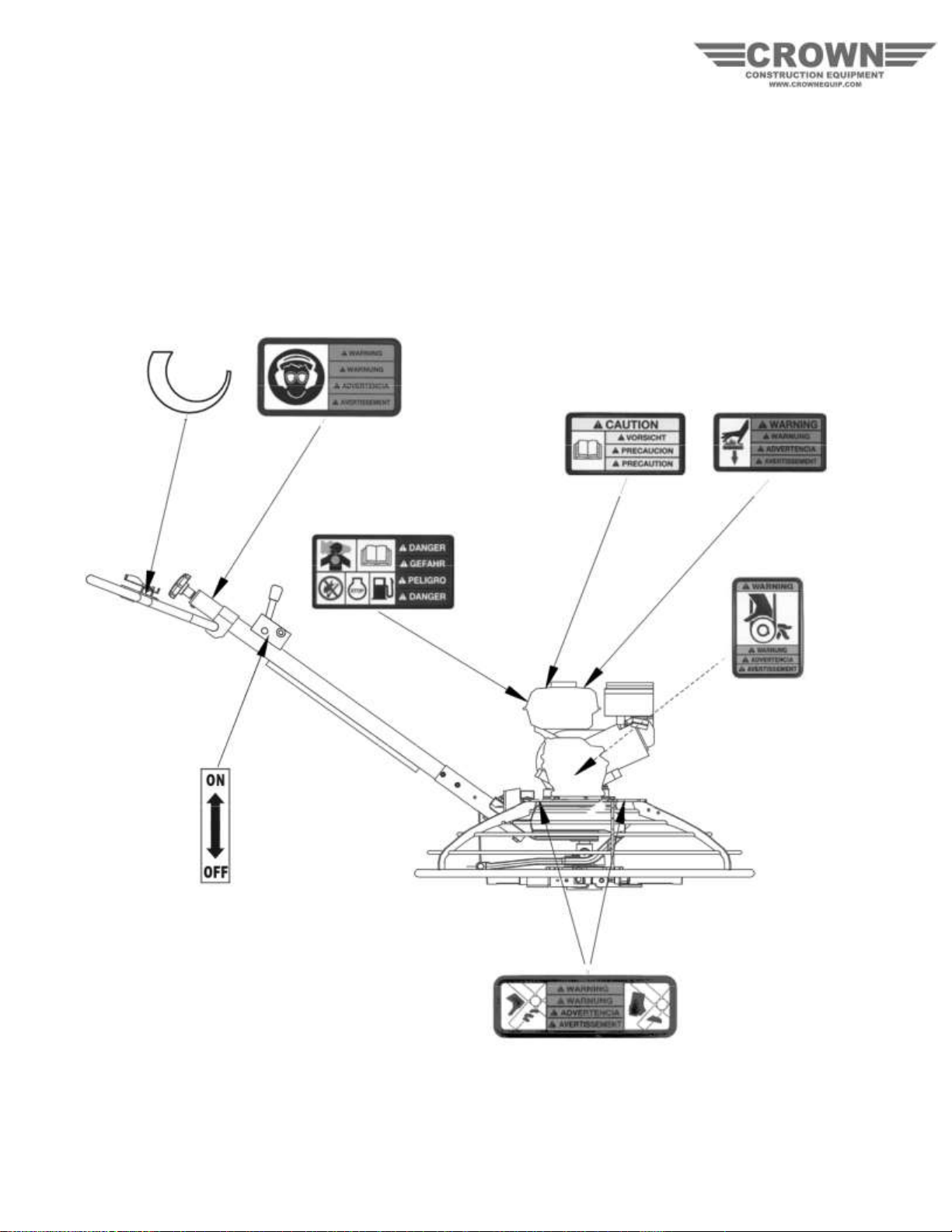

WARNING: Familiarity and proper training are required for the safe operation

of equipment. Equipment operated improperly or by untrained personnel can

be dangerous. Read the operating instructions contained in both this manual

and the engine manual and familiarize yourself with the location and proper

use of all controls. Inexperienced operators should receive instruction from

someone familiar with the equipment before being allowed to operate the

machine.