FAILURE POINT REDUCTION

Each wire connection on a robot represents a possible failure point. A loose wire, a bad crimp, something

plugged in backwards – all of these can lead to significant problems during a match. The Falcon 500 helps

reduce the number of connections (failure points) by up to 50%. This means that your robot will be more

robust than ever before. Simply plug in the Falcon 500 to your robot’s power distribution system, connect

it to CAN or PWM, and you’re ready to go! Let’s look at some examples:

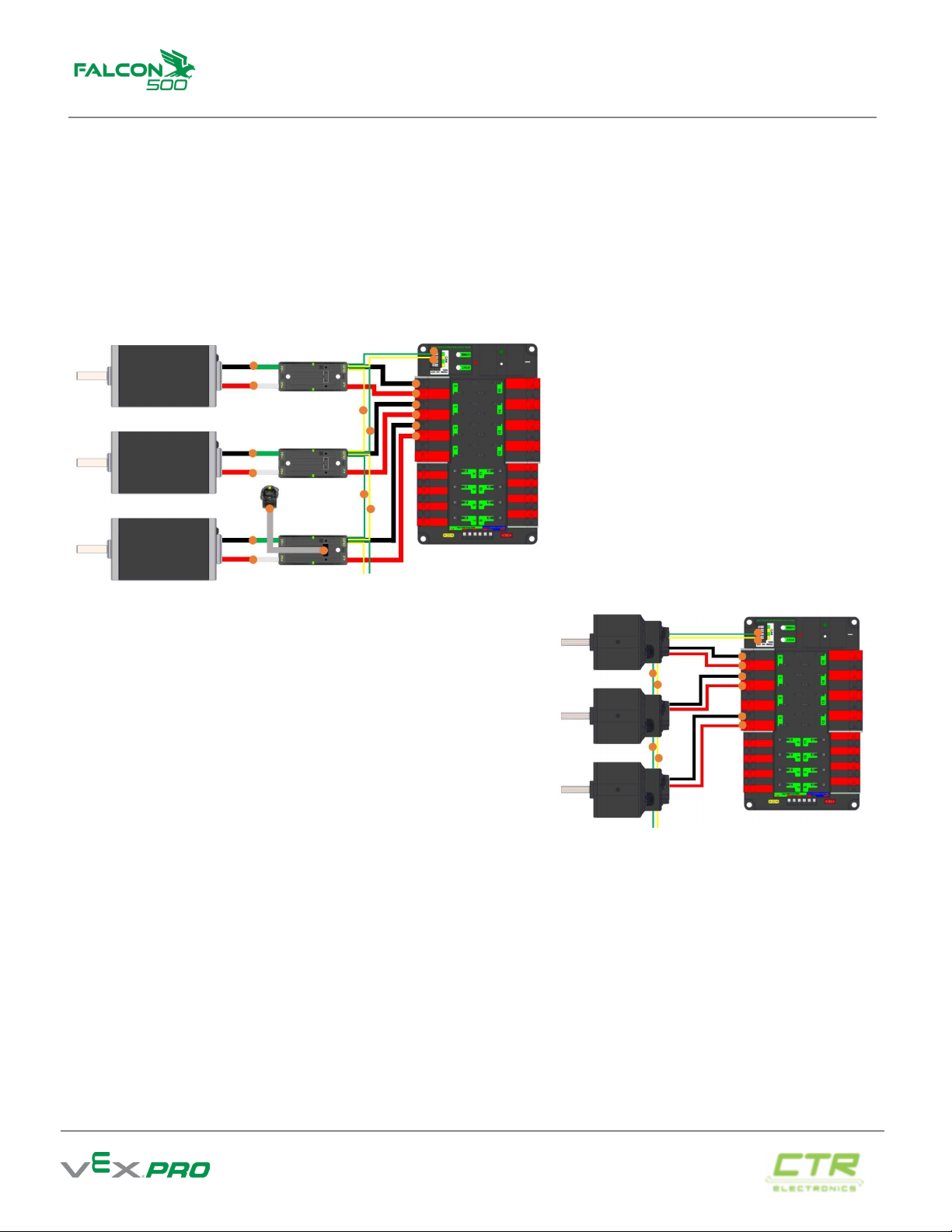

The diagram to the left is what it

would look like to wire (3x) CIM

Motors and a Mag Encoder to your

robot.

Each of the (20x) orange dots

represent a connection that can fail,

causing problems for your robot in the

middle of a match.

The diagram to the right is what it looks like to wire (3x) Falcon

500 motors to your robot. Both diagrams have the same number

of motors and sensor capability.

While the brushed motor example shows (20x) possible failure

points, the Falcon 500 example has just (12x). This is a

significant reduction in the number of possible wiring problems

that can exist on a robot by switching from common brushed

motors to the Falcon 500.

What about other brushless options in FRC? Since the motor controller is integrated into the Falcon 500,

so is the sensor and sensor wiring. This means that there is no sensor cable between the motor and

controller that can become unplugged during a match, eliminating more potential failures. In addition,

the phase wiring between the controller and the motor is handled inside the Falcon 500. This makes it

impossible for teams to mismatch the motor’s phases with the motor controller’s phases, eliminating

even more failure points on a robot.