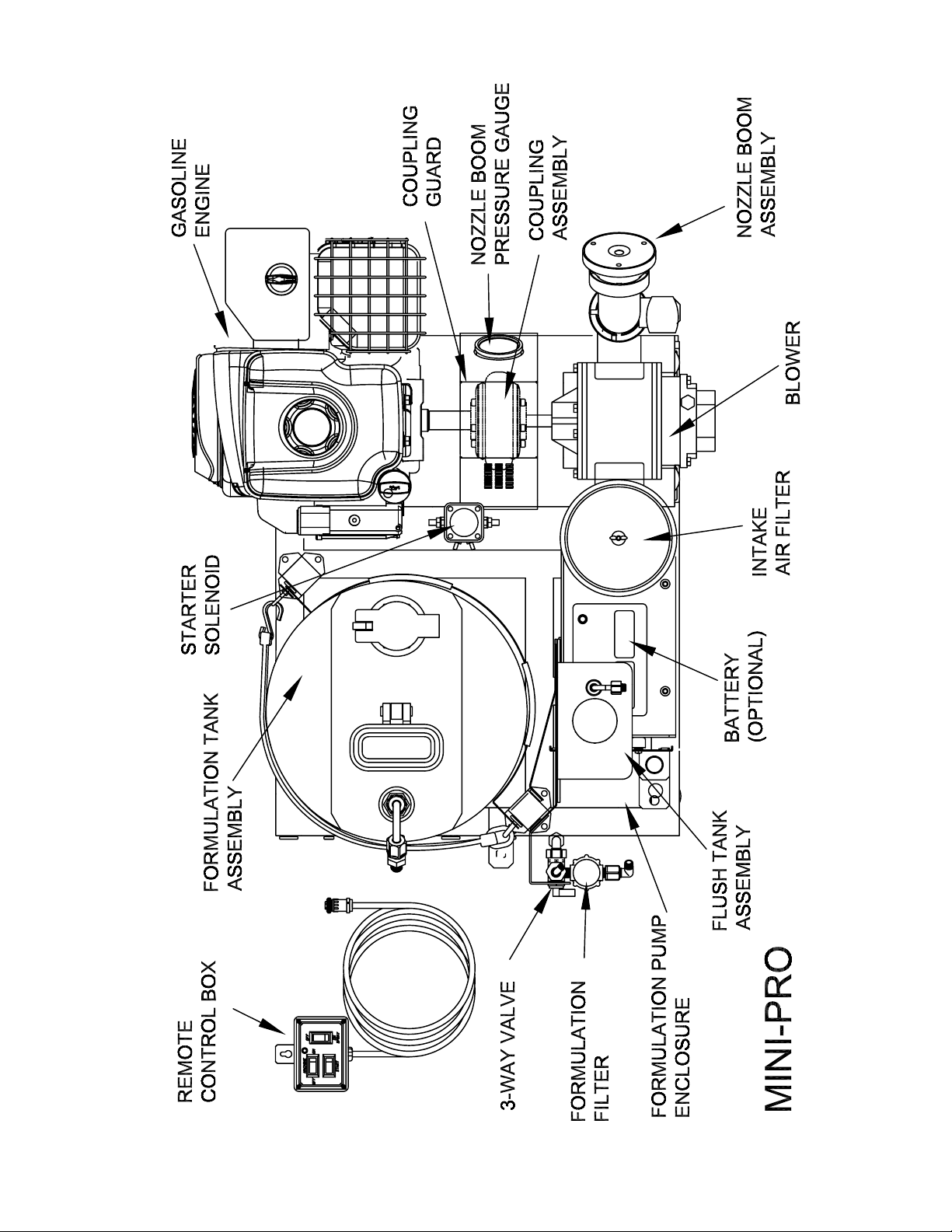

TYPE : Aerosol Generator, Non Thermal, Insecticide, Ultra-Low-Volume (ULV)

ENGINE : Briggs & Stratton, 4-cycle, single cylinder, gasoline engine, 8 HP,

equipped with electric starter and alternator. The Intek engine feature an advanced

OHV design, offer more power per cubic inch displacement, and provide increased

fuel efficiency. These compact, powerful engines are easy to use and have a long life.

Equipped with a muffler that has a deflector and spark arrester, which is required by

law in some States. Fuel tank of 4 Quarts (3.8 L) capacity. Operating Speed of 2,500

RPM

BLOWER : Roots - Dresser Universal RAIRPositive displacement Blower, straight

lobe, rotary type, direct drive, size 24. Output Air Pressure : Rated at 0 - 7 PSI

Output Air Flow : Rated at 0 - 156 CFM

Exclusive gear box design, Figure 8" shape actually improves oil distribution for

longer gear and bearing life with smoother operation.

Taper mounted timing gears, carburized and ground alloy steel gears are precision

machined and taper fitted to alloy steel shaft, eliminating the need for unreliable

timing pins. Original Roots impeller design, dynamically balanced and center-

timed. Long-life anti-friction bearings. All bearing points are engineered for long

service life.

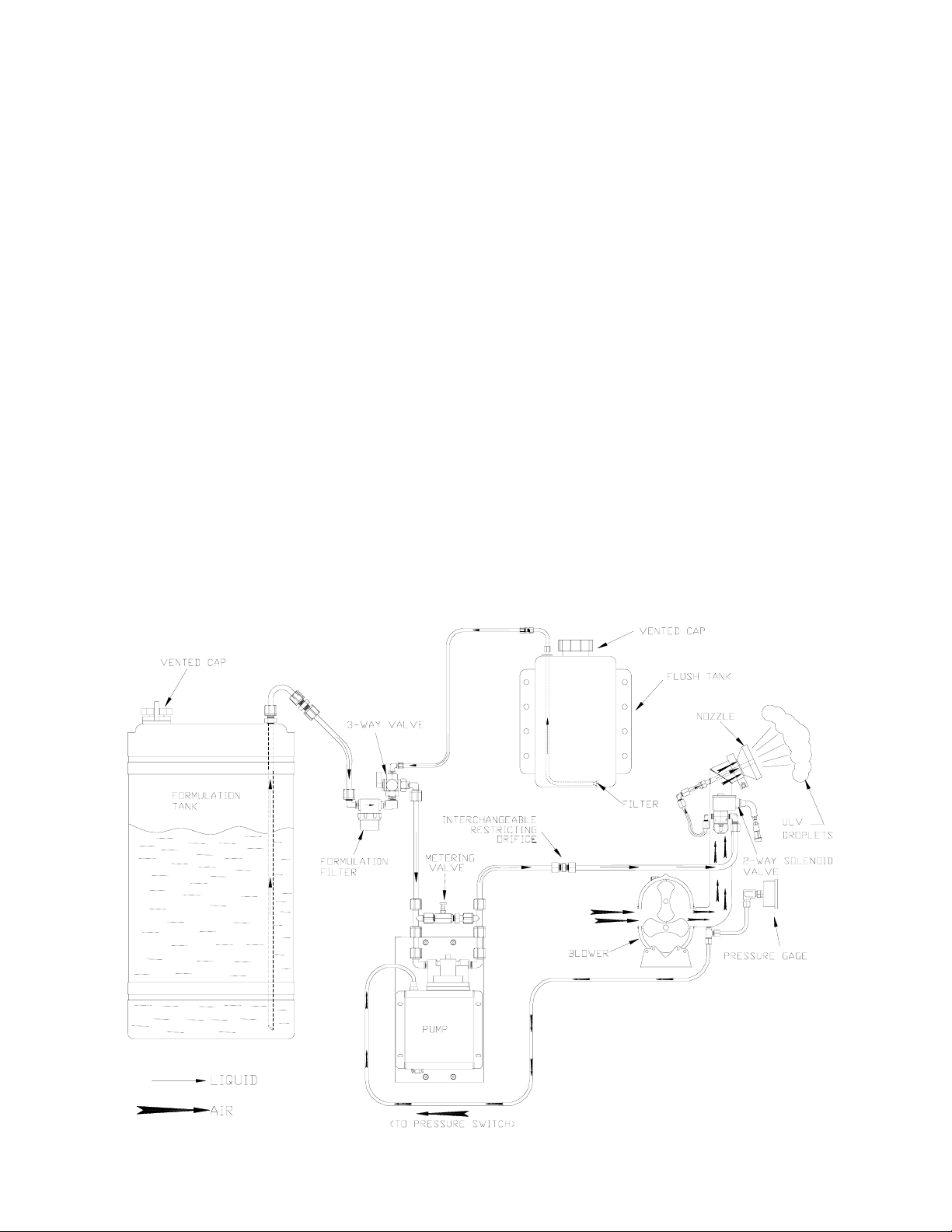

FORMULATION PUMP: Self-priming positive displacement Diaphragm Pump, Viton

elastomers, dry running capabilities, driven by a 12 VDC permanent magnet motor.

The pump head includes an internal pressure relief valve to allow the pump to

recirculate the liquid so it does not build up excess system pressure to protect the

pump. Adjustable output from 0 to 128 oz./min. (0 - 3840 ml./min).

NOZZLE SYSTEM: Boom mounted, cluster type with 360°horizontal adjustment

(azimuth) . Single nozzle.

2-WAY SOLENOID VALVE ( SHUT-OFF VALVE ): A corrosion resistant 2-way

solenoid valve is located at the Nozzle Boom assembly and is used for a positive and

instantaneous shut-off of the formulation flow. This is done by placing the SPRAY

switch located on the remote control box into either OFF (Pump stops and 2-way

valve closes) or ON position (Pump runs and 2-way valve opens).

PARTICLE SIZE: 5 - 20 Microns Volume Media Diameter (VMD) depending on flow

rate and viscosity. Bigger droplets can be obtained with higher flow rates and/or lower

boom pressure.

4