SH-7000-Chroma-EN-04/17 4

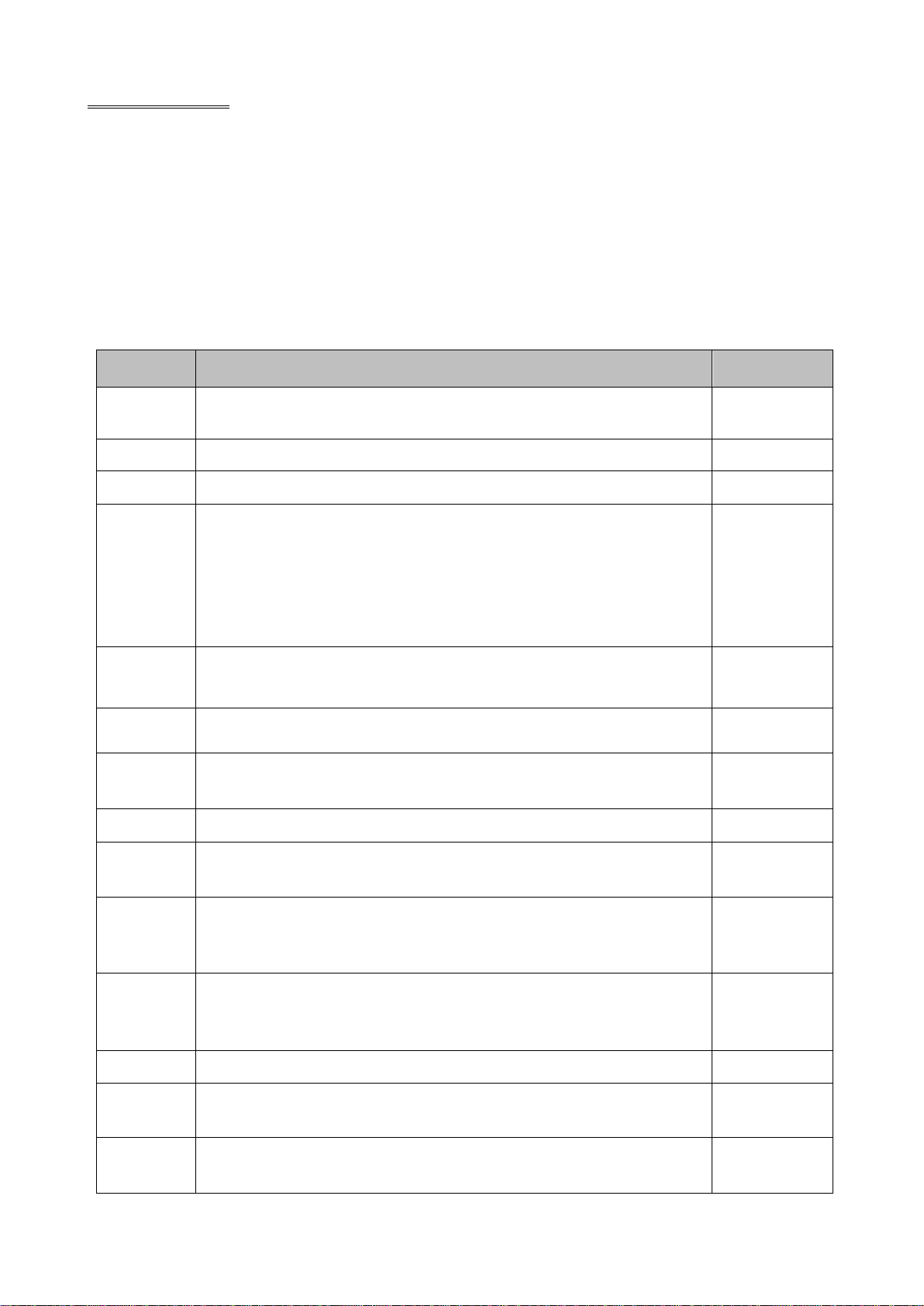

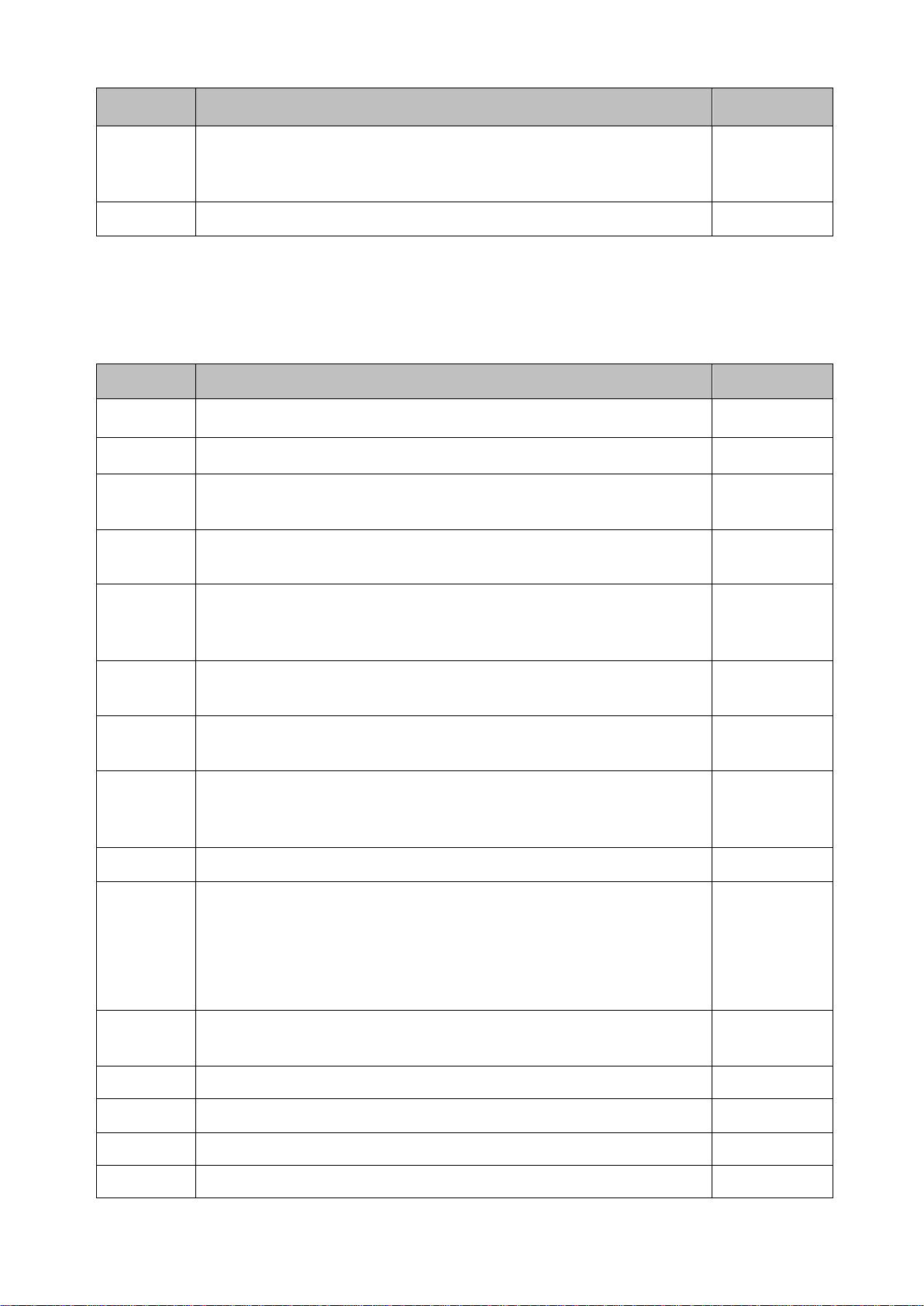

Table of Contents

1TECHNICAL DESCRIPTION...................................................................................................5

Control: ....................................................................................................................................5

Power Supply:..........................................................................................................................5

Software:..................................................................................................................................6

Specifications, instructions for use, warranty, performance data, EMC behaviour:................6

2SETUP MODE:............................................................................................................................7

2.1 STARTING THE PUMP IN SETUP MODE ...................................................................................7

2.2 DESCRIPTION OF PUMP SETUP................................................................................................7

2.3 BASIC SETTINGS....................................................................................................................8

2.4 OPTIONAL SETTINGS.............................................................................................................9

3TROUBLE SHOOTING ...........................................................................................................11

4INTERNAL ALARMS..............................................................................................................15

4.1 MEANING OF ERROR CODES:................................................................................................15

5REPAIR ......................................................................................................................................17

5.1 REPLACEMENT OF MAIN PCB.............................................................................................17

5.2 DISMANTLING THE PUMP BLOCK.........................................................................................18

5.3 REPLACEMENT PUMP BLOCK BACK PLATE AND SPRINGS...................................................20

5.4 REPLACEMENT OF PRESSURE SENSOR.................................................................................21

5.5 REPLACEMENT OF STOP-FLOW MECHANISM .......................................................................21

5.6 REPLACEMENT OF THE PERISTALTIC COVER.......................................................................24

5.7 REPLACEMENT OF FRONT HOUSING AIR DETECTOR PLATE................................................25

5.8 REPLACEMENT OF UPSTREAM PRESSURE SENSOR...............................................................26

5.9 DISMANTLING THE DOOR....................................................................................................28

5.10 DOOR SCREWS DESCRIPTION ...............................................................................................29

5.11 REPLACEMENT OF DISPLAY PCB..........................................................................................30

5.12 REPLACEMENT OF THE TOUCH SCREEN AND FRONT FOIL ...................................................31

5.13 REPLACEMENT OF THE DOOR AIR DETECTOR PLATE..........................................................32

5.14 ADDITIONAL OPTIONS AND AMENDMENTS ..........................................................................33

5.14.1 Stop flow counter plate ..................................................................................................33

6INITIALISATION AND UPDATES........................................................................................34

6.1 RELEASE NOTE ...................................................................................................................34

6.2 SW UPDATE........................................................................................................................35

6.3 SW UPDATE AFTER EXCHANGE OF DISPLAY PCB. ...............................................................36

6.4 SW UPDATE AFTER EXCHANGE OF MAIN PCB.....................................................................37

7CALIBRATION.........................................................................................................................39

7.1 PRESSURE SENSOR..............................................................................................................39

7.2 UPSTREAM OCCLUSION PRESSURE SENSOR ........................................................................41

7.3 DOOR PRESSURE.................................................................................................................42

7.4 CALIBRATION OF INFUSED VOLUME (SPEED TUNING)..........................................................42

8MAINTENANCE.......................................................................................................................43

9DRAWINGS AND LAYOUTS .................................................................................................46

10 HISTORY...................................................................................................................................49