iii

Repair and Service Manual

SAFETY INFORMATION

634756

SAFETY INFORMATION

This manual has been designed to assist the owner-operator in maintaining the vehicle in accordance with procedures

developed by the manufacturer. Adherence to these procedures and troubleshooting tips will ensure the best possible

service from the product. To reduce the chance of personal injury and/or property damage, the following instructions

must be carefully observed:

GENERAL

Many vehicles are used for a variety of tasks beyond their original intended use; therefore it is impossible to anticipate

and warn against every possible combination of circumstances that may occur. Warnings cannot replace good common

sense and prudent driving practices. Common sense and prudent driving practices do more to prevent accidents and

injury than warnings and instructions can provide.

The manufacturer strongly suggests anyone operating the vehicle read the entire owner’s guide provided with the pur-

chase of the vehicle, paying particular attention to the CAUTIONS, WARNINGS and DANGERS within.

For any questions or concerns, contact the closest representative, or write to the address on the back cover of this pub-

lication, Attention: Customer Care Department.

E-Z-GO Division of Textron reserves the right to make design changes without obligation to make these changes on

units previously sold and the information contained in this manual is subject to change without notice.

E-Z-GO Division of Textron is not liable for errors in this manual or for incidental or consequential damages that result

from the use of the material in this manual.

This vehicle conforms to the current applicable standard for safety and performance requirements.

This vehicle is designed and manufactured for off-road use. It does not conform to Federal Motor Vehicle Safety Stan-

dards and is not equipped for operation on public streets. Some communities may permit these types of vehicles to be

operated on their streets on a limited basis and in accordance with local ordinances.

Ensure all electrical accessories are grounded to the DC to DC converter negative (-); not to the battery (-) post. Never

use the chassis or body as a ground connection.

Refer to GENERAL SPECIFICATIONS for vehicle seating capacity. Do not exceed number of occupants indicated.

Never modify the vehicle in any way that will alter the weight distribution of the vehicle, decrease

it’s stability, increase the speed or extend the stopping distance beyond the factory specification.

Such modifications can result in serious personal injury or death.

Modifications that increase the speed and/or weight of the vehicle will extend the braking distance and may reduce the

stability of the vehicle. Do not make any such modifications or changes. The manufacturer prohibits and disclaims

responsibility for any such modifications or any other alteration which would adversely affect the safety of the vehicle.

Speed should be moderated by the environmental conditions, terrain and common sense.

GENERAL OPERATION

ALWAYS:

• Use the vehicle in a responsible manner and maintain the vehicle in safe operating condition.

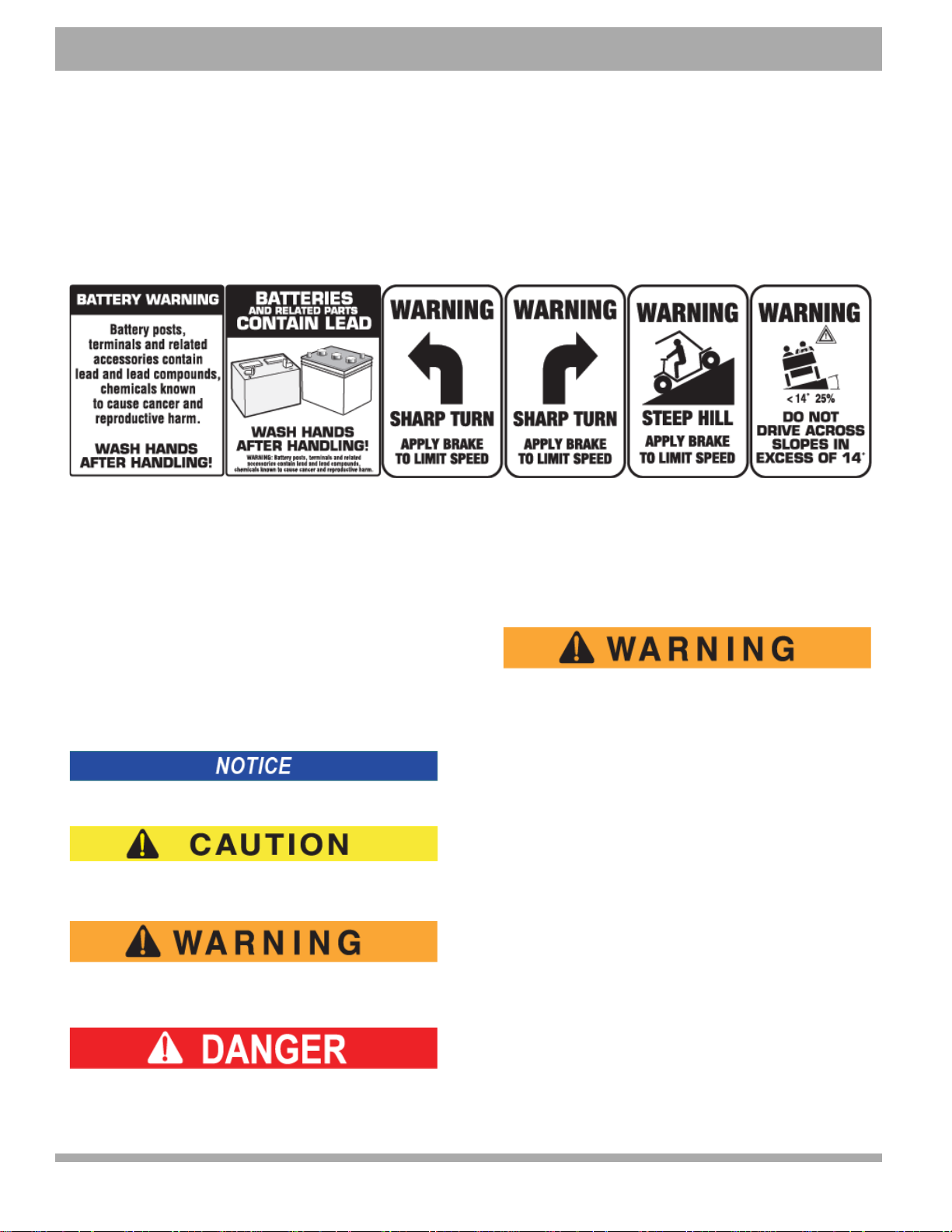

• Read and observe all warnings and operation instruction labels affixed to the vehicle.

• Follow all safety rules established in the area where the vehicle is being operated.

• Reduce speed to compensate for poor terrain or conditions.

• Apply service brake to control speed on steep grades.

• Reduce speed in damp or wet areas.

• Use caution when approaching sharp or blind turns.

• Use caution when driving over loose terrain.

• Use caution when driving in areas where pedestrians are present.