Page 10 of 62

Installation Requirements

This gas fire is intended for decorative purposes. The installation must be in

accordance with National Regulations and must be carried out by a qualified

Gas Safe Registered installer. Building work should only commence after a

thorough survey of the intended location of the impending installation has been

completed and it has been established that the unit can be installed and

operated without risk to the owner or tenants of the property or their

neighbours.

This fire must be installed and used in accordance with these instructions.

Prior to installation, ensure that the local distribution conditions (identification

of the type of gas and pressure and the adjustment of the appliance) are

compatible.

Clearances between the fire and all combustible materials must conform to

National Regulations. The builders opening or fireplace opening must be

constructed of a non- combustible material.

For some countries a non-combustible hearth must be fitted in front of the fire

in accordance with National Regulations (e.g. United Kingdom).

Before the fire is installed a flue test in accordance with National Regulations

should be carried out. Any flue damper plate or flue restrictor must be

removed or fixed permanently in the fully open position, or shall only be fitted

in accordance with National Regulations.

Where existing chimney systems are to be used in conjunction they should

have been swept and undergone thorough examination to ensure that they are

in a sound and safe condition, as well as providing an adequate draw when the

gas fire unit is in operation. A simple smoke test will reveal whether or not the

chimney is working correctly. If the chimney has been used with a solid fuel

appliance in the past it must be swept before the appliance is installed. The

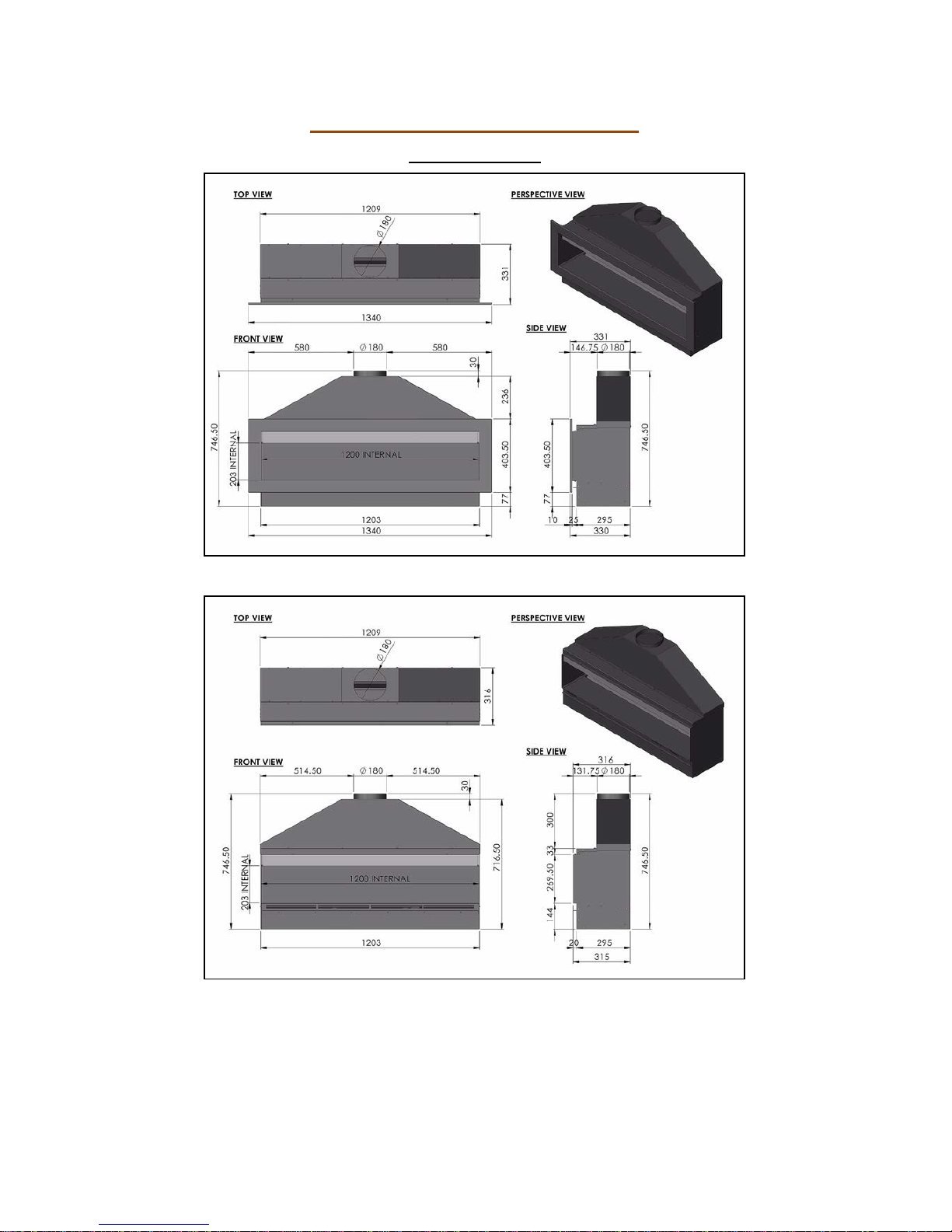

unit must not be installed unless the chimney/flue length is at least the

distance indicated on page 5 (minimum flue height). The fire and flue system

should be checked regularly to ensure that it is free from obstruction.

Check gas pipe work to ensure the correct flow rate for the appliance.

The minimum flue requirements for the FR1200 are a Class 1 Chimney or

177.8mm flue liner with a minimum length of 3m. The enclosure and flue must

be sealed in line with building regulations.

This fire is approved for use with Natural Gas Only.

Once installed all additional gas inlet holes in the enclosure must be sealed

with metal tape to avoid flame reversal which will damage the remote.