-2-

SAFETY PRECAUTIONS

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY.

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFAC-

TURER'S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY VOID

THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANT RESULT-

ING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE THOR-

OUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY CHECKS AND

SERVICING GUIDELINES. TO DO OTHERWISE, INCREASES THE RISK OF

POTENTIAL HAZARDS AND INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION

FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED, A CHECK

SHOULD BE MADE OF THE FOLLOWING:

SUBJECT:FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY AS

TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS. THIS IS

ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE TRANS-

PORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS

INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN RELIEFS, POWER

SUPPLY CORDS, AND OTHER HARDWARE HAVE BEEN REINSTALLED PER

ORIGINAL DESIGN. BE SURE, THAT THE SAFETY PURPOSE OF THE

POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD SOL-

DER JOINTS, SOLDER SPLASHES OF SHARP SOLDER POINTS. BE CER-

TAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION TO

PARTS AND COMPONENTS, FOR FRAYED LEADS, DAMAGED INSULATION

(INCLUDING A.C. CORD), AND REPLACE IF NECESSARY. FOLLOW ORIGI-

NAL LAYOUT, LEAD LENGTH AND DRESS.

5.NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR A

RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND PRO-

TRUDING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF RESISTOR,

CAPACITORS, ETC. MUST BE REPLACED WITH EXACT FACTORY TYPES.

DO NOT USE REPLACEMENT COMPONENTS OTHER THAN THOSE SPECI-

FIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE STE ALWAYS PERFORM AN A.C. LEAKAGE

TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET. (THE CHAN-

NEL SELECTOR KNOB, ANTENNA TERMINALS, HANDLE AND SCREWS) TO

BE SURE THE SET IS SAFE TO OPERATE WITHOUT DANGER OF ELECTRI-

CAL SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS

TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE

SENSITIVITY, IN THE FOLLOWING MANNER : CONNECT A 1500 OHM 10

WATT RESISTOR, PARALLELED BY A .15 MFD. 150V A.C. TYPE CAPACI-

TOR BETWEEN A KNOWN GOOD EARTH GROUND (WATER POPE, CON-

DUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500 OHM

RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG AND

REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC

PART. VOLTAGE MEASURED MUST NOT EXCEED .75 VOLTS R.M.S THIS

CORRESPONDS TO 0.5 MILLIAMP A.C. NAY VALUE EXCEEDING THIS LIMIT

CONSTITUTES A POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED

IMMEDIATELY.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSON-

NEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL

SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE.

HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN THE HIGH VOLT-

AGE IS AT THE FACTORY SPECIFIED LEVEL. THE PROPER VALUE IS GIVEN

IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLT-AGES MAY

CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY

AND UNDER CERTAIN CIRCUMSTANCES, AMY PRODUCE RADIA-TION IN

EXCESS OF DESIRABLE LEVELS.

2.ONLY FACTORY SPECIFIED C.R.T ANODE CONNECTORS MUST BE

USED.DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN COLOR

SETS. ALWAYS RE-INSTALL THEM.

3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN ACCU-

RATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF THE

METER SHOULD BE CHECKED PERIODICALLY AGAINST A REFERENCE

STANDARD. SUCH AS THE ONE AVAILABLE AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY THERE

IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY TIME A COLOR

CHASSIS IS SERVICED, THE BRIGHTNESS SHOULD BE RUN UP AND DOWN

WHILE MONITORING THE HIGH VOLTAGE WITH A METER TO BE CERTAIN

THAT THE HIGH VOLTAGE DOES NOT EXCEED THE SPECIFIED VALUE AND

THAT IT IS REGULATING CORRECTLY. WE SUGGEST THAT YOU AND YOUR

SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE

REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING

PROCEDURE, AND THAT THE HIGH VOLTAGE READING BE RECORDED ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN A

PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE, AVOID BEING

UNNECESSARILY CLOSE TO THE PICTURE TUBE AND THE HIGH VOLTAGE

SUPPLY. DO NOT OPERATE THE PRODUCT LONGER THAN IS NECESSARY

TO LOCATE THE CAUSE OF EXCESSIVE VOLTAGE.

6.REFER TO HV, B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS (WHERE

USED).

SUBJECT : IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTEGRA

IMPLOSION PROTECTION SYSTEM. BUT CARE SHOULD BE TAKEN TO

AVOID DAMAGE DURING INSTALLATION. AVOID SCRATCHING THE TUBE.

OF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR

CLOSELY FITTING SHELF SPACE, OVER OR CLOSE TO HEAT DUCT, OR IN

THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS

WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT REAR VENTING.

THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE

SCARVES OR OTHER COVERINGS WHICH MIGHT OBSTRUCT VENTILA-

TION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL

MOUNTING KIT, MUST FOLLOW THE FACTORY APPROVED MOUNTING

INSTRUCTIONS. A PRODUCT MOUNTED TO A SHELF OR PLATFORM MUST

RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT THICKNESS IN SPAC-

ERS)TO PROVIDE ADEQUATE AIR FLOW ACROSS THE BOTTOM, BOLTS OR

SCREWS USED FOR FASTENERS MUST NOT TOUCH ANY PARTS OR

WIRING. PERFORM LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS MOUNT-

ING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRY-

ING TO ROLL A CART WITH SMALL CASTERS ACROSS THRESHOLDS OR

DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND WHICH

HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES. INC. FOR

USE WITH THEIR SPECIFIC MODEL OF TELEVISION RECEIVER OR

GENERICALLY APPROVED FOR USE WITH T.V.S OF THE SAME OR LARGER

SCREEN SIZE.

8.CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE

OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO HOME AND

FAMILY.

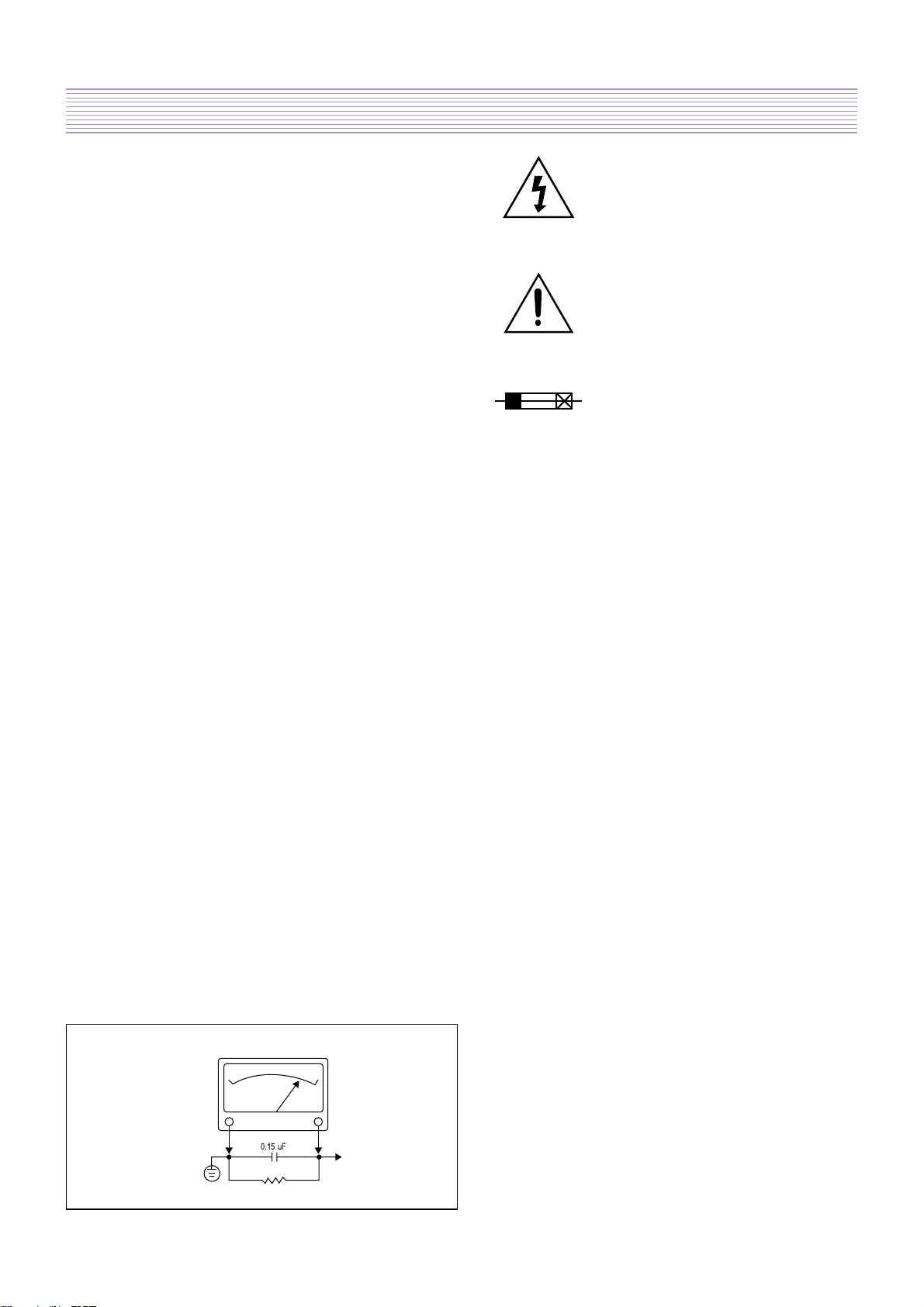

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL,

WITHIN AN EQUILATERAL TRIANGLE, IS INTENDED TO

ALERT THE SERVICE PERSONNEL TO THE PRES-ENCE

OF UNINSULATED “DANGEROUS VOLTAGE”

THAT MAY BE OF SUFFICIENT MAGNITUDE TO CON-

STITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL

TRIANGLE IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION ON SERVICE LITERATURE.

SUBJECT : GRAPHIC SYMBOLS