O-UC12-FEB23-3 Page 1

Health and Safety

Only a qualified refrigeration

engineer/technician, who is familiar with

refrigeration systems and components

including all controls, should perform the

installation and start-up of the system. To avoid potential

injury, use care when working around coil surfaces or

sharp edges of metal cabinets. All piping and electrical

wiring should be installed in accordance with all

applicable codes, ordinances, and local by-laws.

Before Installation

•Ensure the units received are the correct models for the

intended application.

•If the holding charge (4 bars ± 1bar nitrogen) is not

present, do not use the product and contact the sales

representative immediately. (Manufacturer’s warranty is

void for damage caused by incorrect application or unit

mishandling).

•The holding charge should be safely released through

the schrader port on the suction header.

•Check there is no damage to the units (piping not dented,

fan motor’s electrical box with no sign of cracks). Any

damage should be reported to the supplier immediately.

•Check to ensure tightness for the wiring and the fan.

•Check that the proposed equipment locations are suitable

and provide adequate support for the weight of the units.

Offloading and Lifting

•Whenever handling a unit with packaging, it should be

from the base (refer the marking on the carton box) and,

where possible, all packing and protection is kept in

position.

•When offloading the unpacked unit on the ground, the

drain pan shall face upwards to avoid denting the drain

pan (slope).

•Lift the unit from two ends for installation. If a lifting

instrument is used, ensure cushion is used to protect the

unit casing from damage.

•Do not drop the unit. Should this inadvertently happen, it

should be immediately inspected for damage.

During Installation and subsequent maintenance

•Installation and maintenance are to be performed only

by qualified personnel who are familiar with local codes

and regulations and experienced with this type of

equipment.

•Safe working methods are identified, and operatives

have suitable PPE.

•Ensure the working area has adequate ventilation during

brazing procedures.

•The units contain moving machinery and electrical power

hazards, which may cause severe injury or death.

Disconnect and shut off power before installation or

service of the equipment.

•Refrigerant release into the atmosphere is illegal. Proper

evacuation, recovery, handling, and leak testing

procedures must always be observed.

•Units must be grounded to the screw terminal labelled

•No maintenance work should be attempted prior to

disconnecting the electrical supply.

•The electrical covers and fan guards must remain always

fitted.

•Use of the units outside of the design conditions and the

application for which the units were intended may be

unsafe and be detrimental to the units, regardless of

short- or long-term operation.

•The units are not designed to withstand loads or stress

from other equipment or personnel. Such extraneous

loads or stress may cause failure/leak/injury.

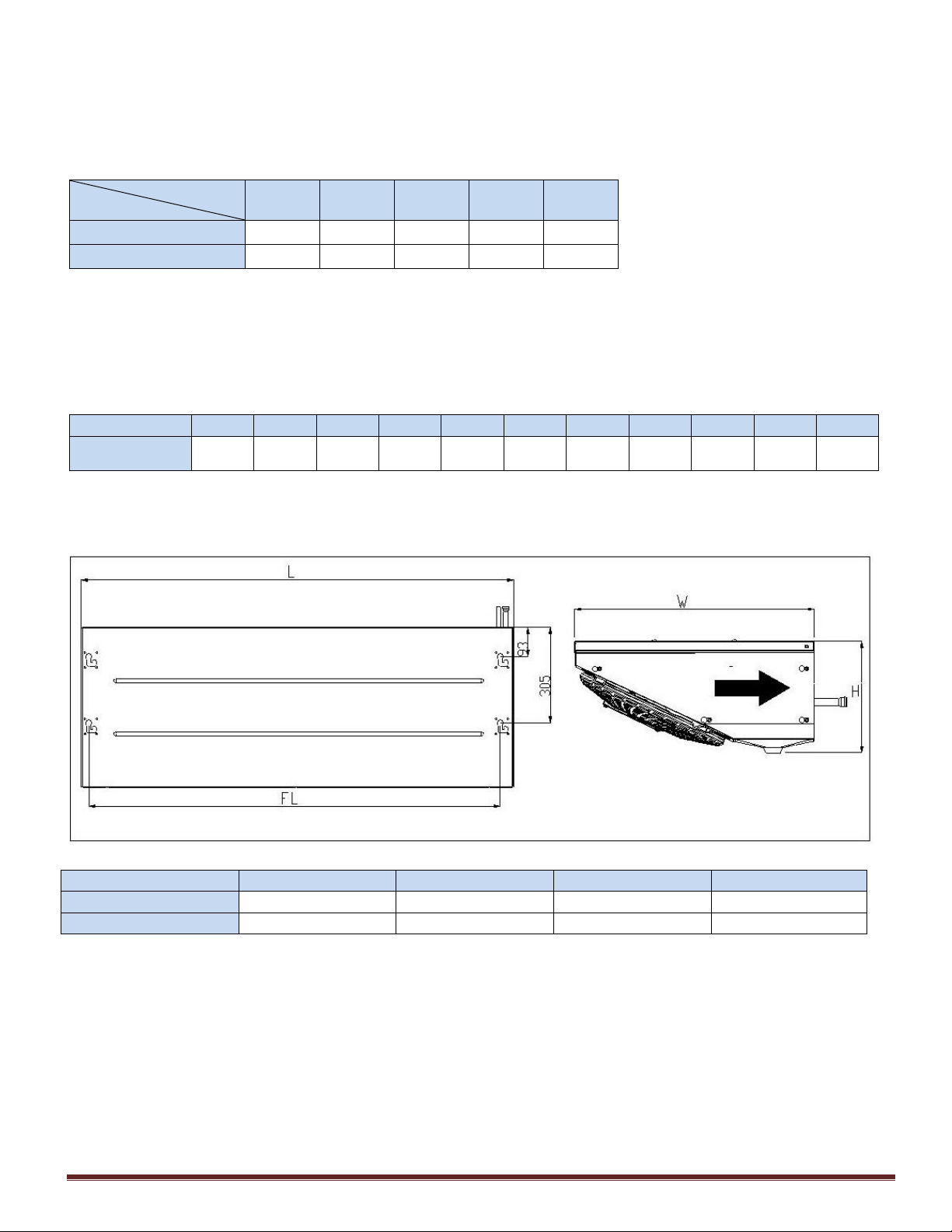

Installation

Unit location and Fixing

•All indoor units must be level in all directions, to ensure

water condensation can be properly drained out.

•The indoor units can be mounted directly to the ceiling

utilizing the fixing holes on the top of the unit. No

additional brackets are required.

•Position the indoor unit where the optimum airflow can be

achieved. Avoid locating in corners or in alcoves which

may restrict airflows. For best performance, it is

desirable to arrange the air blowing toward the door to

minimize the entrance of warm moist air when door is

open. Light fixtures, shelving and product boxes must be

arranged in such that it does not block the air intake and

air discharge from the unit cooler.

•A minimum 10mm raw bolt type fixing is required with a

large steel washer to bear the indoor unit weight. It is

important to ensure that the wall/ceiling can withstand

the unit weight and that all fixings are secure.

•The installation location should allow sufficient space for

air flow and maintenance around the units:

•The fan face must be located a minimum of 600mm (H)

from walls to assure unrestricted air intake.

•Ensure that the ceiling can withstand the unit weight

and that all fixings are secure.