Page 6 of 56

1.2. Specifications

AC INPUT

Mains, voltage ......... 400 VAC, 3 phase, 47 - 63 Hz

Control voltage ..................... 230 VAC, 47 - 63 Hz

AC voltage variation .................................. ±10%

See page 56 for connection to AC mains connector.

DC OUTPUT

Power range ............................................ 3-75 kW

Current: ....... 50 A - 100 A - 150 A - 200 A versions

Voltage. .................... 60 V - 100 V - 120 V versions

PERFORMANCE

Warm up time (cold) .................................. 30 min

Warm up time (stand-by) ........................... 15 min

Drift:

Long term 8 hours ................................. ±10 ppm

Line regulation:

+/- 10 % slow. T > 1 min. ....................... + 5 ppm

+/- 1 % fast. T > 3 ms . ....................... + 5 ppm

Load regulation:

Output ripple and noise

Voltage – Peak-to-peak ....... < 150 mV @ 0-100 kHz

Load Range:

Time Constant (L/R) ................................ 0 - 1 sec

Inductance (L) ......................... 0 - 1 H (standard)

TEMPERATURE COEFFICIENT

Ambient 15 – 40°C ................................. 5ppm/°C

Ambient 15 – 30°C ................................. 1ppm/°C

Current setting resolution ..................... 20 bit DAC

Current reproducibility ............................ ± 10ppm

Absolute current calibration .............. -0 / +400ppm

Current read back resolution ................. 16 bit ADC

Voltage read back resolution ................. 16 bit ADC

Current control range (setting range) ..... 1 – 100%

Ramp speed (0 – 100%).... 0.1 – 10 s (adjustable)*

Current loop bandwidth ........................ 2 – 100 Hz

Voltage loop bandwidth .......................... >200 Hz

*Ramp speed for the bipolar version is limited in

the second and fourth quadrant. See page 21.

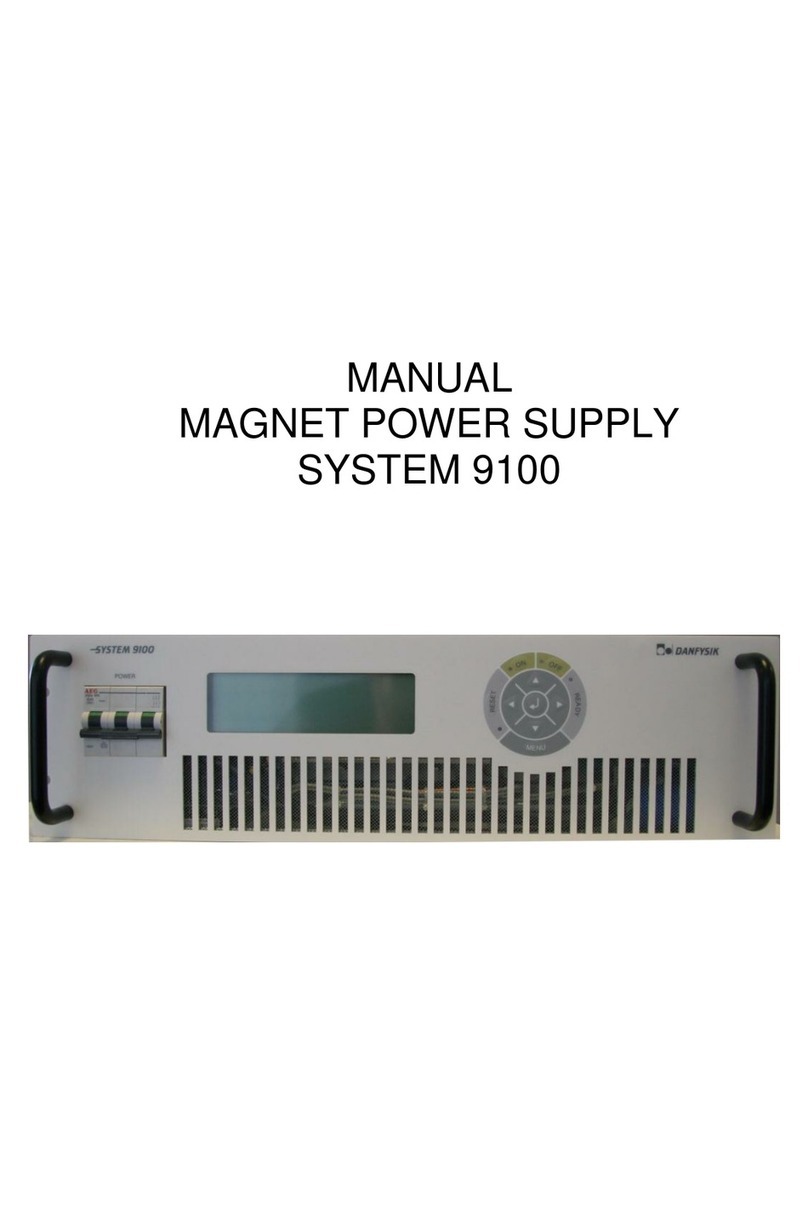

CONTROL PANEL

ALPHANUMERIC LCD DISPLAY:

Preset output current, 6 digits .......................... [A]

Actual output current, 5 digits .......................... [A]

Output voltage, 2 digits ................................... [V]

Interlock status text string

PUSH BUTTONS AND LED'S

OFF .............................................. [Button]/[LED]

Reset (interlock) ............................ [Button]/[LED]

ON ................................................ [Button]/[LED]

Menu .................................................... [Button]

Out of regulation ....................................... [LED]

Remote control / interfacing

RS232 as standard (RS422 and RS485, or SPI are

available on request)

The following status messages are available via the

remote control interface:

ON/OFF command

Reset command

ON/OFF status

Remote status

Output current

Output voltage

Ambient temperature

Delta temperature

Internal power supply 15 V

Internal power supply 5 V

I set value

V set value

The following controls are available via the

analogue control interface:

Set current

Set voltage

Output current read back

Output voltage read back

Interlock status

Over voltage

Over current

Over temperature

Fan fault

Earth leakage

AC fault

Out of regulation

External interlock (ext. 1 – 4)

Summary interlock