5

3. INSTALLATION REQUIREMENTS

Kit Overview

The Water Feature Solution Kit is designed for plug-and-play installation and comes complete with all the necessary

hardware and fittings to do so. Because each installation is different a few locally purchased components are

required to complete installation:

-Hoses –Dankoff Solar recommends flexible suction and discharge hoses, and The Water Feature comes

with the necessary fittings and clamps for this type of hose. Inlet hose size is 1 ¼” and outlet hose size is

1”. Simply ask for ‘suction hose’ at your local hardware supply store to purchase the lengths you will need

for your installation

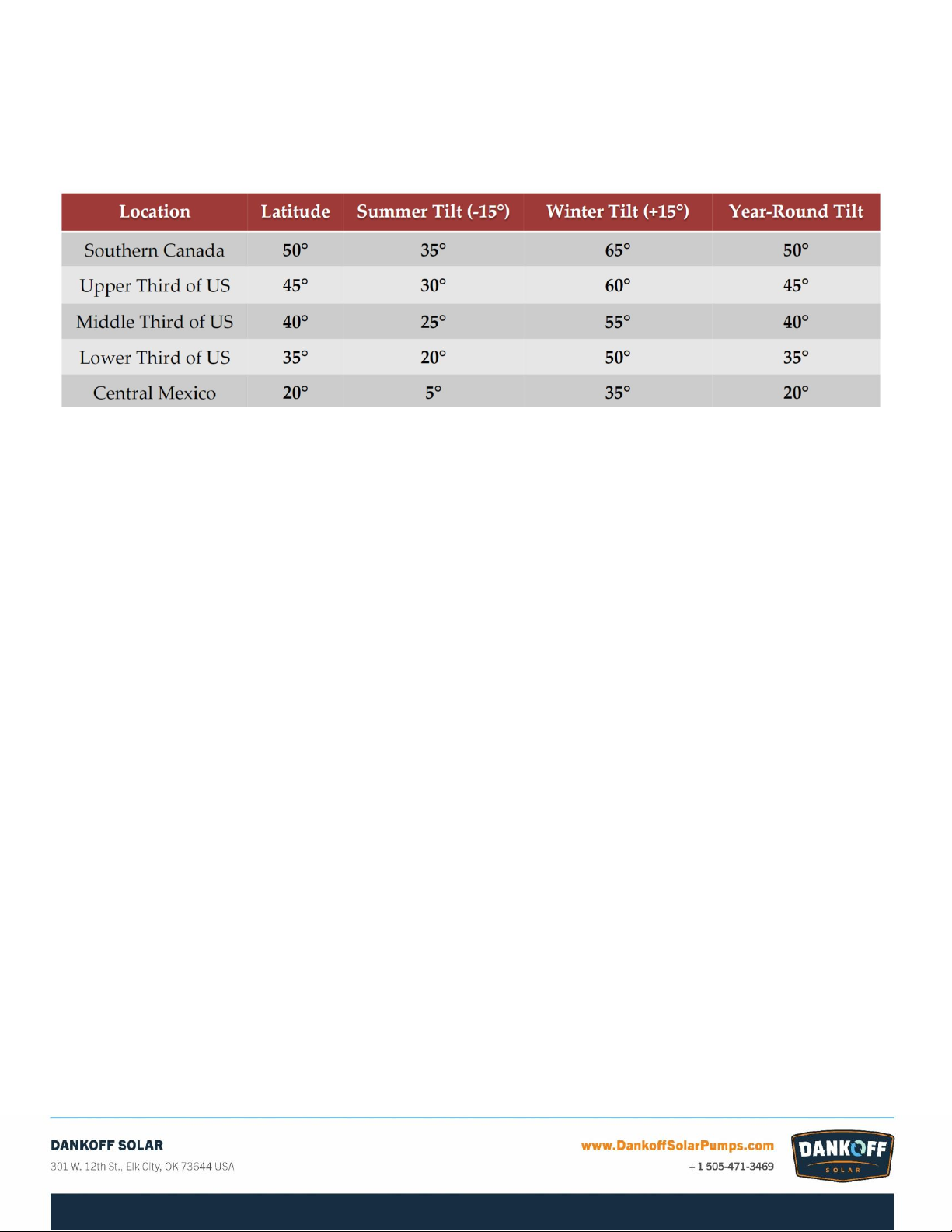

-Rack Mounting Pole –The Panel Rack in The Water Feature Solution Kit includes a gimble that will accept a

3” mounting pole. Dankoff Solar recommends using Schedule 80 pipe, installed 36” below the frost line

using Quickrete, with a minimum of 36” above the ground to accept the rack. PV’s must not be shaded or

blocked at any point during the day to get the stated performance.

-Grounding Rod –Because of the ready availability and to reduce the shipping weight of The Water Feature

Solution Kit, all of the components to properly ground the system are supplied, with the exception of the

grounding rod itself, which can be purchased at any hardware or electrical supply store.

-Pump House/Cover –Because every installation environment is different, the Solution Kit does not include

a generic pump house to shield the pump from the elements, since the pump can be installed in a variety of

ways. Dankoff Solar recommends that the SunCentric pump be shielded from the elements to get the most

out of its 20 year life, and there are many available options that can be purchased locally.

Some ideas include: a curved piece of sheet metal with open ends (the cover should be twice as long as the

pump); a metal barrel cut in half the long way and placed over the pump; any weatherproof box inverted

over the pump; a dog house set it over the pump with the pipes passing through the doorway.

Non-submersible pumps

Do not submerge pump or motor in water, or allow water to drip on the motor.

Filtration requirements

SunCentric Pumps are somewhat dirt tolerant and can be run from many clean water sources without filtration.

However, to prevent possible large debris contamination and to help keep the pump primed, a Dankoff Solar Fine

Intake Strainer Foot Valve (PN –11044) has been provided with the proper fittings.

Pump must not run dry

Water is the lubricant for the pump. If the pump runs completely dry, it will overheat and fail. If pumping from a

tank, cistern or any water source that can run low accidentally, we recommend using a float switch.

A float switch (PN –11004, pump down switch) placed in the supply tank closes when the tank water supply is at a

high level. When the water level drops to a low level, the switch will open and remove power from the pump motor.

This has not been supplied with The Water Feature Solution Kit, as it will only be used in a limited number of

Customer applications.