Datem Neptune 5000 User manual

Neptune 5000

© Copyright Datem Limited 2014

1

Neptune 5000

Technical Manual

Technical Manual

2

Revision History

Page

Number

Issue

Date Description Authority

All Sections 1 21/07/08 Issued to MS. MS

Multiple 2 16/03/10 Electronics Update. MS

All 3 22/07/11 Issued to MS MS

All 4 10/12/12 Client Release AB

All 5 19/03/13 Client Release MS

All 6 05/02/14 Client Release MS

All 7 22/10/14 Client Release AB

This document is the property of DATEM and should not be disclosed without prior written

consent.

Neptune 5000

© Copyright Datem Limited 2014

3

Contents

Re ision History ..................................................................................... 2

Introduction ........................................................................................... 8

System O er iew ................................................................................ 8

System Specification ............................................................................ 9

General System Maintenance ................................................................ 9

Software .............................................................................................. 10

Description ........................................................................................ 10

Specification ...................................................................................... 10

Operational Information ...................................................................... 10

Maintenance ...................................................................................... 10

Trouble Shooting ................................................................................ 11

Topside Control Box ............................................................................... 12

Description ........................................................................................ 12

Specification ...................................................................................... 13

Electrical Installation ........................................................................... 13

Topside Power Supply PCB ................................................................... 16

Topside Telemetry Board ..................................................................... 18

LCD Displays...................................................................................... 20

Maintenance ...................................................................................... 21

Frame Assembly .................................................................................... 22

Description ........................................................................................ 22

Specification ...................................................................................... 22

Assembly .......................................................................................... 22

Maintenance ...................................................................................... 23

Technical Manual

4

Compensator Assembly ......................................................................... 25

Description ....................................................................................... 25

Specification ..................................................................................... 26

Assembly .......................................................................................... 26

Operational Information ..................................................................... 28

Maintenance ..................................................................................... 28

Transformer Pod Assembly .................................................................... 31

Description ....................................................................................... 31

Specification ..................................................................................... 33

Assembly .......................................................................................... 33

Electrical Installation .......................................................................... 35

Operational Information ..................................................................... 37

Maintenance ..................................................................................... 37

Electronics Pod Assembly ....................................................................... 38

Description ....................................................................................... 38

Specification ..................................................................................... 40

Subsea Power Supply PCB .................................................................. 41

Subsea Connector PCB ....................................................................... 42

Subsea Microcontroller Board .............................................................. 45

Subsea Telemetry Board ..................................................................... 47

In erter Pod Assembly .......................................................................... 49

Description ....................................................................................... 49

Specification ..................................................................................... 50

Assembly .......................................................................................... 51

Motor / Gearbox Assembly ..................................................................... 59

Neptune 5000

© Copyright Datem Limited 2014

5

Description ........................................................................................ 59

Specification ...................................................................................... 59

Assembly .......................................................................................... 59

Maintenance ...................................................................................... 60

Thruster Assembly ................................................................................. 61

Description ........................................................................................ 61

Specification ...................................................................................... 61

Assembly .......................................................................................... 61

Maintenance ...................................................................................... 65

Chassis ............................................................................................. 65

Mechanism ........................................................................................ 65

Bearing Housing ................................................................................. 67

Assembly .......................................................................................... 67

Straightener ...................................................................................... 68

Slip-ring ............................................................................................ 73

Cone .................................................................................................... 75

Description ........................................................................................ 75

Specification ...................................................................................... 76

Assembly .......................................................................................... 76

Operational Information ...................................................................... 79

Maintenance ...................................................................................... 80

Cone Rod Assembly ............................................................................... 81

Description ........................................................................................ 81

Specification ...................................................................................... 81

Assembly .......................................................................................... 81

Technical Manual

6

Operational information ...................................................................... 82

Cone-rod Remo al ............................................................................. 82

Cone-Rod Fitting ............................................................................... 83

Maintenance ..................................................................................... 87

Encoder Assembly ................................................................................ 88

Description ....................................................................................... 88

Specification ..................................................................................... 89

Assembly .......................................................................................... 89

Operational information ...................................................................... 89

Maintenance ..................................................................................... 91

Cone-Up Sensor Assembly ..................................................................... 93

Description ....................................................................................... 93

Specification ..................................................................................... 93

Assembly .......................................................................................... 94

Operational Information ..................................................................... 96

Maintenance ..................................................................................... 96

Altimeter Assembly ............................................................................... 97

Description ....................................................................................... 97

Specification ..................................................................................... 97

Assembly .......................................................................................... 97

Operational information ...................................................................... 97

Maintenance ..................................................................................... 98

Fault Finding ........................................................................................ 99

Tools and Equipment ............................................................................ 100

Recommended Mechanical Tool Kit ..................................................... 100

Neptune 5000

© Copyright Datem Limited 2014

7

Recommended Electronics Tool Kit ..................................................... 100

Recommended Specialist Tools ........................................................... 100

Appendix A ......................................................................................... 101

Sample instructions for the wirelock® kit. ........................................... 101

Appendix B ......................................................................................... 103

Material safety data sheet for wirelock® kit. ........................................ 103

Appendix C ......................................................................................... 109

Material safety data sheets for loctite 242 threadlocker. ........................ 109

Appendix D ......................................................................................... 114

Material safety data sheets for HM10 hydraulic oil. ............................... 114

Technical Manual

8

Figure 1: Neptune 5000 CPT System

This document and the content is ©Copyright Datem Limited 2014. No part of this

document may be copied in any way for commercial redistribution, republication, or

dissemination without the explicit written permission of Datem Limited.

Introduction

System Overview

Neptune 5000 Mk II is the Hea y Duty Cone Penetration system designed and

manufactured by Datem. The system uses the Datem Digital Cone to pro ide

accurate in-situ soil data from the transition zone to water depths up to 3000

metres, and will allow seabed penetration of up to 20 metres.

The system consists of the subsea thruster and frame, illustrated in figure 1, a

topside control box for powering the system and pro iding computer

connection, and Datem’s dedicated PC software for control and data

acquisition.

There are a ariety of optional extras that can be purchased from Datem for

use with this system, but this technical manual only co ers the basic features.

Additional technical manuals are a ailable for the optional features. This

Neptune 5000

© Copyright Datem Limited 2014

9

document is intended to gi e technical staff a basic understanding of the

o erall system, its assemblies, and rele ant information to enable routine

maintenance and repair.

System Specification

Dimensions 2.1m * 2.1m * 2.6m

Weight in Air 4000kg approx

Weight in Sea Water 3500 kg approx

Maximum Operating Pressure 300Bar

Thrust Capacity 35kN

Maximum Penetration 20 Metres

Water Depth 3000 Metres

Power requirement 240Vac 1ph 50/60 Hz, 16A

Penetration Speed

2cm/sec ±10%

Retraction Speed 5cm/sec approx.

Cone 5cm

2

/ 10cm

2

/ Custom

Cone Type Non Subtraction Piezo Digital Cone

Frame Inclination Resolution 1.0°

Acquisition RS 232 19,200 baud

Cone Data Rate Selectable up to 20Hz

Frame Sensor Data Rate 1 Hz

Topside Software Windows 7, Vista & XP Compatible

General System Maintenance

When the system is in operation, it should be washed down with clean, salt-

free water whene er it is returned to the deck of the ship. This will reduce

corrosion, and re eal any damage to the frame, pods, compensator, thruster,

or cables.

The electrical cables connected to the sensors, pods, and auxiliary equipment

should be isually inspected regularly to ensure there are no chafes or cuts in

the insulation. The connectors on both ends of the cables should be tightly

fitted with no face gap, and the lock-rings should be finger-tight.

All fastenings should be regularly checked to ensure they are present, tight,

and there is no damage to them or the items they are fitted to.

Reference should be made to the following sections of the manual to fulfil

detailed maintenance requirements, rele ant to each indi idual sub-system

during operation.

Technical Manual

10

Software

Description

The system operation is controlled directly from a Topside computer running

dedicated Neptune 5000 control and data acquisition software. Transmission

from the PC uses either standard RS232 protocol at 19,200 baud or Ethernet.

The data is transmitted to the telemetry system housed in the Topside Control

Box.

Specification

The Neptune 5000 control and acquisition computer software requires a

Personal Computer (PC) that meets the following minimum requirements.

Operational Information

Please refer to the Software manual for information on operating the Control

and Data Acquisition Software.

Maintenance

The only means of maintaining the software is to ensure that the hard dri e

has plenty of space and that running processes on the computer are kept to a

minimum, thus allowing the software to run at maximum speed with no delay.

Remo ing any unwanted applications can be achie ed by na igating to the

computers control panel and then selecting “Add/Remo e Programs”.

It is also good practice to regularly run the Scandisk software (recommended

once e ery month), to ensure that the hard disk is in good condition. Another

recommendation is to ensure that good housekeeping practices are adopted

with regards to file names and locations. This enables the data files from e ery

push job to be located easily and quickly.

Processor

2.0 GHz

Spare Hard Disk Space

80 GB

Memory

2.0 GB RAM

Graphics

128 MB

Resolution (Viewing Area)

1024 x 768 minimum

Ethernet Port

1 For Ethernet Communication

Operating System

Windows 7, Vista, XP

Neptune 5000

© Copyright Datem Limited 2014

11

Trouble Shooting

Where problems are encountered with software, it is generally related to the

installation and un-installation of other software on the PC. The recommended

solution to such problems is to re-install the Neptune 5000 software, using the

installation CD ROM pro ided.

If communication cannot be established when running the software a mis-

configured communication port could be the cause. Ensure that the Ethernet

communication IP addresses are assigned correctly:

IP Address: 192.168.0.55 - 192.168.0.255 (between 55 and 255)

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.0.54

Technical Manual

12

Figure 2: Topside Control Box

Topside Control Box

Description

The Topside Control Box, illustrated in Error! Re erence source not ound.,

is housed in a shock mounted IP65 enclosure. It contains the main system

Topside Transformer, Power Supply Board, Telemetry Board, Data Coupling

Board and LCD Displays.

The Topside Control Box has three connectors on the front. These are a

network connection for Ethernet, a 3 pin male for mains power in, and a 3 pin

female for high oltage power out and the superimposed data. There are also

two LCD displays, one for system current and one for the system high oltage,

and four illuminated push button switches. Three cables are supplied for use

with the Topside Control Box, Mains Supply, PC Ethernet and High Voltage

Deck Umbilical. Only these supplied cables should be used with the system.

Always ensure that all the cables are fitted correctly before supplying power to

the Topside Control Box. When power is supplied, the “MAINS POWER” red

push button switch will illuminate indicating that the supply is a ailable and

the Topside Control Box is in Standby mode. To switch on the Topside Control

Box, press the “MAINS POWER” green push button switch. The LCD displays

will switch on, the “MAINS POWER” green push button switch will illuminate,

the “MAINS POWER” red push button switch will go out and the “HIGH

VOLTAGE” red push button switch will illuminate. The Topside Control Box is

now li e but the CPT high oltage supply is not on.

Neptune 5000

© Copyright Datem Limited 2014

13

To switch on the CPT high oltage supply, press the “HIGH VOLTAGE” green

push button switch. This green button will illuminate and the “HIGH VOLTAGE”

red push button will go out. The subsea CPT is now li e.

Specification

Dimensions

0.4m x 0.6m x 0.8m Nominal

Weight

46 Kg

IP rating

65

Power requirement

240Vac 1ph 50/60 Hz, 16A from on

line

UPS with adjustable output oltage

Umbilical Out

put

650Vac 1ph 50/60 Hz

Meter Readings

System current

Umbilical HV oltage.

Main Fuse rating

MCB: 16A Type B

WARNING:

Appropriate safe working practices should be followed to ensure that all

hazards are minimised. It should be noted that although the power

switches may be turned off, there are still li e terminals inside the box.

Electrical Installation

Wiring schematic diagrams of the Topside Control Box are illustrated on the

following pages. It should be noted that none of the circuit boards used in the

Topside Control Box contain any user ser iceable parts, other than fuses. For

this reason there are no circuit board diagrams included in the manual. The

indi idual circuit boards are co ered in greater detail later in this document.

Technical Manual

14

Figure 3: Topside Control Box Wiring Schematic

Neptune 5000

© Copyright Datem Limited 2014

15

Figure 4: Topside Control Box Wiring Layout

Technical Manual

16

Figure 5: Topside Power Supply Board

Topside Power Supply PCB

Overview

The Topside Power Supply PCB pro ides the power needed by the Topside

Telemetry PCB, the High Voltage and Mains Current sensing circuits, and the

LCD displays. The Topside Power Supply Board is illustrated in Error!

Re erence source not ound.. The board contains the sensing circuits used

to measure the umbilical High Voltage and the Mains Input Current and

outputs these measurements for indication on the oltmeter and ammeter

displays.

Topside Power Supply Circuit Description

The Topside Power Supply Board has the following plug connections:

PL1 Supply input to the Current Sensing Circuit

PL2 Supply output from the Current Sensing Circuit

PL3 Supply input to the High Voltage Sensing Circuit

PL4 Supply Output from the High Voltage Sensing Circuit

PL5 Sensor output to Voltmeter Display

PL6 Sensor output to Ammeter Display

PL7 Voltmeter Display power

PL8 Ammeter Display power

PL9 Telemetry PCB Power

The supply input on PL1 passes through the current sensing circuit and is then

split to pro ide power to the power supply circuitry before passing to PL2.

Neptune 5000

© Copyright Datem Limited 2014

17

The Power Supply Circuitry pro ides +15Vdc, -15Vdc, +5Vdc, -5Vdc and 0V.

The +/-15Vdc and 0V is used to power the Topside Telemetry Board and the

+/-5Vdc and 0V is used to power the sensing circuits and the LCD displays.

Green LED indicators show the status of the four dc oltages. During normal

operation all four indicators will be illuminated. If any are not illuminated this

is indicati e of a fault and the Topside Control Box should be switched off. The

fault should be in estigated and rectified before switching on the Topside

Control Box.

The Current Sensing Circuit consists of a current sensing transformer (CT1)

and amplification stage. The ammeter signals are output on PL6, and PL8

pro ides the +/-5Vdc power to the ammeter display.

The High Voltage output from TXF1 connects to the Topside Power Supply

Board on connector PL3. It then passes through the high oltage sensing

circuitry and then exits the board on PL4. The high oltage sensing circuit

comprises a di ider network, isolating transformer (TR1) and a bridge rectifier.

The oltmeter signals are output on PL5, and PL7 pro ides the +/-5Vdc power.

The Topside Power Supply Board has only one fuse, FU1. This pro ides

protection for the power supply components only. If this fuse blows this is

indicati e of a fault and the Topside Control Box should be switched off. The

fault should be in estigated and rectified before switching on the Topside

Control Box.

WARNING

Whene er the Topside control box is switched on the Topside Power

Supply Board could ha e both 240 ac and 650 ac on arious exposed

components

Specification

Supply Input

240Vac

+/

-

10%

Supply Input Current

500mA

Low Voltage Outputs

+/

-

15Vdc

, +/

-

5Vdc

Fuse ratings

FS1: 1A

Technical Manual

18

Figure 6: Topside Telemetry PCB mounted on Adapter

Topside Telemetry Board

Overview

The Topside Telemetry PCB, illustrated in Error! Re erence source not

ound. and the Topside Data Coupling Board, illustrated in Error! Re erence

source not ound., pro ide the telemetry link with the Subsea Telemetry PCB

located in the Subsea Electronics Pod and the Subsea Data Coupler PCB

located in the Subsea Transformer Pod.

The telemetry system gi es a transparent, full-duplex serial link between the

Topside PC and the Subsea Microcontroller capable of transferring data at

19200 baud. The digital information is superimposed on the high- oltage CPT

supply by means of frequency-shift keying (FSK). The Topside Telemetry

Board transmits using a different carrier frequency than the Subsea Telemetry

Board (1.00MHz and 1.37MHz, respecti ely), so that the data reception circuit

is able to decode alid subsea messages while filtering out its own

transmissions.

Neptune 5000

© Copyright Datem Limited 2014

19

Figure 7: Data Coupler PCB

The Data Coupler PCB is used to superimpose Topside FSK data on to the high

oltage CPT supply and, con ersely, to reco er FSK data from the Subsea

Telemetry PCB. The high oltage supply is connected to the data coupling

board ia J1. The data is passed to J2, the gold coax connector, which is in

turn connected to the telemetry board.

Since the oltage le els of the reco ered FSK data are dependent on the

length of the umbilical cable, both telemetry boards carry out an automatic

“tuning” sequence during power-up, in order to set the reco ery threshold

oltage. If, for example, power has been applied to the Topside Control Box

but not to the subsea CPT, the Topside Telemetry PCB will repeat its tuning

sequence until the Subsea Telemetry Board has been powered up. Once

communication has been established, each board continuously transmits a

“handshake” message while checking for recei ed handshake messages. (This

process is independent of any communications between the Topside PC and

the Subsea Microcontroller.) A breakdown in telemetry communications,

indicated by a loss of handshake messages, immediately causes both boards

to repeat the tuning sequence.

LED Indicators

Se en LED indicators are fitted to the Topside Telemetry Board. Three green

LEDs show the power supply status: “+15V” and “-15V” are generated by the

Topside Power Board, while “+5V” is deri ed from the +15V supply by an on-

board oltage regulator. Four yellow LEDs monitor communications acti ity:

“Rx0” is illuminated whene er a character is recei ed from the Topside PC;

Technical Manual

20

Figure 8: LCD Voltmeter and Ammeter Displays

“Tx0” when a character is transmitted to the Topside PC; “Tx1” when a

character is transmitted to the Subsea Telemetry Board; “Rx1” when a

character is recei ed from the Subsea Telemetry Board.

Automatic Tuning

The automatic telemetry tuning sequence takes approximately 5 seconds if

both telemetry boards are acti e and there are no hardware faults. During

tuning, the “Tx1” LED is illuminated, while the “Rx1” LED turns on and off at

about 1 second inter als. Once two-way communication has been established,

both “Tx1” and “Rx1” will blink ery rapidly at about equal intensity, showing

that handshake messages are being transmitted and recei ed. After a

successful tuning sequence the Topside Telemetry Board stores its tuning

results together with those obtained from the Subsea Telemetry Board. These

results are displayed on the Engineering Screen of the Neptune 5000 program.

(“Le el” is a code related to the recei ing circuit threshold oltage; “Quality” is

a alue corresponding to the number of consecuti e alid tuning strings

recei ed while ramping up the threshold oltage – the “Quality” alue

decreases as the umbilical length increases.) If the tuning sequence keeps

repeating, it may be that the Subsea Telemetry Board is not powered up or

the umbilical is not connected.

LCD Displays

The Topside control box has two LCD display modules mounted behind

Perspex windows on the front panel. The display modules are factory set up to

display either System Umbilical Voltage or Topside control box Mains Current

input.

Table of contents

Popular Industrial Electrical manuals by other brands

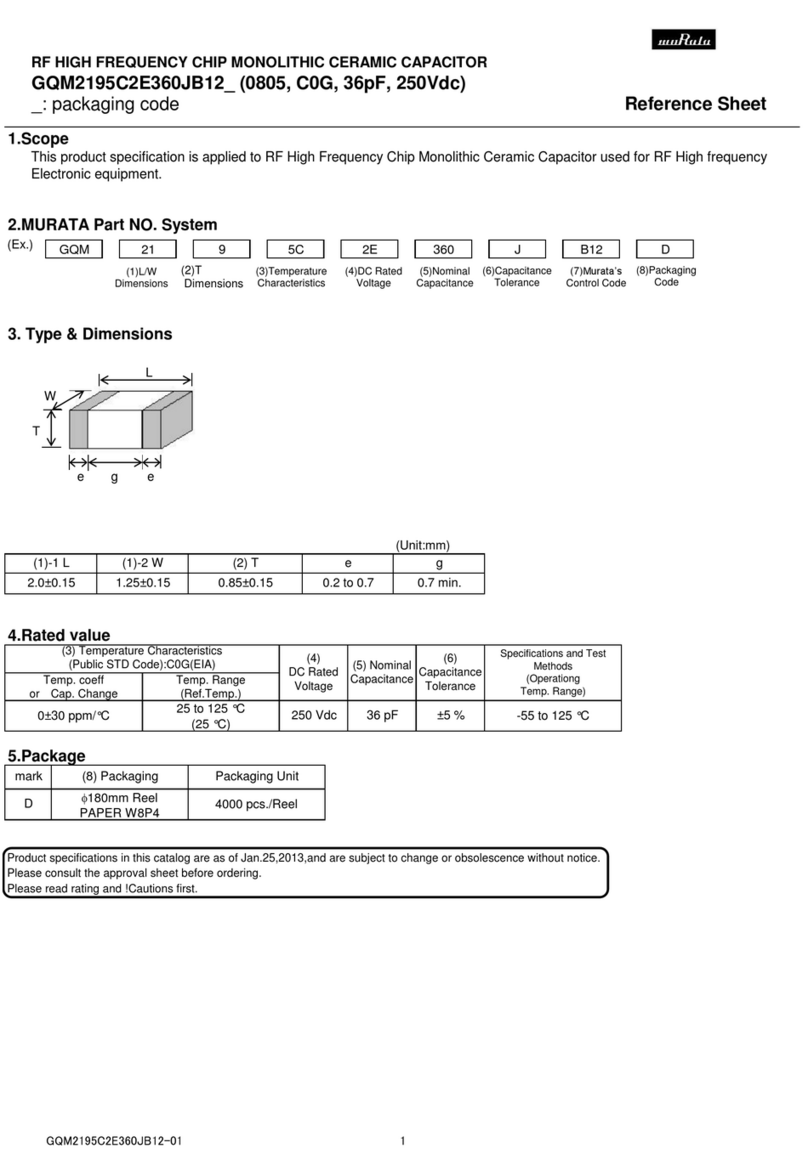

Murata

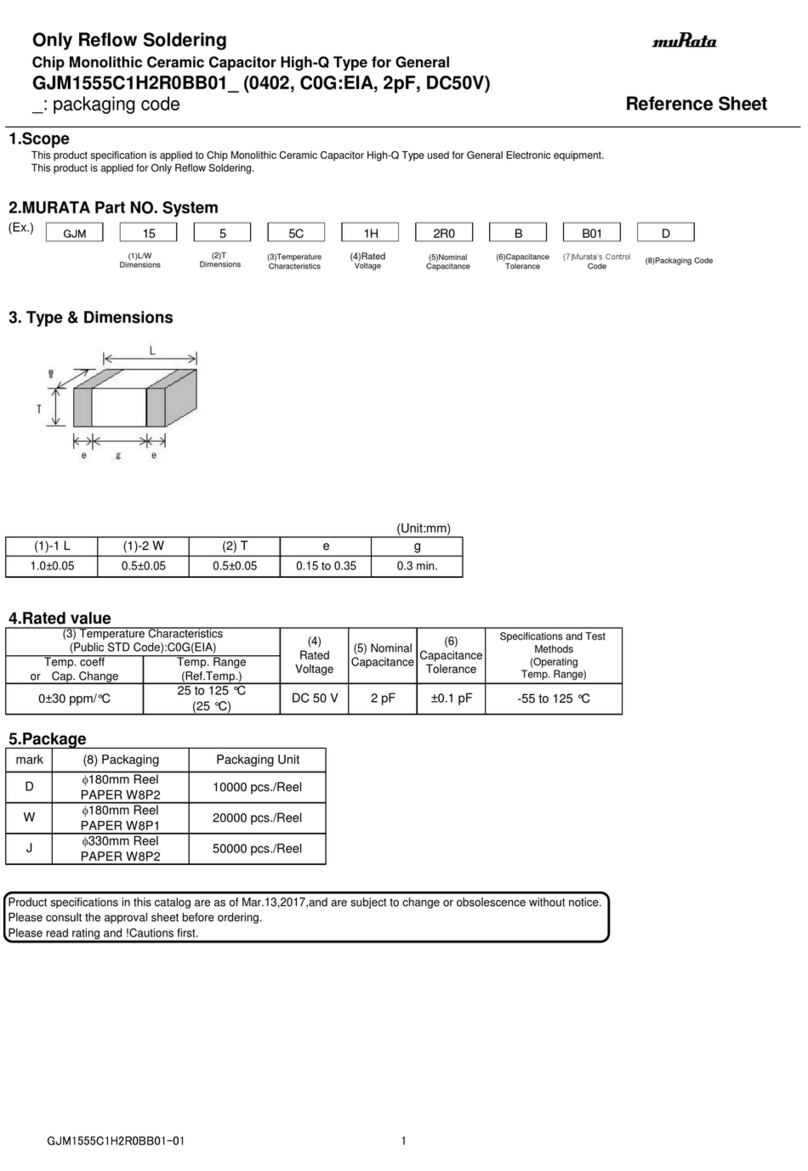

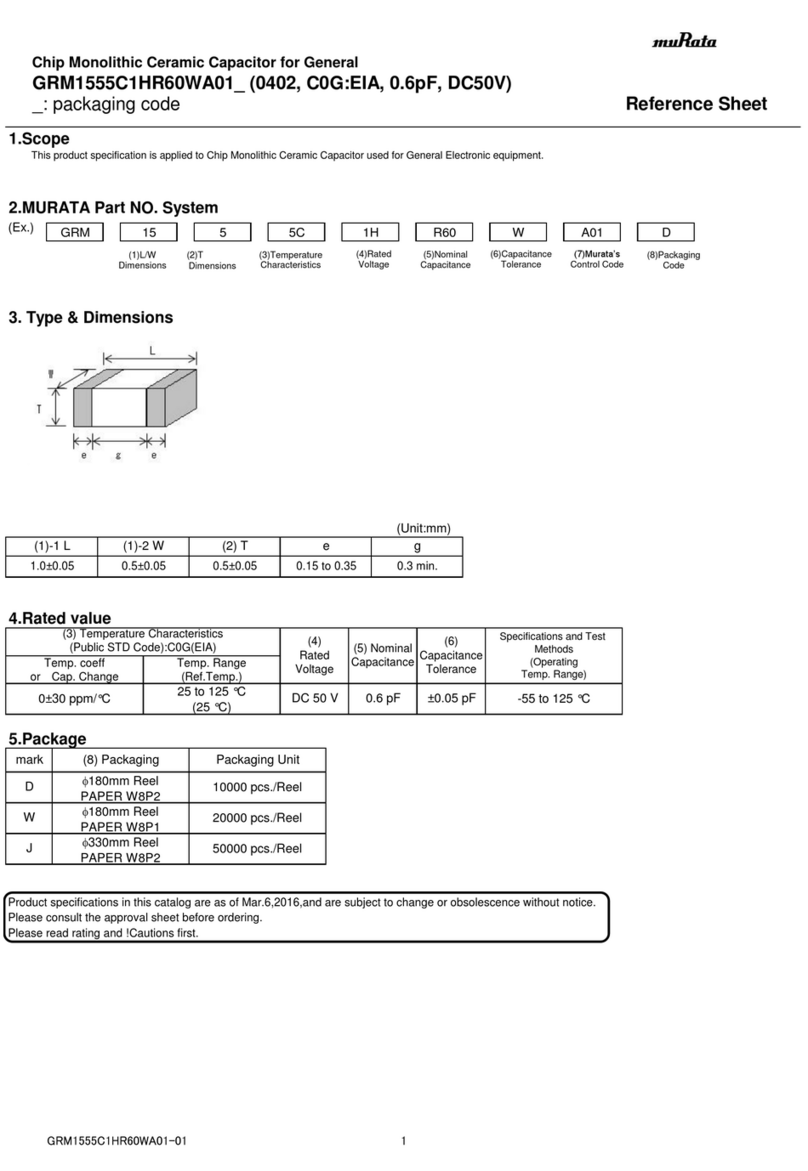

Murata GRM1555C1HR60WA01 Series Reference sheet

Pfisterer

Pfisterer MV-CONNEX 3 installation instructions

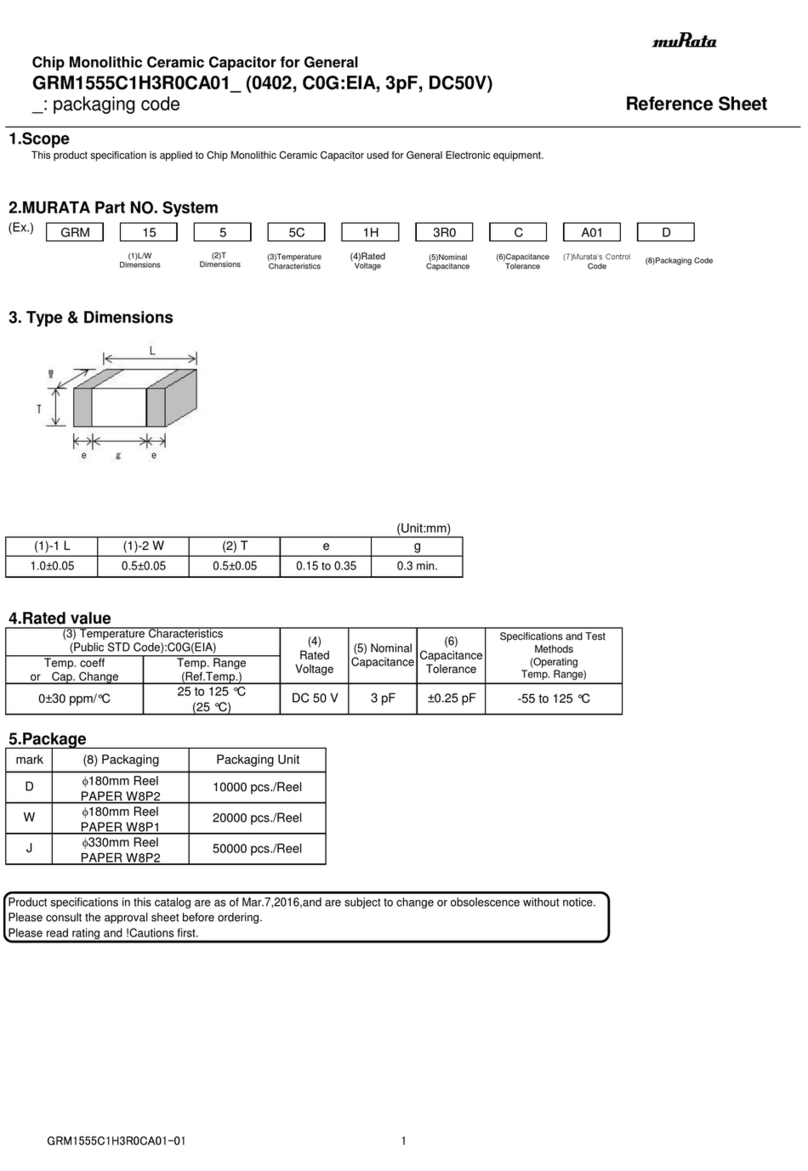

Murata

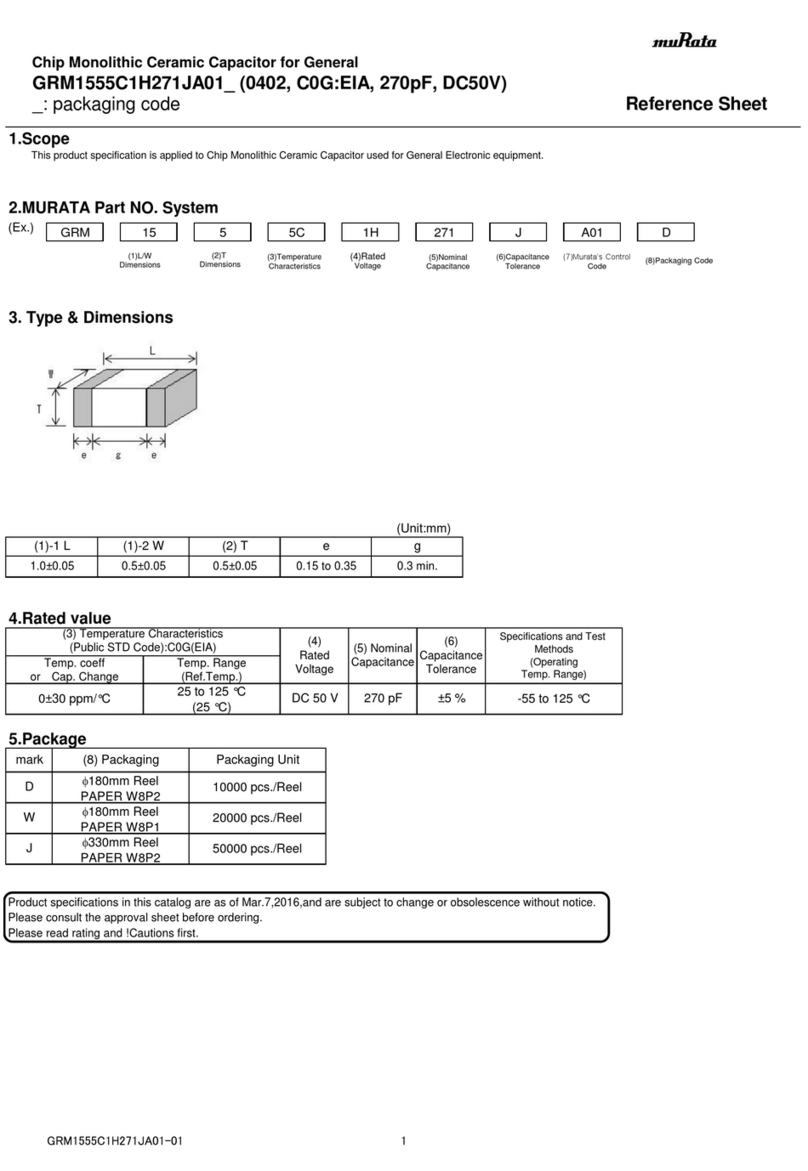

Murata GRM1555C1H271JA01 Series Reference sheet

Leviton

Leviton 23030-L Installation

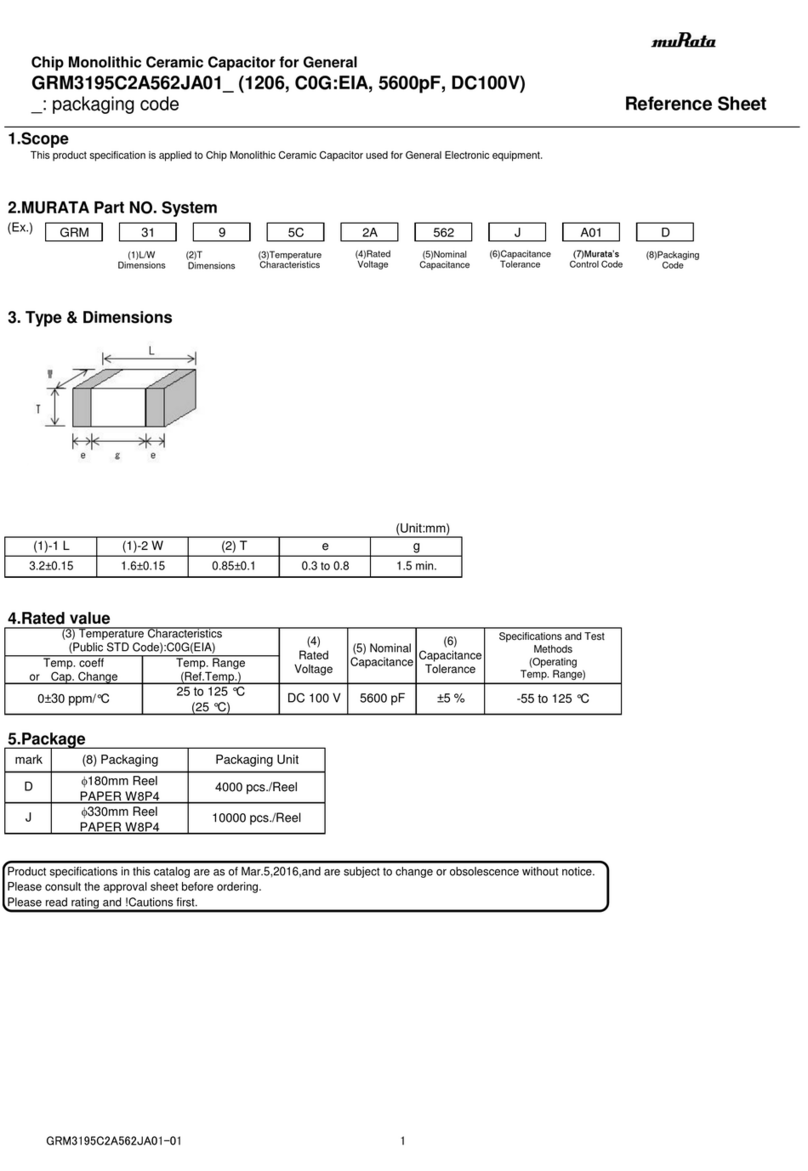

Murata

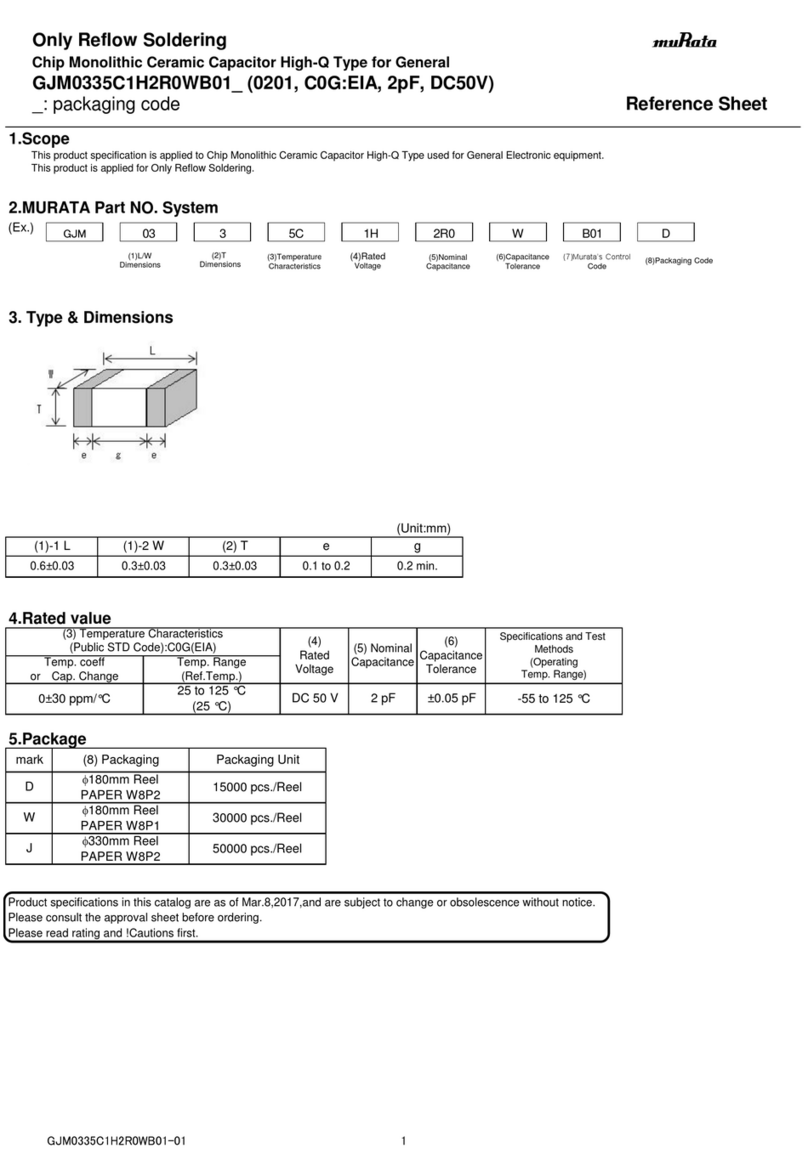

Murata GJM0335C1H2R0WB01 Series Reference sheet

Murata

Murata GQM1555C2D1R1WB01 Series Reference sheet

SSS Siedle

SSS Siedle VNG 602-02 Product information

HEIDENHAIN

HEIDENHAIN LB 302 Mounting instructions

Siemens

Siemens 3TF68 Q Series operating instructions

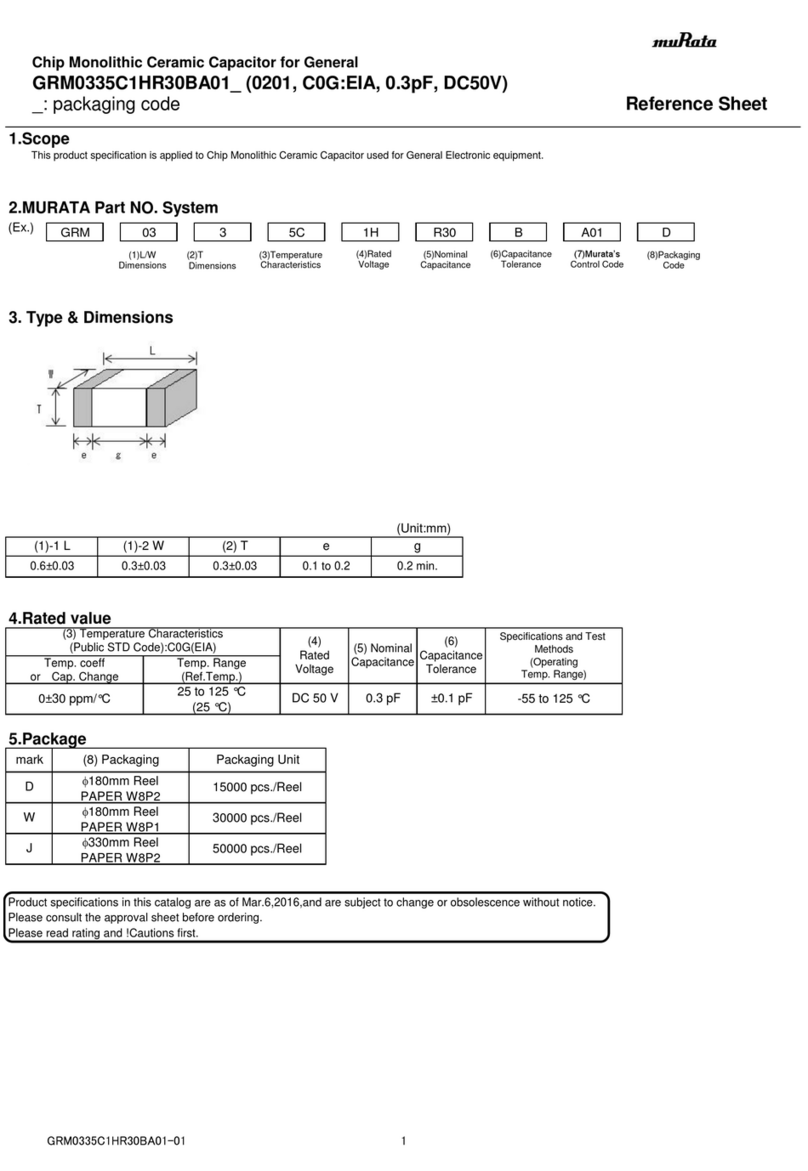

Murata

Murata GRM0335C1HR30BA01 Series Reference sheet

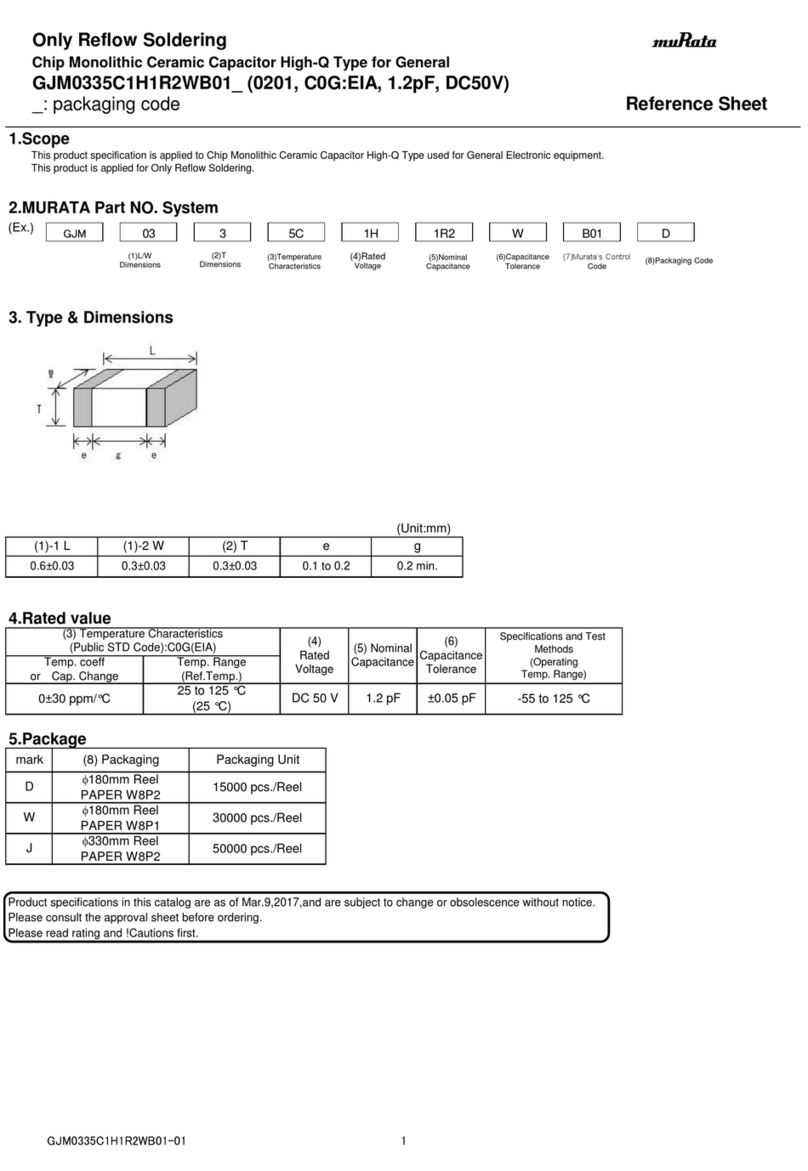

Murata

Murata GJM0335C1H1R2WB01 Series Reference sheet

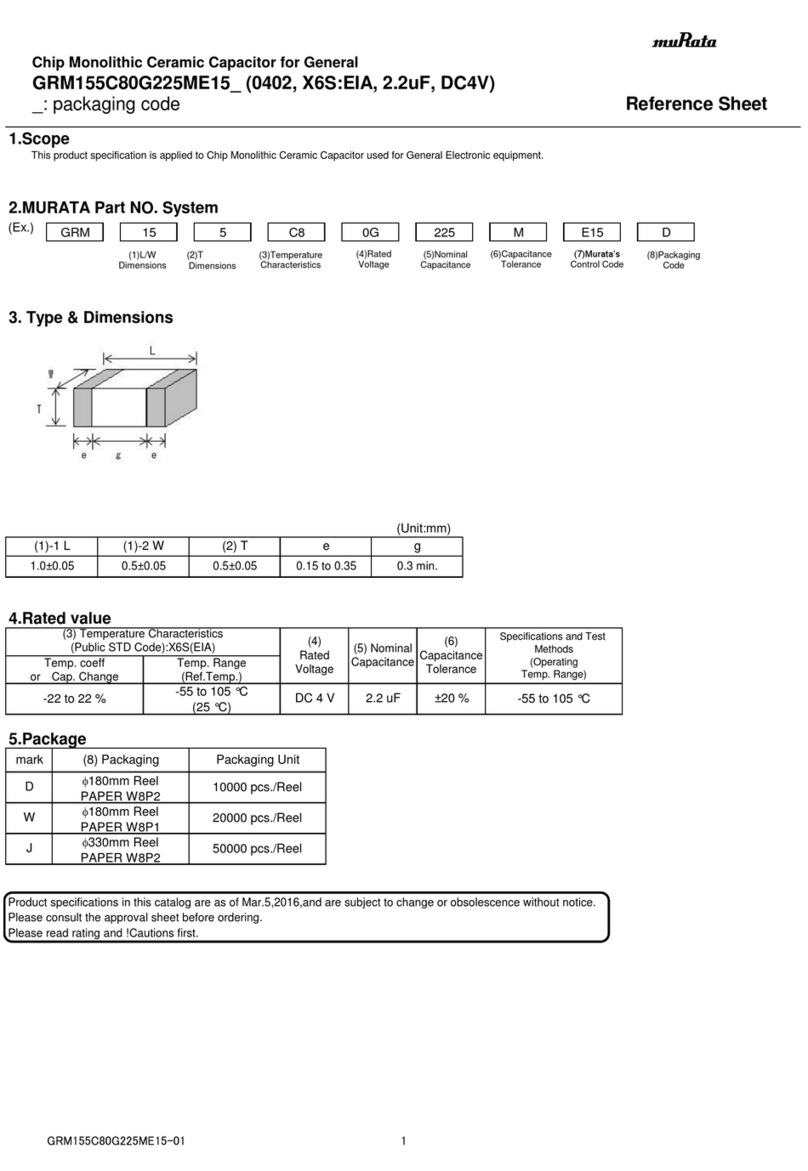

Murata

Murata GRM155C80G225ME15 Series Reference sheet