Datum Trak-Slider User manual

Trak-Slider Instructions

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

1/4-20 x 3/4"

Hex Head Bolt

1/4-20 x 1/2"

Allen Cap Screw

1/4-20 x 3/8"

Pan Head Phillips

Machine Screw

#8 x 3/8"

Tek Screw Phillips

1/4-20 Flanged

Hex Nut

1/4-20 Nylock Nut

1/4 USS Flat Washer

1/4-20 "J" Type

Tinnerman Nut Wheel End Stop

3/4"SQ x 1/2" High

Black Self Adhesive

Rubber Bumper

3/4" Hex x 5/16-18 x 1 1/4" Max

Hex Stem/Base Glide

3/16" Allen Key

Short Arm

NOTE: All Hardware shown actual size.

Gusset

Rivet

2

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

Top Stabilizer Channel

A11858-36

Connector Channel

B11810-36

End Cap

B11798

Stainless Steel Front Cap

B11811-36

Conversion Plate

B11808

Tri-Slider Top Stabilizer

Bracket Assembly

TSRB

Tri-Slider Hat Channel

TSHC

Carriage Assembly

D11885

Decking

D11812

Rail Assembly

D11884

PARTS LIST

Safety Stop

A11891

One Piece Bi-Slide Roller Bracket

B12764

3

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

NOTE: All shelving used on a Datum Bi/Tri Slider system must have the same overall height. The

shelving must also have a minimum of 1-1/2" of clearance from the floor to the filing surface of the

bottom shelf.

TOOLS REQUIRED: 7/16" wrench & socket set

7/32" socket

small flat blade screwdriver

phillips screwdriver

5/16" drill bit

screw gun

4 foot bubble level

water level, laser level or transit

hammer

STEP 1: Assemble the rear stationary shelving sections according to the manufacturer's instructions

and position on the floor. Be sure to level this row before moving on to the next assembly step.

When using Datum stackable shelving you must use 2" bases with built-in leveling guides and 1"

tops. It is recommended that stationary sections be secured to wall.

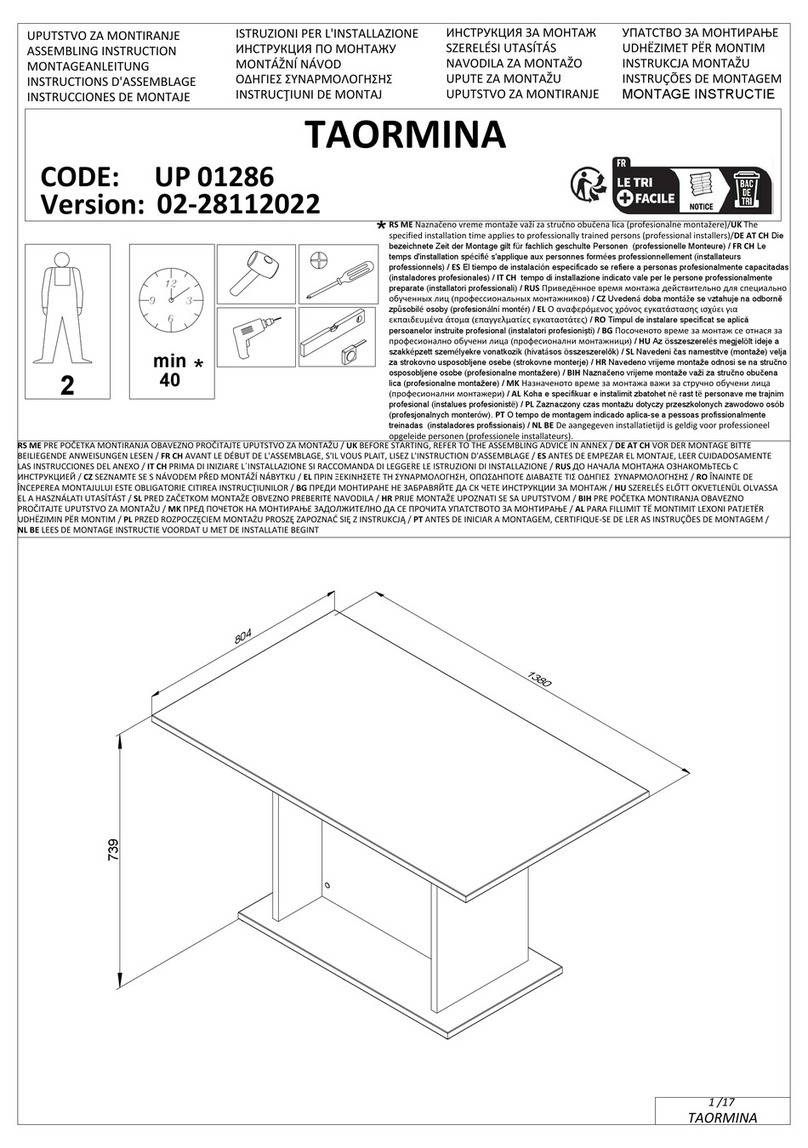

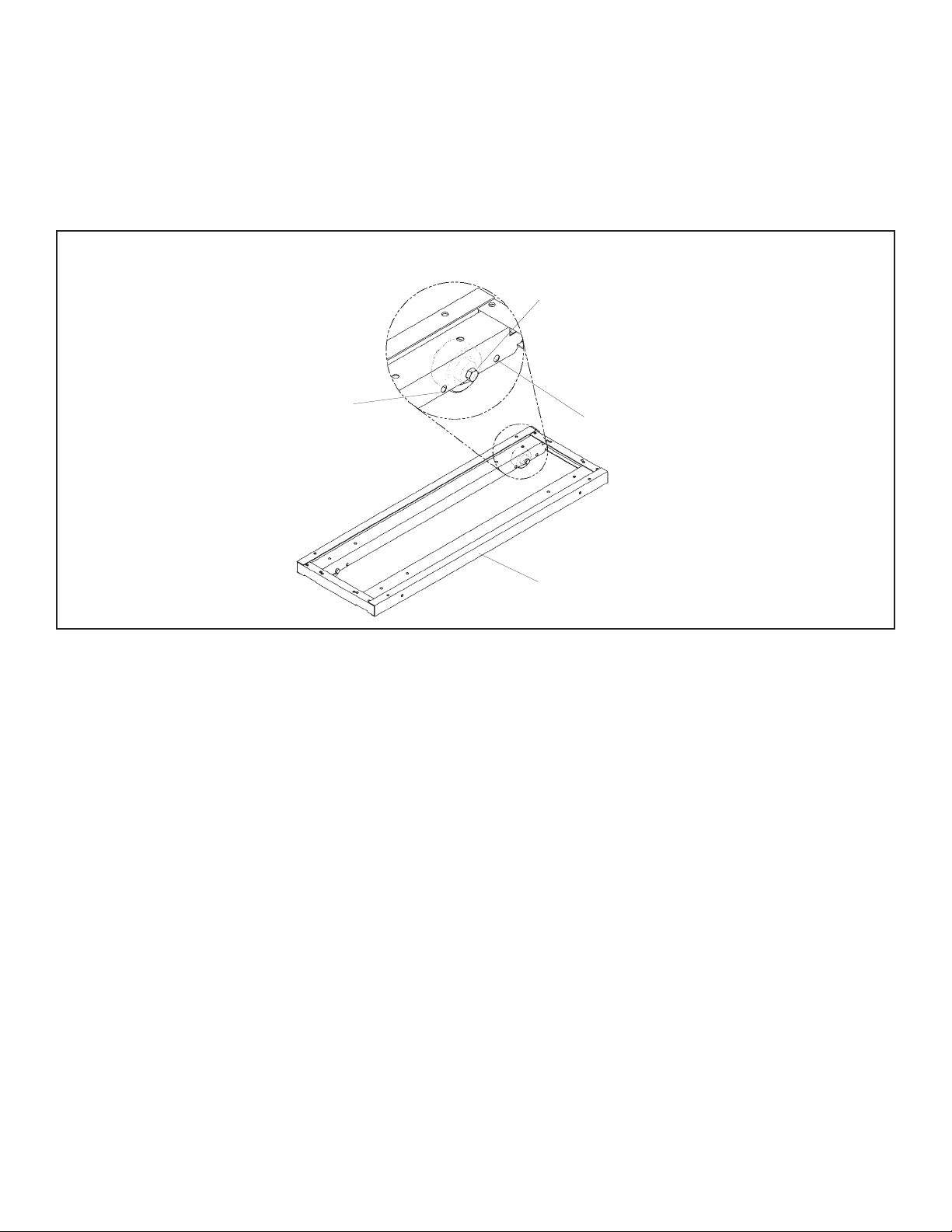

STEP 2: Attach the top stabilizer channels to the tops of the stationary sections. Position each

channel flush with the front and even with the sides of each of the top section (Holes are pre-

punched in the 1" high top when using Datum Stackable Shelving.) Attach the channel using three

1/4-20 X 3/4" bolts and flange nuts. Repeat for each rear stationary section. (See figure 1.)

STEP 2A: FOR TRI/QUAD SLIDER SYSTEM ONLY. Follow directions in step 2; however, attach

additional top stabilizer channels directly in back of the first row using three 1/4-20 x 3/4" bolts and

flange nuts. (As described in step 2, holes are pre-punched for Bi and Tri-Slider hat channels only

when using Datum 1" high tops.) Repeat for each rear stationary section.

NOTE: For Quad-Slider systems it will be necessary to pre-drill tops for attachment of top stabilizer

channel.

4

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

1/4-20 x 3/4" Hex Head Bolt

1/4-20 Flanged Hex Nut

Top Stabilization Channel

FIGURE 1

5

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

NOTE: All systems will consist of one starter rail assembly and the required amount of add-on rail

assemblies. Example: A B632LT consists of (1) #36LTBSST; starter and (2) 36LTBSAO; add-on

(Part numbers are found on each box.) The starter rail assembly contains one section of rail and

hardware. The add-on rail assembly contains one section of rail, hardware and one mobile carriage.

All mobile carriages are preset at the factory to include 2" of overtravel. Systems up to a 4/3

configuration for Bi/Tri/Quad do not require overtravel. Overtravel can be increased or decreased as

needed, please refer to the diagram below for more information.

STEP 3: Install 12 leveling glides per rail section making sure that each one is screwed in and flush

with the bottom of the rail assembly.

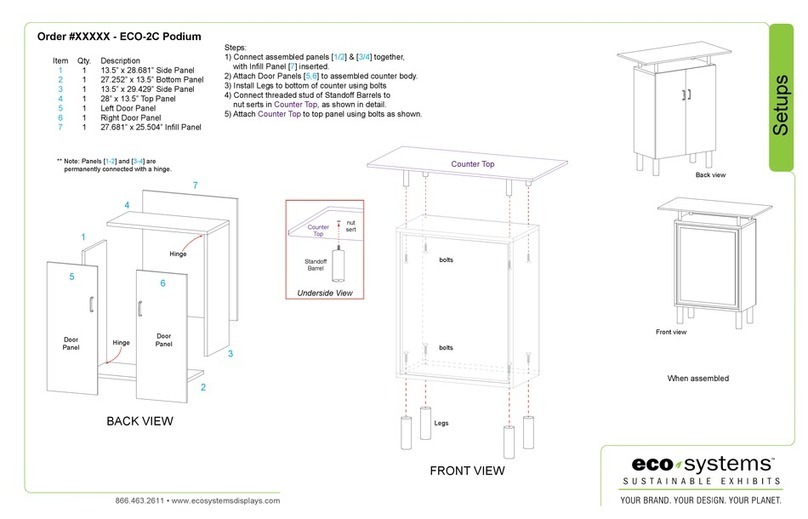

STEP 4: Position stationary connector channels on the front bottom of each stationary base. Attach

each connector channel using a minimum of (4) #8 x 3/8" tek screws (See figure 2, detail A).

STEP 5: Join rail assemblies together using (4) 1/4-20 X 3/4" bolts and flange nuts. Rail sections will

have corresponding holes for attaching side to side (See figure 2, detail B2). Position rail assembly

on floor, do not attach to connector channel at this time.

STEP 6: Attach the deck end cap to the rail section starting from the left end of the rail assembly

using (2) 1/4"-20 X 3/4" bolts and flange nuts (See figure 2; details B1, B3). Repeat procedure for

right side of system.

STEP 6A: FOR TRI/QUAD SLIDER SYSTEMS ONLY. Position additional row(s) of rail sections in

front of Bi-Slider rail sections described above. Attach deck end cap to Bi-Slider and Tri-Slider track

assembly using (4) 1/4-20 X 3/4" bolts and flange nuts. Repeat procedure for right side of system.

STEP 7: Attach the assembled rail section to the connector channel. The rail assembly will have

corresponding slots which will secure to the connector channel. (See figure 2).

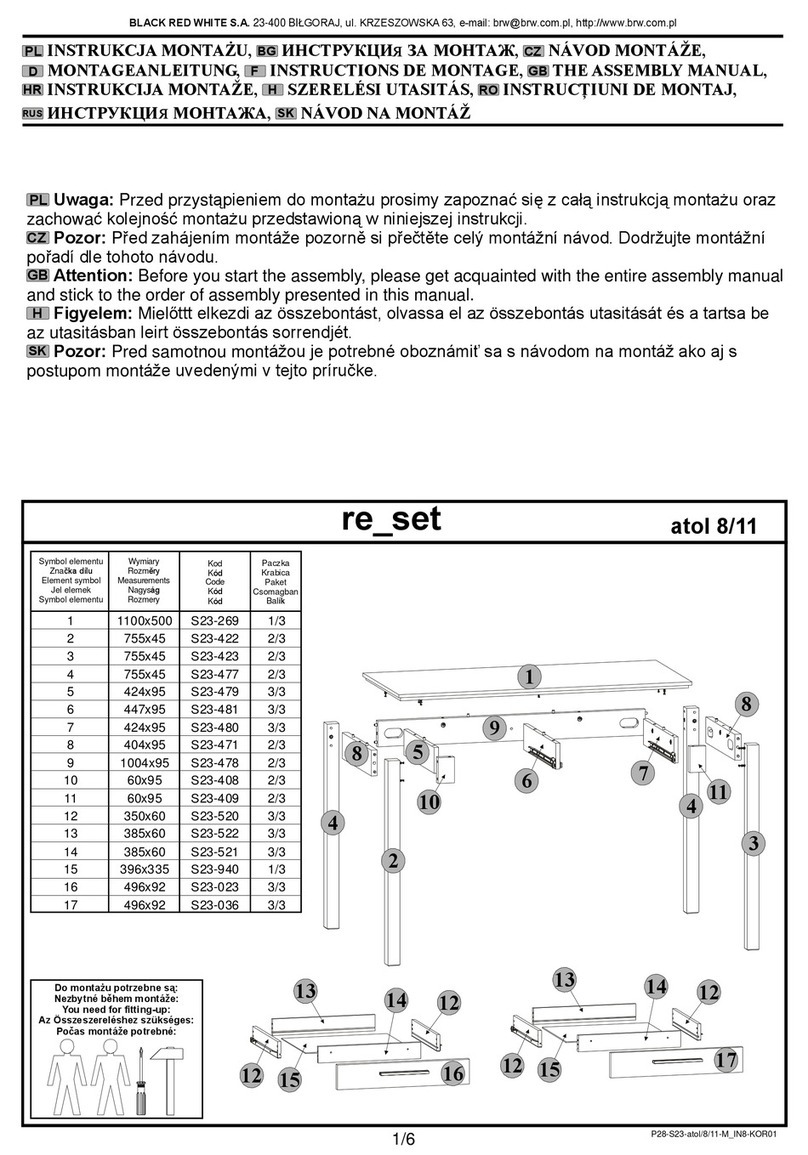

Standard Placement Of Wheel Assembly

For 2" Overtravel (Center Holes). No Need

To Adjust For Systems Up To A 7/6

Bi/Tri/Quad Configuration.

Placement Of Wheel Assembly For No

Overtravel (Outside Holes). Adjustable If

Necessary Up To A 4/3 Bi/Tri/Quad

Configuration.

Placement Of Wheel Assembly For 4"

Overtravel (Inside Holes). For Systems

Greater Than 7/6 Configurations.

Typical Bi/Tri Slider Mobile Carriage

Proper Placement Of Carriage Wheels For Overtravel

6

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

FIGURE 2

DETAIL A

DETAIL B

DETAIL C

DETAIL D

Tek Screw

Connector Channel Glide

1/4-20 Flanged

Hex Nut

End Cap

Front Cap

Support

7

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

STEP 8: LEVELING: Determine highest point on the rail assembly. Working out from this point,

level the rail by adjusting the leveling glides. IMPORTANT! For system to function properly all rails

must be level from left-to-right, front-to-back, and rail to rail. All leveling glides must be in contact

with the

floor.

STEP 9: Install decking. Deck sections interlock with the rail assembly and should be flush with the

top of the rails when installed. (See figure 3).

STEP 9A: TRI/QUAD SLIDER SYSTEMS ONLY. Install additional sections of decking which span

between two rail assemblies (See figure 3).

STEP 10: Attach stainless steel front cap to each rail section by snapping over front rail cross-mem-

bers (See figure 3, Detail C). Repeat for remaining rail sections.

FIGURE 3

DETAIL C

DETAIL D

Stainless Steel Front Cap

1/4-20

Allen Cap Screw

Wheel End Stop

Decking

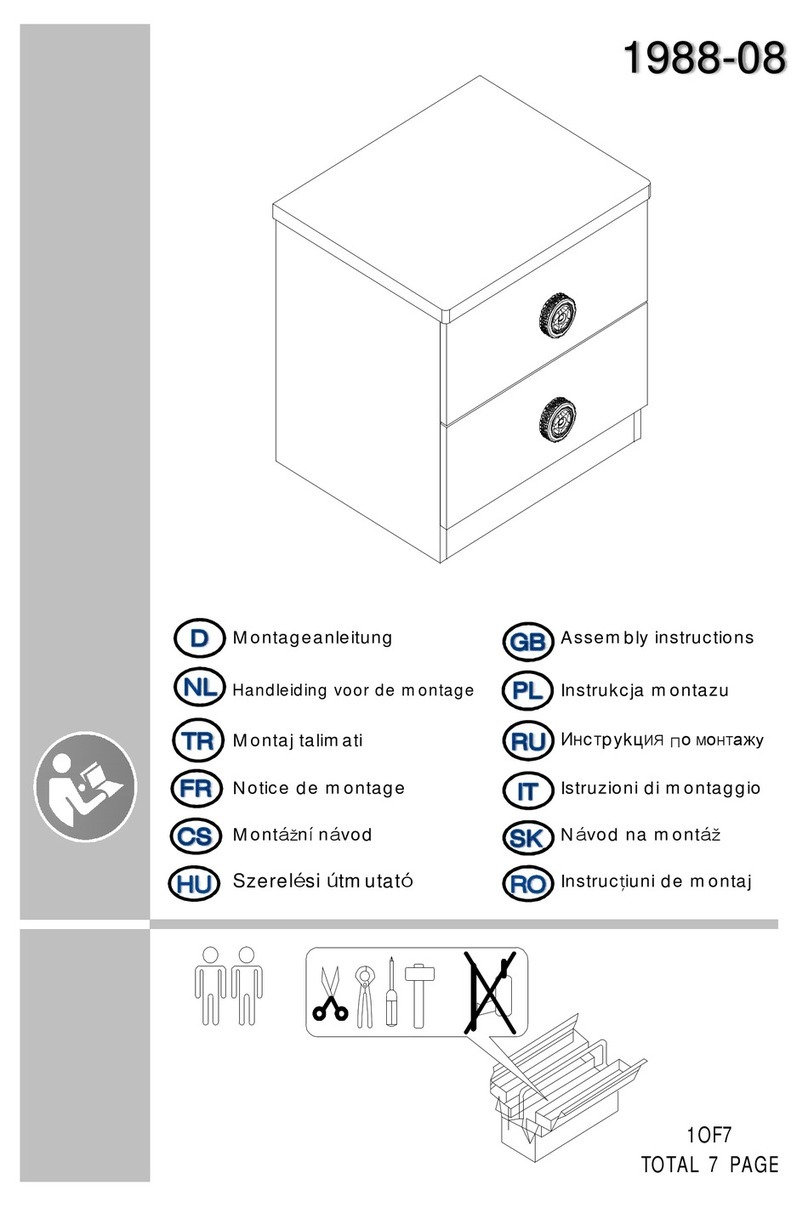

STEP 11: Attach 2" bases to mobile carriage using (4) 1/4-20 x 3/4" hex bolt and 1/4-20 nylock nut

(See figure 4). NOTE: When using Datum 2" bases, the carriages and bases will have pre-punched

holes for attachment.

STEP 11A: When installing 4-post shelving conversion plates are required to prevent shelves from

shifting on carriage (See figure 4). Assemble four-post shelving as per manufacturer's instructions

and attach to carriage. NOTE: It is recommended that single rivet shelf supports (Not included) be

used for secure attachment to mobile carriage.

STEP 12: Assemble Datum ThinStak Shelving, as per assembly instructions supplied, and attach to

2" base.

8

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

STEP 12B: Note: Gussets are used on moveable shelving units only. Assemble shelving as per

shelving instructions. Before securing top cover to top tier, slide a gusset into each rear corner of the

top cover and secure with 1/4-20 screws and nuts as shown. Secure remaining screws and nuts as

shown in shelving instructions. Repeat steps for all moveable units.

STEP 13: Install rolling carriages onto rail.

FIGURE 4

1/4-20 x 3/4" Hex Head Bolt

1/4-20 x 3/4" Hex Head Bolt

2" Stackable Base

Carriage Assembly

Conversion Plate

1/4-20 Nylock Nut

1/4-20 Nylock Nut

Self Adhesive Bumper

Install Rivets Here

4 Holes Per Tier

Install Additional Rivets Here When

Using On Trak-Slider Carriage

1/4-20 Pan Head Phillips

Screw

1/4-20 Flange Nut

Gusset

Tier

Top Cover

Important: Step 12a-12b for Datum Thinkstak Shelving

STEP 12A: Each movable shelf section will require 6 rivets per shelf opening. Please refer to the diagram

below for proper rivet placement. Additional rivets are included in each hardware kit.

9

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

FIGURE 5

1/4-20 x 3/4" Hex

Head Bolt (3 reqd.)

1/4-20 Nyloc Nut

(3 reqd.)

1/4-20

Nylock Nut

(Typical)

Quad-Slider

Top Stabilizer

1/4-20 x 3/4"

Hex Head Bolt

(Typical)

Tri-Slider

Top

Stabilizer

Tri-Slider

Hat

Channel

Quad-Slider

Hat

Channel

Top Cover

(Movable Unit

New Style Roller

Bracket

1/4" Flat Washer

STEP 14: Mount a top stabilizer bracket assembly to the top of each Bi-Slider rolling section using (3) 1/4-20 x 3/4" hex

bolts, (3) flat washers and (3) 1/4-20 nylock nuts (holes are prepunched when using 1" tops). See figure 5.

STEP 14A: Tri/Quad Slider system only. Mount the Tri-Slider hat section to each front rolling section using eight hex

1/4-20 x 3/4" bolts and (8) 1/4-20 nylock nuts. Attach Tri-Slider top stabilizer bracket to hat channel using (4) hex 1/4-20

bolts (See figure 5).

NOTE: If the top roller mount assembly rubs along the stabilizer channel, the roller must be adjusted. Loosen the two

bolts which secure the rollers to the roller bracket assemblies. Adjust so that each roller moves freely in the channel.

Firmly re-tighten each bolt after adjustment.

STEP 15: After all carriages have been installed, install wheel end stops onto rail using one 1/4"-20 x 1/2" allen cap

screw (See figure 3-detail D). One pair of end stops are required for each end of system.

STEP 16: Remove (1) 1/4-20 x 3/4" hex head bolt from far left and far right side of top stabilizer channel. Insert over-

head safety stop to each end of top stabilizer channel and re-attach using the 1/4-20 x 3/4" nut and bolt

(See figure 6).

STEP 17: Install 1 pair of black self-adhesive rubber bumpers to each rolling carriage (See figure 4). NOTE: One pair

is needed between two mobile carriages.

10

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

FIGURE 6

Safety Stop

SAFETY PRECAUTIONS

1) Read through these instructions again insuring that all steps were completed.

2) Recheck and tighten any loose bolts or fittings.

3) Check to see that all top stabilizer channels are securely fastened to the tops of the stationary sections.

4) Check to insure that the end stops are securely fastened to the rail assemblies.

5) If attaching stationary section to wall make sure to follow manufacturers recommendations.

LOADING FILES

Loading a Bi/Tri Slider system in the correct manner is very important. It balances the paper weight load

throughout the entire system and minimizes the odds of having to move the rolling sections every time the system is

accessed. Careful planning of this phase of the installation will make filing and retrieval a lot easier.

It is recommended the system be loaded first from the left rear section followed by the first rolling section on the

left side of the Bi-Slider. If a Tri-Slider is installed, next load the first rolling section on the left side of the front row

(See figure 7).

Repeat loading from the rear to the front until completed.

RE-LEVELING THE DATUM BI/TRI SLIDER SYSTEM

It rarely occurs; however, after the Bi/Tri Slider system has been loaded, the rolling sections may begin to move

or creep on their own. While this problem is more annoying than hazardous, it may be corrected by re-leveling the rail

assembly. The Datum Bi/Tri Slider system has been designed so that the deck plates can be easily removed for access

to the leveling glides.

To remove the deck plates, move the rolling sections to one side. Then, insert a slotted screw driver into the slot

provided on the decking and with even pressure pull the deck plates up and remove.

Next, re-adjust the leveling glides by turning them one-quarter turn at at time either raising or lowering the rail

assembly to the desired height to stop the unwanted movement. It is very important that all leveling glides maintain con-

tact with the floor. When this adjustment has been completed, re-install the deck plates.

If other problems occur which have not been addressed in these assembly instructions, please call Customer

Service at 888-891-1970 x 8958.

Thank you for purchasing and installing this system.

1

2

3

4

5

6

7

8

9

1

2

4

5

7

8

10

11

13

36912

BI-SLIDER

TRI-SLIDER

FIGURE 7

BI-SLIDER

TRI-SLIDER

11

American Filing Solutions P.O. Box 891719, Temecula, CA 92589 Toll Free: (888) 891-1970 x 8958 Fax: (888) 891-9970 Email: [email protected] www.FilingToday.com

Table of contents

Popular Indoor Furnishing manuals by other brands

WATSON

WATSON 360.394.1300 Assembly

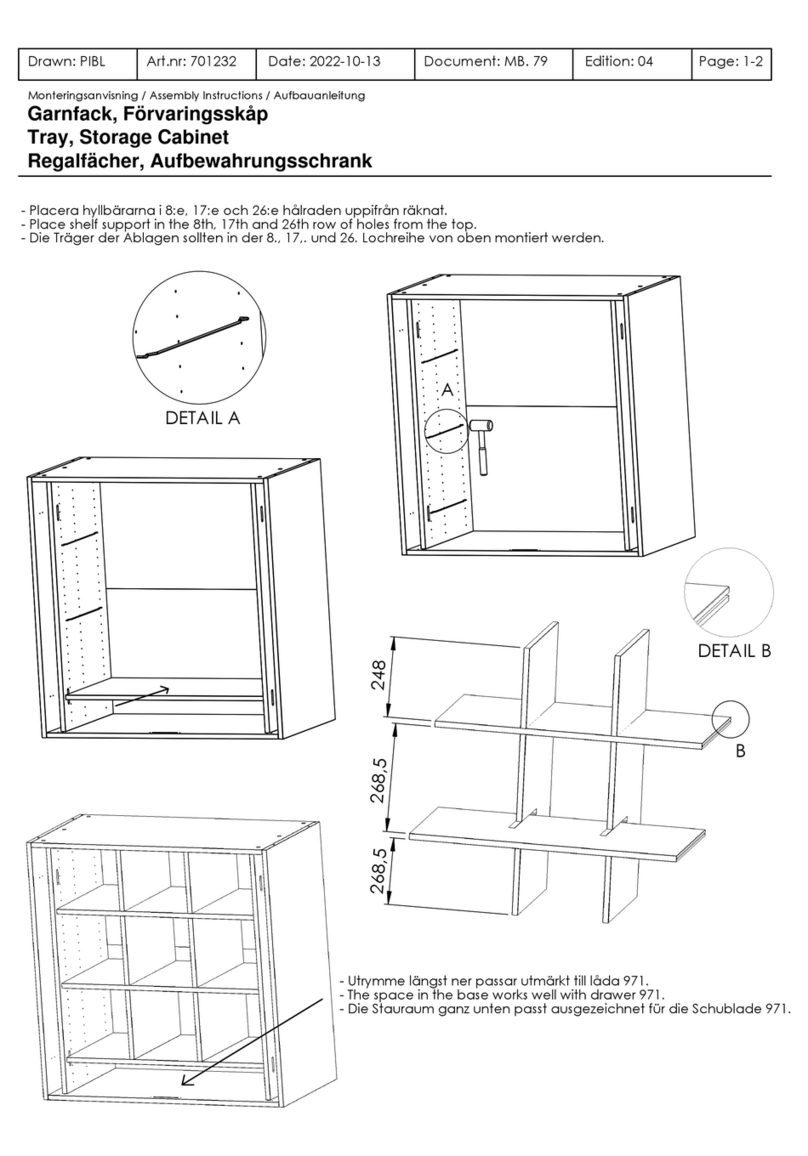

Sjobergs

Sjobergs 701232 Assembly instructions

Studio Designs

Studio Designs HOME CORBEL 74000 Assembly instructions

PHI VILLA

PHI VILLA THD5-0601-118 Use and care guide

Livarno Living

Livarno Living 114815 Assembly instruction

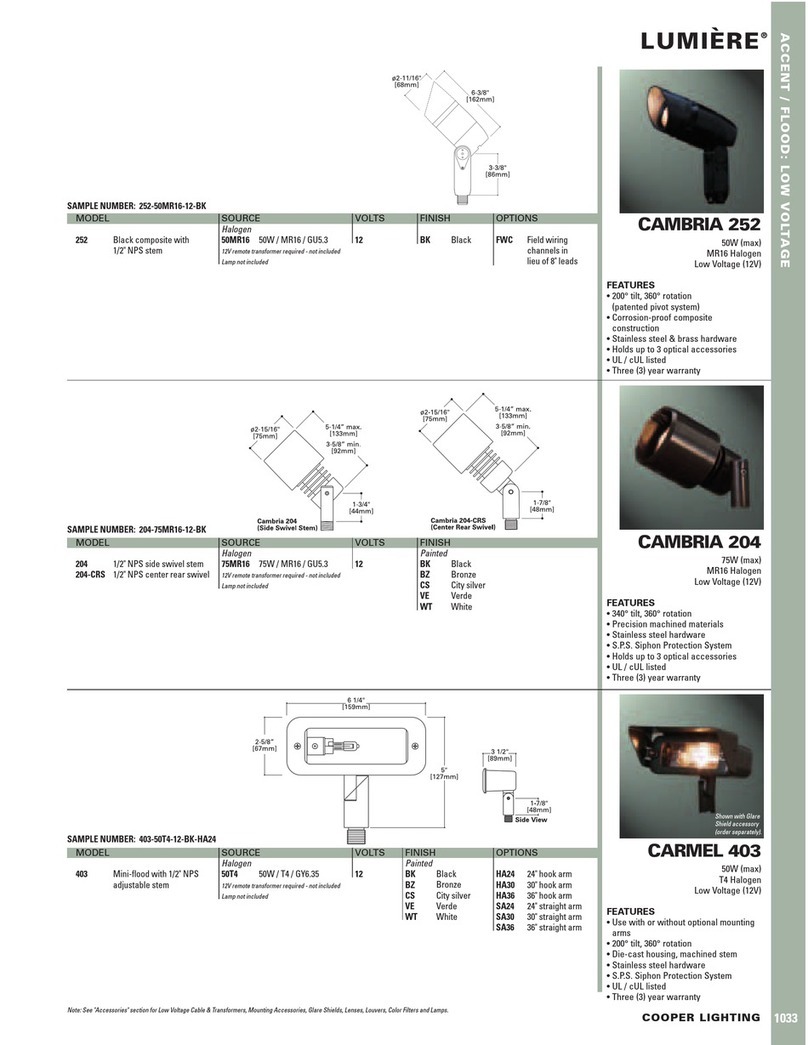

Cooper Lighting

Cooper Lighting Cambria 403 Specification sheet

FMD Furniture

FMD Furniture HALLO 2 210-002 Assembly instructions

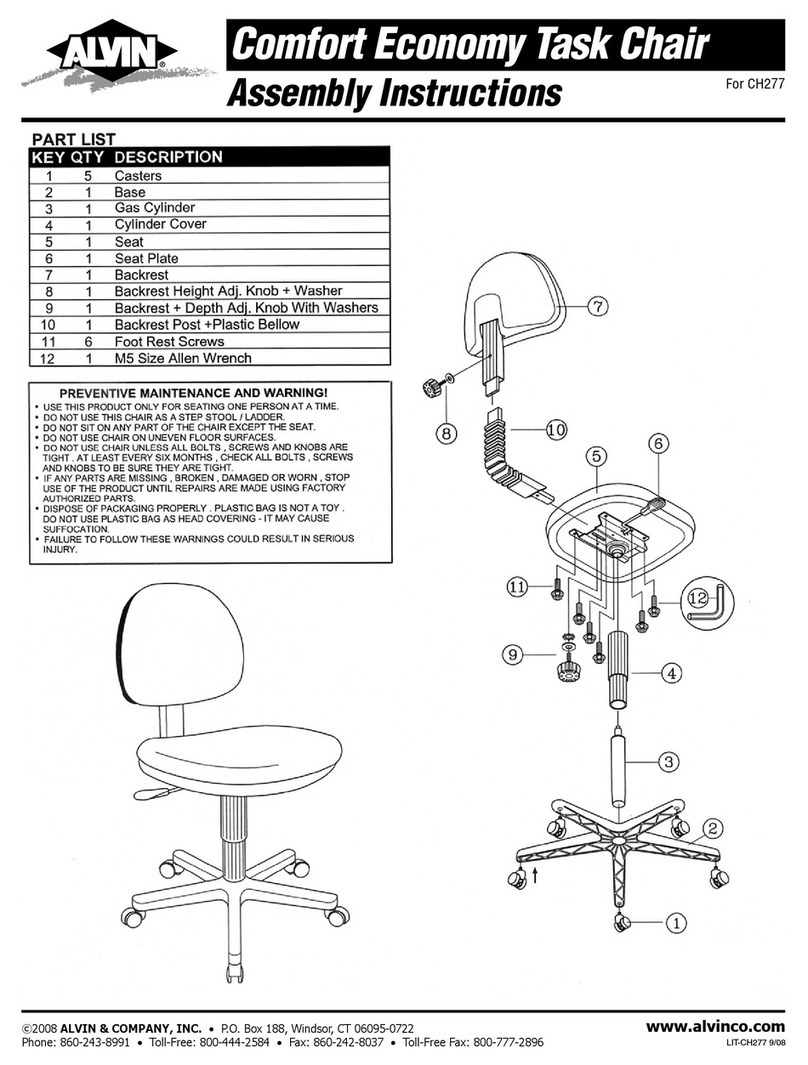

Alvin

Alvin Comfort Economy CH277 Assembly instructions

Easylife

Easylife EL6697 instruction manual

Triarch

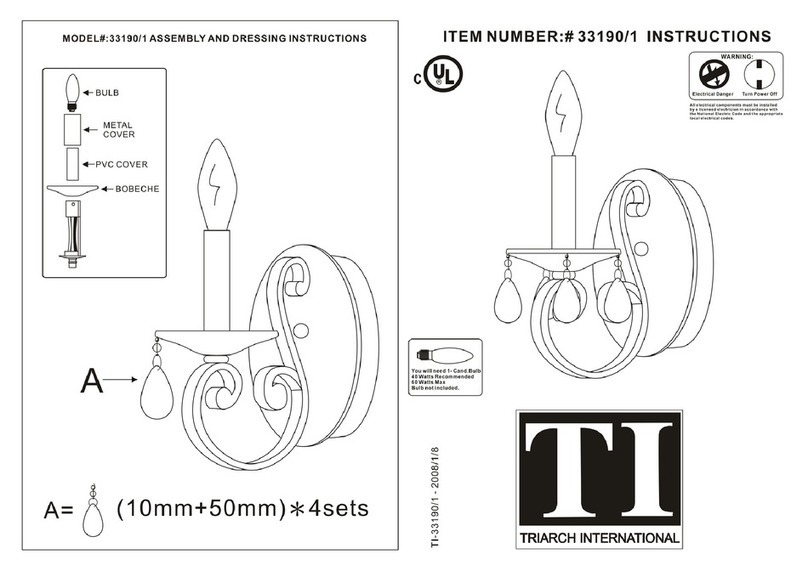

Triarch Indoor Lighting 33190/1 instructions

Mocka

Mocka Jesse Entertainment Unit Assembly instructions

Assa Abloy

Assa Abloy Traka Touch Series user guide