2

with the National Electrical Code and local codes and ordinances. In the event

of an electrical short circuit, grounding reduces risk of electric shock by provid-

ing an escape wire for the electric current.

WARNING - Improper use of the grounding plug can result in a risk of

electric shock.

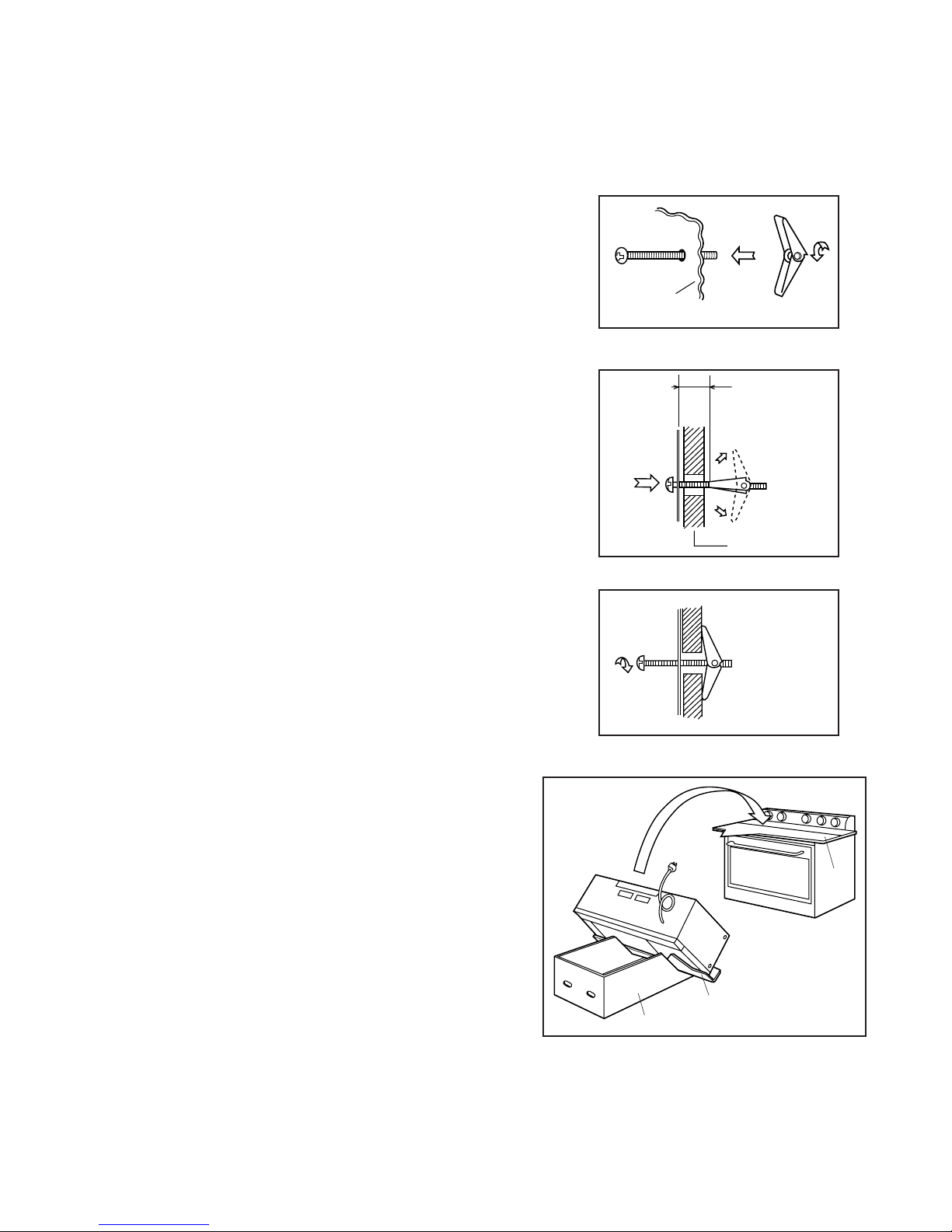

The microwave oven is equipped with a 3-prong grounding plug. DO NOT

UNDER ANY CIRCUMSTANCES CUT OR REMOVE THE GROUNDING PIN FROM

THE PLUG.

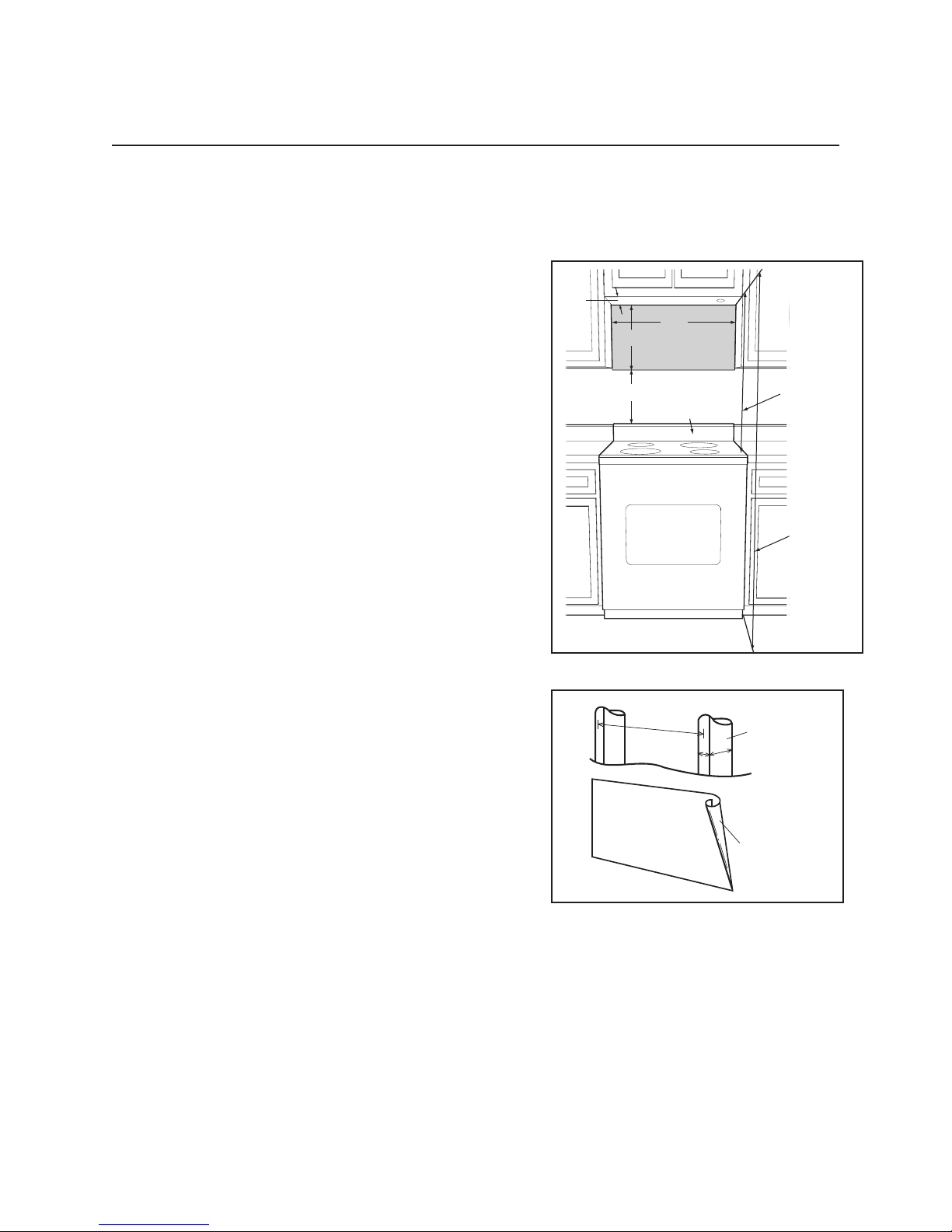

The Power Supply Cord and plug must be connected to a separate 120 Volt AC,

60 Hz, 15 Amp, or more branch circuit, single grounded

receptacle. The receptacle should be located inside the

cabinet directly above the Microwave Oven/Hood mount-

ing location.

Notes:

1. If you have any questions about the grounding or

electrical instructions, consult a qualied electrician or

serviceperson.

2. Neither Fisher & Paykel nor the dealer can accept

any liability for damage to the oven or personal injury

resulting from failure to observe the correct electrical

connection procedures.

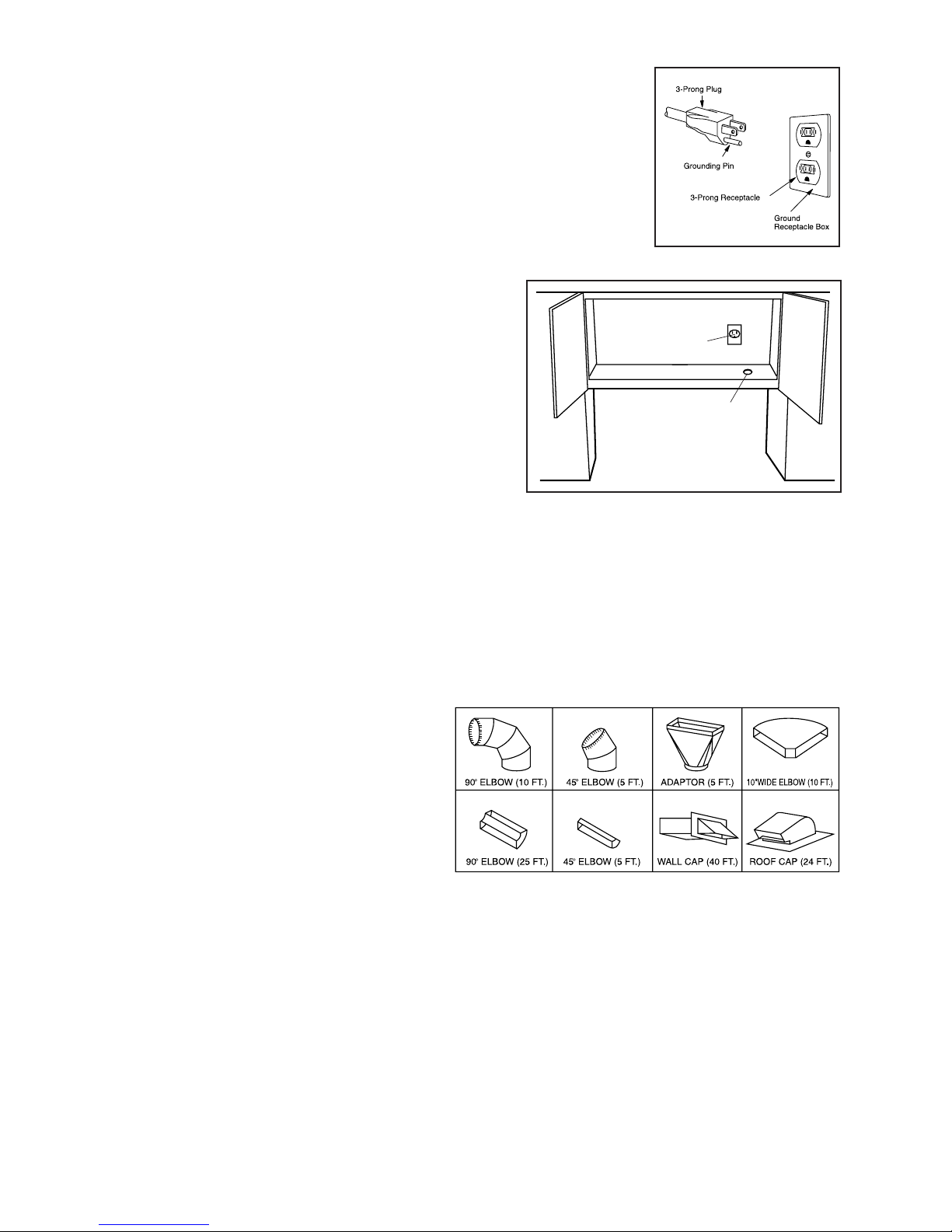

4. HOOD EXHAUST DUCT

When the hood is vented to the outside, a hood exhaust duct is required. All ductwork must be metal; absolute-

ly do not use plastic duct. Check that all connections are made securely. Please read the following carefully:

EXHAUST CONNECTION: The hood exhaust has been designed to connect to a standard 3-1/4" x 10" rectangu-

lar duct. If round duct is required, a rectangular-to-round adapter must be used.

REAR EXHAUST: If a rear or horizontal exhaust is to be used, care should be taken to align the exhaust with

the space between the studs, or wall should be prepared at the time it is constructed by leaving enough space

between wall studs to accommodate exhaust.

MAXIMUM DUCT LENGTH: For satisfactory air

movement, the total duct length of 3-1/4" x 10"

rectangular or 6" diameter round duct should not

exceed 140 feet.

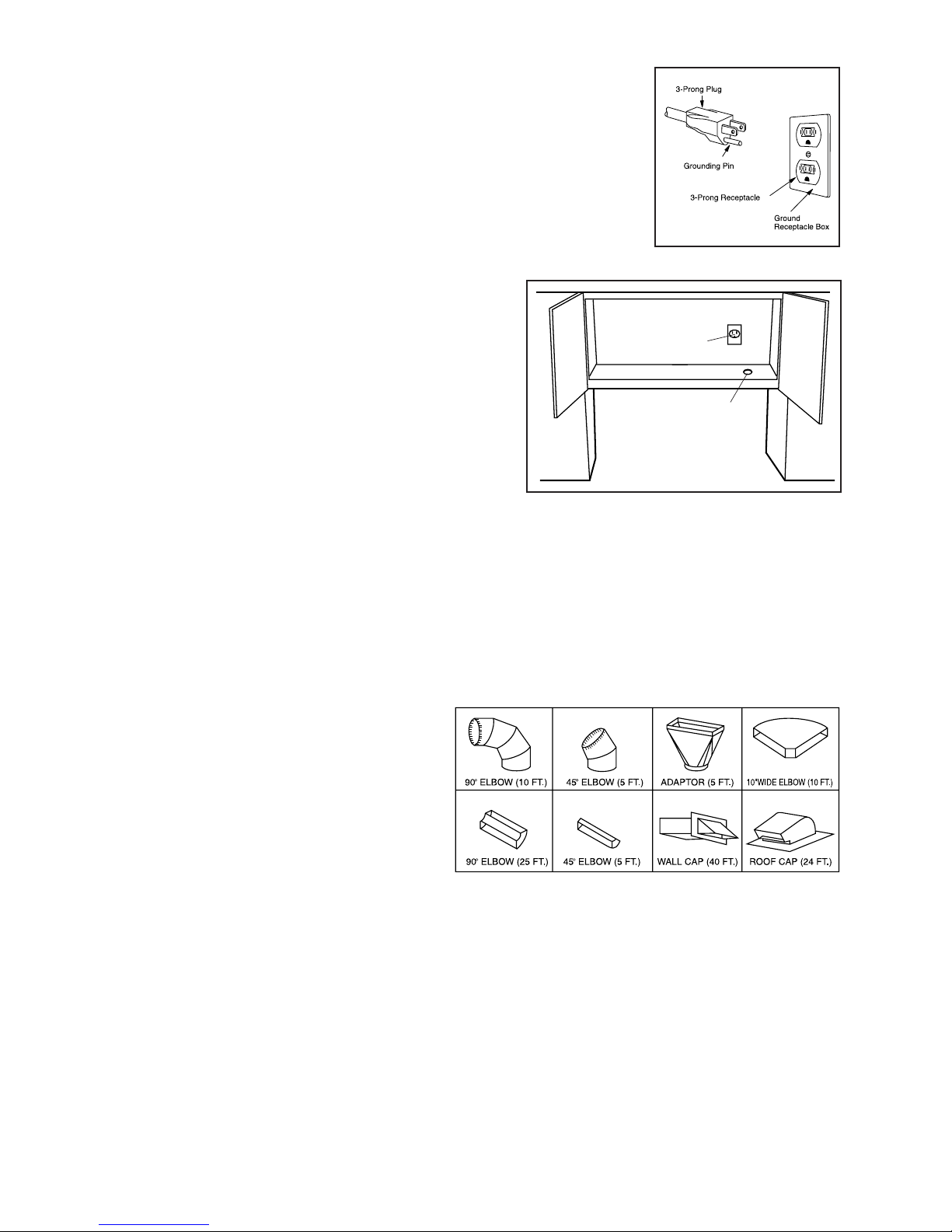

Elbows, adapters, wall, roof caps, etc. present

additional resistance to air ow and are equiva-

lent to a section of straight duct which is longer

than their actual physical size. When calculating

the total length, add the equivalent lengths of

all transitions and adapters plus the length of all

straight duct sections. Figure 4 shows the approximate feet of equivalent length of some typical ductwork parts.

Use the values in parentheses for calculating air ow resistance equivalent, which should total less than 140 feet.

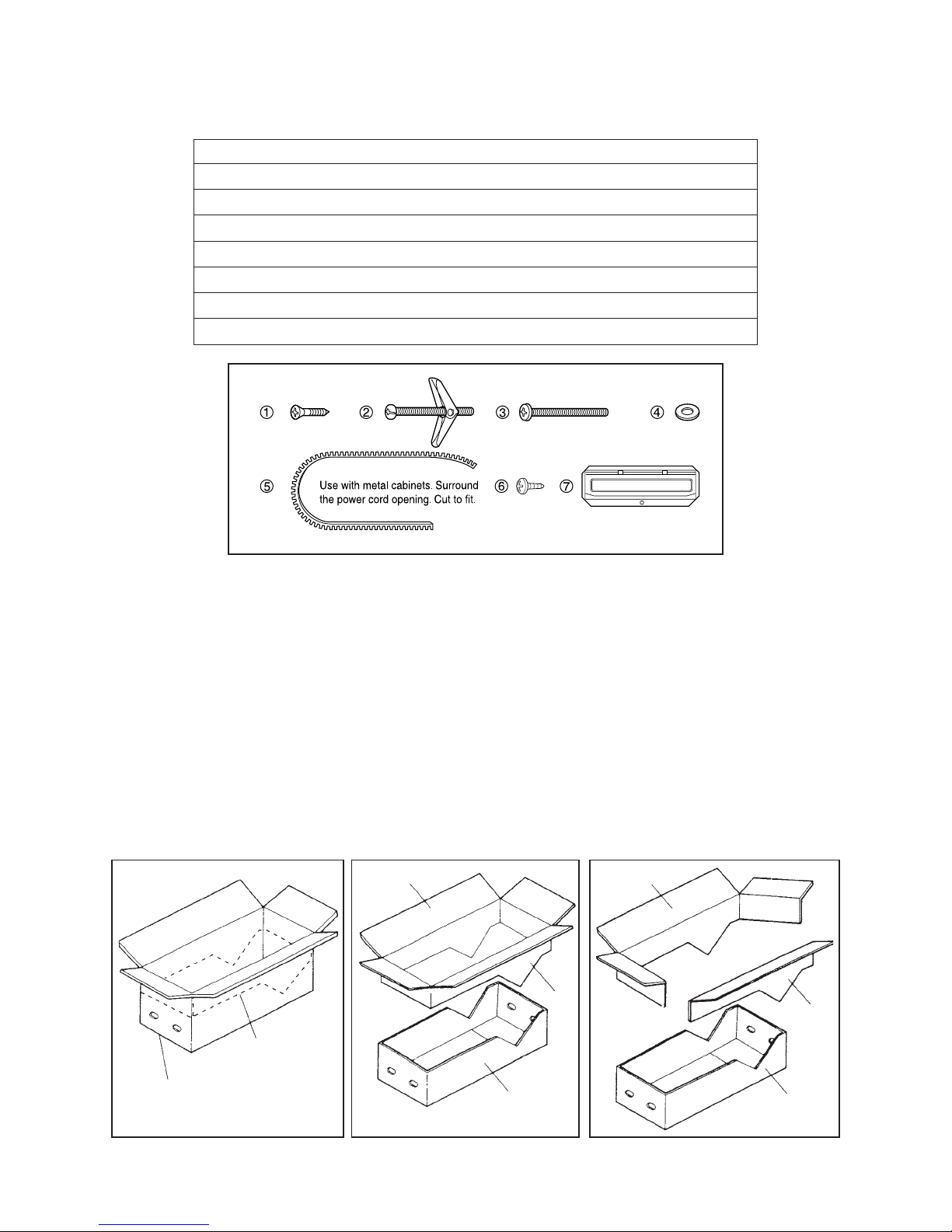

5. TOOLS RECOMMENDED FOR INSTALLATION

• PhillipsScrewdriver • 1-1/2"WoodBitorMetalHoleCutter(ifmetalcabinetisused)

• ElectricDrill • 1/2",5/8"and3/32"DrillBits

• Scissors • Sawtocutexhaustopening(ifneeded)

• Pencil • Measure

• Tape • ProtectiveDropClothforproductandrange—youmayalso

use carton for protection

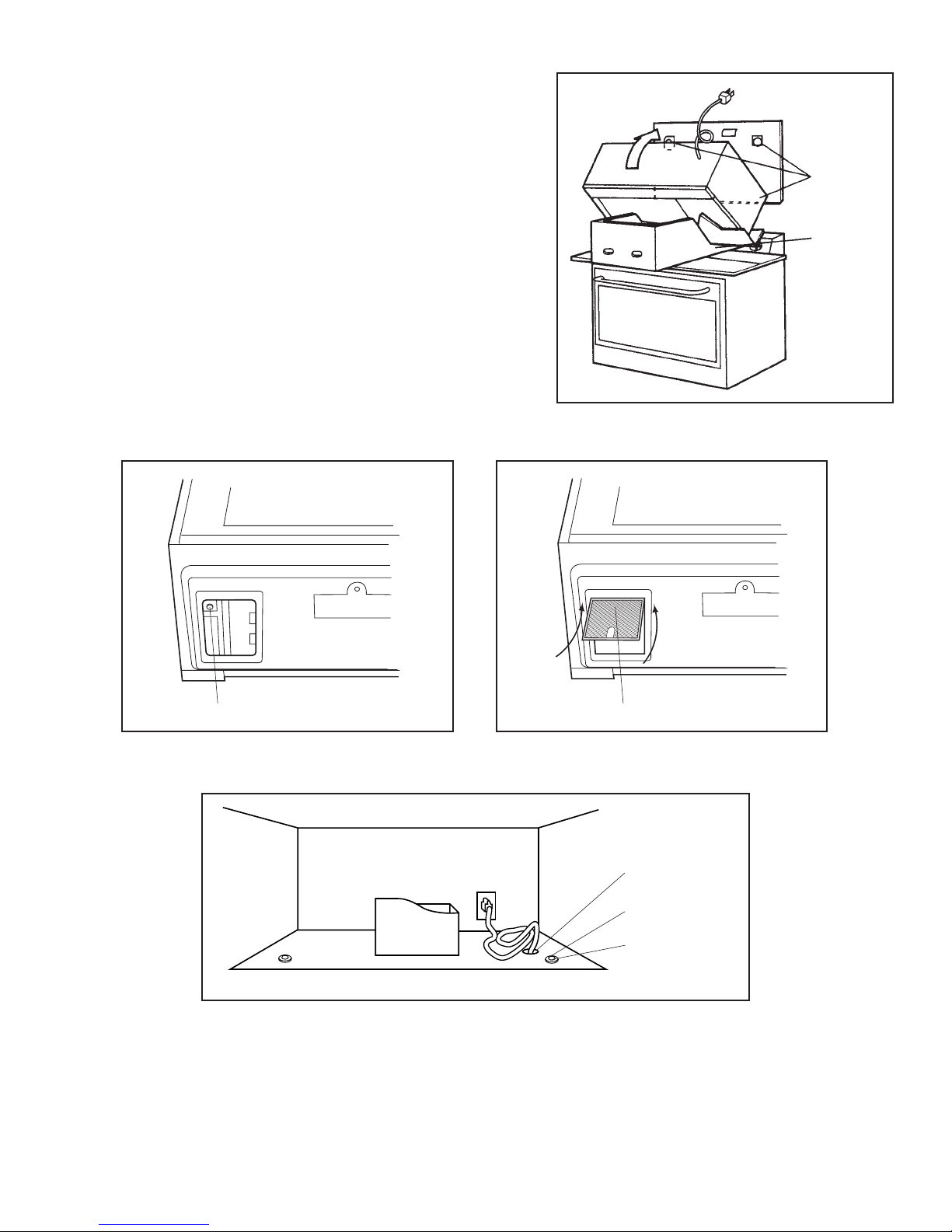

Figure 3

Opening for Power

Cord

Ground

Receptacle

Figure 4