Before lighting the stove you must check that the installation has been carried out as per instructions

and complies with current building regulations.

Health and Safety Precautions

All work must be carried out to the required Health and Safety at Work Act 1974.

There must not be an extractor fan fitted in the room.

There must be an air vent for all stoves of 5 kilowatt and over or meet current building regulations.

Stoves must be fitted to BS8303, BS6461 PT1-2 1984 building regulations.

All local regulations, including those referring to national and European standards need to be complied

with when installing the appliance.

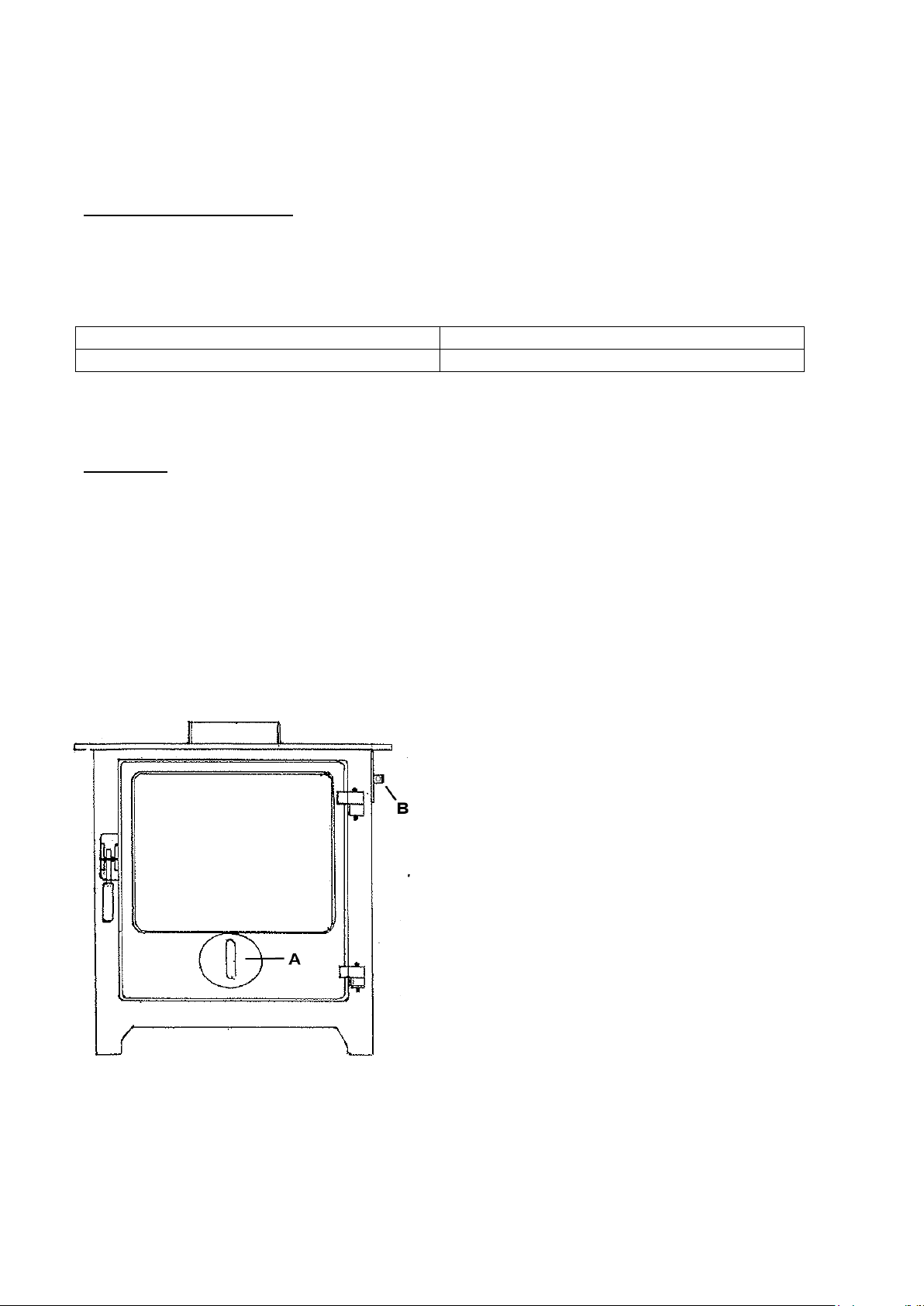

Flue Connections and Outlets

Dartmoor W5 stoves have the option of taking the flue from the top or the back or using a vertical

back box. Horizontal flue from back of stove should not exceed 150mm.

All flue connections must be sealed with fire cement. Doors in the register plate must be present or a

soot box fitted in the back or side of the fireplace to enable access to clean the chimney when the stove

is installed without a liner.

If the chimney has been lined and cannot be swept through the stove an access door on the first length

of flue must be installed for cleaning access.

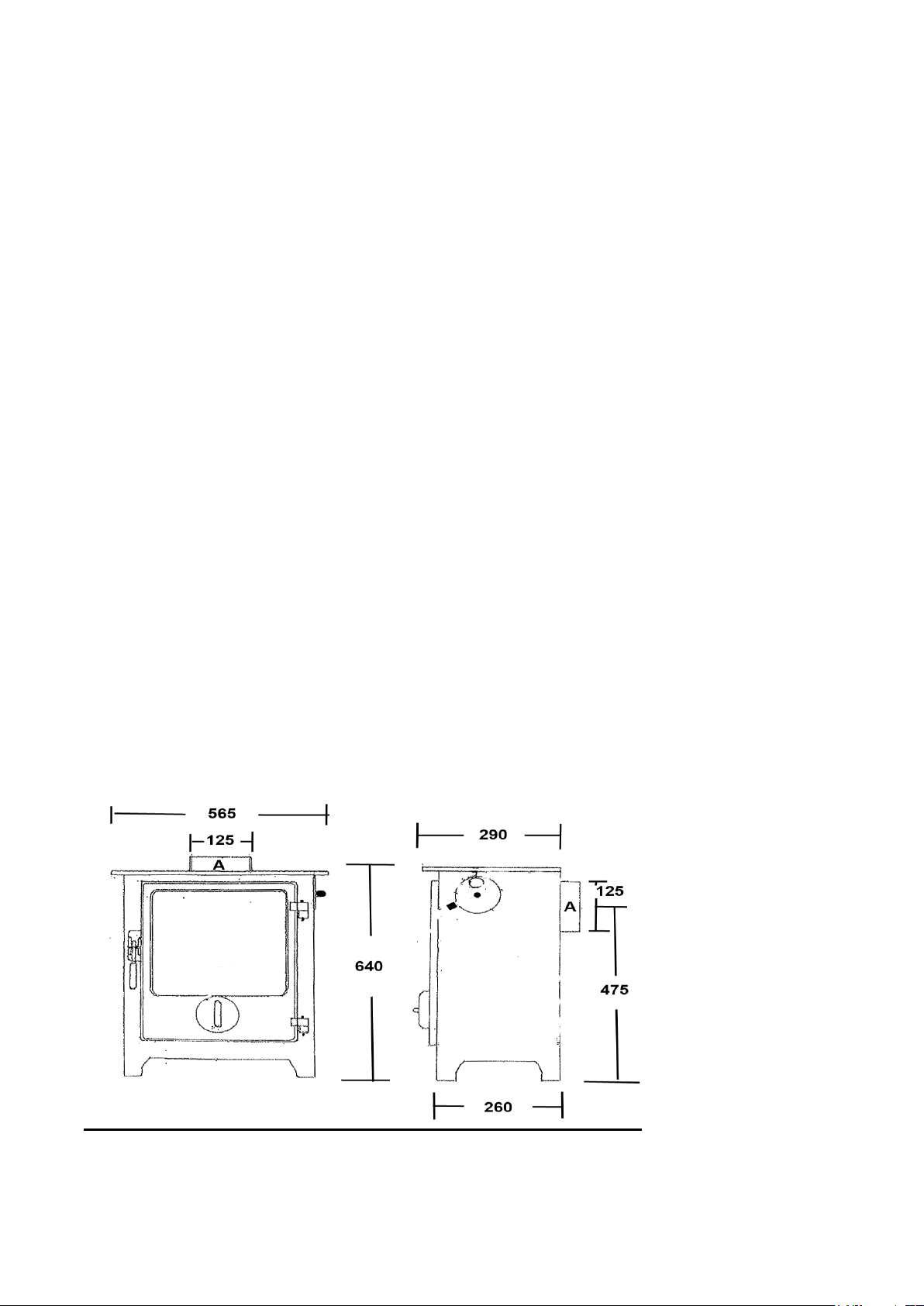

The Dartmoor W5 model requires a 125mm (5”) first length of flue then stepping up into a minimum

of 150mm (6”) liner. When using this stove with the smoke exempt air stop fitted the flue liner can be

reduced to 125mm (5”). We strongly advise a minimum diameter of 150mm (6”) flue liner be fitted

when possible. The installation of a flue liner is recommended.

N.B

All stoves must but installed by a suitably qualified person, such as a HETAS engineer or with the

supervision of building control.

As with all stoves fireguards must be installed when young children are present.

Stove Performance

Dean Forge Dartmoor W5 Wood Burning 5kW nominal 80.6% Net Efficiency

Dean Forge Dartmoor W5 Solid Fuel (Ancit) 5kW nominal 76.0% Net Efficiency

Dean Forge Dartmoor W5 SE Wood Burning 5kW nominal 80.6% Net Efficiency

Dean Forge Dartmoor W5 SE Solid Fuel (Ancit) 5kW nominal 73% Net Efficiency

All stoves are tested to nominal outputs and will often well exceed these kilowatt ratings.

Chimney

The Dartmoor stoves must have a minimum chimney height of 4m measuring from the stove outlet,

the chimney must not be less than 150mm (6”) internal diameter.

These stoves are not suitable to be used in a flue-shared situation.

If the chimney draw is too high a flue stabilizer will have to be installed. When the chimney is warm

the draw should not be lower than 0.10 water gauge.

All appliances have been tested at 12 PA with the doors closed.