deconta WM 400 V Manual

Guide book

Water treatment instantaneous water heater system

WM 400 V

Producer: deconta GmbH

Im Geer 20, 46419 Isselburg

Description: Instantaneous water heater system WM 400 V

Type No.: 25

Serial-No.: .................

Guide book

Instantaneous water heater system WM 400 V

Page 2 from 17

Table of contents

On page

1 Introduction 3

2 Basic safety advice 4

3 Transport and storage 5

3.1 Delivery 5

3.2 Transport 5

3.3 Storage 5

4 Scope of delivery

Scope of delivery by sale and rent 6

4.1 Scope of delivery 6

4.2 Return delivery after the rental period 6

5 Technical description 7

5.1 Intended use 7

5.2 Device description 7

5.3 Sewage pump 8

5.3.1 Version with 2 sewage pumps 8

5.4 Waste water filter system 9

5.5 Continuous-flow water heater 11

6 Technical data 12

6.1 Water treatment 12

6.2 Sewage pump 12

6.3 Waste water filter system 12

7 Initial operation 13

7.1 Pin assignment of personnel lock system Quick-Dush 13

7.2 Preparing for operation 13

8 Maintenance and care 14

8.1 Daily care 14

8.2 Sewage pump 14

8.3 Geyser 15

9 Possible disturbances and their repair 16

10 Proposal text 17

Guide book

Instantaneous water heater system WM 400 V

Page 3 from 17

1 Introduction

Thank you for choosing a deconta product!

With this system you get a practical solution with simple operation that was made in a

compact and functional way.

The deconta products guarantee:

Stability, Long life and aptness on site

Mechanics with „kick“

Pleasing design

Command with technical „acuteness“

Thanks to our experience in the field of asbestos remediation, the construction of this

engineered equipment is focused on safety.

For your protection, the use of the engineered equipment outside of the asbestos

removal should be agreed upon beforehand with deconta. deconta will help you with

pleasure and will take then also the liability by the external original use

In case of damages (mechanical or electric) or in a breakdown, deconta can help you in

a short term with his express service.

We have to point out to you that the non-observance of this guide book causes the

expiration of your warranty claims.

The copy right of this guide book remains the property of deconta. This guide book is

destined for the field service and survey personnel. It contains instructions and drafts of

technical nature which can not be used completely or in extracts for the purpose of

competition or can not be distributed among others.

Guide book

Instantaneous water heater system WM 400 V

Page 4 from 17

2 Basic safety advice

deconta has to engage you as the user to follow the guide book and to employ this

engineered technology only in accordance with the regulations and not in an

inappropriate way! In the event of non-observance, deconta assumes no liability.

The handling of the appliance technology is only allowed for instructed staff, because you

have to consider the contaminated materials and devices as dangerous goods. The

exact knowledge of the guide book is for your staff an important condition for the

handling of the machine.

Necessary repairs, maintenance and cleaning, in particular in the field of electrical

equipment should be realized by qualified staff or if necessary by the express service

deconta in order to guaranty and keep the function and the security.

The safety and security equipments have to be treated with care and the indicated

security advices have to be kept in a readable state.

The installation and the operation of the device can only be executed according to the

guide book or after consultation with deconta.

In order not to restrict the safety, any changes on the machine are prohibited. Wishes of

modifications can be made only with the agreement of deconta.

Supplementary to this guide book, the standard, legal and remaining binding rules

concerning the accident prevention and the protection of the environment have to be

observed.

Guide book

Instantaneous water heater system WM 400 V

Page 5 from 17

3 Transport and storage

3.1 Delivery

The waste water filtration plant is delivered from deconta works on a pallet packed with

a plastic film.

Transport damages have to be documented at once during the handing over of the

carrier or another supplier. Please note the possible damages on the way bill additionally.

3.2 Transport

In order to avoid damages due to faulty handling or imprudence, please handle with care

during transport. Special tools for loading or unloading procedures are not necessary.

3.3 Storage

The water treatment (Wastewater pump and cartridge filter) must be drained.

To avoid damages, this device has to be kept only in dry rooms inaccessible to

unauthorized persons

Guide book

Instantaneous water heater system WM 400 V

Page 6 from 17

4 Volume of delivery for sale and rent

4.1 Scope of delivery

The scope of delivery of a water treatment consists in, regardless of whether purchased

or rented, unless other arrangements have been made:

Guide book

Water treatment geyser

Cartridge filter 50µ, 1µ

Sieve element 220µ

4.2 Return delivery after the rental period

To protect our customers and in terms of the dangerous goods transport regulations, we

must insist on following terms of return delivery:

Thoroughly cleaned (ready for use)

Without residual fiber binder

Without damage

Without filter

Guide book

Instantaneous water heater system WM 400 V

Page 7 from 17

5 Technical description

5.1 Use according to the regulations

By asbestos sanitation works within closed rooms, you have to exclude that the asbestos

fibres leave the area of operation uncontrolled and endanger the human health and the

environment. For this reason, persons must leave the area of operation through a lock

system and take a shower before they exit.

The deconta water treatment assumes the heating of the shower water and takes over

the filtering of the contaminated sewage water

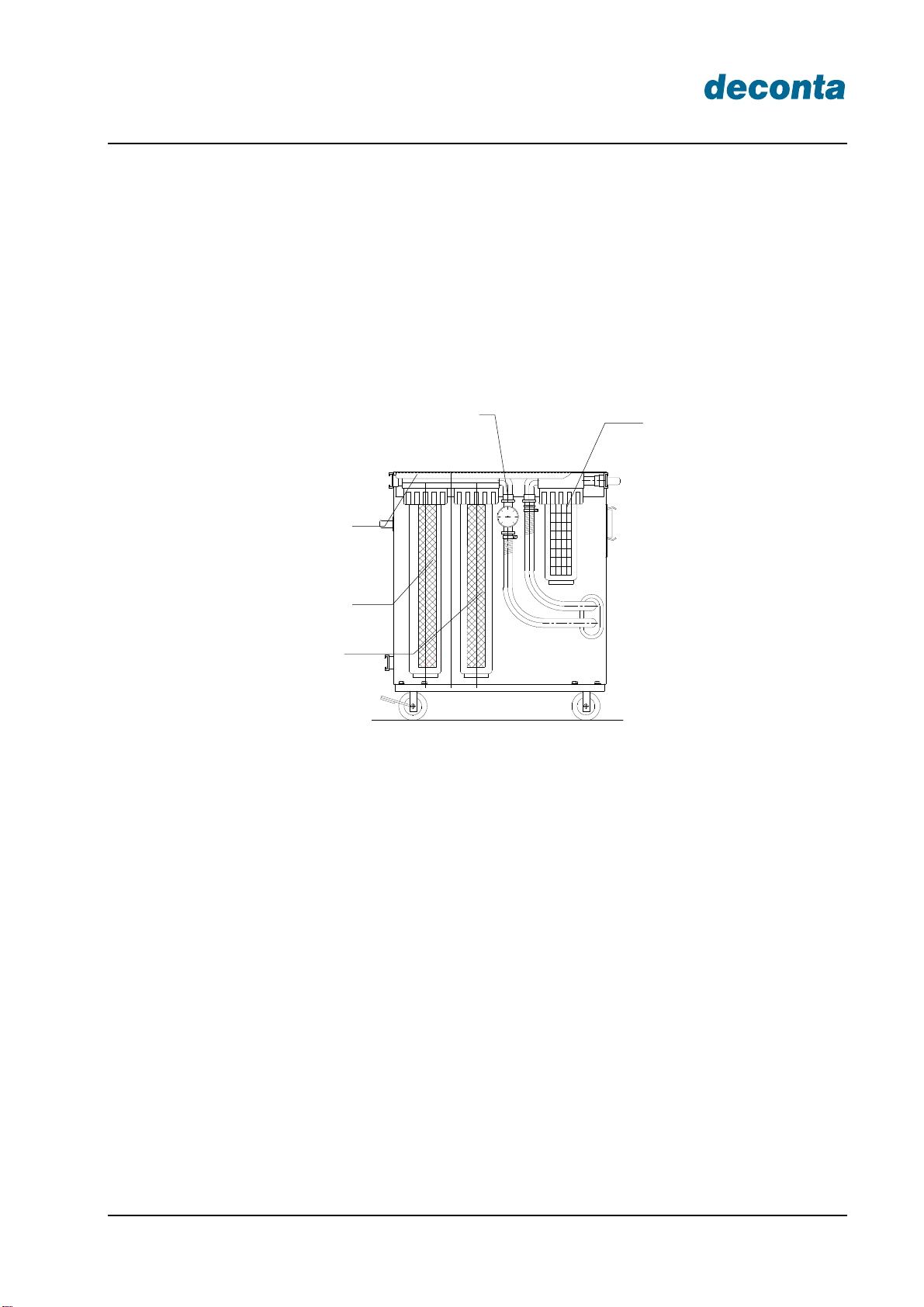

5.2 Device description water treatment

The built-in geyser in the water treatment provides the heating of shower water. The

sewage pump will automatically start along with the shower process. This sucks out the

waste water from the shower. Through a pre-filter and two fine filters, the wastewater is

cleaned so far that it can be fed to a sewer.

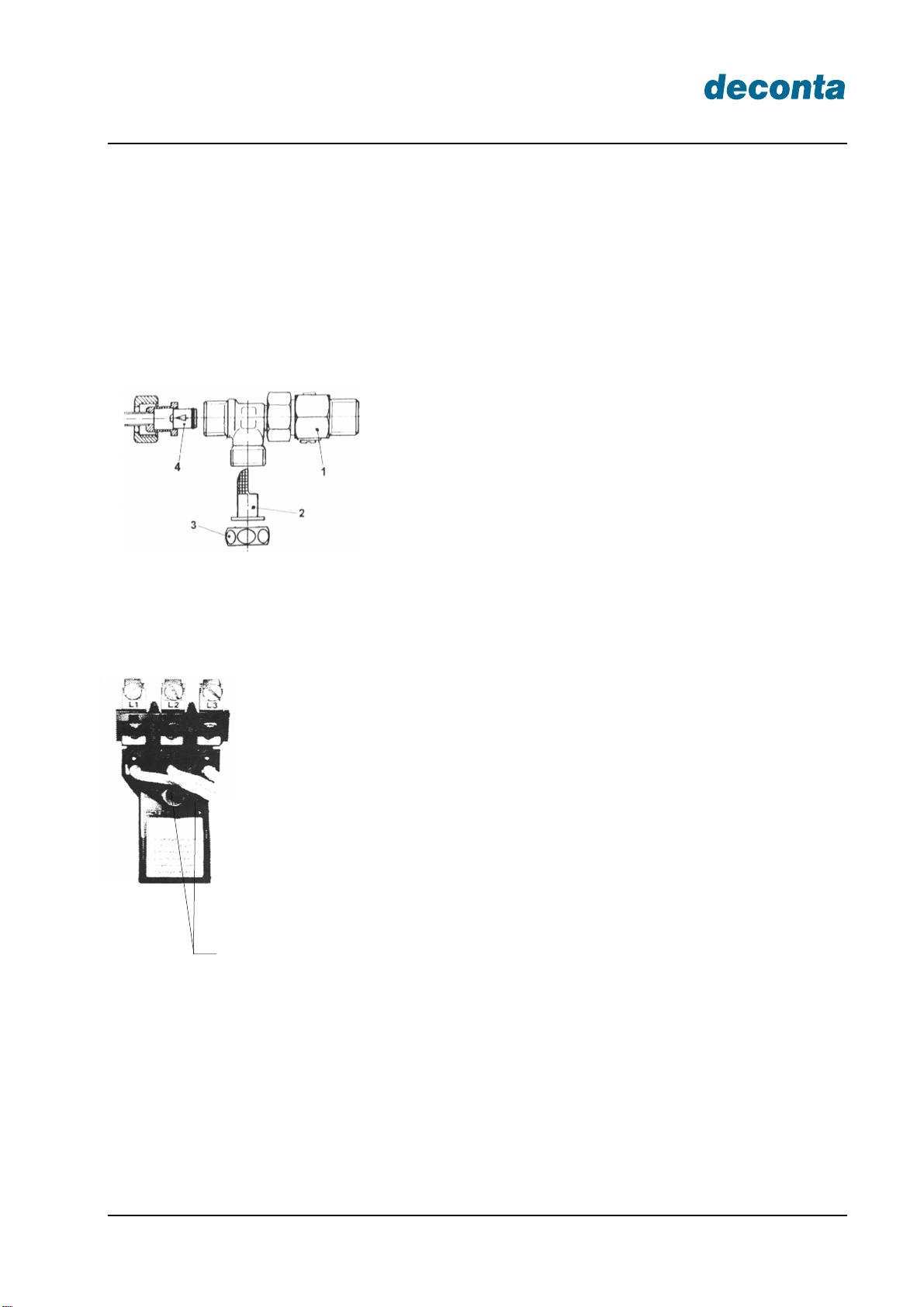

Sewage pump

Ge

y

ser Fine filter

Pre-filter with support

core and sieve

Pressure switch filter monitoring Manometer Filter

monitoring

Guide book

Instantaneous water heater system WM 400 V

Page 8 from 17

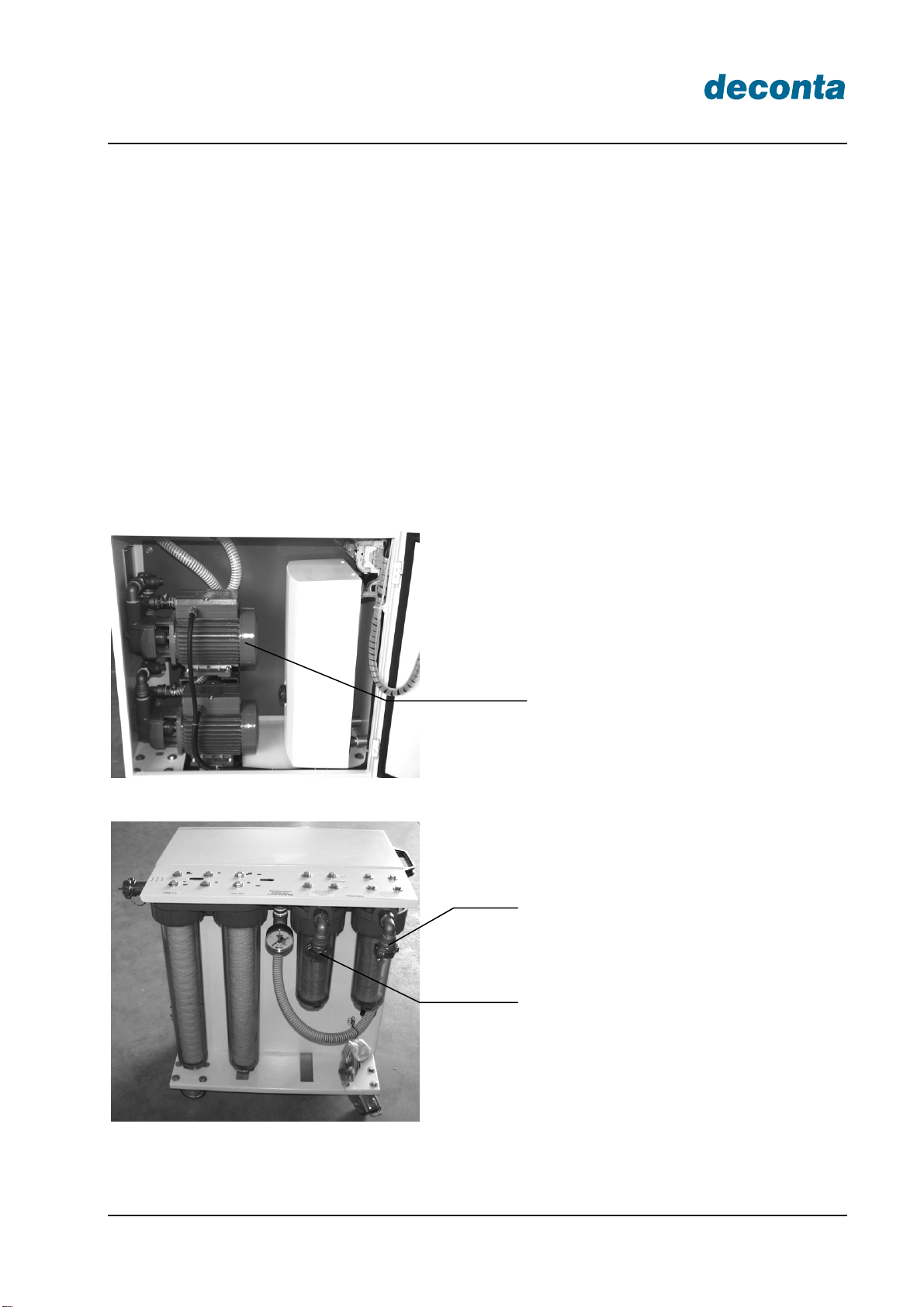

5.3 Waste water pump

The self-priming sewage pump is installed, ready for operation, in the water treatment.

She sucks the contaminated shower water through the pre-filter and then pumps it

through the two fine filters. The built-in pressure switch protects the filter plant from

excessive overpressure. While showering one automatic ensures that the pump is

started and runs during the entire process. A manual starting is possible with the key

"sewage pump start"

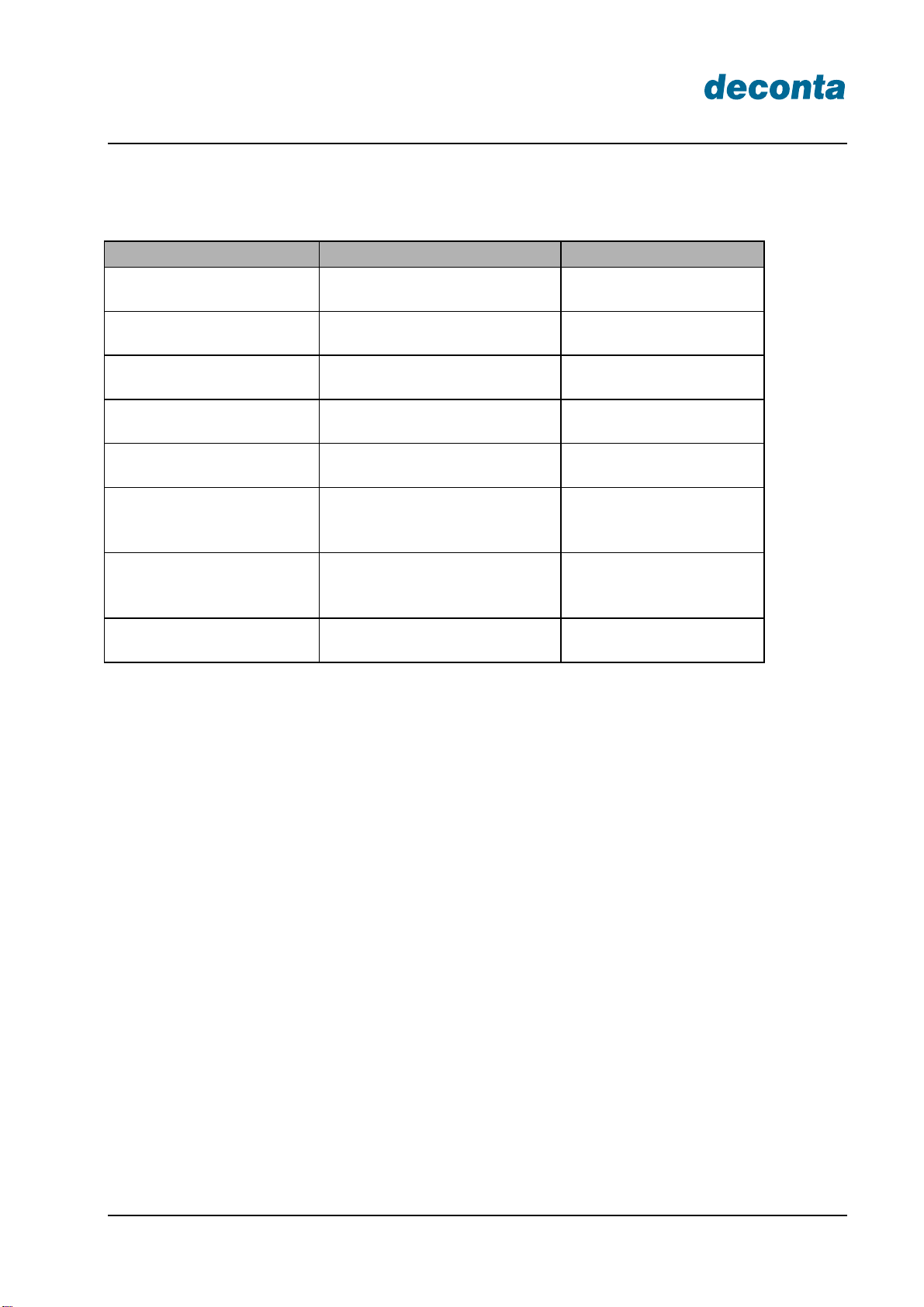

5.3.1 Model with 2 waste water pumps

Optionally, the WM 400 V can be equipped with a second sewage pump. This sucks in

parallel with the first sewage pump the contaminated shower water through a separate

filter and pumps it then subsequently through the two common fine filters. Typical use

case is a 5-chamber lock with two shower chambers

Optionl sewage pump

Sewage water suction connection

1. Pump

Sewage water suction connection

2. Pump

Guide book

Instantaneous water heater system WM 400 V

Page 9 from 17

5.4 Waste water filtration plant

The waste water filter system is used for filtration of contaminated shower water.

In the three-stage filtration system consisting of a pre-filter (220), a pressure gauge for

filter monitoring and two fine filters (50, 1), the water is filtered and discharged through

the drain line.To achieve a constant flow pump, the fine filters have to be changed at a

too strong fouling.

We recommend a filter change of the two fine filter at about 3.0 bar

The pre-filter is to clean up pollution

Filter change:

Unscrew the cap nut

Remove and dispose of the filter

Insert the new filter cartridges

Tighten the cap nut

Damaged filter cartridges can not be reused

All the filters mentioned must be disposed of in accordance with statutory regulations.

Pre-filter 220

Filter gauge filter monitoring

Screw cap

Fine filter 1

Fine filter 50

Guide book

Instantaneous water heater system WM 400 V

Page 10 from 17

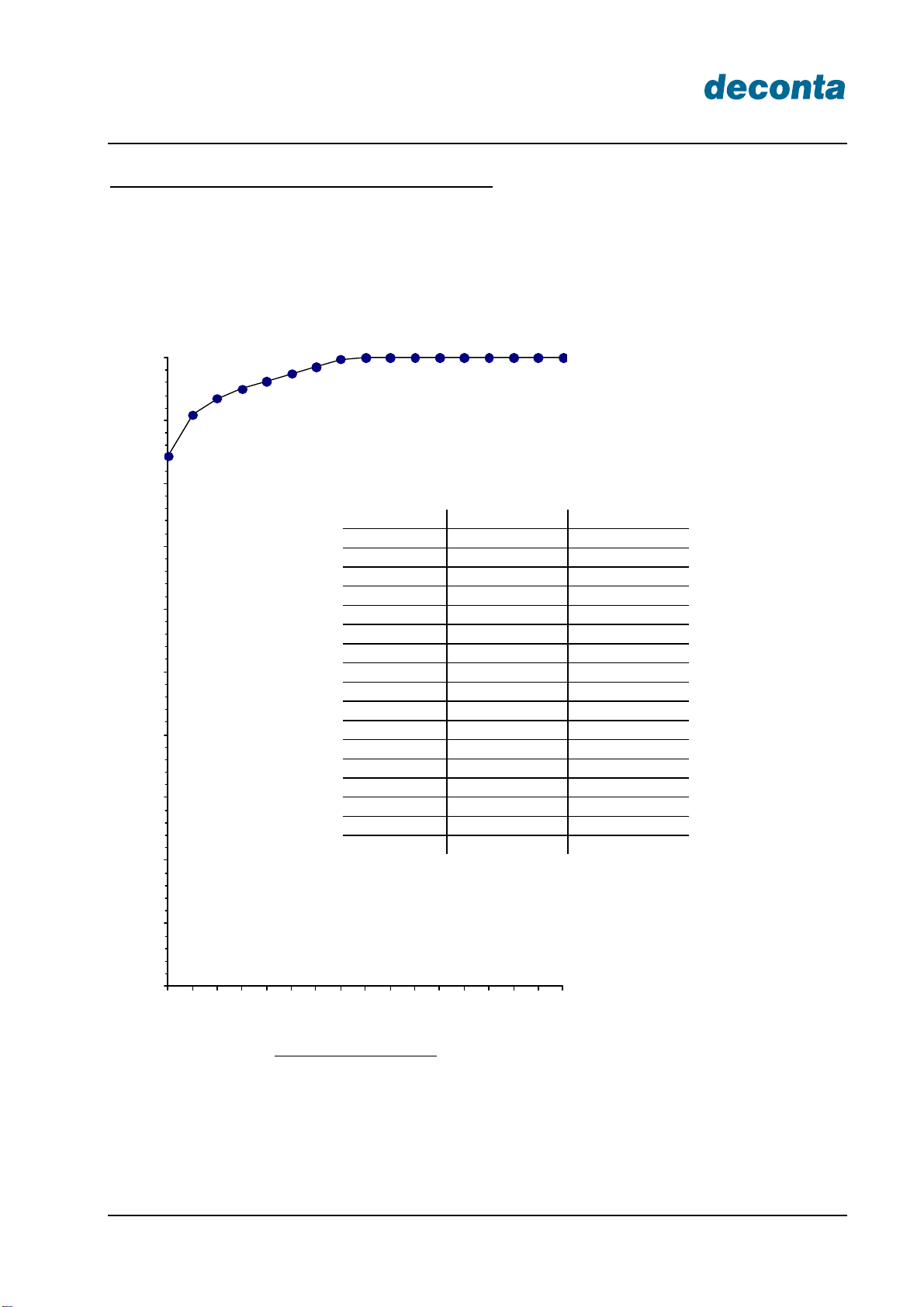

5.4.1 Effectivity of the waste water filtration

Test: Filter separation winding candle 1 Micrometer

Diameter in Micrometer

Mea.point Diameter % Effectivity

1 0,77 84,3

2 0,97 90,9

3 1,22 93,5

4 1,54 95,0

5 1,93 96,2

6 2,44 97,4

7 3,07 98,5

8 3,87 99,7

9 4,87 99,8

10 6,14 100,0

11 7,74 100,0

12 9,75 100,0

13 12,28 100,0

14 15,47 100,0

15 19,49 100,0

16 24,56 100,0

17 30,94 100,0

1

2345678 9 10 11 12 13 14 15 16 17

0

10

20

30

40

50

60

70

80

90

100

0,77

0,97

1,22

1,54

1,93

2,44

3,07

3,87

4,87

6,14

7,74

9,75

12,3

15,5

19,5

24,6

30,9

Guide book

Instantaneous water heater system WM 400 V

Page 11 from 17

5.5 Instantaneous water heater

The instantaneous water heater is completely electronically controlled and heats the

water as it flows. The electronic regulation and control unit detect the water flow, the inlet

temperature and the temperature selector at the specified outlet temperature. The

microprocessor calculates the required value and turns on the appropriate heat output.

When closing the hot water valve, the heater is turned off independently and the

electronic all poles system disconnected from the mains. The device consists essentially

of the heating block, the power module with triacs, the electronic module, a safety

temperature and pressure limiter and the pressure differential switch.

Heating coils are used as a radiator, which are surrounded by flowing water directly. By

this heating mode and with 0.5 litres of very low water content, a high efficiency is

ensured. The amount of water is limited by a built-in flow control by fully open hot water

valve to max.10l / min flow rate so that a suitable outlet temperature for the shower

(about 40º C) remains.

Thanks to the built-in temperature and pressure safety limiter, a double safety shut-off is

reached by over pressure and over temperature. The pressure limiter triggers by a rise in

pressure to about 22 bars, the temperature limiter triggers at about 55º C in the intake

and at about 70º C in hot-water outflow. In response of the pressure or temperature

limiter the device is disconnected at once from the mains.

Prior to press again the pushbutton on the safety temperature and pressure limiter, the

cause of the disorder is to be determined and resolved by a qualified person

Guide book

Instantaneous water heater system WM 400 V

Page 12 from 17

6 Technical data

6.1 Water treatment:

Length x Width x Height 550 x 680 x 710 mm

Weight 57 kg

Power supply 400 Volt, 32A 3+N+PE

Euro plug CEE-6h

Protection level IP 54

Personal security via RCD circuit breaker

Water connection ¾“ hose and Geka-connection

Suction and pressure side

Output power

Instantaneous water heater 21 KW

6.2 Sewage pump

Tension : 230V,50 Hz

Speed : 2900 1/min

Power :0,45kW

Weight : 9,8 Kg

Output max. : 31.5 l/min

max. Medium temperature : 90°C

Protection level : IP44 S1

Single-phase (alternating current) motor 230 V

with built thermostatic switch

Capacitor inside the terminal box

Insulation Class F

6.3 Sewage water filtering plant

Filter size:

Pre-filter : 220

Fine filter : 50

Fine filter : 1

Connections :¾“ hose with Geka connection

Technical changes reserved

Guide book

Instantaneous water heater system WM 400 V

Page 13 from 17

7 Initial operation

7.1 Connection assignment to the personal lock system Quick-Dush

Establish the current supply of the water management (400V, 32A 3+N+PE)

Establish the fresh water supply of the water management to the connection “fresh

water filling”.

Establish connection “warm water exit” with the shower roof element

Establish connection “sewage water suction” with the shower floor element

Connect the drain hose connection with "waste water” and sewer

7.2 Preparing for operation

Open fresh water intake

Fill the sewage pump (see chapter 8.2 )

Set the temperature of shower water at the thermostat

Set the main switch to „ON“

The system is now operational

Note:

Before the start up of the sewage pump, it is to verify whether the shaft can be turned by

hand. On this purpose a screwdriver has to be put in the notch on the shaft extension of

the fan side and move the shaft. With new pumps, the strong initial rotational resistance

of the wheel will come loose after running.

Guide book

Instantaneous water heater system WM 400 V

Page 14 from 17

8 Maintenance and care

The suction hoses, pumps, filter housings and filter are contaminated after the

first use. Repairs and maintenance have to be executed only under the observance

of all relevant safety measures.

8.1 Daily maintenance

- Control if the hoses have a continuous flow

- Control of the sewage water filter pressure gauge

- Visual inspection of the pre-filter for contamination

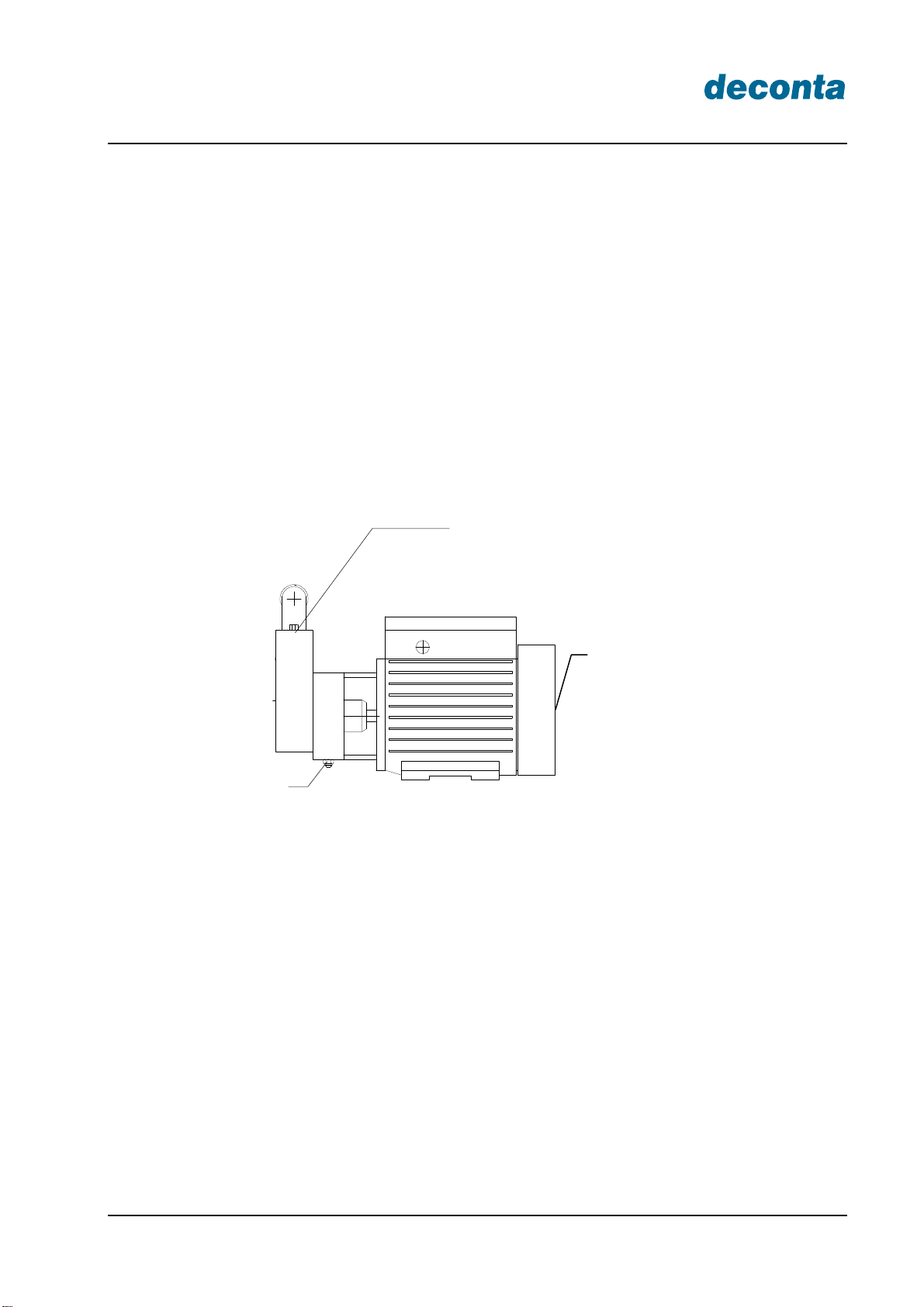

8.2 Sewage water pump

In case of frost danger, the stopped pump has to be emptied through the drain plug.

After a long standstill this is to check, before restarting, if the wheel has been blocked by

deposits caused by impurities, sediment and other causes. You may clean with

appropriate measures.

Caution! All works on the unit are to be performed only if the electrical power has been

turned off.

Before commissioning, the pump must with the fluid through the vent port to be fully

populated

Note: The pump must not be operated without liquid filling. Before operating, the pump

must be filled completely with the fluid through the vent port

Exhaust port

Drain plug

Notch on the

shaft end for

screwdriver

Guide book

Instantaneous water heater system WM 400 V

Page 15 from 17

8.3 Heater:

Clean the sieve:

1. Turn off the cold water at the stop (1)

2. Loose the cap nut (3) with the key SW 24

3. Remove and clean the sieve (2)

4. Reassemble in reverse order

5. Open the cold water at stop; control the impermeability

1= cold water connection with stop

2= Sieve

3= Cap nut SW 24

4= Flow regulator with check valve

The safety limiter

Changes in the safety temperature and pressure limiters are not

allowed! In all the disorders, we recommend to consult the service.

For the activation of the safety limiter, after the remedy of a previous

disorder, a screwdriver or similar should be introduced through the

opening of the cap and carefully pressed until the limiter clicks.

Information: Upon request, deconta concludes a service contract with you.

Opening for

screwdriver

Guide book

Instantaneous water heater system WM 400 V

Page 16 from 17

9 Possible disorders and their corrections

Fault Possible cause Corretion

Shower water too hot Faulty electronics Repair by a

professional

Shower water too cold Faulty power supply Power supply see

chapter 6.1

Warm water flow too low Sieve clogged in heater Clean the sieve

chapter 8.3

Output of the pump

goes back Saturation rate of the filter

too high Change filter

Impeller of the pump

does not turn Initial rotational resistance

too high See chapter 7

Pump does not start

during prolonged

shutdown

Impeller blocked e.g. by

deposits Clean impeller

Temperature and

pressure limiter has

triggered

Pressure surges in water

mains

Identify pressure

shocks and correct

(see chapter 8.3)

Heater does not start Water hose blocked too

little water Clean water hose

Caution! Changes in the safety of temperature and pressure limiters are not

allowed!

Guide book

Instantaneous water heater system WM 400 V

Page 17 from 17

10 Proposal text

Water treatment system „instantaneous water heater“, to work for use in asbestos

remediation. Transported on castors with fixing device. Easy to clean, powder-coated

sheet metal housing. Infinitely adjustable shower water temperature 30°C and 60°C.

Electronic volume and temperature of the shower water. Built-in safety temperature and

pressure limiter. Three-stage waste water filter system with automatic filter monitoring

and filter rapidly change system Self-priming and dry run protected water pump.

Electronic control of the extraction process in the shower. Water connection system

Geka. Personal protection by RCD switch. CE marking on the components.

.

Table of contents

Popular Water Heater manuals by other brands

Heatrae Sadia

Heatrae Sadia Megaflo Eco SolaReady instructions

PVI Industries

PVI Industries 50 L 130 A-GCML Installation & maintenance manual

Bosch

Bosch 125B LP Installation and operating instructions

Ferroli

Ferroli PEGASUS D LN Instructions for use, installation and maintenance

Navien

Navien NPE-180A installation manual

Timberk

Timberk SWH FSL1 30 V instruction manual