5

Read and Review this entire Manual with special emphasis on

Pages 6-9 prior to any installation work.

LLOOCCAALLIINNSSTTAALLLLAATTIIOONNRREEGGUULLAATTIIOONNSS

This water heater must be installed in accordance with these in-

structions, local codes, utility company requirements and/or, in the

absence of local codes, the latest edition of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and

Propane Installation Code.

LLOOCCAATTIIOONN

AA..The water heater should be installed in a clean, dry location as

close as practical to the gas vent terminals. Long hot water lines

should be insulated to conserve water and energy. The water

heater and water lines should be protected from exposure to freez-

ing temperatures.

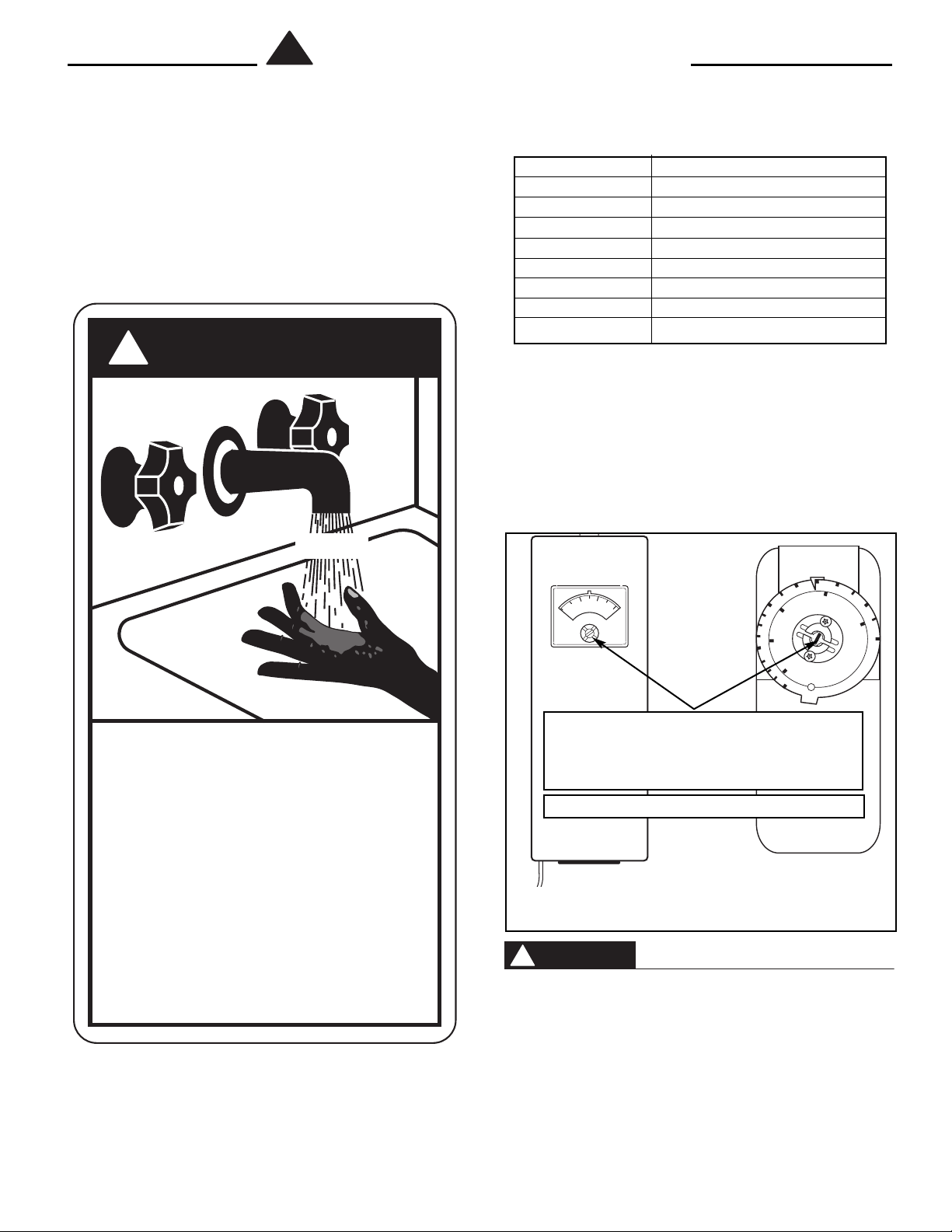

BB..A gas fired water heater should not be installed in a space where

liquids which give off flammable vapors are to be used or stored.

Such liquids include gasoline, LP gas (butane and propane), paint

or adhesives and their thinners, solvents or removers. Because of

natural air movement in a room or other enclosed space, flammable

vapors can be carried some distance from where their liquids are

being used or stored. The open flame of the water heater’s inter-

mittent pilot or main burner can ignite these vapors causing an

explosion or fire which may result in severe burns or death to those

in range, as well as property damage. For these reasons, instal-

lation of a gas fired water heater in a garage is not desirable.

If a location in a garage is the only alternative, the gas water heater

should be installed so that the open flame of the pilot and main

burner are no less than 18 inches above the garage floor. The

water heater must be located or protected so it is not subject to

physical damage by moving vehicles or area flooding. Raising the

gas fired water heater will reduce BUT NOT eliminate the possibili-

ty of lighting the vapor of any flammable liquids which may be

improperly stored or accidentally spilled.

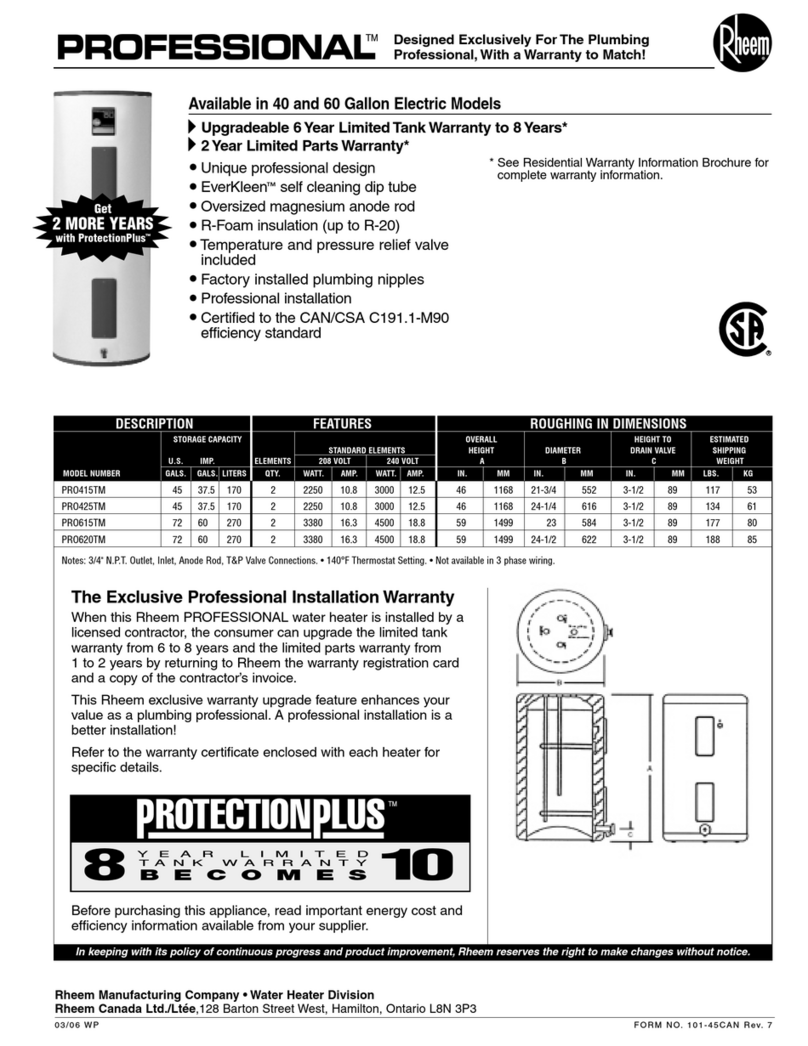

CC..All models are certified for installation on combustible floors and

in alcoves. The minimum side and top clearance to walls and ceil-

ing for providing protection of combustible materials are shown

on the water heater’s rating label. A front clearance of 18 inches

(46 cm) should be provided for adequate inspection and servicing.

If the water heater must be installed on carpeting, place a metal

or wood panel beneath water heater extending beyond its full

width and depth at least 3 inches (7.6 cm) in all directions. If the

water heater is installed in an alcove, the entire floor must be cov-

ered by the panel.

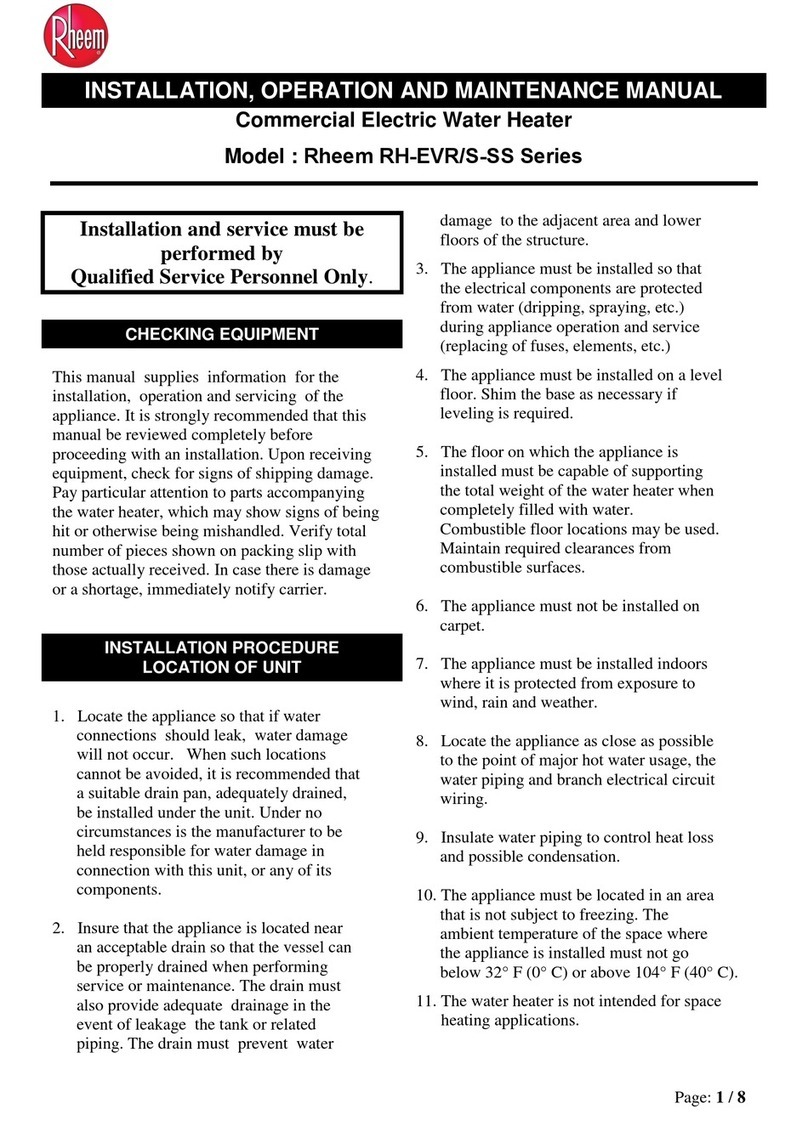

The water heater should not be located in an area where leakage

of the tank or connections will result in damage to the area adja-

cent to it or to lower floors of the structure. When such areas can-

not be avoided, it is recommended that a suitable catch pan, ade-

quately drained, be installed under the water heater. The pan

MUST NOT restrict the flow of combustion air flow to bottom of

water heater.

NNOOTTIICCEE::AAuuxxiilliiaarryyccaattcchhppaanniinnssttaallllaattiioonnMMUUSSTTccoonnffoorrmmttootthhee

aapppplliiccaabblleellooccaallccooddeess..

DD..RREESSTTAAUURRAANNTTSS—

—If the water heater is to be installed in a restau-

rant or other location where the floor is frequently cleaned, it must

be elevated to provide at least six inches (15 cm) of clearance

from the floor to comply with NSF International recommendations.

A factory-designed leg extension kit is available for this purpose

from the distributor or store where the water heater was purchased.

EE..CCOOMMBBUUSSTTIIOONN&&VVEENNTTIILLAATTIIOONNAAIIRR——Proper operation of the

water heater requires air for combustion and ventilation. If the

water heater is installed in a building of conventional frame, ma-

sonry or metal construction, and there are no other appliances

installed that require an air supply, infiltration air is normally ad-

equate for proper combustion and ventilation, and an outside air

supply for the water heater may not be required. However, if the

water heater is installed in a confined space, or the building is of

unusually tight construction, then an outside air supply must be pro-

vided. Provisions for Combustion and Ventilation air must com-

ply with the applicable codes and standards as defined in the Local

Installation Regulations section on page 5.

FFOORRIINNSSTTAALLLLAATTIIOONNSSIINNTTHHEEUUNNIITTEEDDSSTTAATTEESS::

If the water heater is to be installed in a confined space, defined

as one having a volume of less that 50 cubic feet (1.4 cu. meters)

per 1000 Btu/h of the total input of all appliances within that space,

an air supply must be provided. The air must be supplied through

two permanent openings of equal area, one of which is to be located

approximately 12 inches (30cm) above the floor and the other of

which is to be located approximately 12 inches (30cm) below the

ceiling. The minimum net free area of each opening must be not

less than one square inch per 1000 Btu/h of the total input of all the

appliances in the enclosure or structure, if each of the openings

communicates with other unconfined areas inside the structure.

If the required air is to be supplied directly from outdoors (or a

freely ventilated attic or crawl space), or through vertical ducts,

there must be two openings located as specified above, and each

must have a minimum net free area of not less than one square

inch (6.5 sq. cm) per 4,000 Btu/h of the total input rating of all ap-

pliances in the en-closure.

NNOOTTEE::IIfftthheeooppeenniinnggssaarreettoobbeeccoovveerreeddwwiitthhaapprrootteeccttiivveessccrreeeenn

oorrggrriillll,,tthheenneettffrreeeeaarreeaaoofftthheeccoovveerriinnggmmaatteerriiaallmmuussttbbeeuusseeddiinn

ddeetteerrmmiinniinnggtthheessiizzeeoofftthheeooppeenniinnggssmmeennttiioonneeddaabboovvee..PPrrootteecc--

ttiivveessccrreeeenniinnggffoorrtthheeooppeenniinnggssMMUUSSTTNNOOTTbbeessmmaalllleerrtthhaann11//44iinncchh

((..6644ccmm))mmeesshhttoorreessiissttccllooggggiinnggbbyylliinnttoorrootthheerrddeebbrriiss..

For additional information regarding combustion and ventilation

air supply requirements, refer to the latest edition of the Ameri-

can National Standard / National Fuel Gas Code, ANSI Z223.1

FFOORRIINNSSTTAALLLLAATTIIOONNSSIINNCCAANNAADDAA::

While the requirements for U.S. installations outlined above are

generally true in Canada, precise requirements for combustion

and ventilation air supplies are detailed in the CAN/CGA B149 In-

stallation Codes; under “Venting Systems and Air Supply for Ap-

pliances”. To ensure that the water heater is properly installed,

those requirements must be followed.

Large exhaust fans can lower the air pressure inside a building

or room and interfere with proper venting and operation. Com-

mercial kitchens or other locations that must maintain a high flow

of exhaust air should have the water heater installed in a sepa-

rate room with combustion and ventilation air supplied directly

from outside as described above.

FF..C

COORRRROOSSIIVVEEAATTMMOOSSPPHHEERREESS——The heater should not be in-

stalled near an air supply containing halogenated hydrocar-

bons. For example, the air in beauty shops, dry cleaning es-

tablishments, photo processing labs, and storage areas for

liquid and powdered bleaches or swim pool chemicals often

Introduction