CP19

5

7. CLEANING PROCEDURE AND MAINTENANCE

First, empty the product tank. Fill it with water or the appropriate solvent, spray until it is

completely clean and dry the gun.

Finally, grease properly all the points where wear occurs more often such as the needle,

threads, trigger, and so on.

8. SAFETY DATA SHEET

Take in mind the following rules:

Do not use the spray gun in those operations for which it has not been designed.

Read all the warnings on the products you use.

Use approved masks.

Do not aim gun at people or animals.

Disconnect it from the compressed air network before any repair.

Use the gun in a well-ventilated area where there are no risks of explosion or fire.

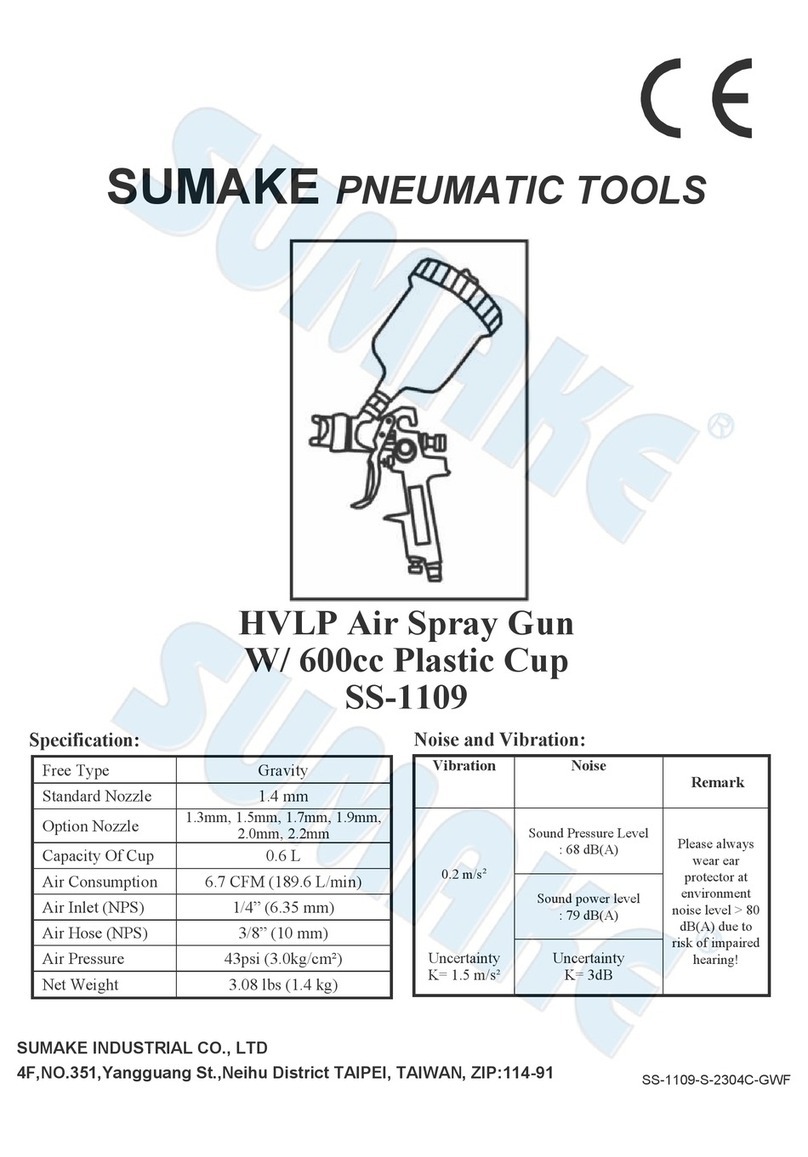

Never exceed pressure of 8 bar.

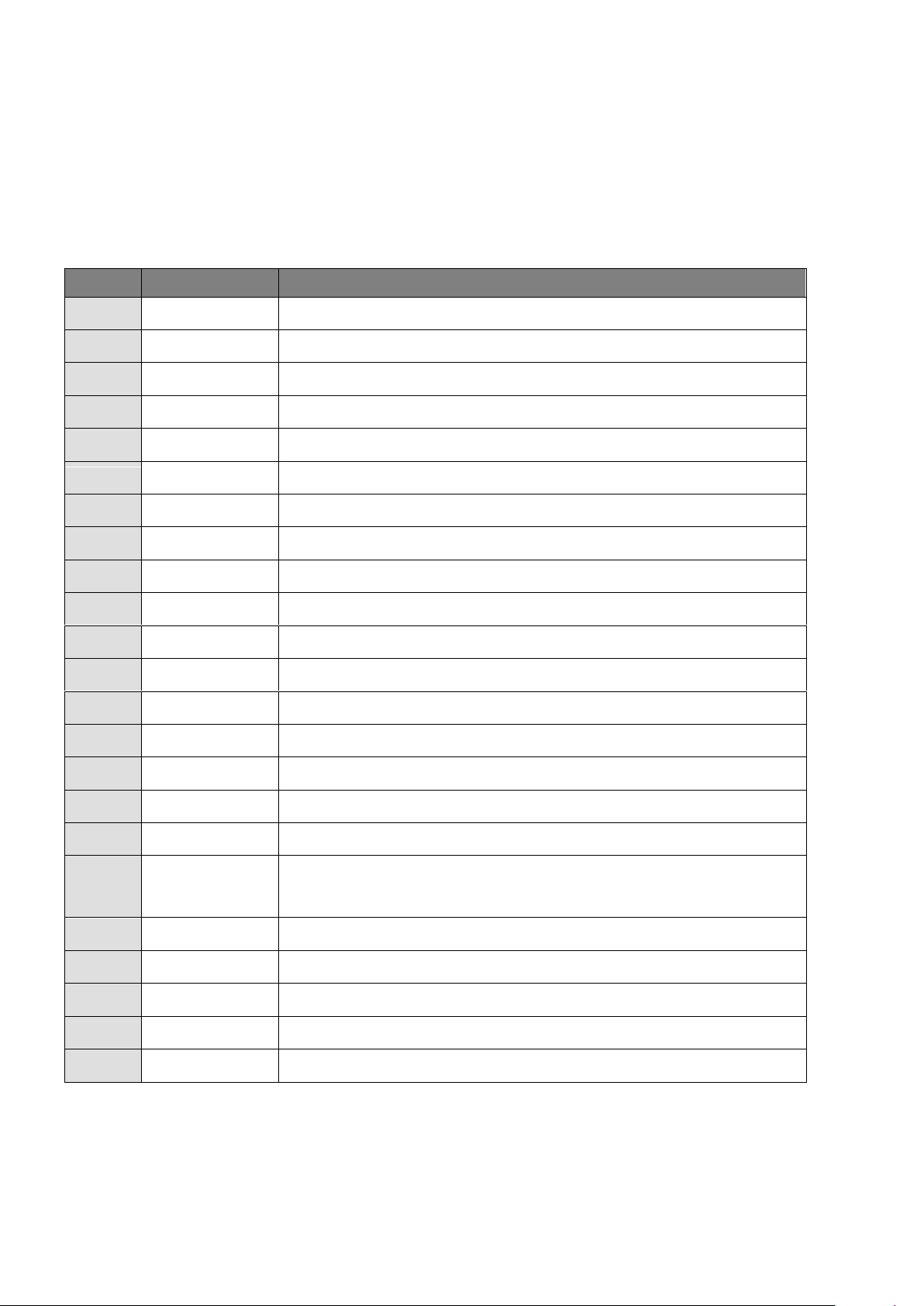

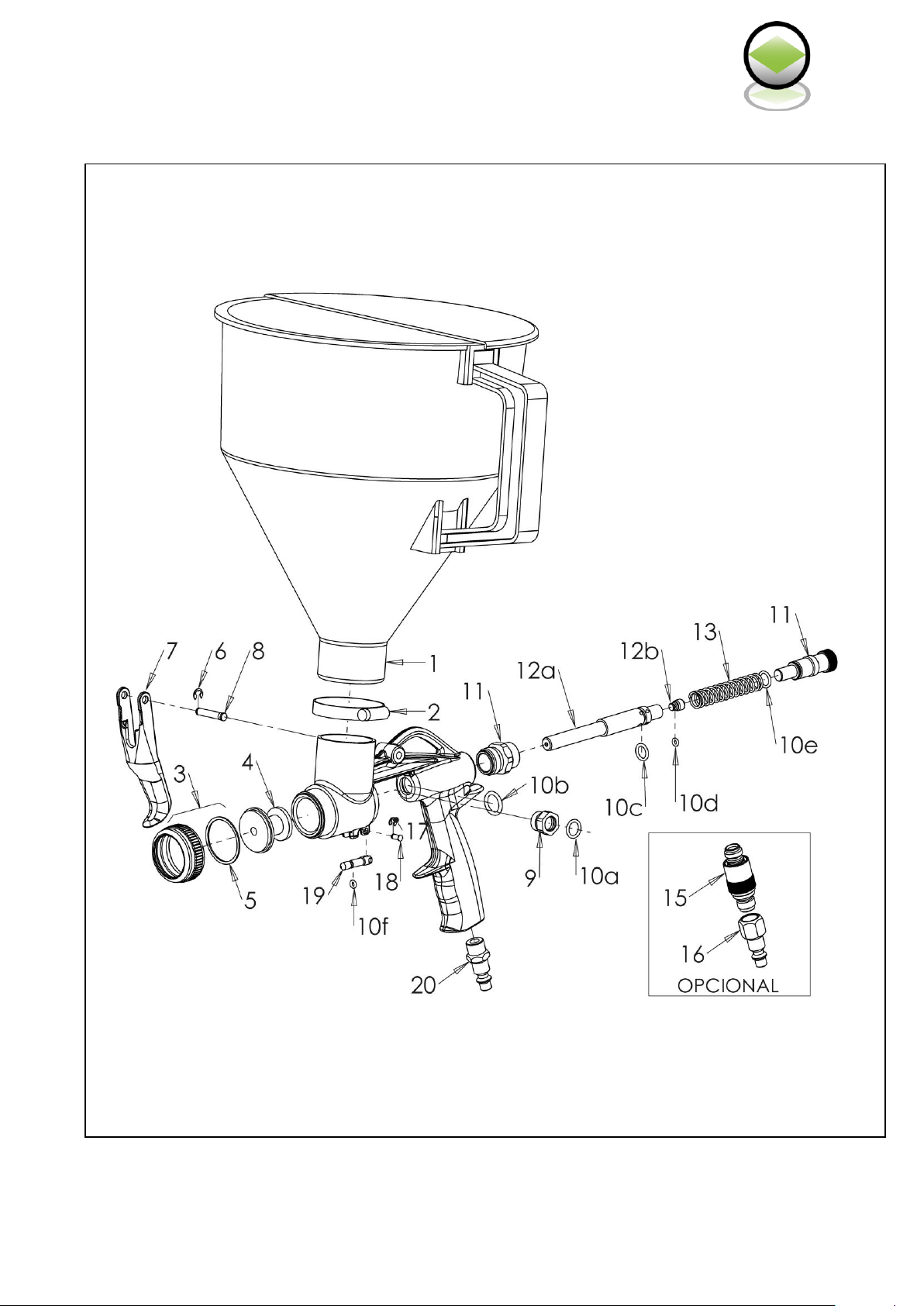

Once the work is finished, close the product regulator completely (no.12 of the exploded

view) to prevent vaporization.

9. WARRANTY CERTIFICATE

1. It extends only and exclusively against any manufacturing defect.

2. The period of validity is 2 years from the date of purchase.

3. Warranty covers the repair in our facilities or our technical services.

4. The machine, whose fault is due to bumps, falls or similar facts, is excluded from any

warranty.

ATTENTION:

A misuse of the equipment can cause accidents, defects or malfunctioning.

Please, read carefully the following instructions.