2 Inverter type and specification

14

brake

Power

consumption

brake

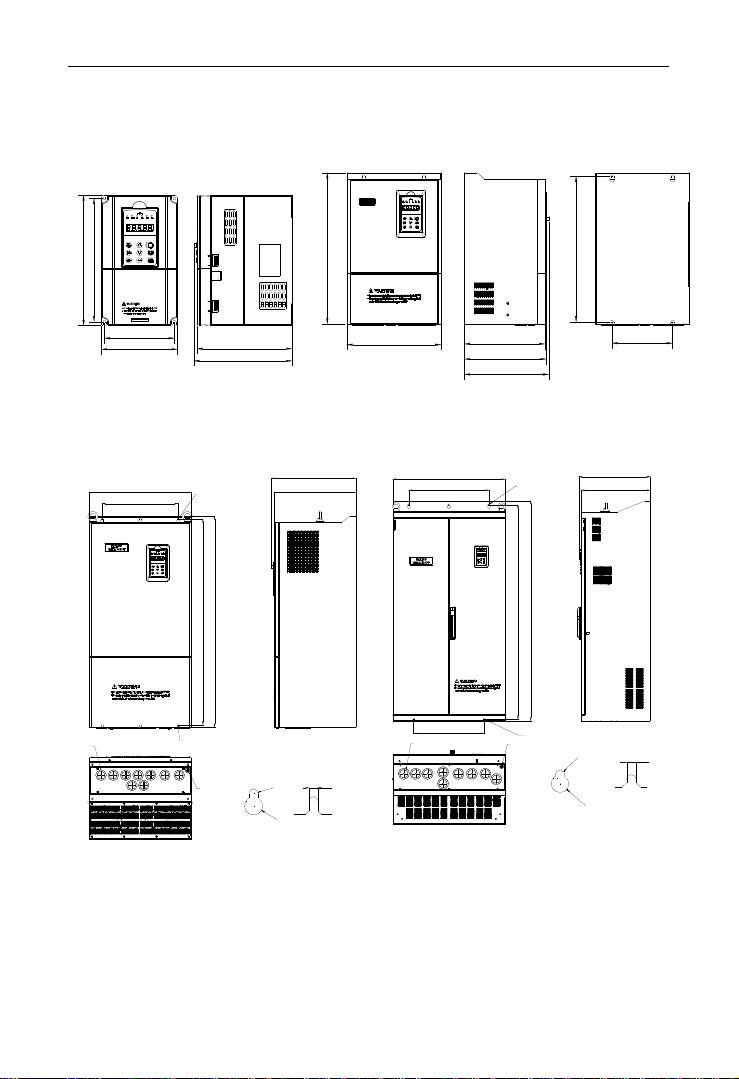

DGI600 3 phase 15KW & under power range with inbuilt brake

unit,only add brake resistor between(+)and PB.

18.5KW & up power range is possible to add brake unit between

(+)and(-)outside; or extra connect brake unit with adding brake

resistor between(+)and PB.

DGI500 series can connect brake unit between(+)and(-)outside.

DC brake Start, stop action for option, action frequency 0~15Hz,action

current 0~100% of rated current,action time 0~30.0s

jog Jog frequency range:0Hz~up limit frequency;jog acceleration

and deceleration time 0.1~6000.0 seconds for setting.

Multi-section speed

run

Realized by inbuilt PLC or control terminal; with 15 section speed,

each section speed with separately acceleration and deceleration

time; with inbuilt PLC can achieve reserve when power down.

Inbuilt PID controller Convenient to make closed-loop control system

Automatic energy

saving run

Optimize V/F curve automatically to achieve power saving run

according to the load status.

Automatic voltage

regulate(AVR)

Automatically keep output voltage constant, when the power grid

voltage fluctuation

Automatic current

limiting

Current limited automatically under run mode in avoid of inverter

over-current frequently to trip.

carrier modulation Modulate carrier wave automatically according to the load

characteristic.

Speed tracking restart Make rotating motor smoothly start without shocking

Running function

running command

specified channel

Keypad specified, control terminal specified, communication

specified can switch through various means.

Running frequency

specified channel

Main & auxiliary specified to a realize one main adjusting and one

fine control. Digital specified, analog specified, pulse specified,

pulse width specified, communication specified and others, which

can be switched by many means at any time.

Binding function Run command channel and frequency specified channel can bind

together randomly and switch synchronously

Input output characteristic

Digital input channel

Channel 8 for universal digital input, max. Frequency 1KHz,

channel 1 can be used as pulse input channel, max. Input 50KHz,

which can be expanded to channel 14 .

Analog input channel

Channel 2 for analog input channel, AI1 can choose 4~20mA or

0~10V output,AI2 is differential input channel,4~20mA or

-10~10V for option,which can be expanded to channel 4 analog

input.

Pulse output channel 0.1 ~20KHz pulse square signal output to achieve setting

frequency, output frequency and other physical quantity output.

Analog output channel

Channel 2 for analog signal output, AO1 can choose 4~20mA or

0~10V,AO2 can choose 4~20mA or 0~10Vto achieve setting

frequency, output frequency and other physical quantity output,

which can be expanded to channel 4 analog output.