Deif SIM-Q MKII Installation instructions

Table of contents

1. WARNINGS AND LEGAL INFORMATION...............ERROR! BOOKMARK NOT DEFINED.

3.5 LEGAL INFORMATION AND RESPONSIBILITY........................ERROR!BOOKMARK NOT DEFINED.

3.6 ELECTROSTATIC DISCHARGE AWARENESS ........................ERROR!BOOKMARK NOT DEFINED.

3.7 SAFETY ISSUES...............................................................ERROR!BOOKMARK NOT DEFINED.

3.8 DISCLAIMER....................................................................ERROR!BOOKMARK NOT DEFINED.

3.9 DEFINITIONS ...................................................................ERROR!BOOKMARK NOT DEFINED.

2. APPLICATION – GAS ENGINE AND CHP CONTROL............. ERROR! BOOKMARK NOT

DEFINED.

2.1 FUNCTIONALITIES............................................................ERROR!BOOKMARK NOT DEFINED.

2.2 SCOPE OF SUPPLY..........................................................ERROR!BOOKMARK NOT DEFINED.

2.3 NEEDED INFORMATION FOR QUOTATIONS..........................ERROR!BOOKMARK NOT DEFINED.

3. SOLUTION DESCRIPTION, ENGINE.......................ERROR! BOOKMARK NOT DEFINED.

3.1 DM 400 GAS –MAIN CONTROLLER...................................ERROR!BOOKMARK NOT DEFINED.

3.2 AIR/FUEL MIXERS.............................................................ERROR!BOOKMARK NOT DEFINED.

3.3 THROTTLE VALVE AND ACTUATOR.....................................ERROR!BOOKMARK NOT DEFINED.

3.4 DIGITAL IGNITION CONTROL SYSTEM.................................ERROR!BOOKMARK NOT DEFINED.

3.5 ANTI KNOCKING SYSTEM ..................................................ERROR!BOOKMARK NOT DEFINED.

4. SOLUTION DESCRIPTION, RETROFITS ................ERROR! BOOKMARK NOT DEFINED.

5. SOLUTION DESCRIPTION, CHP .............................ERROR! BOOKMARK NOT DEFINED.

5.1 AVAILABLE COMBINED CONTROLS.....................................ERROR!BOOKMARK NOT DEFINED.

5.2 USER INTERFACE ............................................................ERROR!BOOKMARK NOT DEFINED.

APPLICATION NOTES

Document no.: 4189330024A

•3 functions: Normal, Fast and Test

•Easy adjustment and verification

•2000 µF leakage capacitance

•Working voltage up to 690 V AC

and up to 1000 V DC

•IEC 61557-8

•Class approval

Selectable Insulation Monitor, SIM-Q MKII

INSTALLATION/OPERATION INSTRUCTIONS

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 2 of 18

Table of contents:

1GENERAL INFORMATION................................................................................................... 3

1.1 WARNINGS,LEGAL INFORMATION AND SAFETY ....................................................................3

1.1.1 Warnings and notes................................................................................................. 3

1.1.2 Legal information and disclaimer.............................................................................3

1.1.3 Safety issues ........................................................................................................... 3

1.1.4 Electrostatic discharge awareness.......................................................................... 3

1.1.5 Factory settings .......................................................................................................3

1.2 ABOUT THE INSTALLATION INSTRUCTIONS ...........................................................................4

1.2.1 General purpose...................................................................................................... 4

1.2.2 Intended users......................................................................................................... 4

1.2.3 Contents and overall structure.................................................................................4

2DESCRIPTION....................................................................................................................... 5

2.1 GENERAL DESCRIPTION OF SIM-Q MKII.............................................................................5

3INSTALLATION..................................................................................................................... 6

3.1 CONNECTION ....................................................................................................................6

3.1.1 Connection of AC auxiliary supply...........................................................................7

3.1.2 Connection of DC auxiliary supply........................................................................... 8

3.2 DIMENSIONS .....................................................................................................................8

3.3 CHANGING THE DEFAULT SETTINGS....................................................................................9

3.4 CONFIGURATION OF THE MEASURING RANGE .................................................................... 10

3.5 ADJUSTMENT OF THE SET POINT.......................................................................................10

3.6 FUSE..............................................................................................................................11

3.7 WARNING -MEGGER TEST DURING COMMISSIONING.......................................................11

4OPERATION........................................................................................................................12

4.1 LED INDICATORS ............................................................................................................12

4.1.1 Normal mode ......................................................................................................... 13

4.1.2 Fast mode.............................................................................................................. 14

4.1.3 Test mode..............................................................................................................15

4.2 RESPONSE TIME GRAPHS.................................................................................................15

4.3 TECHNICAL SPECIFICATIONS ............................................................................................16

5DETERMINATION OF CAPACITY WITHIN AN APPLICATION........................................ 17

5.1 LEAKAGE CAPACITANCE IN A CONNECTED NETWORK.......................................................... 17

5.2 LEAKAGE CAPACITANCE IN A DISCONNECTED NETWORK.....................................................18

5.3 LEAKAGE CAPACITANCE USING THE SIM-Q MKII FAULT FINDING FUNCTION ........................18

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 3 of 18

1 General information

1.1 Warnings, legal information and safety

1.1.1 Warnings and notes

Throughout this document, a number of warnings and notes with helpful user information will be

presented. To ensure that these are noticed, they will be highlighted as follows in order to

separate them from the general text.

Warnings

Warnings indicate a potentially dangerous situation, which could result in death,

personal injury or damaged equipment, if certain guidelines are not followed.

Notes

Notes provide general information, which will be helpful for the reader to bear in mind.

1.1.2 Legal information and disclaimer

DEIF takes no responsibility for installation or operation of the product. If there is any doubt about

how to install or operate the product, please contact DEIF.

The unit is not to be opened by unauthorised personnel. If opened anyway, the warranty

will be lost.

Disclaimer

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

The English version of this document always contains the most recent and up-to-date information

about the product. DEIF does not take responsibility for the accuracy of translations, and

translations might not be updated at the same time as the English document. If there is a

discrepancy, the English version prevails.

1.1.3 Safety issues

Installing and operating the unit may imply work with dangerous currents and voltages. Therefore,

the installation should only be carried out by authorised personnel who understand the risks

involved in working with live electrical equipment.

Be aware of the hazardous live currents and voltages. Do not touch any AC

measurement inputs as this could lead to injury or death.

1.1.4 Electrostatic discharge awareness

Sufficient care must be taken to protect the terminal against static discharges during the

installation. Once the unit is installed and connected, these precautions are no longer necessary.

1.1.5 Factory settings

The product is delivered from factory with certain factory settings. These are based on average

values and are not necessarily the correct settings for the product. Precautions must be taken to

check the settings before running the product.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 4 of 18

1.2 About the installation instructions

1.2.1 General purpose

The general purpose of this document is to give the user important information to be used in the

installation of the unit.

Make sure to read this document before starting to work with the unit. Failure to do this

could result in human injury or damage to the equipment.

1.2.2 Intended users

These Installation Instructions are mainly intended for the operator and the person responsible

for the design and installation. In most cases, this would be a panel builder designer. Naturally,

other users might also find useful information in the document.

1.2.3 Contents and overall structure

This document is divided into chapters, and in order to make the structure simple and easy to

use, each chapter will begin from the top of a new page.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 5 of 18

2 Description

2.1 General description of SIM-Q MKII

The SIM-Q MKII is intended for insulation monitoring on a single-phase or a 3-phase IT power

system with or without neutral. The special characteristic of an IT power system is the fact that

no live conductor is connected directly to earth. The SIM-Q MKII is connected to the power system

by connecting the terminal marked Pto one of the phases (or the neutral). The FE input is then

connected to the safety cable. To be able to monitor any kind of insulation failure, all accessible

conductive building structures must be connected to the cable marked FE (functional earth).

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 6 of 18

3 Installation

3.1 Connection

If a test function is wanted, an arrangement based on a resistor and a push-button can be

mounted as illustrated in the drawings below. The value of the resistor can be any value from 0

Ωto the max. allowed insulation value. The SIM-Q MKII can be supplied from the IT system under

supervision, but it can also be supplied from another source, for example a 24 V DC source; see

the label for supply information.

The following functions can be selected by means of the switch that is available at the front of the

SIM-Q MKII: Monitoring, fault finding and test.

3-phase, AC 1-phase, AC

1-phase, DC

Recommended fuse size: max 2 A.

With the switch in monitoring mode, the SIM-Q MKII will run a fast measuring mode the first 15

seconds after a power-up. This mode can be used to perform a switchboard test. When a known

resistor is connected for testing, the auxiliarysupply is disconnected and reconnected at the same

time (not shown in the illustration). The response time for measuring the known resistor will be

approximately 6 seconds. The two red LEDs will be illuminated, but the relay contact will not be

activated. After 15 seconds, the SIM-Q MKII automatically changes to normal monitoring mode.

As an alternative, the test can be carried out in fault finding mode. The response time will be 1

second, and if the set point is exceeded the relay output will be activated. If the switch is moved

to the “Test” position, an internal function test of the SIM-Q MKII is carried out. The reading on

the scale during the test is 0 Ω, and the relay output is activated.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 7 of 18

3.1.1 Connection of AC auxiliary supply

Type: 80 to 152 V AC

Type: 176 to 288 V AC

Type: 320 to 576 V AC

X1, X2: 100 V AC ±20 %

X1, X2: 220 V AC ±20 %

X1, X2: 400 V AC ±20 %

X1, X3: 110 V AC ±20 %

X1, X3: 230 V AC ±20 %

X1, X3: 450 V AC ±20 %

X1, X4: 127 V AC ±20 %

X1, X4: 240 V AC ±20 %

X1, X4: 480 V AC ±20 %

Label for AC version

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 8 of 18

3.1.2 Connection of DC auxiliary supply

Type: 18 to 30 V DC

X1: -0 V DC Zero

X2: +24 V DC ±25 %

Label for DC version

3.2 Dimensions

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 9 of 18

Note: On SIM-Q MKII

with LF option, S1

must always be in the

2000 μF position!

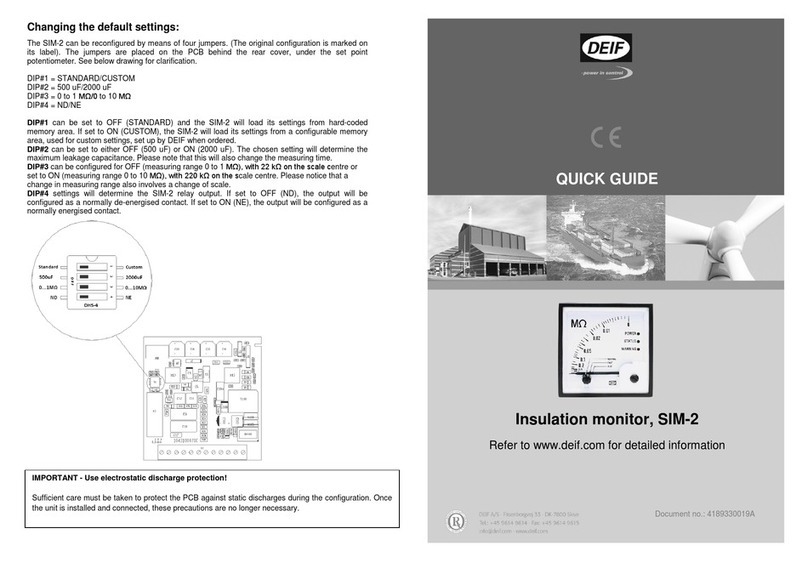

3.3 Changing the default settings

The SIM-Q MKII can be reconfigured by means of four jumpers. (The original configuration is

marked on the label). The jumpers are placed on the PCB behind the rear cover, under the set

point potentiometer. See the drawing below for clarification.

DIP#1 = STANDARD/CUSTOM

DIP#2 = 500 μF/2000 μF

DIP#3 = 0 to 1 MΩ/0 to 10 MΩ

DIP#4 = ND/NE

DIP#1 can be set to OFF (STANDARD), and the SIM-Q MKII will load its settings from a hard-

coded memory area. If it is set to ON (CUSTOM), the SIM-Q MKII will load its settings from a

configurable memory area that is used for custom settings and is set up by DEIF upon ordering.

DIP#2 can be set to either OFF (500 μF) or ON (2000 μF). The chosen setting will determine the

maximum leakage capacitance. Note that this will also change the measuring time. See the

chapter “Calculation of capacity within an application” for determination of the needed max.

capacity setting.

DIP#3 can be configured to OFF (measuring range 0 to 1 MΩ) with 22 kΩon the scale centre, or

it can be set to ON (measuring range 0 to 10 MΩ) with 220 kΩon the scale centre. Notice that a

change in measuring range also involves a change of scale.

DIP#4 settings will determine the SIM-Q MKII relay output. If it is set to OFF (ND), the output is

configured as a normally de-energised contact. If it is set to ON (NE), the output is configured as

a normally energised contact.

Use electrostatic discharge protection!

Sufficient care must be taken to protect the PCB against static discharges during the

configuration. Once the unit is installed and connected, these precautions are no longer

necessary.

Example:

• Standard is selected (all jumpers are active).

• Max. 500 μF leakage capacitor is selected.

• 1 MΩis selected as measuring range.

• ND is selected as relay function.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 10 of 18

1114020xxxA

3.4 Configuration of the measuring range

The SIM-Q MKII can be configured for measuring range 1 MΩto 0 MΩ(1000 to 0 kΩ) with 22 kΩ

on the scale centre, or for 10 MΩto 0 MΩwith 220 kΩon the scale centre. The figure above

shows the position of the switch for selection of either 1 MΩor 10 MΩmeasuring range. Notice

that a change of measuring range also involves a change of scale. Change of scale can be done

by following the instructions below.

Figure 2

•Interrupt signal/supply to the terminals before you exchange the scale.

•Push the scale cover towards the rear edge.

•Remove the scale by means of a screwdriver or the like.

•Insert the new scale and press gently till it snaps into place.

•Push the scale cover back again; after this the unit is ready for mounting.

3.5 Adjustment of the set point

The warning set point is adjusted on the rear of the

housing by means of a screwdriver, see the figure

to the right. Also in test mode, the actual set point

is shown on the meter, and it can be reconfigured

on the rear of the housing. When you power up the

product, the first 10 seconds (default) are used to

show the actual set point that is configured on the

meter.

Two ranges available:

13 kΩto 200 kΩor 40 kΩto 1.5 MΩ.

See example on the label to the right.

Typical setting:

Insulation resistance corresponding to position of the red marking pointer or lower limit of the

section marked with red on the instrument scale. Typically, the insulation alarm limit is 1 kΩper

volt. For example, 400 V system voltage could have an alarm limit of 0.4 MΩ.

If needed, the precise set point can be pre-set in the product from DEIF before delivery (fixed set

point). See data sheet, section "Order specifications".

If you want precise alarm settings, a known resistor corresponding to the red section on the

instrument scale must be connected between P and PE. Then adjust the potentiometer until alarm

is transmitted. For fast response, set the switch on the front in the fault-finding position.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 11 of 18

3.6 Fuse

Recommended fuse for auxiliary supply X2, X3, X4 is max. 2 A.

3.7 WARNING - Megger test during commissioning

If the installation is to be tested by means of a high-voltage "MEGGER", the SIM-Q MKII must be

disconnected at terminal "p" before testing is carried out. Ignoring this may result in damage to

the SIM-Q MKII if the test voltage is higher than 1000 V AC/DC. Besides, the insulation test will

be affected by the built-in DC voltage generator impedance (approximately 250 kΩ).

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 12 of 18

4 Operation

4.1 LED indicators

The SIM-Q MKII is equipped with three LED indicators: two green LEDs and one yellow LED

placed as the lowest one. The LED colours are as described in the table below:

Power

Top LED OFF MCU not yet initialised, or no power.

ON Power on product and MCU has initialised.

Flashing Power-up sequence.

Status

Middle LED OFF No valid measurement.

ON Valid measurement.

Flashing

AAL mode: Measurement is not steady.

DIM mode: Last measurement failed.

Warning

Bottom LED

OFF

Measured insulation resistance is higher than set

point.

Long flash

(75 %, 500 mHz)

Measured insulation resistance is lower than set

point but relay is not active. (ON delay). (AAL

mode during power-up).

Short flash

(25 %, 500 mHz)

Measured insulation resistance is higher than set

point but relay is still active. (OFF delay).

ON

Measured insulation resistance is lower than set

point and relay is activated.

The next paragraphs explain more about LEDs in combination with the meter and switch

positions.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 13 of 18

4.1.1 Normal mode

Start-up monitoring mode

Fast measurement

(Fast mode measurement)

Power LED is flashing

Warning LED is set according to insulation

resistance and set point

Status LED is flashing (1 Hz 50 % duty cycle)

Meter shows the measured resistance in fast mode

Relay is deactivated independently of the measured

insulation resistance

“Power-up fast mode” is programmable in the range

0 to 30 s. Default = 0 s

Start-up monitoring mode

Show set point

Power LED is flashing

Warning LED is off

Status LED is flashing (0.5 Hz 50 % duty cycle)

Meter shows the set point

Relay is deactivated

“Power-up set point” is programmable in the range 0

to 30 s. Default = 15 s

Start-up monitoring mode

DIM-Q measurement

Power LED is on

Status LED is flashing

Warning LED is off

Meter is at unlimited insulation resistance

Relay is deactivated

Change from other mode

to monitoring mode

Power LED is on

Status LED is flashing

Warning LED is off

Meter is at unlimited insulation resistance

Relay is deactivated

Valid measurement

Insulation resistance is

higher than set point

Power LED is on

Status LED is on => valid measurement

Warning LED is off => no insulation error

Meter shows the measured insulation resistance

Relay is deactivated

Valid measurement

Insulation resistance is

lower than set point

Power LED is on

Status LED is on => valid measurement

Warning LED is on => insulation error

Meter shows the measured insulation resistance

Relay is activated

Measurement failed

Resistance drop

Resistance jump

Fail to converge, max.

measurement time

DC error

Power LED is on

Status LED is flashing (1 flash 3 breaks) =>

resistance drop

Status LED is flashing (2 flashes 2 breaks) =>

resistance jump

Status LED is flashing (2 Hz, 50 % duty cycle) =>

fail to converge, max. measurement time

Status LED is flashing (3 flashes 1 break) => DC

error measurement

Warning is set according to last valid measurement

Meter shows last valid measurement

Relay is set according to last valid measurement

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 14 of 18

4.1.2 Fast mode

Power up in fault finding mode

Show set point

Power LED is flashing

Status LED is flashing (0.5 Hz 50 %

duty cycle)

Meter shows the set point

Relay is deactivated

Warning LED is off

“Power-up set point” is programmable

in the range 0 to 30 s. Default = 15 s

Change from other state to fault

finding mode

Power LED is on

Status LED is flashing

Warning LED is off => no insulation

error

Meter shows unlimited insulation

resistance

Relay is deactivated

Measured insulation resistance is

lower than set point and input is

steady

Power LED is on

Status LED is on => valid data

Warning LED is on => insulation error

Meter shows the measured insulation

resistance

Relay is activated

Measured insulation resistance is

higher than set point and input is

steady

Status LED is on => valid data

Warning LED is off => no insulation

error

Meter shows the measured insulation

resistance

Relay is deactivated

Measured insulation resistance is

higher than set point but is not

steady

Insulation resistance is changed more

than 1 %/min.

Power LED is on

Status LED is flashing => resistance is

not steady. The more constant the

light, the closer to a valid result

Warning LED is off => no insulation

error

Meter shows the measured insulation

resistance

Relay is deactivated

Measured insulation resistance is

lower than set point but is not

steady

Insulation resistance is changed more

than 1 %/min.

Power LED is on

Status LED is flashing => resistance is

not steady. The more constant the

light, the closer to a valid result

Warning LED is on => insulation error

Meter shows the measured insulation

resistance

Relay is activated

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 15 of 18

4.1.3 Test mode

Test mode

Power LED is on

Status LED is on

Warning LED is on

Meter shows insulation resistance set

point

Relay is activated

4.2 Response time graphs

The response time of the SIM-Q MKII is dependent on several different factors such as

configuration, settings, capacity in the system and, of course, the resistance itself. The total

response time is opposite proportional with the capacity and the resistance. This means that if

great capacitance and insulation resistance is present in the application, there will be a long

measuring time before the cycle is finished. If the capacity or the resistance gets smaller, the SIM-

Q MKII will reduce the response time.

To comply with IEC 61557-8, the response time must be lower than 30 minutes, which is marked

as the blue area in the graph below.

Outside the blue area, the product will still perform but it will not meet the 30 minutes response

time limit stated in IEC 61557-8.

So, when you select a set point (Ran) in systems with 2000 µF setting, be aware of the resulting

response time.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 16 of 18

Graph above: There are no restrictions when you select set point (Ran) in 500 µF settings.

Graph above: Beware of response time when you select set point (Ran) in 2000 µF settings.

If the installation contains frequency converters that work below20 Hz, the SIM-Q MKII with option

LF should be used instead, as it provides reliable measurements down to 5 Hz.

4.3 Technical specifications

See the data sheet, document no. 4921230028.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 17 of 18

5 Determination of capacity within an application

5.1 Leakage capacitance in a connected network

Measuring of the leakage capacitance in a connected network using a voltmeter and an ammeter

(SL = PE).

Single phase:

CE = A/(V × 2 × phi × f). Phi is 3.14 and f is the frequency in Hz.

3 phases:

CE = A/(V × √3 × 2 × phi × f).

Example for a 3-phase system:

The current is measured to 30 A and the voltage is measured to 400 V:

CE = 30 A/400 V × √3 × 2 × 3.14 × 50 Hz = 137 μF per phase, total CE is 3 × 137 μF = 411 μF.

For a 4-wire network, the CE total = CE × 4.

SIM-Q MKII Installation/operation instructions

DEIF A/S Page 18 of 18

5.2 Leakage capacitance in a disconnected network

Measuring of the leakage capacitance in a disconnected network using a mA meter, a voltmeter

and an AC source with a known frequency.

CE total = mA/(V × 2 × phi × f). Phi = 3.14 and f is the frequency in Hz.

In the example below, the mA is measured to 100 mA and the voltage from the AC source is

measured to 50 V AC:

CE total = 0.1 A/50 V × 2 × 3.14 × 50) = 6.3 μF.

5.3 Leakage capacitance using the SIM-Q MKII fault finding function

The fault-finding function of the SIM-Q MKII can be used to estimate the size of the leakage

capacitor. Notice that this method can only be used when no insulation error is present.

Set the switch in fault finding position.

Discharge the leakage capacitor by short-circuiting P and PE by means of a low impedance load,

for example a bulb suitable for the AC voltage level on the system.

Open the short circuit between P and PE. Then measure the time (t) that elapses until the

instrument indicates approximately 0.5 (0.05) MΩon the scale.

By using the formula C = t/0.3, the approximate leakage capacitor in μF can be calculated.

Example: t = 10 seconds, C = 33 μF.

Table of contents

Other Deif Monitor manuals