0INTRODUCTION.............................................................................................................................. 3

1COMPONENTS................................................................................................................................3

2TECNICAL SPECIFICATIONS........................................................................................................ 4

2.1 CERAMIC FURNACE UNIT.............................................................................................................. 4

2.2 VACUUM PUMP UNIT..................................................................................................................... 4

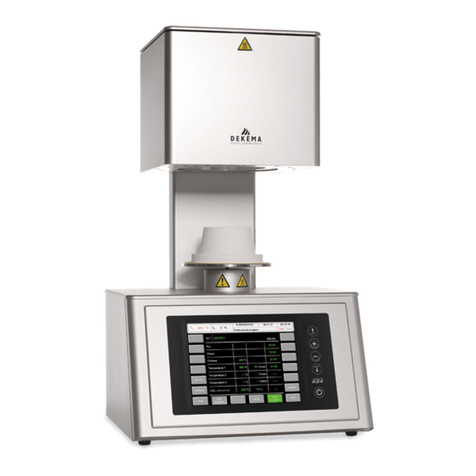

3DESCRIPTION OF THE EQUIPMENT............................................................................................ 5

3.1 FRONT........................................................................................................................................ 5

3.2 BACK.......................................................................................................................................... 6

4SAFETY MEASURES...................................................................................................................... 7

4.1 NOTES REGARDING SAFETY ........................................................................................................ 7

4.2 SETUP ........................................................................................................................................ 8

4.3 OPERATION................................................................................................................................. 8

5STARTUP ...................................................................................................................................... 11

5.1 SETUP ...................................................................................................................................... 11

5.2 INSTALLATION ASSISTANT........................................................................................................... 11

6MAINTENANCE AND SERVICE................................................................................................... 12

6.1 MAINTENANCE........................................................................................................................... 12

6.2 TEMPERATURE CALIBRATION ..................................................................................................... 12

6.3 CHECK-PROGRAM..................................................................................................................... 13

6.4 CHANGING THE BATTERY ........................................................................................................... 14

6.5 REPLACING THE HEATING ELEMENT ............................................................................................ 15

6.6 SERVICE AND TRANSPORT......................................................................................................... 15

6.7 REPLACEMENT PARTS................................................................................................................ 15

7USER INTERFACE........................................................................................................................ 16

7.1 FIRST STEPS............................................................................................................................. 16

7.1.1 CONTROLS ........................................................................................................................ 17

7.1.2 SET PROGRAMS (OPTIONAL)............................................................................................... 19

7.1.3 INDIVIDUAL FIRING PROGRAMS ............................................................................................ 21

7.2 PROGRAM MANAGER................................................................................................................. 23

7.3 PROGRAM DISPLAY.................................................................................................................... 24

7.4 PROGRAM PROCEDURE.............................................................................................................. 26

7.5 PROGRAM EDITOR ..................................................................................................................... 29

7.5.1 INDIVIDUAL PROGRAMS – STANDARD .................................................................................. 30

7.5.2 INDIVIDUAL PROGRAMS – PROFESSIONAL............................................................................ 31

7.5.3 INDIVIDUAL PROGRAMS – PRESS PROGRAMS (ONLY D4PRESS).......................................... 31

7.5.4 SET PROGRAMS................................................................................................................ 32

7.5.5 EDITING WHILE THE PROGRAM IS RUNNING........................................................................... 32

7.6 THE SETUP MENU..................................................................................................................... 32

7.6.1 FURNACE SETTINGS........................................................................................................... 33

7.6.2 MAINTENANCE PROGRAMS ................................................................................................. 34

7.6.3 DATA RECORDING AND TRANSFER....................................................................................... 36

7.6.4 ADDITIONAL FUNCTIONS..................................................................................................... 37

8PRINTING RECORDS AND CONNECTING TO A PC ................................................................. 39

8.1 PRINTING RECORDS .................................................................................................................. 39

8.2 PC CONNECTION (DREAM®).................................................................................................... 41

9PRACTICAL TIPS.......................................................................................................................... 42

10 INDEX............................................................................................................................................. 44

DEKEMA Dental-Keramiköfen GmbH, AUSTROMAT®D4, Version 3, 2006