DeKo DKAG20BL01 User manual

INSTRUCTION MANUAL

20V BRUSHLESS ANGLE GRINDER

1

DEKO TOOLS CO., LIMITED

www.dekotools.com Made in China

IMPORTANT:

Read this instruction manual before operating this product.

Keep the instruction manual for future reference.

Model No.:DKAG20BL01

V2109

2

General Power Tool Safety Warnings

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrig-

erators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk

of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) pro-

tected supply. Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as a

dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will

reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

WARNING: Read all safety warnings, instructions, illustrations and specifications provided

with this power tool. Failure to follow all instructions listed below may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-op-

erated (cordless) power tool.

WARNING:

3

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore

tool safety principles. A careless action can cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool

will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be con-

trolled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the

power tool before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding of moving parts, break-

age of parts and any other condition that may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into

account the working conditions and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

5) Battery tool use and care.

a) Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used with another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other battery packs may

create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys,

nails, screws or other small metal objects, that can make a connection from one terminal to another.

Shorting the battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact acci-

dentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected

from the battery may cause irritation or burns.

e) Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries

may exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

f) Do not expose a battery pack or tool to fire or excessive temperature . Exposure to fire or tempera-

ture above 40 °C may cause explosion. may exhibit unpredictable behaviour resulting in fire, explosion or

risk of injury.

4

g) Follow all charging instructions and do not charge the battery pack or tool outside the temperature

range specified in the instructions. Charging improperly or at temperatures outside the specified range

may damage the battery and increase the risk of fire.

6) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

b) Never service damaged battery packs. Service of battery packs should only be performed by the

manufacturer or authorized service providers.

Specific Safety Warnings For Angle Grinders

DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to

grinder safety rules. If you use this tool unsafely or incorrectly, you can suffer serious personal injury.

Always use proper guard with grinding wheel. A guard protects operator from broken wheel frag-

ments.

Do not use accessories which are not specifically designed and recommended by the tool manu-

facturer. Just because the accessory can be attached to your power tool, it does not assure safe opera-

tion.

The rated speed of the accessory must be at least equal to the maximum speed marked on the

power tool. Accessories running faster than their RATED SPEED can break and fly apart.

The outside diameter and the thickness of your accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

The arbor size of wheels, flanges, backing pads or any other accessory must properly fit the spin-

dle of the power tool. Accessories with arbor holes that do not match the mounting hardware of the

power tool will run out of balance, vibrate excessively and may cause loss of control.

Do not use a damaged accessory. Before each use inspect the accessory such as abrasive wheels

for chips and cracks, backing pad for cracks, tear or excess wear, wire brush for loose or cracked

wires. If power tool or accessory is dropped, inspect for damage or install an undamaged accessory.

After inspecting and installing an accessory, position yourself and bystanders away from the plane of

the rotating accessory and run the power tool at maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test time.

Wear personal protective equipment. Depending on application, use face shield, safety goggles

or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of

stopping flying debris generated by various operations. The dust mask or respirator must be capable of

filtrating particles generated by your operation. Prolonged exposure to high intensity noise may cause

hearing loss.

Keep bystanders a safe distance away from work area. Anyone entering the work area must wear

personal protective equipment. Fragments of workpiece or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

Hold power tool by insulated gripping surfaces only, when performing an operation where the

cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool “live” and shock the operator.

5

Never lay the power tool down until the accessory has come to a complete stop. The spinning acces-

sory may grab the surface and pull the power tool out of your control.

Do not run the power tool while carrying it at your side. Accidental contact with the spinning accesso-

ry could snag your clothing, pulling the accessory into your body.

Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause electrical hazards.

Do not operate the power tool near flammable materials. Sparks could ignite these materials.

Do not use accessories that require liquid coolants. Using water or other liquid coolants may result

in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other

accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point of

the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that is

entering into the pinch point can dig into the surface of the material causing the wheel to climb out or

kickout. The wheel may either jump toward or away from the operator, depending on direction of the

wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can

be avoided by taking proper precautions as given below.

Maintain a firm grip on the power tool and position your body and arm to allow you to resist kick-

back forces. Always use auxiliary handle, if provided, for maximum control over kickback or torque

reaction during start-up. The operator can control torque reactions or kickback forces, if proper precau-

tions are taken.

Never place your hand near the rotating accessory. Accessory may kickback over your hand.

Do not position your body in the area where power tool will move if kickback occurs. Kickback will

propel the tool in direction opposite to the wheel’s movement at the point of snagging.

Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the acces-

sory. Corners, sharp edges or bouncing have a tendency to snag the rotating accessory and cause loss

of control or kickback.

Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety Warnings Specific for Grinding Operations

Use only wheel types that are recommended for your power tool and the specific guard designed for

the selected wheel. Wheels for which the power tool was not designed cannot be adequately guarded

and are unsafe.

The guard must be securely attached to the power tool and positioned for maximum safety, so the

least amount of wheel is exposed towards the operator. The guard helps to protect operator from

broken wheel

fragments and accidental contact with wheel.

6

Wheels must be used only for recommended applications. For example: do not grind with the side of

cut-off wheel. Abrasive cut-off wheels are intended for peripheral grinding, side forces applied to these

wheels may cause them to shatter.

Always use undamaged wheel flanges that are of correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing the possibility of wheel breakage. Flanges for

cut-off wheels may be different from grinding wheel flanges.

Do not use worn down wheels from larger power tools. Wheel intended for larger power tool is not suit-

able for the higher speed of a smaller tool and may burst.

Safety Warnings Specific for Sanding Operations

Do not use excessively oversized sanding disc paper. Follow manufacturer’s recommendations, when

selecting sanding paper. Larger sanding paper extending beyond the sanding pad presents a laceration

hazard and may cause snagging, tearing of the disc or kickback.

Safety Warnings Specific for Wire Brushing Operations:

Be aware that wire bristles are thrown by the brush even during ordinary operation. Do not over stress

the wires by applying excessive load to the brush. The wire bristles can easily penetrate light clothing

and/or skin.

If the use of a guard is recommended for wire brushing, do not allow any interference of the wire

wheel or brush with the guard. Wire wheel or brush may expand in diameter due to work load and centrif-

ugal forces.

Safety Warnings Specific for Polishing Operations

Do not allow any loose portion of the polishing bonnet or its attachment strings to spin freely. Tuck away

or trim any loose attachment strings. Loose and spinning attachment strings can entangle your fingers

or snag on the workpiece.

Additional Safety Warnings

GFCI and personal protection devices like electrician’s rubber gloves and footwear will further enhance

your personal safety.

Always use proper guard with grinding wheel. A guard protects operator from broken wheel fragments.

Keep handles dry, clean and free from oil and grease. Slippery hands cannot safely control the power

tool.

Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and may lead to loss of control.

Check damaged parts. Before further use of the power tool, a guard or other part that is damaged

should be

carefully checked to determine that it will operate properly and perform its intended function. Check

for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or other part that is damaged should be properly

repaired or replaced by an authorized service center. Following this rule will reduce the risk of shock,

fire, or serious injury.

Inspect for and remove all nails from lumber before using this power tool. Following this rule will

reduce the risk of serious personal injury.

7

Battery & Charger

Before using battery charger, read all instructions and cautionary markings

on battery charger, battery pack, and product using battery.

1).

Do not disassemble charger or operate the charger if it has received a sharp blow, been

dropped or otherwise damaged in any way.

Replace damaged cord or plugs immediately. Incorrect

reassembly or damage may result in electric shock or fire.

2).

Do not recharge battery in damp or wet environment. Do not expose charger to rain or

snow.

If battery case is cracked or otherwise damaged, do not insert into charger. Battery short or fire

may result.

3).

Charge only DEKO approved rechargeable batteries.

See Specifications. Other types of batter-

ies may burst causing personal injury and damage.

4).

Charge battery pack in temperatures above +50 degrees F (10 degrees C) and below +104

degrees F (40 degrees C). Store tool and battery pack in locations where temperatures will

not exceed 120 degrees F (49 degrees C).

This is important to prevent serious damage to the

battery cells.

5).

Battery leakage may occur under extreme usage or temperature conditions.

Avoid contact

with skin and eyes. The battery liquid is caustic and could cause chemical burns to tissues. If liquid

comes in contact with skin, wash quickly with soap and water. If the liquid contacts your eyes, flush them

with water for a minimum of 10 minutes and seek medical attention.

6).

Place charger on flat non-flammable surfaces and away from flammable materials when

re-charging battery pack.

The charger and battery pack heat during charging. Carpeting and other

heat insulating surfaces block proper air circulation which may cause overheating of the charger and

battery pack. If smoke or melting of the case are observed unplug the charger immediately and do not

use the battery pack or charger.

1.

Battery Care and Disposal

1).

When batteries are not in tool or charger, keep them away from metal objects.

For example,

to protect terminals from shorting. DO NOT place batteries in a tool box or pocket with nails, screws, keys,

etc. Fire or injury may result.

WARNING :

WARNING :

2). DO NOT PUT BATTERIES INTO FIRE OR EXPOSE TO HIGH HEAT. They may explode.

Battery Disposal

Do not attempt to disassemble the battery or remove any component projecting

from the battery terminals. Fire or injury may result. Prior to disposal, protect exposed terminals with

heavy insulating tape to prevent shorting.

WARNING :

Some dust created by power sanding, sawing, grinding, drilling, and other con-

struction activities contains chemicals known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

Lead from lead-based paints,

Crystalline silica from bricks and cement and other masonry products, and

Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially designed to filter out microscopic particles.

8

Symbol Explanation

In this manual and/or on the machine the following symbols are used:

Read instruction manual before use.

Denotes risk of personal injury or damaged to the tool.

Do not dispose of power tools and batteries/rechargeable batteries into

household waste!

Dispose the products according to the regulation and requirement oflocal

council.

Conforms to relevant legislation and safety standards.

Keep the battery away from the fire.

Keep the battery away from moisture or water.

It is environmental friendly and could be recycled.

Wear ear defenders.

Wear safety goggles.

Wear breathing apparatus.

Charging temperature do not exceed 40°C.

MAX.40

Battery

Rated Voltage

Max wheel Dia.

No load speed

Spindle thread

Charger Input

Product Weight

DC 20V

Model name DKAG20BL01

125mm (5”)

3000/min, 8500/min

M14

Lithium-Ion Battery

100-240V~, 50/60Hz

1.57kg (bare tool)

Product Specifications

NOTE: For detailed specifications of Battery Pack/Charger, please refer to rating label on the

battery/charger of your tool.

9

WARNING :

WARNING :

Functional Description

Intended Use

You may use this product for grinding, cut off, sanding, wire brushing and polishing.

Assembly

Disconnect battery pack from tool before making any assembly, adjust-

ments or changing accessories.

Such preventive safety measures reduce the risk.

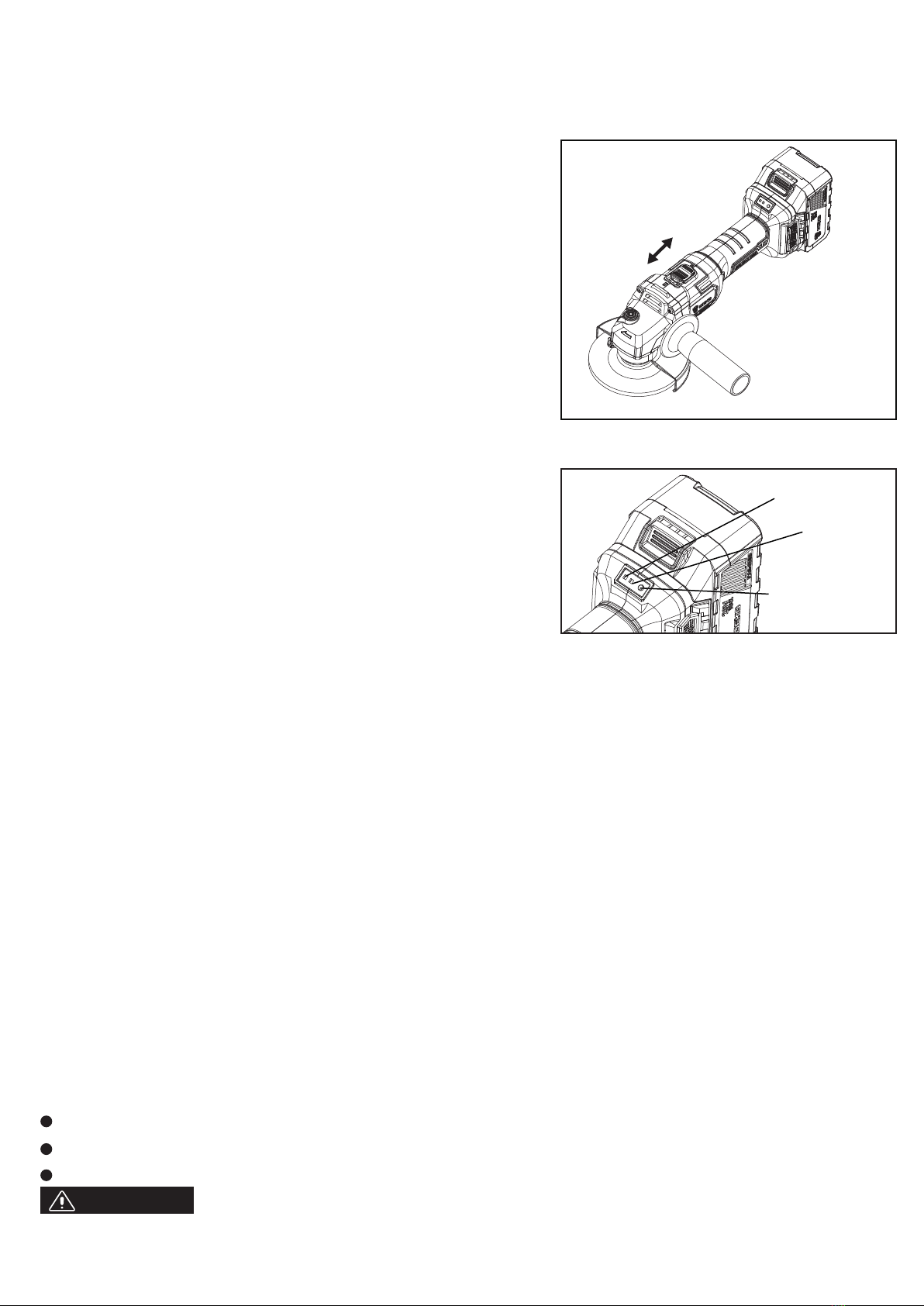

Auxiliary Handle Installation

The auxiliary handle must always be used to help prevent loss of control and possible

serious injury.

The auxiliary handle can be installed on the

left or right side of the grinder, depending on

operator preference.

1.Insert the side handle into the desired oper-

ating position.

2.Turn the side handle clockwise to securely

tighten.

REMARK: Your tool may not come with wheels/accessories or batteries. Please refer to the

detailed sales information in our online shop or information provided by the dealer.

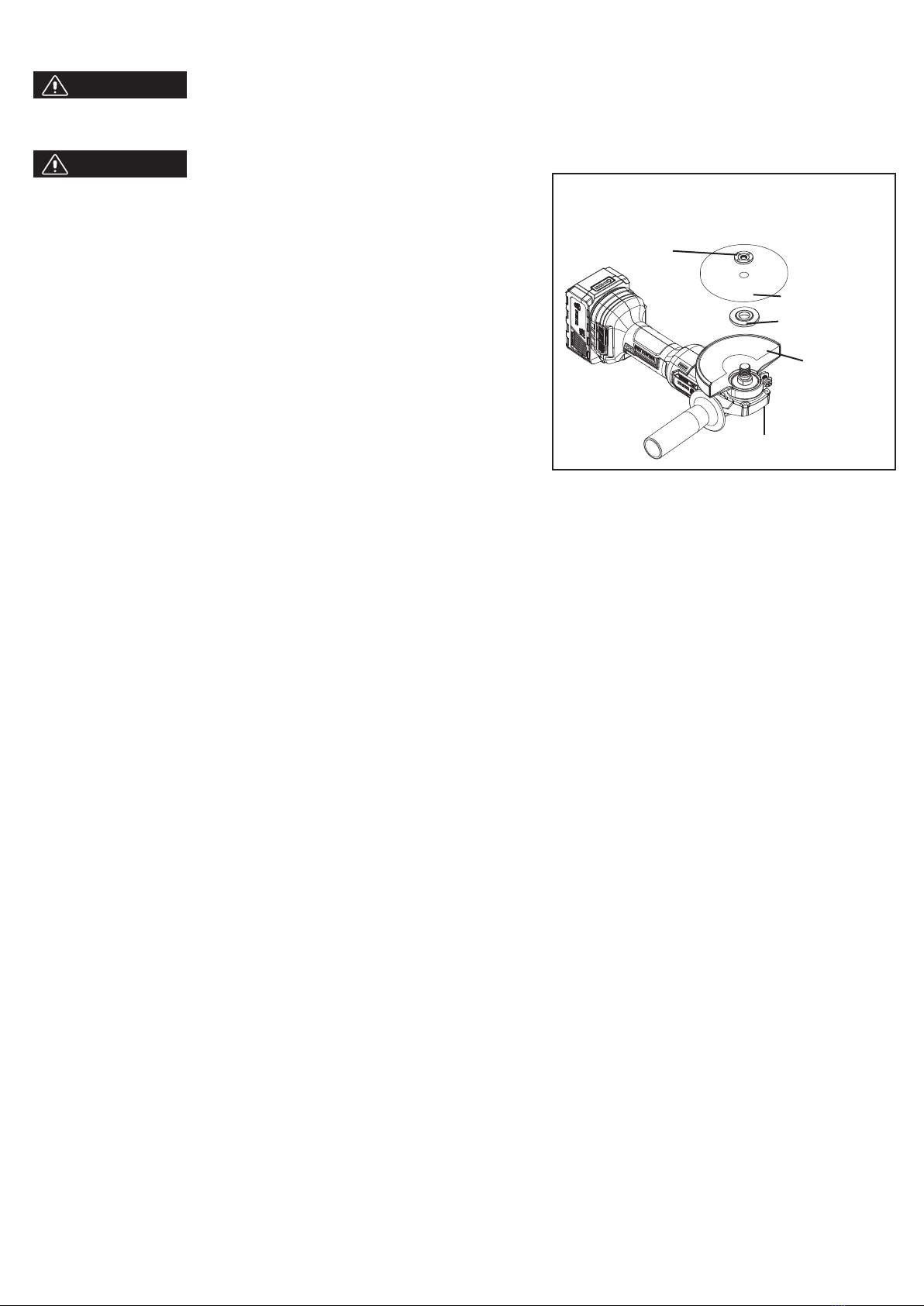

On/Off switch

Auxiliary handle

Grip handle

Spindle lock

Wheel guard Lock nut wrench

2-speed selector button

Air vents

Dust screen

Battery pack

Battery release button

Wheel/accessories

Speed indicator

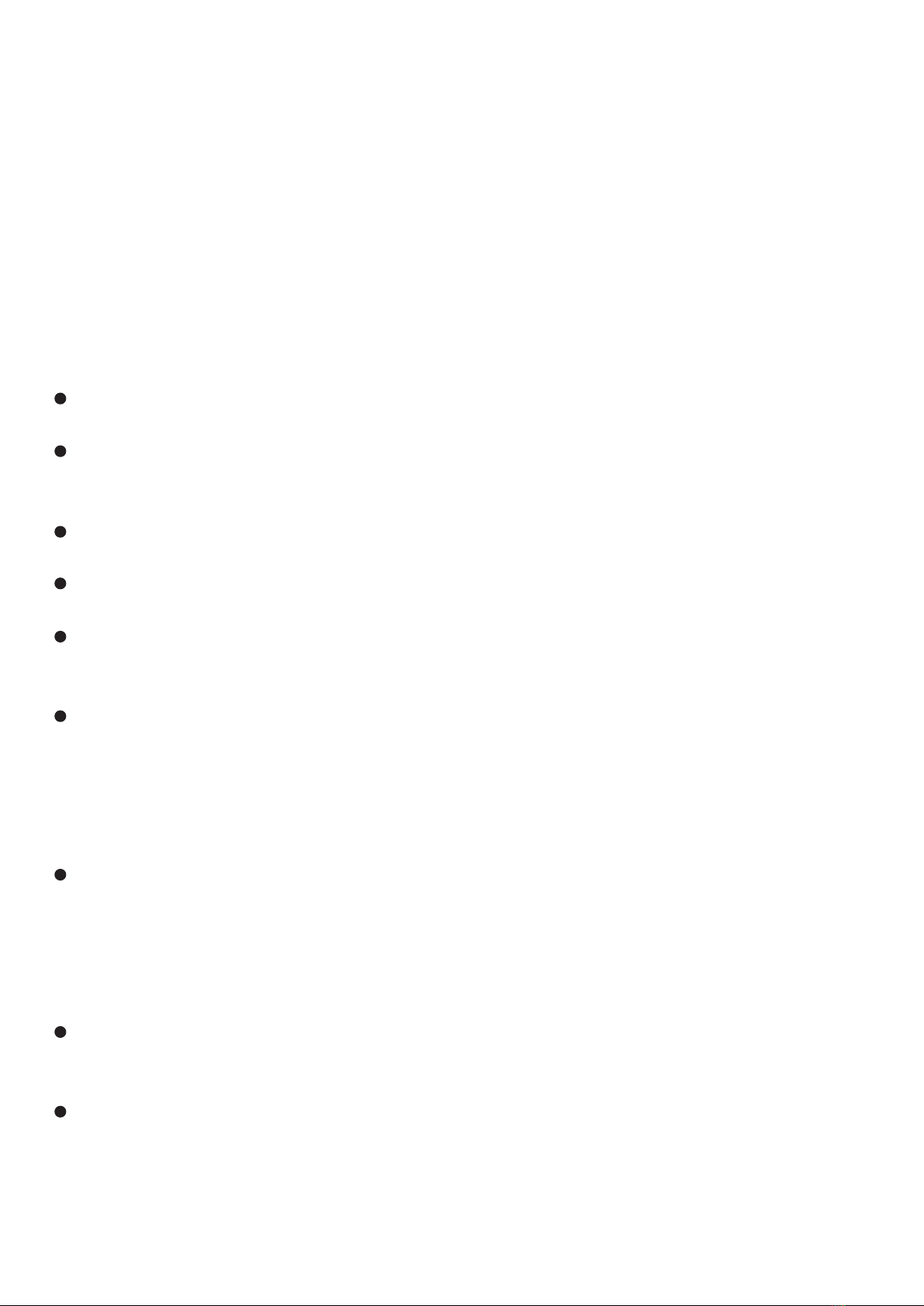

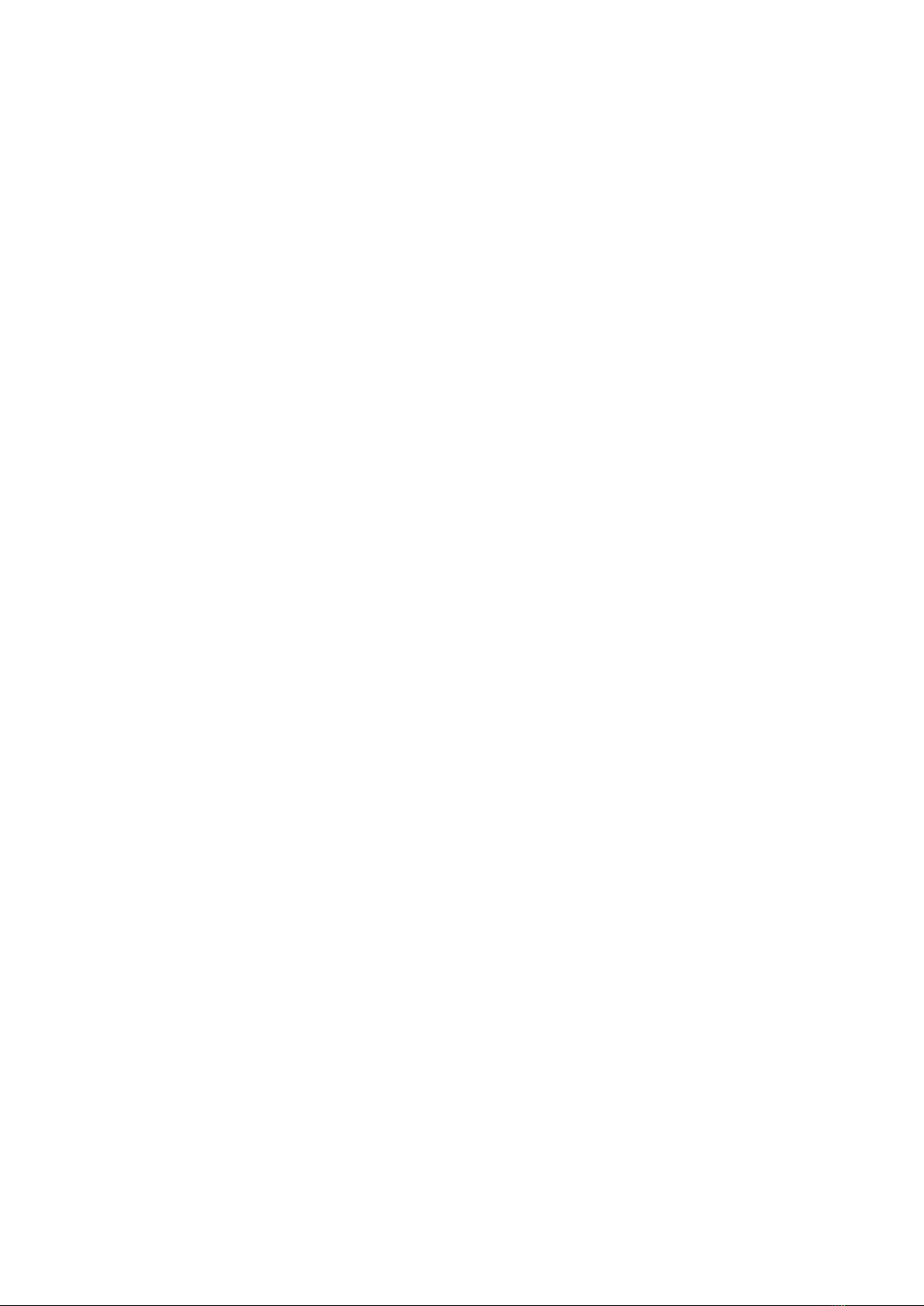

Wheel Guard Installation

When using a depressed center grinding wheel/Multi disc, flex wheel, wire wheel brush or cut-off wheel,

the wheel guard must be fitted on the tool so that the closed side of the guard always points toward the

operator.

1.Loosen the screw on the wheel guard by using a regular

philips screwdriver.

2.Mount the wheel guard onto the spindle neck. The closed

side of the guard must points toward in the direction of the

operator.

3.Tighten the screw on the wheel guard by using the philips

screwdriver.

4.To remove the guard, follow the installation procedure in

reverse.

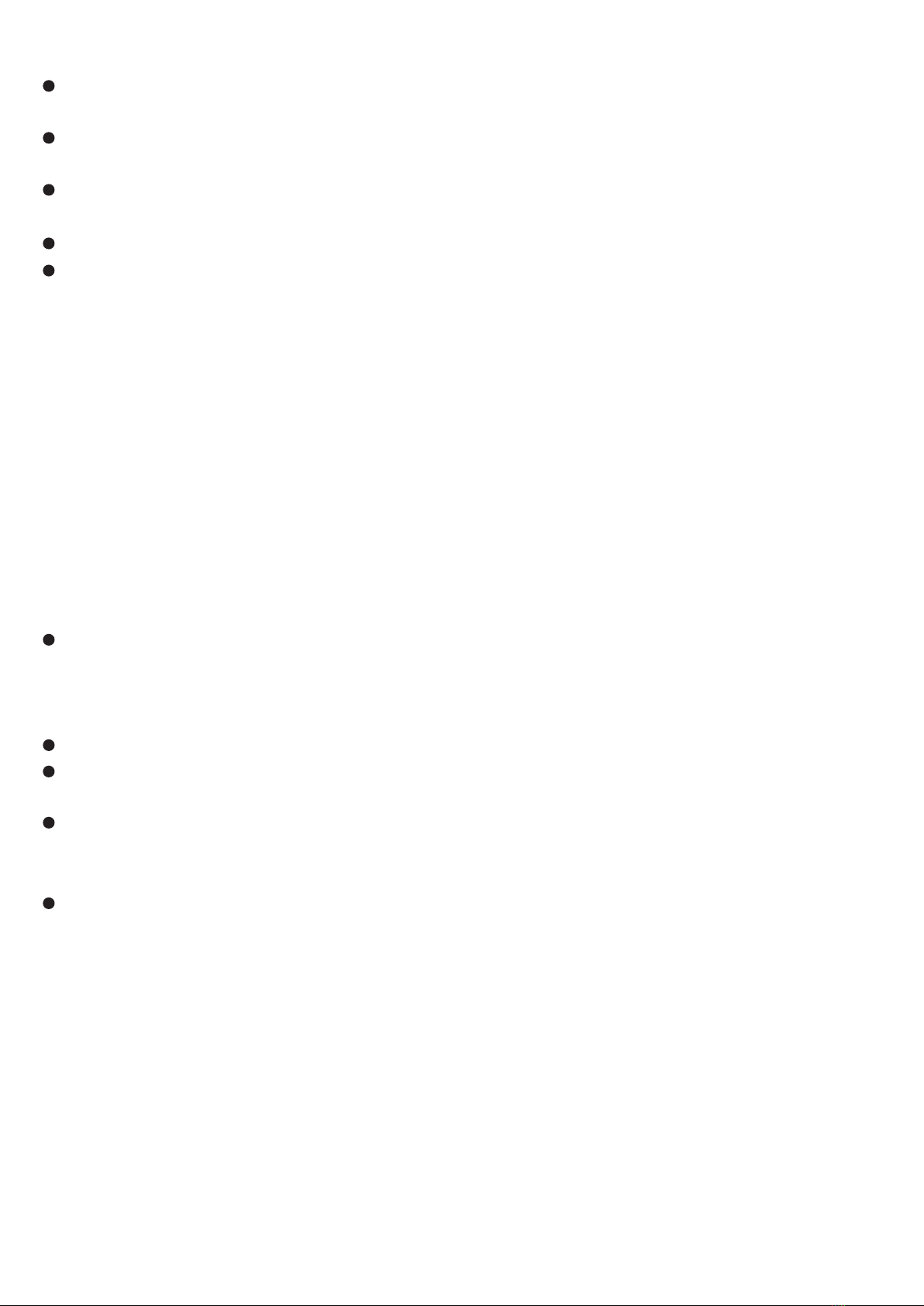

Grinding Wheel Installation

1.Depress the spindle lock button and rotate the lock nut until

the spindle locks.

2.Loosen the lock nut from the spindle by the supplied lock

nut wrench.

3.Remove the lock nut, but do not remove the backing flange.

4.Make sure the flats on the bottom of the blacking flange are

engaged with the flats on the spindle.

5.Place the grinding wheel and lock nut over the spindle.

6.Depress the spindle lock button and rotate the wheel clock-

wise until the spindle locks in position.

7.Tighten the lock nut securely with the supplied wrench while

holding the spindle lock.

8.To remove the wheel, follow the installation procedure in

reverse.

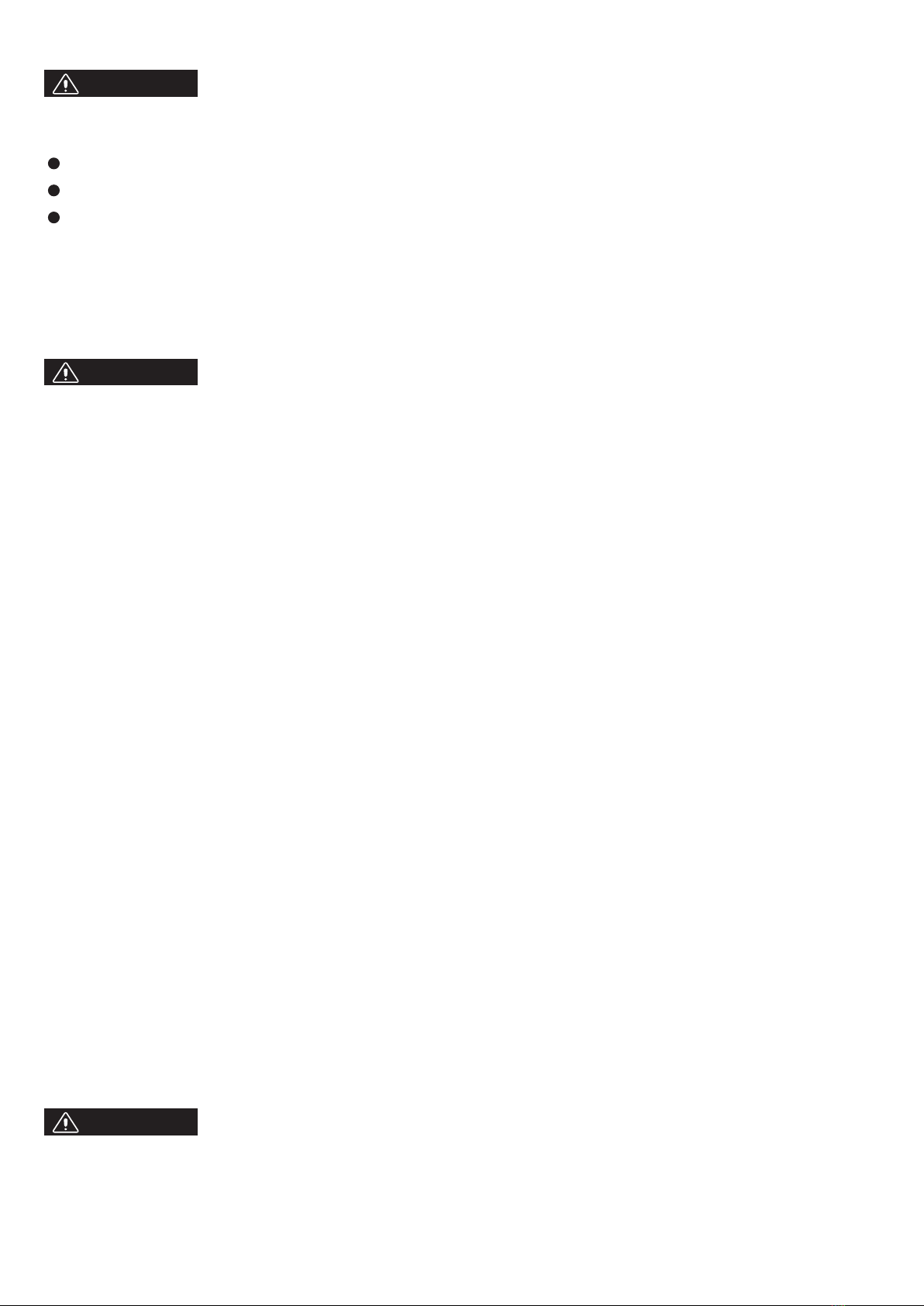

Battery Installation

Press the battery release button to insert the battery pack into or release from the power tool. There is

battery indicator light on the battery. There are 4 LED (one red light, three green lights) light to show the

status of the capacity level of the battery:

4 LED's are lit: Battery fully charged

1 LED (Red) is lit: Battery almost discharged

Please recharge the battery in time if the level of charge is below usable limit.

10

Screw on the wheel guard

Lock nut

Wheel

Backing flange

Spindle

Spindle lock

Battery release button

Charging input port

Indicator light

General Operation

1. If you have just installed an accessory or are beginning a period of work, test the wheel by letting it spin

for one minute before applying it to the work- piece. WARNING! Never use a accessory that has been

dropped. Out-of-balance or damaged accessories can mar workpiece, damage the tool, and cause stress

that may cause accessory failure.

2. Use a clamp, vise or other practical means to hold the workpiece, freeing both hands to control the tool.

3. WARNING! Hold tool securely with both hands.Start the tool.

NOTE: If the battery is inserted when the tool is ON, the tool will not run. Turn the tool OFF, then back ON

to begin work.

4. Allow accessory to come to full speed before beginning work.

5. Control pressure and surface contact between accessory and workpiece. WARNING! Never bang

accessory onto work.Too much pressure causes accessory failure or slows speed.

6. When finished, turn off the tool and make sure it comes to a complete stop before laying it down.

Grinding operation

Always carefully select and use grinding wheels and accessories that are:

correct size as written on tool’s nameplate.

rated at or above 8500rpm.

correct accessory, wheel type and grit for the job.

a grinding wheel guard must be used during grinding operation.

On/Off Switch with Lock

The switch can be locked in the“ON” position, a convenience

for long grinding operations.

To turn the tool ON without locking it, slide the switch button

forward to “I” by applying pressure ONLY at the REAR portion of

the button. When pressure is released the switch button will

snap to “0” position

To lock the switch ON, slide the switch button forward to “1”

and press “IN” the FRONT portion. The switch will not snap

back to “0” position.

TOunlock the switch, simply press and release the REAR

portion of the button. The switch will snap back automatically

Operating Instructions

2-Speed Selector

This tool is equipped with a 2-speed gear system. Press the

speed selector button to choose low speed (3000rpm) or high

speed (8500rpm)

For grinding,cutting and sanding operation, please select the

high speed.

For wire brushing and polishing operation, please select the

low speed.

WARNING :

11

0/Off

1/On

2-speed

selector button

high speed

low speed

Always hold the tool firmly with one hand on grip handle and the other on the auxiliary handle. Turn the

tool on and then apply the wheel or disc to the workpiece.

If the wheel is flat, the tool is difficult to control. If the angle is too steep, the pressure is concentrated on

a small area, causing burning to the work.

1. Select the high speed. Allow the tool to reach full speed before touching the tool to the work surface.

Excessive or sudden pressure on the wheel will slow grinding action and put dangerous

stresses on the wheel. When grinding with a new wheel, be certain to grind while pulling tool backwards

until the wheel becomes rounded on its edge. New wheels have sharp corners, which tend to “bite” or cut

into work piece when pushing forward.

Allow the tool to reach full speed before touching the tool to the work surface.

2. Apply minimum pressure to the work surface, allowing the

tool to operate at high speed. Grinding /Sanding rate is greatest

when the tool operates at high speed.

3. Maintain a 10° to 15° angle between the tool and work

surface.

4. Continuously move the tool at a moderate speed to avoid

creating gouges in the work surface.

5.Remove the tool from work surface before turning tool off.

Allow the tool to stop rotating before laying it down.

2. Apply minimum pressure to the work surface, allowing the

tool to operate at high speed. Grinding /Sanding rate is greatest

when the tool operates at high speed.

3. Maintain a 10° to 15° angle between the tool and work

surface.

4. Continuously move the tool at a moderate speed to avoid

creating gouges in the work surface.

5.Remove the tool from work surface before turning tool off.

Allow the tool to stop rotating before laying it down.

Cut off Operation

Always carefully select and use cut-off wheels and accessories that are:

correct size as written on tool’s nameplate.

rated at or above 8500rpm.

WARNING :

12

Sanding operation

Always carefully select and used sanding wheels and accessories that are:

correct size as written on tool’s nameplate.

rated at or above 8500rpm

correct accessory, wheel type and grit for the job.

Use a wheel guard during sanding operation. Always hold the tool firmly with one hand on grip handle and

the other on the auxiliary handle. Turn the tool on and then apply the wheel or disc to the workpiece.

If the wheel is flat, the tool is difficult to control. If the angle is too steep, the pressure is concentrated on

a small area, causing burning to the work.

1. Select the high speed. Allow the tool to reach full speed before touching the tool to the work surface.

When using an abrasive cut-off wheel, be sure to use only the special wheel

guard designed for use with cutoff wheels.

The special wheel guard may not be included with this

tool but is required when using a cutting wheel.

NEVER use cut-off wheel for side grinding.

Wire Brush Operations

Wire brushes are intended to clean structural steel, castings, sheet metal, stone and concrete. They are

used to remove rust, scale and paint.

1. Select the low speed. Allow the tool to reach full speed before touching the tool to the work surface.

2. Apply minimum pressure to the work surface.

3. Continuously move the tool at a moderate speed to avoid creating gouges in the work surface.

4. Remove the tool from work surface before turning tool off. Allow the tool to stop rotating before laying

it down.

Polishing Operations

This tool can be used for polishing.

1. Select the low speed. Allow the tool to reach full speed before touching the tool to the work surface.

2. Apply minimum pressure to the work surface.

3. Continuously move the tool at a moderate speed.

4. Remove the tool from work surface before turning tool off. Allow the tool to stop rotating before laying

it down.

Maintenance

General maintenance

This tool is equipped with durable and high-performance BRUSHLESS MOTOR. it requires no changes of

carbon brush.

Keep your tool, battery pack and charger in good repair by adopting a regular maintenance program.

Inspect your tool for issues such as undue noise, misalignment or binding of moving parts, breakage of

parts, or any other condition that may affect the tool operation.

Cleaning

1.Select the high speed. Allow the tool to reach full speed

before touching the tool to the work surface.

2.The tool should always be used in such way that the sparks

are directed away from user.

3.Apply minimum pressure to the work surface, allowing the

tool to operate at high speed. Cutting rate is greatest when the

tool operates at high speed.

4.Do not exert side pressure onto the cutting disc. Do not tilt or

oscillate the tool as wheel may burst,

5.Remove the tool from the work surface before turning the

tool off. Allow the tool to stop rotating before laying it down.

WARNING :

WARNING :

13

Lock nut

cut off wheel

Backing flange

Cut off guard

Spindle lock

To avoid accidents always disconnect the tool from the power supply before

cleaning or performing any maintenance.

The tool maybe cleaned most effectively with compressed

dry air. Always wear safety goggles when cleaning tools with compressed air.

Air vents and switch levers must be kept clean and free of foreign matter. Do not at tempt to clean by

inserting pointed objects through openings.

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various

types of commercial solvents and can be damaged by their use. Use clean cloths to remove dirt, dust, oil,

grease, etc.

Transport

The contained lithium-ion batteries are subject to the Dangerous Goods Legislation requirements. The

user can transport the batteries by road without further requirements. Dispatch batteries only when the

housing is undamaged. When being transported by third parties (e.g.: air transport or forwarding agency),

special requirements on packaging and labelling must be observed. For the preparation of the item being

shipped, please observe possibly more detailed national regulations and consult an expert for hazardous

material.

Disposal

Service

If the equipment should fail some day in spite of our quality controls and your maintenance, only have it

repaired by an authorized electrician. If the supply cord of the appliance is damaged, this has to be done

by the manufacturer or his agent or electrician in order to avoid a safety hazard.

We provide 2-year quality warranty from purchasing date and friendly customer service. Our after-sales

service responds to your questions concerning maintenance and spare parts. Please contact your local

distributor or send emails to our service teams:

DEKO customer service for Aliexpress: dante@gipower.com.cn

The warranty will not apply to the following cases:

(i) where this product has been subjected to misuse, abuse, accident or want of care;

(ii) where this product has been used for a purpose for which it was not designed or is not suited;

(iii) where the service of this product has been undertaken by a non-authorised person or company or if

non-approved parts have been used.

WARNING :

14

The machine, rechargeable batteries, accessories, and packaging should be sorted for envi-

ronmental-friendly recycling. Do not dispose of power tools and batteries/rechargeable

batteries into household waste! Please recycle them at collection points provided for the

purpose. Ask your local authority for information about recycling.

DEKO TOOLS CO., LIMITED

Add: No. 227, Kesheng Road, Jishigang,

Haishu District, 315000 Ningbo, Zhejiang, China

www.dekotools.com

Made in China

15

16

Table of contents

Popular Grinder manuals by other brands

red roo

red roo SG30TRX Safety precautions and operating instructions

eisenblatter

eisenblatter VARILEX WSF 1600 operating instructions

EINHELL

EINHELL E-WS 125/950 operating instructions

DeWalt

DeWalt DWE46102 instruction manual

HIKOKI

HIKOKI GM 13Y Handling instructions

Black & Decker

Black & Decker KG900 manual

Baileigh Industrial

Baileigh Industrial BG-248-2 Operator's manual

GÜDE

GÜDE WS 18-0 BL Translation of the original instructions

HIKOKI

HIKOKI G 18ST Handling instructions

Meec tools

Meec tools 010-319 User instructions

Chicago Pneumatic

Chicago Pneumatic CP7405 Operator's manual

HIKOKI

HIKOKI G 12STA(S) Handling instructions