Delta Elektronika ISO AMP Series User manual

1 / 7 DELTA ELEKTRONIKA B.V. rev. Febr. 2021

DELTA

ELEKTRONIKA B.V.

Vissersdijk 4, 4301 ND www.DeltaPowerSupplies.com

DC POWER SUPPLIES Zierikzee, the Netherlands Tel. +31 111 413656

ISO AMP-series

ISO AMP CARD

ISO AMP MODULE

PRODUCT MANUAL

Contents:

1 –Safety Instructions

2 –Sicherheitshinweise

3 –Installation

4 –Operation & Calibration

5–EU Declaration of Conformity

6–UK Declaration of Conformity

Product Manuals and Driver & Example Software

For several Applications there are Application Notes available on our website.

See PRODUCTS\INTERFACES.

SAFETY INSTRUCTIONS ISO AMP

2 / 7 DELTA ELEKTRONIKA B.V. rev. Febr. 2021

This marking shown on the product, its packing or its literature indicates that it should not be disposed with

other wastes at the end of its working life, but should be collected separately to recycle it responsibly to

promote the sustainable reuse of material resources.

2

SAFETY INSTRUCTIONS –ISO AMP - series

2.1

Caution

The following safety precautions must be observed during all phases of operation, service and repair of this equipment.

Failure to comply with the safety precautions or warnings in this document violates safety standards of design,

manufacture and intended use of this equipment and may impair the built-in protections. Delta Elektronika shall not be

liable for user’s failure to comply with these requirements.

2.2

Installation Category

The Delta Elektronika interfaces have been evaluated to installation category II (Over voltage category II).

2.3

Grounding

This product is a safety Class 1 equipment. For safety isolation both the metal assembly terminals next to the 15p

connector must be firmly connected to the metal chassis of a grounded Delta Elektronika power supply. Any interruption

of the protective ground conductor, or disconnection of the metal terminals will cause a potential shock hazard that might

cause personal injury.

For grounding of the power supply, see the specific power supply operating manual for detailed safety instructions.

2.4

Live Circuits

Operating personnel should not remove the unit covers. No internal adjustment or component replacement is allowed by

non Delta Elektronika qualified personnel. Never replace components with the power cable connected. To avoid injuries,

always disconnect power, remove external voltage sources and discharge circuits before touching components.

2.5

Parts Substitutions & Modifications

Parts substitutions and modifications are allowed by authorized Delta Elektronika service personnel only. For repairs the

unit must be returned to a Delta Elektronika service facility.

2.6

Removal of (safety) covers

Safety cover(s) are used to cover potentially hazardous voltages.

Observe the following when removing safety cover(s):

Switch off the unit and disconnect the unit from the AC mains supply and from the DC power application.

Wait for 5 minutes to allow internal capacitors to discharge, then unscrew and remove the cover(s).

Always place the cover(s) back before connecting the unit to the mains supply again.

2.7

Environmental Conditions

The Delta Elektronika power supplies safety approval applies to the following operating conditions:

Usage : Indoor use only.

Warning! Not intended to be used in the presence of children or animals!

Ambient temperature : -20 to 50 °C.

Maximum relative humidity : 95%, non condensing, up to 40 °C, 75%, non condensing, up to 50 °C.

Altitude : Do not use above 2000 m sea level.

Warning! Electrical Creepage & Clearance not valid for higher altitudes!

Pollution degree : 2

2.8

Symbols & markings

WEEE (Waste Electrical & Electronic Equipment)

1.1

Correct Disposal of this Product

Applicable in the European Union.

Caution risk of electrical Shock.

Instruction manual symbol. The instrument will be marked with this symbol when it is

necessary fort he user to refer to the instruction manual.

Protective ground conductor terminal.

Off (supply).

On (supply).

SAFETY INSTRUCTIONS ISO AMP

3 / 7 DELTA ELEKTRONIKA B.V. rev. Febr. 2021

3

SICHERHEITSHINWEISE –ISO AMP - series

3.1

Vorsicht

Die folgenden Sicherheitsvorkehrungen müssen in allen Betriebs-, Service- und Reparaturphasen dieses Geräts befolgt

werden. Die Nichteinhaltung der Sicherheitsvorkehrungen oder Warnungen in diesem Dokument verstößt gegen die

Sicherheitsstandards im Hinblick auf Bauart, Produktion und vorgesehene Nutzung dieses Geräts und kann die

eingebauten Schutzvorrichtungen beschädigen. Delta Elektronika haftet nicht dafür, wenn der Nutzer diesen

Anforderungen nicht nachkommt.

3.2

Installationskategorie

Die Delta Elektronika Schnittstellen wurden der Installationskategorie II (Überspannungskategorie II) zugeordnet.

3.3

Erdung

Dieses Produkt ist ein Gerät der Sicherheitsklasse 1. Zur Sicherheitsisolierung müssen beide Metallmontageklemmen

neben dem 15p-Stecker fest mit dem Metallgehäuse eines geerdeten Delta Elektronika Netzteils verbunden sein. Jede

Unterbrechung des Schutzleiters oder das Abschalten der Metallklemmen führt zu einer potenziellen Schockgefahr, die

zu Personenschäden führen kann.

Zur Erdung des Netzteils siehe spezifische Betriebsanleitung für die Stromversorgung.

3.4

Spannungsführenden Stromkreise

Bedienungspersonal darf die Geräteabdeckungen nicht entfernen. Interne Einstellungen oder Bauteileaustausche sind

ausschließlich qualifiziertem Personal von Delta Elektronika gestattet. Bauteile nie bei eingestecktem Stromkabel

austauschen. Um Verletzungen zu vermeiden, vor dem Berühren von Bauteilen immer den Strom trennen, externe

Spannungsquellen entfernen und Stromkreise entladen.

3.5

Teileaustausch & Modifikationen

Teileaustausch und Modifikationen sind ausschließlich autorisiertem Delta Elektronika-Service-Personal gestattet.

Reparaturen am Gerät dürfen nur durch eine Delta Elektronika-Serviceeinrichtung durchgeführt werden.

3.6

Entfernung von (Sicherheits-) Abdeckungen

Sicherheitsabdeckung(en) werden verwendet, um potenziell gefährliche Spannungen abzudecken. Beachten Sie

Folgendes, wenn Sie die Sicherheitsabdeckung(en) entfernen:

Gerät ausschalten, Gerät von dem AC-Versorgungsnetz und DC-Anwendung trennen.

Warten Sie 5 Minuten um interne Kondensatoren zu entladen. Abschrauben und entfernen von Abdeckung(en).

Bevor Sie das Gerät wieder mit dem Versorgungsnetz verbinden, montieren Sie vorher jedes Mal die Abdeckung(en).

Plötzliches Machen oder Brechen von hohen Gleichstrom kann große Funken verursachen, auch bei niedriger

Spannung. Gefahr von thermischen Verbrennung und Feuer!

3.7

Umgebungsbedingungen

Die Stromversorgungssicherheitszulassung von Delta Elektronika gilt für die folgenden Betriebsbedingungen:

Gebrauch : Nur Innengebrauch. Warnung! Nicht für die Verwendung in Gegenwart von

Kindern oder Tieren vorgesehen!

Umgebungstemperatur : -20 bis 50 °C.

Maximale relative Luftfeuchtigkeit : 95%, nicht kondensierend, bis zu 40 °C, 75%, nicht kondensierend, bis zu 50 °C

Höhe : Nicht über 2000 m Meeresspiegel verwenden.

Warnung! Elektrische Creepage & Clearance nicht gültig für größere Höhen!

Verschmutzungsgrad : 2

3.8

Symbole und Markierungen

Diese Kennzeichnung auf dem Produkt, seiner Verpackung oder seiner Literatur weist darauf hin, dass

es am Ende seiner Lebensdauer nicht mit anderen Abfällen entsorgt, sondern separat gesammelt

werden sollte, um es verantwortungsvoll zu recyceln, um die nachhaltige Wiederverwendung von

Material zu fördern.

WEEE (Waste Electrical & Electronic Equipment)

3.9

Korrekte Entsorgung dieses Produkts

Anwendbar in der Europäischen Union.

Vorsichtsgefahr bei elektrischen Schlag.

Bedienungsanleitung Symbol. Das Gerät wird mit

diesem Symbol gekennzeichnet, wenn der Benutzer

auf die Bedienungsanleitung verweisen muss.

PE-leiterklemme.

Aus (Versorgungsnetz).

Ein (Versorgungsnetz).

INSTALLATION ISO AMP

4 / 7 DELTA ELEKTRONIKA B.V. rev. Febr. 2021

4

INSTALLATION

Warning! carefully read the chapter "Safety Instructions" in

this manual before connecting or operating the unit!

4.1

HUMIDITY & CONDENSATION

During normal operation, humidity will not harm the interface,

provided the air is not aggressive. The heat normally

produced in the power supply will keep it dry.

Avoid condensation inside the interface, to prevent break-

down. Condensation can occur during a period the interface

or power supply has been switched off (or operating at no

load) and the ambient temperature is increasing. Always allow

the interface to dry before switching it on again.

4.2

TEMPERATURE & COOLING

The storage temperature range is –40 to +85 °C.

The operating temperature range is –20 to +50 °C.

Please note: a lower temperature extends the lifetime of the

interface.

4.3

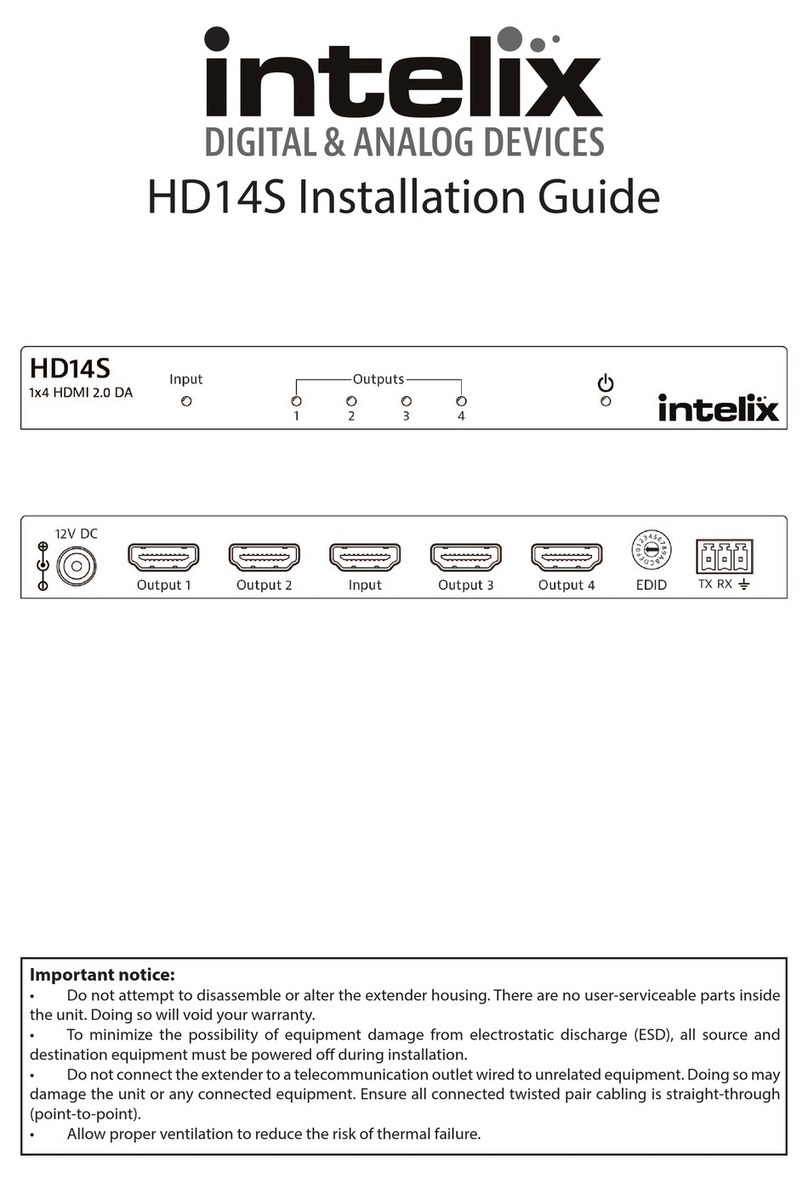

INSTALLING THE ISO AMP MODULE

Mount the ISO AMP MODULE using the wall or rail mounting

adapter.

Connect the power supply to the ISO AMP MODULE with the

supplied 15 pole cable.

Connect a 15-30 V DC supply voltage to the 2-pole

connector. + and - are indicated on the module, see fig 4 -1.

Finally connect your programming source to the connector

marked ‘TO PROG. SOURCE’, see fig 4 -1 and fig 4 - 2.

For use with other units than Delta Elektronika power

supplies, make sure to connect pin 1 to pin 8 on the

connector 'To Power Supply', see fig 4 - 3.

4.4

WALL OR RACK MOUNTING

Use the included mounting plate, see fig 4 - 4, for attaching

the module to a rack or a wall.

No special cooling is required, the module does not heat up

more than 10 degrees above ambient temperature.

4.5

INSTALLING THE ISO AMP CARD

The ISO AMP CARD should always be factory installed and

calibrated together with the power supply.

Contact factory for more information.

For operation, connect a 15 pole cable to the ISO AMP

connector at the rear side of the power supply.

For the following steps, please advice the operating manual of

the power supply for exact details.

fig 4 - 2

To programming source.

fig 4 - 1

Front panel connections.

fig 4 - 3

To power supply.

fig 4 - 4

A wall mounting adapter is standard supplied with

the ISO AMP Module

CONFIGURATION & CALIBRATION ISO AMP

5 / 7 DELTA ELEKTRONIKA B.V. rev. Febr. 2021

5

OPERATION & CALIBRATION

5.1

GENERAL

If you have a question about the unit, please contact our

engineers using the address Support@Delta-Elektronika.nl.

In case the unit is defect, please first fill out the RMA-form

before sending the unit to us. Adding a detailed fault

description will help us to repair the unit as soon as

possible. Do not try to repair the unit yourself.

On our website the RMA-form can be found under

'Support'.

5.2

POWER SUPPLY SET-UP

For settings of remote programming and monitoring please

refer to the power supplies’ manual.

Note that the warning that the Ø of the programming input

of the power supply is no longer connected to the minus

DC Power Terminal, when the ISO AMP is used.

The ES- and SM-series power supplies do not need any

maintenance or calibration. However, care must be taken

that the cooling of the unit is not obstructed.

5.3

ISO AMP CONFIGURATION

The ISO AMP can be configured for both 5V and 10 V

signal levels. Selecting a signal level is done by closing or

opening DIP-jumpers.

Take proper ESD precautions before setting the jumpers.

See fig. 5 - 1 for lay-out for ISO AMP PCB P512 rev.B.

A closed jumper is 0- 5V, an opened jumper 0-10 V. The

signal level for each of the four analog channels can be

selected individually. See table 5 -1.

The full scale of the analog channels of the ISO AMP is

factory calibrated within 0.1% for a 5 V signal level.

Configuring jumper J1...J4 for 10 V signal levels without re-

calibrating can introduce an extra full scale error of 0.1%.

Table 5 - 2 shows the full scale calibration trimmers.

Warning: before proceeding with the calibration of the ISO

AMP make sure that your measuring equipment has the

correct voltage and current rating.

5.4

ISO AMP VOLTAGE CALIBRATION

Connect a suitable, high accuracy volt meter to the output

terminals of the power supply and put the CV programming

switch on the power supply in the position ‘PROG’.

Apply 5.000 V or 10.000 V (depending on the jumper

setting) to the CVPROG input.

Calibrate the output voltage of the power supply with R51.

Connect the volt meter to the CVMON connection and

calibrate the CVMON signal with R29.

5.5

ISO AMP CURRENT CALIBRATION

Switch off the power supply, connect a suitable, high

accuracy current meter across the output terminals of the

power supply.

Put the CC programming switch on the power supply in the

position ‘PROG’.

Apply 5.000 V or 10.000 V (depending on the jumper

setting) to the CCPROG input.

Calibrate the output current of the power supply with R40.

Connect a volt meter to the CCMON connection and

calibrate the CCMON signal with R18.

Warning! Wrong calibration can damage the unit.

5.6

Other

If there is a fault or inaccuracy that cannot be compensated

with the calibration range, please fill out the RMA-form on

our website www.DeltaPowerSupplies.com. See previous

paragraph 1).

fig 5 - 1

Location of jumpers and trimmers on P512 revision B.

Signal

Jumpers

CVprg

closed=5 V, open=10 V

CCprg

closed= +/-5 V, open= +/-10 V

CVmon

closed=5 V, open=10 V

CCmon

closed= +/-5 V, open= +/-10 V

table 5 -1

Jumper settings.

Signal

Trimmers (full scale)

CVprg

R51

CCprg

R40

CVmon

R29

CCmon

R18

table 5 -2

Trimmer settings.

fig 5 - 2

Legend for jumpers for ISO AMP (P512B).

fig 5 - 3

Legend for trimmers ISO AMP (P512 B).

CE DECLARATION ISO AMP

6 / 7 DELTA ELEKTRONIKA B.V. rev. Febr. 2021

6

EU Declaration of Conformity –ISO AMP - series

We Delta Elektronika

Vissersdijk 4

4301 ND ZIERIKZEE

The Netherlands

Declare under sole responsibility that the following interfaces:

ISO AMP CARD

ISO AMP MODULE

Meet the intent of Directives

2014/30/EU Electromagnetic Compatibility (EMC)

2014/35/EU Low Voltage Directive (LVD)

2011/65/EU Reduction of Hazardous Substances (RoHS2)

Compliance was demonstrated to the following specification as listed in the official Journal of the European

Communities:

EN 61000-6-3:2007 Generic Emissions (residential, light industrial)

+A1:2011

EN 61000-3-2:2014 Power Harmonics

EN 61000-3-3:2013 Voltage fluctuation and flicker

EN 61000-6-1:2007 Generic Immunity (residential, light industrial)

EN 61000-6-2:2005 Generic Immunity (industrial environment)

EN 61010-1:2010 Safety of electrical equipment for measurement, control and laboratory use

EN 63000:2018 Assessment of electrical and electronic products with respect to RoHS

J. Koopman

Managing director,

Zierikzee, February 2021

DELTA

ELEKTRONIKA B.V.

Vissersdijk 4, 4301 ND www.DeltaPowerSupplies.com

DC POWER SUPPLIES Zierikzee, the Netherlands Tel. +31 111 413656

UK DECLARATION ISO AMP

7 / 7 DELTA ELEKTRONIKA B.V. rev. Febr. 2021

DELTA

ELEKTRONIKA B.V.

Vissersdijk 4, 4301 ND www.DeltaPowerSupplies.com

DC POWER SUPPLIES Zierikzee, the Netherlands Tel. +31 111 413656

7

UK Declaration of Conformity –ISO AMP - series

Product: ISO AMP Series

Model Numbers: ISO AMP CARD, ISO AMP MODULE.

Manufacturer:

Name: Delta Elektronika B.V.

Address: Vissersdijk 4, 4301 ND Zierikzee, The Netherlands

This declaration is issued under sole responsibility of the manufacturer

Product Description: Isolation amplifier for DC Power supplies

Specification: Analog and Digital levels 0 - 5V or 0 - 10V, +12VDC/25mA aux power output.

The object of the declaration described is in conformity with the relevant UK Statutory Instruments (and their

amendments):

2016 No. 1091 Electromagnetic Compatibility Regulations 2016

2016 No. 1101 Electrical Equipment (Safety) Regulations 2016

2012 No. 3032 Restriction of the Use of Certain hazardous Substances in

Electrical and Electronic Equipment Regulations 2012

Standard Title

BS EN 61000-6-3:2007 +A1:2011 Electromagnetic compatibility (EMC). Generic standards. Emission standard for

residential, commercial and light-industrial environments.

BS EN 61000-6-2:2005 Electromagnetic compatibility (EMC). Generic standards. Immunity standard for

industrial environments.

BS EN 61000-6-1:2007 Electromagnetic compatibility (EMC). Generic standards. Immunity standard for

residential, commercial and light-industrial environments.

BS EN 61000-3-2:2014 Electromagnetic compatibility (EMC). Limits. Limits for harmonic currents

produced by equipment connected to public low-voltage systems with input

current <= 16 A per phase.

BS EN 61000-3-3:2013 Electromagnetic compatibility (EMC). Limits. Limitation of voltage changes,

voltage fluctuations and flicker in public low-voltage supply systems. Equipment

with rated current ≤ 16 A per phase.

BS EN 61000-4-2:2009 Electromagnetic compatibility (EMC). Part 4-2: Testing and measurement techniques -

Electrostatic discharge immunity test.

BS EN 61010-1:2010 Safety requirements for electrical equipment for measurement, control, and

laboratory use. General requirements.

BS EN IEC 63000:2018 Technical documentation for the assessment of electrical and electronic products with

respect to the restriction of hazardous substances.

Signed for and on behalf of: Delta Elektronika B.V.

Place of issue: Zierikzee, Netherlands

Date of issue: 26th of February 2021

Name: J. Koopman

Position: Managing director

Signature:

Table of contents