3

PRODUCT SERVICE

If the unit requires service, contact the service department at your dealer or DENTSPLY Neytech, Yucaipa,

California. Describe the particular problem and give the serial number of the pump.

BEFORE RETURNING THE PUMP, DO THE FOLLOWING:

1. The original packing material should be used for the return shipment.

2. Call DENTSPLY Neytech for a RMA number (Return Material Authorization). This is used to track and

identify your pump. Material received without this number may not be identifiable.

3. Equipment damaged in shipment as the result of improper packing may not be repaired at the expense of

the carrier. DENTSPLY Neytech will not be responsible for damages resulting from improper packing.

Ship Prepaid To: DENTSPLY Neytech

Equipment Division

909-795-2461 RMA Number __________

FAX 909-795-5268 13553 Calimesa Blvd.

Yucaipa, CA 92399-2303 USA

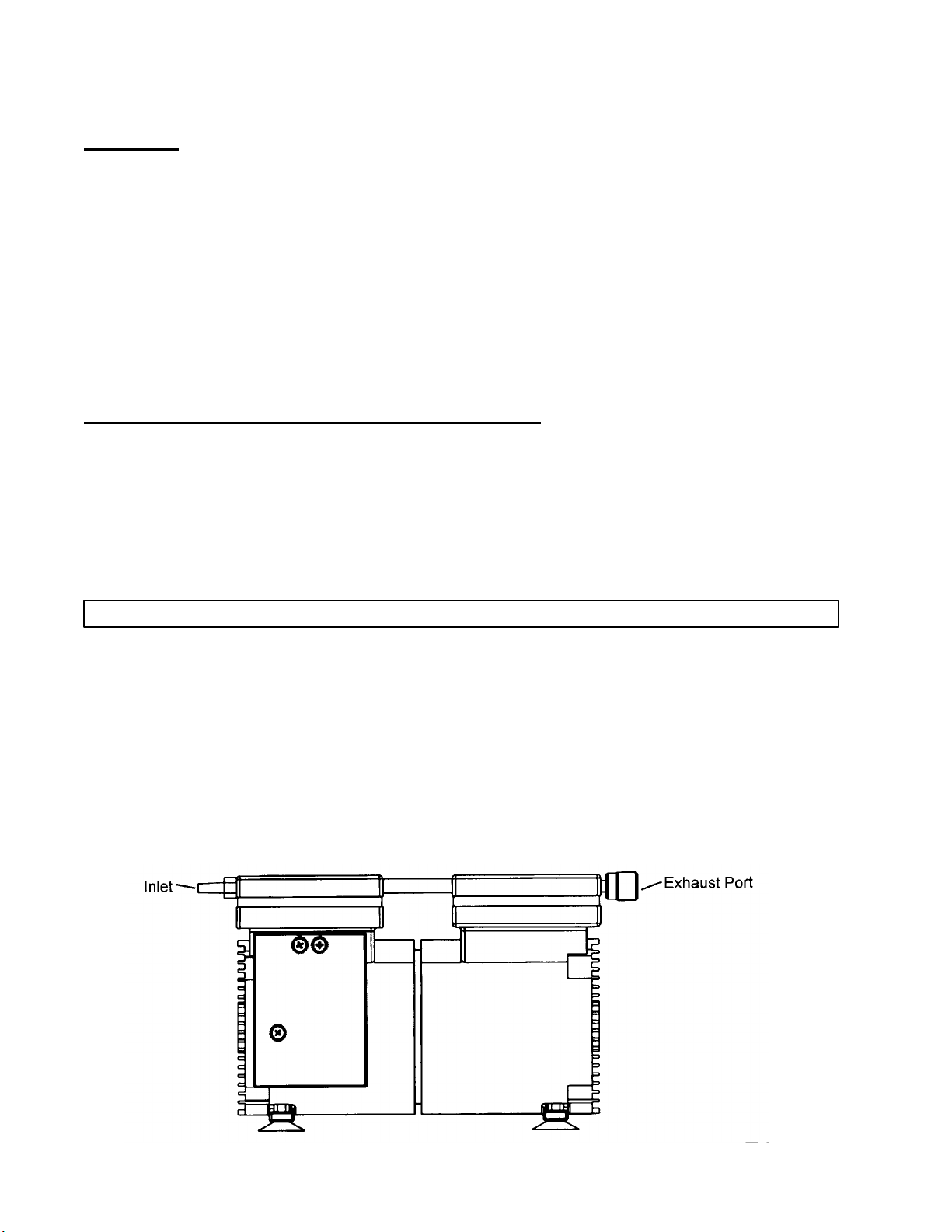

Dimensions:

Pumping Flow:

Ultimate Pressure:

Voltage:

Power:

Thermal Protector:

Pump Weight:

Shipping Weight:

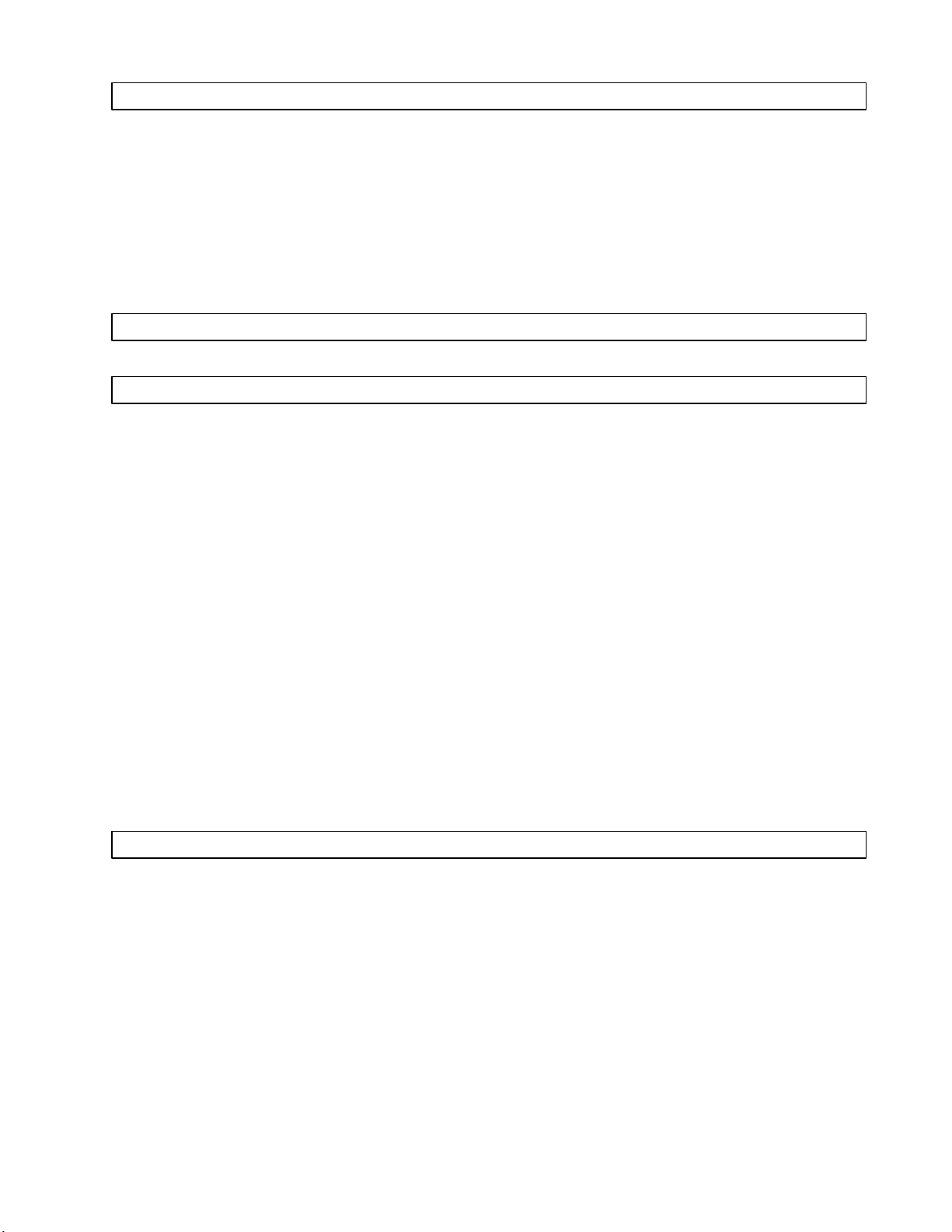

TROUBLESHOOTING

SPECIFICATIONS 276mm (12.75") L x 159mm (6.25") W x 211mm (8.3") H

72 L/min, (2.5 CFM) with 50Hz supply

90 L/min, (3.2 CFM) with 60Hz supply

20 mm absolute

100-120V

230V

300 Watts

Auto Reset

9.5Kg (21lbs)

10Kg (22lbs)

MAINTENANCE

The pump is maintenance free. No oil lubrication is required.

Fault

1. Pump won’t start

2. Pump doesn’t reach

ultimate pressure

3. Pump is excessively

noisy

4. Pump gets too hot

Possible Cause

a. No main power supply

b. Low voltage

c. Capacitor defective

d. Full vacuum in piping

e. Motor defective

f. Thermal protector switch on

a. Pipes, hoses or connections leaking

b. Inlet filter or exhaust filter dirty

c. Cylinder or cup seal defective

d. Plate valve defective

e. Vacuum gauge defective

a. Damaged bearing

b. Plate valve defective

c. Cylinder or cup seal defective

d. Vibration being transferred to enclosure

a. Cooling air supply is obstructed

b. Ambient temperature is too high

Remedy

a. Check main power

b. Check voltage

c. Check capacitor, replace if necessary

d. To install a vacuum break valve, or

order pump with restart movement

from us

e. Return for factory repair

f. Wait for pump to cool down, then it will

restart automatically

a. Check and seal or renew

b. Clean filter cartridge, or replace with a

new one if necessary

c. Renew cylinder or cup seal

d. Replace valve

e. Use correct measuring vacuum gauge

a. Factor repair

b. Replace valve

c. Renew cylinder or cup seal

d. Use suitable anti-vibration mounting

a. Set pump in well ventilated area

b. Set pump up in cooler area