DerJet Hawker Hunter MK 58 User manual

DerJet Hawker Hunter MK 58 -- 1/6 Scale

BuildingInstructionManual(April2014)

1.Introduction

CongratulationsonthepurchaseoftheHawkerHunter,producedbyDerJetModelCompany,TAIWAN!

This1/6scalelegendaryjetwasdevelopedonthebaseofaWorldMastersmodeldevelopedandflownby

three‐timesvicechampionRetoSennofSwitzerland.Thus,youdidnotonlybuyamagnificentflyingplane,

thisARFkitisdesignedtoallowparticipationincompetitionssuchasthe13,5kgclassattheJetWorld

Mastersorothers.TheseoutlineshavebeenoriginatedbyFlightfactory.chGmbHonthebaseofthefirst

Hunterkits.Subsequently,minorchanges/improvementsinthemanufacturingofthekitarenotincluded.

(Thesebuildingguidelinesareinnocasemeanttoguaranteeanycoverofdamageormalfunctioncaused

bynegligence,misuse,accident,unauthorizedrepairormodificationasthefinalusecannotbecontrolled

bythemanufacturernortheauthor).

2.TechnicalData

1/6Scale:Wingspan:1720mm,Length:2340mm,Dryweight:11,5–12,5kg,

Turbine:120–140Nthrustpower,RC:10‐12channels(8servos)

3.Requiredequipment

Servos: Ailerons:usestandardsizeservoswithatleast2x10kg/cmtorquesuchasFutaba

BLS451orBLS452(MG)

Elevator:use15mmsizeservoswithatleast2x5kg/cmtorquesuchasFutaba

BLS153,GraupnerHBS660BBorSpektrumAS5030

Rudder:usestandardsizeservowithsome10kg/cmtorquesuchasFutaba

BLS451/452,S3305/3172HVorSavöxSC‐0252MG/0254MG

Flaps:usestandardsizeservoswithatleast2x20kg/cmtorquesuchasFutaba

BLS155/175HVorSavöxSH‐1256TG

RCpowersupply:WerecommendusingadualpowersupplysystemsuchasPowerBoxSystemsInthefirst

threeHunters,weusedoncePowerBoxEvolution(withexternaldoorsequencer)andfor

convenience,twicePowerBoxCockpitSRS(withintegrateddoorsequenceranddual

satellitereception)poweredbyLiPo7,4Vwith2x2800mAhcapacityorLiFe6,6Vand2x

3200mAhcapacity.

Turbine: ThelightandyetsolidconstructionoftheDerJetModelHunterallowsforawiderangeof

turbines.Flyingwithwith12‐14Nofthrustpowerissufficientforflightperformance.Yet,

itallowssafetake‐offsfromeverysurfaceatthecostofslightlyhigherspeedinthefinal

landingapproach.TheuseofaJetCatP90RXi(10,5kgthrust)byoneSwisspilotallowed

bothcomfortabletake‐offs(40monhardsurfacerunway)andsmoothrealisticflyingwith

reasonablyshortlandings.

4.Optionalaccessories:ToupgradeyourDerJetModelHawkerHuntertoafull‐scalejet,theoptionalparts

arehighlyrecommendedbothforstaticandflightdisplayincludingunderwingtanksanddetailedkitofcannon

blastdeflector,antenna.

5.Mainwingcompletion

Buildingthewingsisstraightforwardanddoesnottakemuchtime.Ifyoudobothwingsatthesametime,just

makesurethatonepairofservosisoppositehandedasshowninthepictures.Startwiththeinstallationofthe

servos,whichfitperfectlyintothefactory‐installedservomounts.

Justusetheservogrommetsandtheservocoverwillkeeptheservowellfixedandinplace.Watchoutforthe

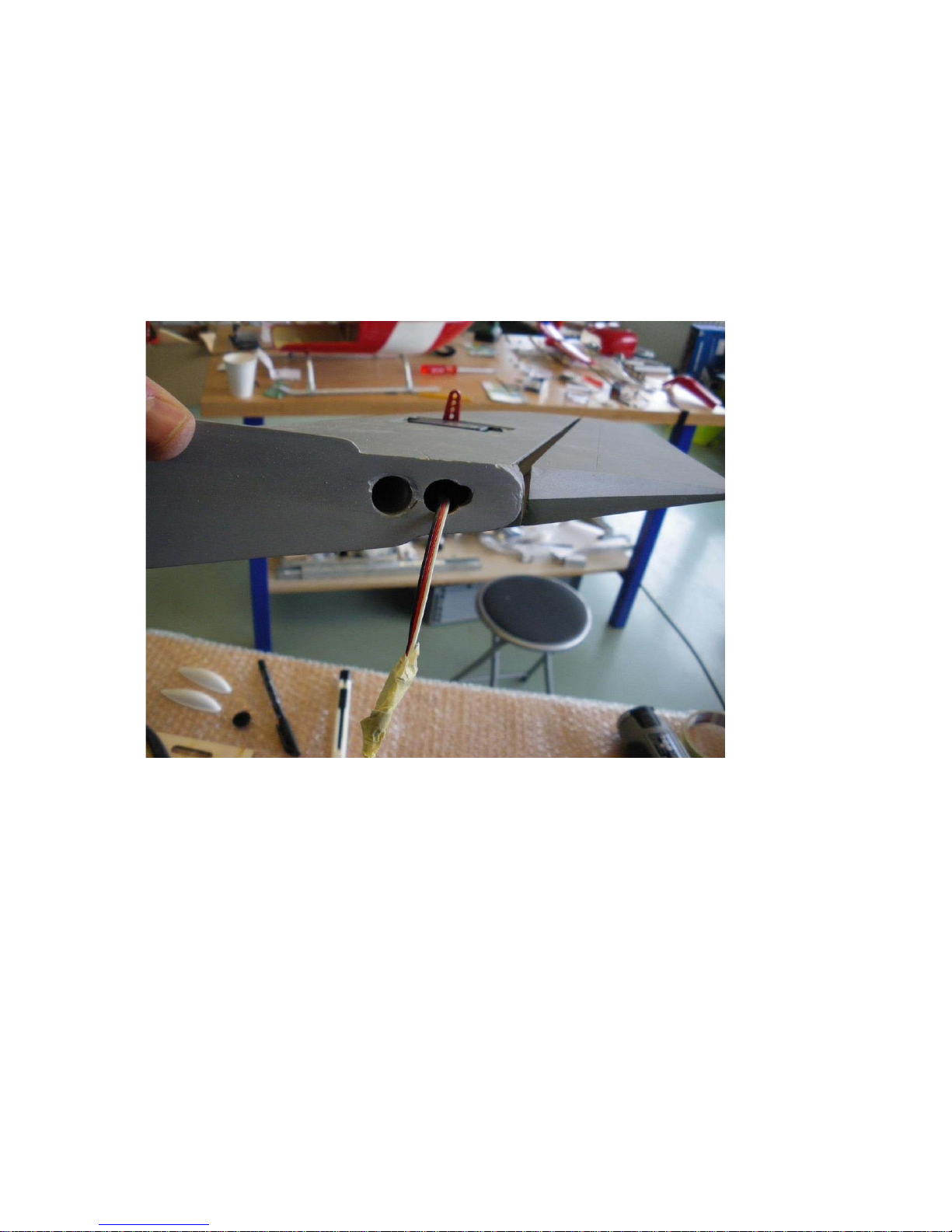

servoleadtomovefreeandpreventitfrombeingscratchedbysharpfibreedges.Shouldyouwishtoinstall

functionalpositionlights,youhavetodrillaholeof4mmfromthelightlocationtowardstheaileronservomount

throughwoodenformers.Iglueda4mmdrillintoanaluminiumtube5x4mmtoallowdrillingtothedistance.

Oncedrilled,pre‐installthelightwiresorfinishinstallationofthelightsbeforemountingtheaileronservo.

Runtheservoandlightwireswiththefactory‐installedwhitelinetowardstheinnersideofthewinganddothe

samewiththeflapservo.Makesuretheneutralpositionoftheservohorniscorrectbeforefinallypositioningthe

twoservos.Startnowwiththeflapanddrawthepositionofthethreeflaphingesfromthewingtotheflap.

Carefullydrilla5mmholeintotheflaps,startingwithsmallerdrillsandsmartlyincreasingthediameter.Rougher

methodsmightresultintodamagedsurfaceofthepaintedflap.Repeatthisdrillingtoopentheholesforthe

hingesonthewing,positioningtheholeasfarawayaspossiblefromtheflaptoallowfreemovement.

Gluethethreehingesintotheflapafterhavingcontrolledeasyandsmoothtravel,usinga24hrsgluesuchasUHU

Endfest300andthickeningmaterialsuchasthixotropicpowder.Youmaywanttoshortenthehingestofitthe

holesoneithersideoftheflapsandwingasshowninthepicture.

Addonetinydropofoilintothehingepointtoavoidbeinggluedtogether.Makesuretheoildoesnotspillover

thehingewhereitshouldbeglued!Oncedry,gluetheothersideofthehingesintothewing,usingthesameglue

andfixitwellduringthedryingprocess.

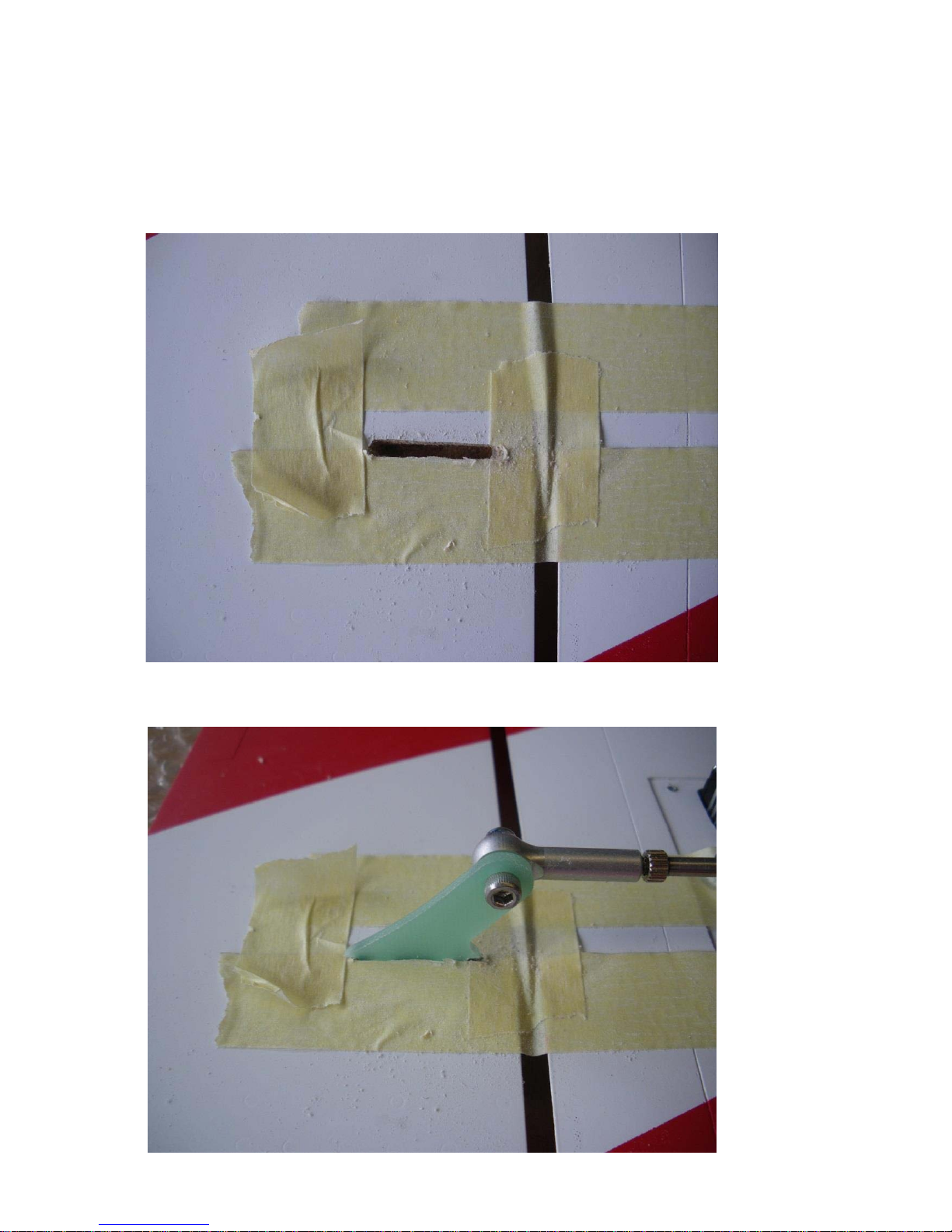

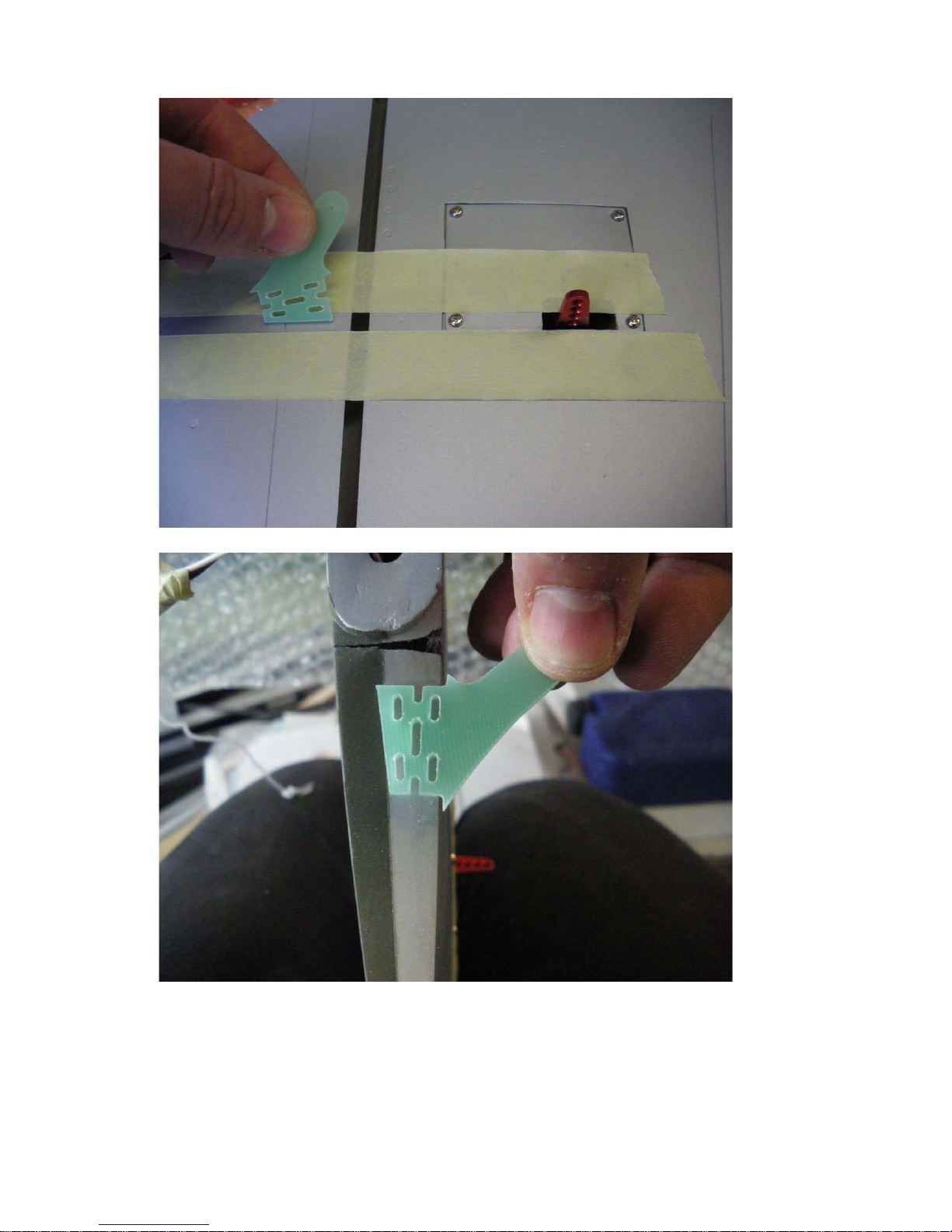

Once dry, mark the positions for the control horns for both the aileron and flap using masking tape.

Placethecontrolhornfortheaileronsuchasthepilotholeisrightoverthemovinglineoftheflex‐strapofthe

aileron,allowingtheservototravelatthesameforceupanddown.

Theflapcontrolhorncanbeinstalledslightlytotherearedgeofthewing,allowinglargertravelandthusmore

leveragedforcefromtheflapservo.Carefullyopennowtherequiredslotlengthsforthecontrolhornsusinga

dremelcuttingdiscorothertoolsyouarefamiliarwith.

Nowdrilla3mmhole(orsmallerifusingaclevis)intothehornsandroughenthelowerpartwheretheywillbe

gluedintothecontrolsurface.Applysufficientamountofglueintotheslotsaswellasonthehornsforperfectly

solidfit.Fixthecontrolhornsduringdrying.

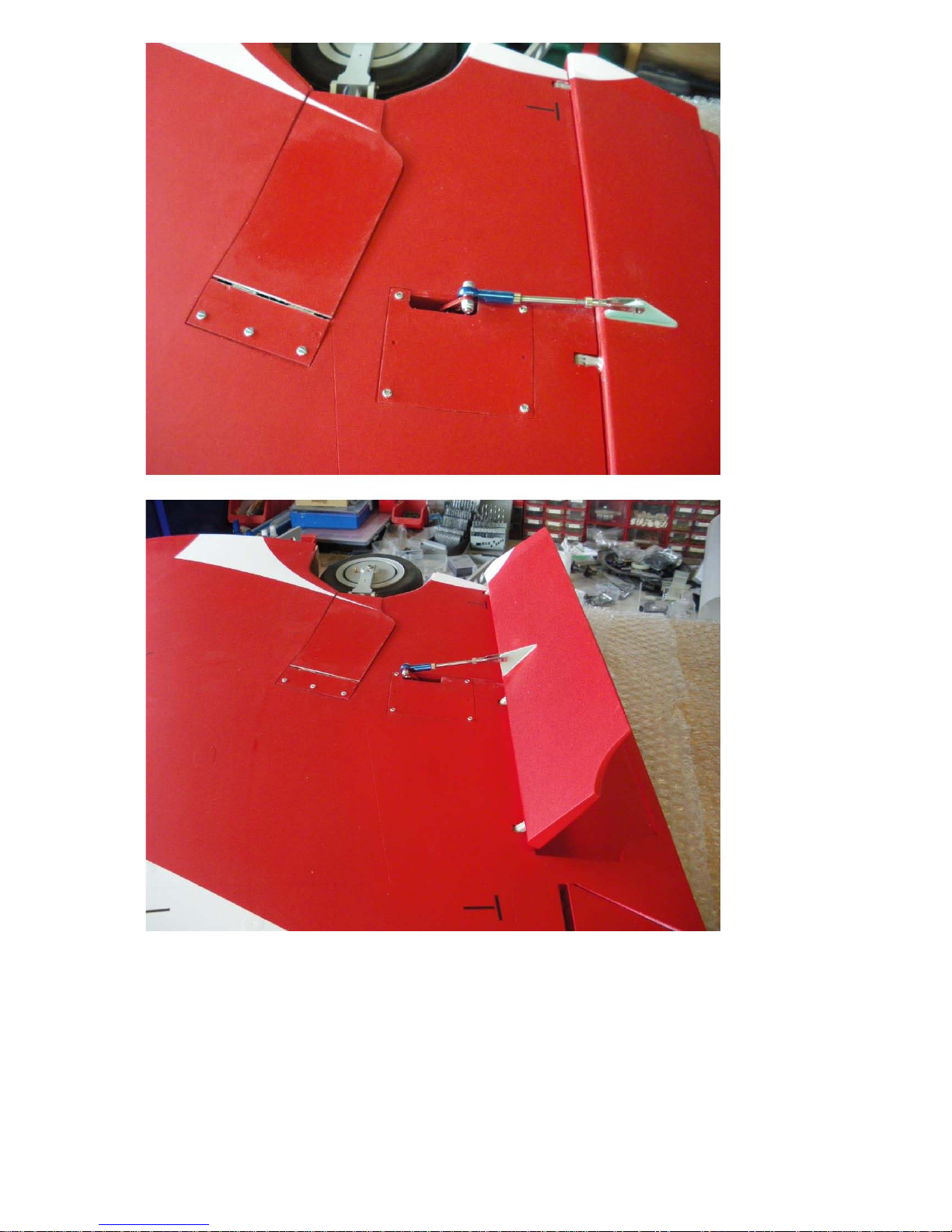

Oncethegluehasfullycured,installthepushrodsandre‐mounttheservohatchcoverssuchastheservohorns

canmovefreeintothecoverslots.

I

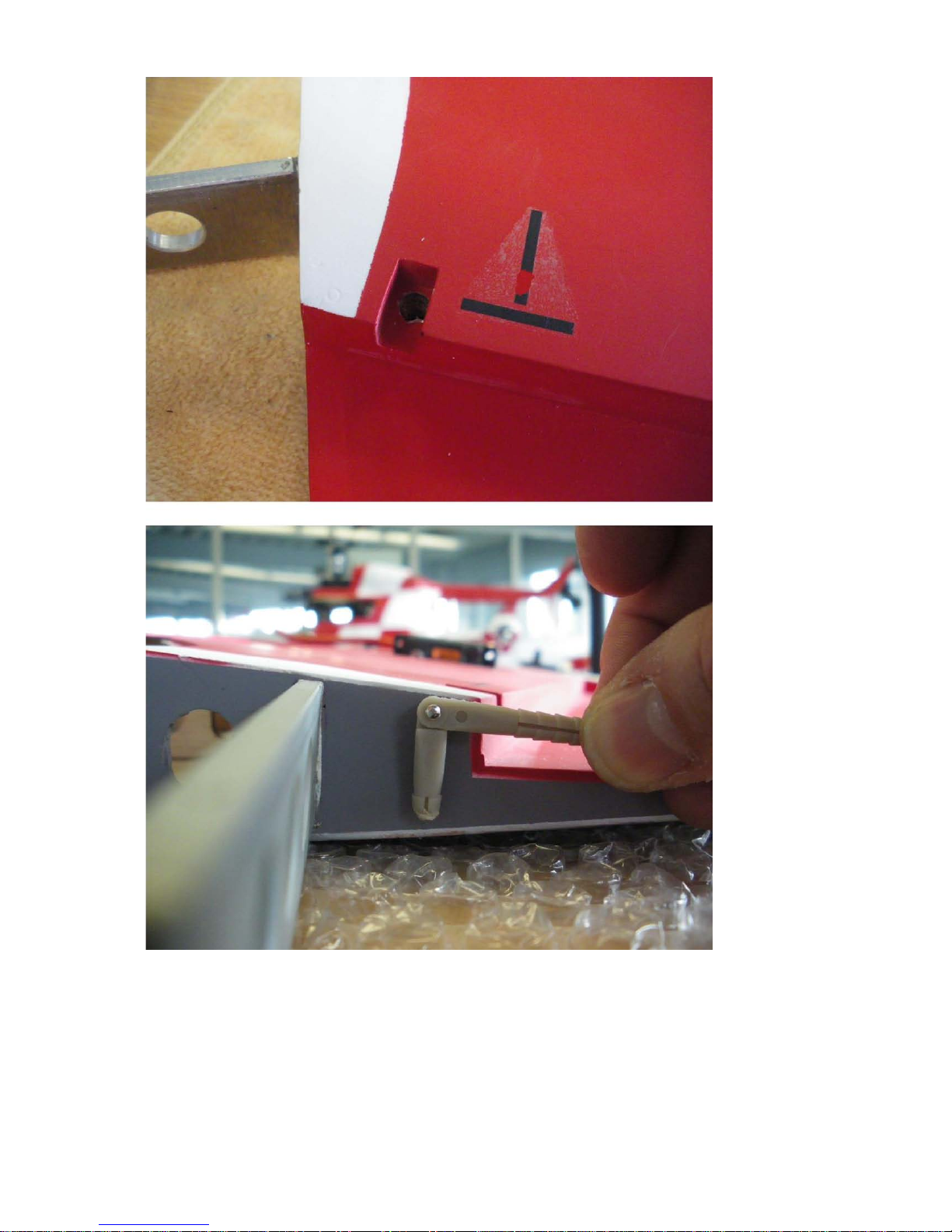

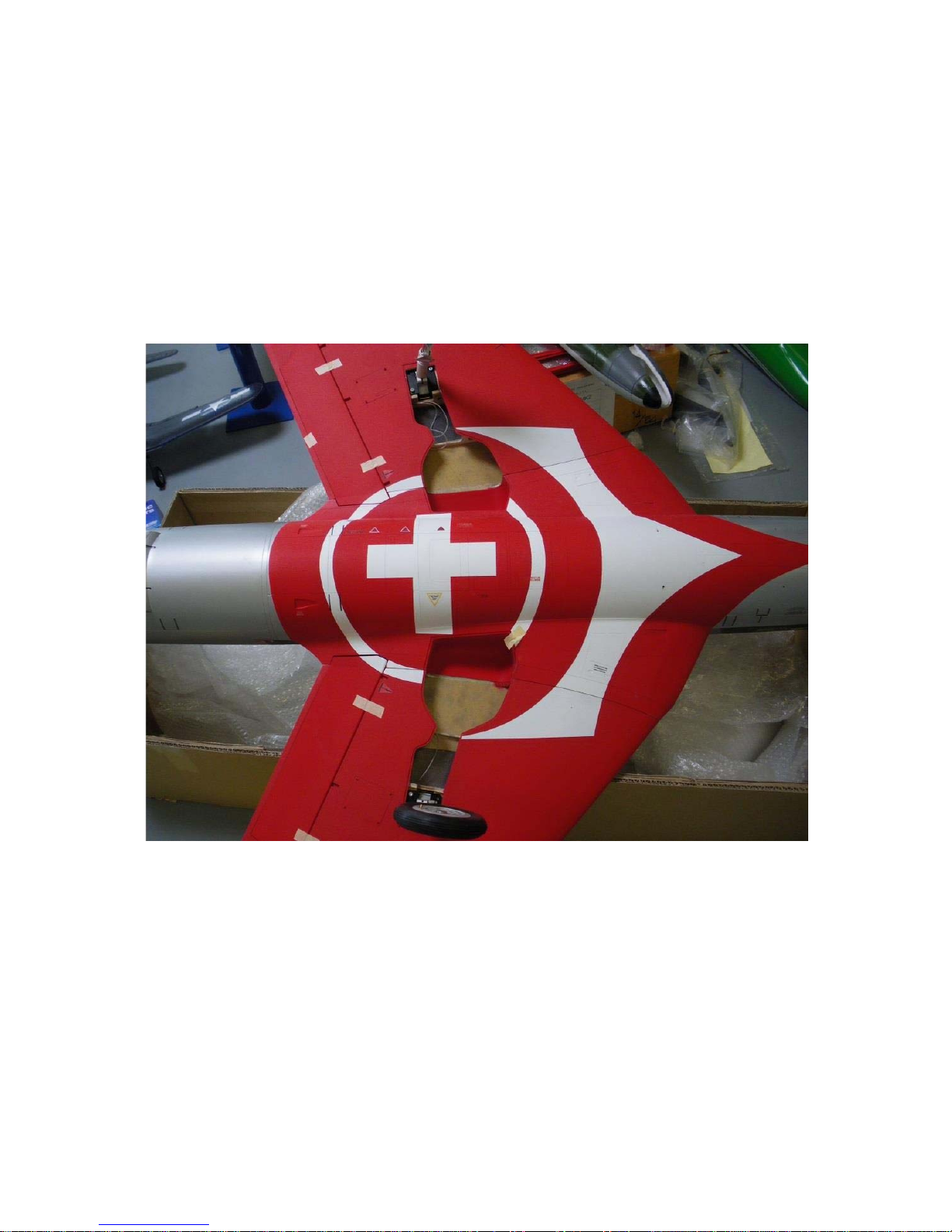

Itisrecommendedtomountthemainlandinggearanditsdoorsintwosteps.Asthemechanicsandlegsaswellas

thewheelsarefactory‐assembled,thefirststepisdonequickly.

Beforescrewingthemechanicsinplace,fixthe3mm‐tubes(twodifferentcolorsofyourchoicefromthehardware

pack)overthesmallfittings.Runthetubesintothewingandsmoothlybackthroughtheholesinthewooden

formersandmakesuretheymovefreelyanddonotbend.Leaveenoughlengthsofarandcutitlatertoyour

preferredlength.InstallnowthemechanicswitheitherwoodscrewsorwithM4screwsandself‐tappingnuts

underneaththewoodensupports.Bothhavebeentestedinpracticeandthesimplewoodscrewssustainwell

evenonroughsurfaces.Tracknowthewheelangletemporarilyuntilyouaredonewiththefinalassemblyanddo

aroll‐out.

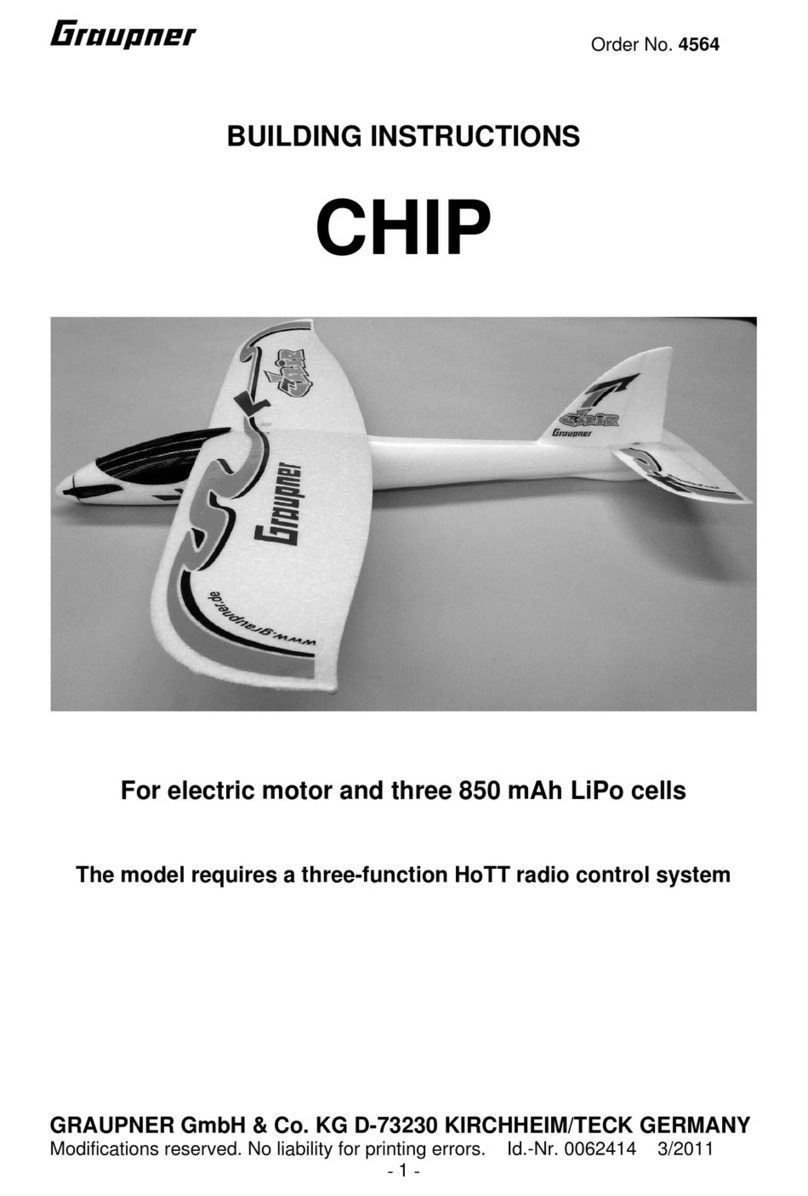

Markthepositionofthescrewholesoverthemaingeardoorsusingthemaskingtape.

6.Horizontalstabilizerassembly

Asforthemainwings,finishingthestabiseveneasiertodoastheycomewithfactory‐installedservomountsas

wellastheelevatorfixedwithflex‐strips.Thatleavesyouwiththechoiceofservostoinstallandgluingthecontrol

horns.Thishasbeenexplainedinthemainwingsectionwhichyoumaysimply“copyandpaste”thisforthestab.

Thedesignoftheservomountsleavesawiderangeofsuitableservosatyourdiscretion.TheFutabaBLS153

shouldprovidehighsecurityandenoughpower.Werecommendtochooseservoswithatleastapprox.5kg/cmof

torqueandpreferablymetalgears.Iusedadouble‐sidedfoamytapetocovertheservosideandtouchingthe

hatchcover,whichadditionallyholdstheservoinplaceoncethecoverisfirmlyscrewedinplace.

Sosimplyassemblethetwostabswiththeincludedsolidcarbonstabsandjustdrillasmall2mmholeineachof

thelowersidepartsofthestabsandusea2,2mmself‐tappingscrewtoholdtheminplace.

7.Rudderassembly

Thekitagainleavesyouwiththechoiceofinstallingservohorn,pushrodandcontrolhornoutsidesuchasforthe

aileronsandelevators,whichisstraightforward.Astheverticalfinprovidessufficientspacetomountastandard

sizedservoandletthepushrodruninside,itmayincreaseyourappetiteforamorescale‐likesolutionwithbarely

seeinganymechanics.Inanycase,therudderisfixedwithtwohinges.Wellglued,theyhaveprovedenough

strengthtoresistanyrudderforce.Irecommendtofirstgluethehingesintotherudder.Whenplacingtheminto

theexistingholes,watchthehingepointstobeinlineandasfarinsoyoubendata90°angleandagainparallelto

eachother.

Table of contents

Popular Toy manuals by other brands

DF-models

DF-models DF-100 FPV instruction manual

LGB

LGB 22832 instruction manual

Fisher-Price

Fisher-Price T3174 quick start guide

REVELL

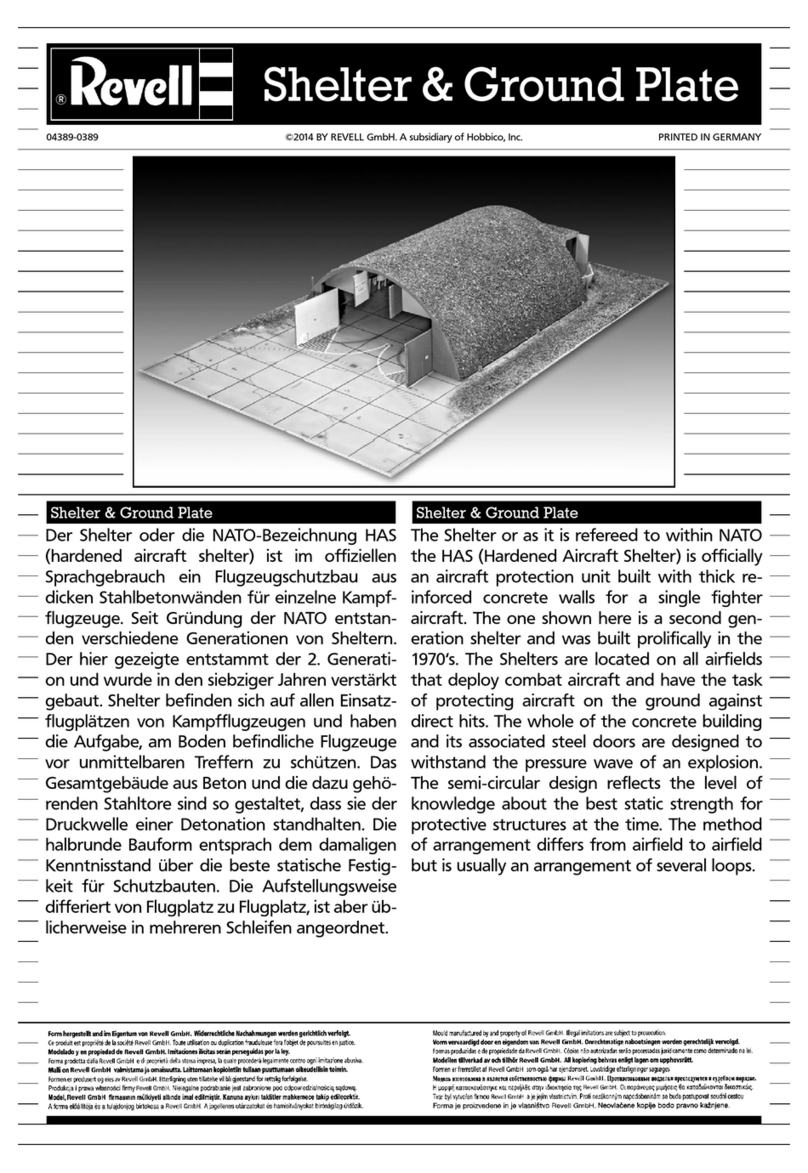

REVELL Shelter & Ground Plate Assembly manual

KidKraft

KidKraft Harley Davidson Roaring Softail Rocker Assembly instructions

TinkerHouse

TinkerHouse SATCOMM INSTALLATION Build instructions