DERRICK HYPERPOOL SHAKER User manual

HYPERPOOL SHAKER

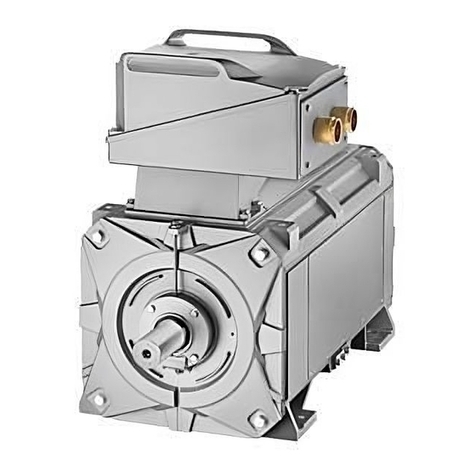

SGX MOTOR

Issued 15 Jun 12

Maintenance & Operation Manual

DISCLAIMER

Derrick Corporation has taken care to ensure that all of its maintenance and operation manuals are accurate. However, we offer no

guarantees or warranties in this regard. Our manuals are provided only as a guide to assist with the maintenance and operation.

Derrick Corporation takes no responsibility for any losses, damage, or injuries that may occur as a result of using any of our manuals.

It is ultimately the operator’s responsibility to ensure that the operation, repair, and maintenance of equipment complies with all

applicable national and local regulations, including safety regulations.

THIS MANUAL IS PROVIDED BY DERRICK CORPORATION ON AN “AS IS” BASIS AND DERRICK CORPORATION EXPRESSLY

DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL DERRICK CORPORATION BE LIABLE

FOR ANY DIRECT, IND

IRECT, INCIDENTAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES OF ANY KIND WHATSOEVER WITH

RESPECT TO THE MANUAL AND EQUIPMENT.

Derrick Equipment Company

15630 Export Plaza Drive

Houston, Texas 77032

Phone: 281.590.3003

Toll Free: 1.866.DERRICK

Fax: 281.442.6948

www.derrickequipment.com

UNIT NUMBER IS KEY TO DERRICK SERVICE

All inquiries to Derrick must include the equipment unit number. The

stainless steel unit number tag attached to each piece of Derrick equipment

is your key to efficient service and support.

Typical Derrick Unit Number

This unique number gives vital information to Service personnel who use it to

identify the correct parts when filling orders, provide accurate responses to

service questions, track documentation, and trace the equipment’s history or

configuration. In short, the unit number provides the critical information

needed to ensure that Derrick customers receive the best possible

service.

The unit number consists of a two-character alphabetic prefix that identifies

the equipment type and a series of numeric characters that signify the

sequence of the machine’s manufacture. For example, unit number

MA000001 would be the first screening machine manufactured by Derrick.

Alphabetic prefixes currently in use are:

MA - Screening Machine AD - Desilter and Desander

DG - Degasser AG - Mud Agitator

CF - Centrifuge SF - Screen Frame

To ensure that it will remain intact over many years of rigorous service, the

heavy-gage tag is riveted to a structural member such as the shaker support

structure. It is not to be confused with any other identifier on the machine

such as a vibrator motor serial number.

For convenient availability, the unit number is also recorded in the Operation

and Maintenance manual shipped with the equipment. When contacting

Derrick for any equipment question or need, always have the unit number in

your possession. It’s the best way to get the most efficient service from our

dedicated Service and Engineering personnel.

ABOUT THIS MANUAL

In this electronic manual, all sections and paragraphs listed in the CONTENTS

are linked to the corresponding text.

Navigate the electronic manual as follows:

1. To view any desired information, display the CONTENTS page and move the

cursor to the desired paragraph or section title.

2. To display the desired information, click on the listing when the pointing

finger appears over the text.

3. When finished viewing the text, press Alt + left arrow key to return to the

CONTENTS page.

4. If desired to return to the same information, press Alt + right arrow. To locate

a different item, repeat steps 1 and 2.

5. Blank pages are included to facilitate accurate two-sided printing on a

standard copier. To print any individual section, simply enter the PDF page

number range at the top of the screen (not the page number at the bottom of

each page).

This document contains proprietary information of Derrick Corporation. It is intended solely for the information and use of parties

operating and maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed

to any other parties for any other purpose without the expressed written permission of Derrick Corporation.

Continuous improvement is a policy of Derrick Corporation. All instructions and procedures are subject to change without notice.

CONTENTS

15 Jun 12 TOC-1

HyperPoolShaker

Section

Page

Date

1 - Introduction................................................................

..........................

1-1 15 Jun 12

Overview ..............................................................................................

1-1

Safety................................................................................................

...

1-1

Equipment Use................................................................

.....................

1-2

Equipment Orientation................................................................

..........

1-2

Description and Operation................................................................

....

1-2

Major Components................................................................

...............

1-2

Product Support................................................................

....................

1-7

2 - Safety....................................................................................................

2-1

15 Jun 12

Introduction................................................................

...........................

2-1

Warnings................................................................

..............................

2-1

Material Safety Data Sheets (MSDSs)................................

..................

2-3

3 - Installation................................................................

............................

3-1 15 Jun 12

General ................................................................

................................

3-1

Safety................................................................................................

...

3-1

Installation Sequence ................................................................

...........

3-2

Storage................................................................................................

.

3-2

Site Preparation and Clearance Requirements................................

.....

3-2

Moving/Positioning the Equipment........................................................

3-3

Desilter and Desander Installation................................

........................

3-5

Equipment Leveling................................................................

..............

3-7

Mounting and Securing Equipment................................

.......................

3-7

Shipping Brackets................................................................

.................

3-8

Feed and Discharge Connections................................

.........................

3-8

Electric Power Connections................................................................

..

3-10

Screen Panel Installation................................................................

......

3-12

Machine Startup ................................................................

...................

3-13

CONTENTS

TOC-2 15 Jun 12

HyperPoolShaker

Section

Page

Date

4 - Operating Instructions.........................................................................

4-1

15 Jun 12

General................................................................................................

.

4-1

Operating Safety................................................................

...................

4-1

Initial Startup................................................................

.........................

4-1

Normal Startup................................................................

......................

4-2

Normal Shutdown ................................................................

.................

4-2

Emergency Shutdown................................................................

...........

4-2

Desilter and Desander Operation................................

..........................

4-3

AWD Operation................................................................

.....................

4-6

Angle Adjustment................................................................

..................

4-7

Pool Configuration ................................................................

................

4-8

Screen Retention System Operation................................

.....................

4-9

5 - Maintenance................................................................

..........................

5-1 15 Jun 12

General................................................................................................

.

5-1

Routine Maintenance................................................................

............

5-1

Screen Frame................................................................

.......................

5-2

Screen Panel Replacement ................................................................

..

5-4

Vibrator Motors................................................................

.....................

5-5

AWD Jack Maintenance................................................................

........

5-5

Screen Bed Material Replacement................................

........................

5-6

Hydrocyclone Removal and Installation ................................

................

5-7

Recommended Spare Parts................................................................

..

5-10

6 - Screen Retention System ................................................................

....

6-1 15 Jun 12

General................................................................................................

.

6-1

Description................................................................

............................

6-1

Operation................................................................

..............................

6-2

Screen Panel Replacement ................................................................

..

6-2

Inspection and Repair................................................................

...........

6-2

7 - Vibrator Motor - SGX............................................................................

7-1

15 Jun 12

Description................................................................

............................

7-1

Repair Restrictions................................................................

................

7-2

Safety ...................................................................................................

7-2

Storage................................................................................................

.

7-3

Operating Environment................................................................

.........

7-3

Replacement Parts ................................................................

...............

7-3

Removal and Installation................................................................

.......

7-5

CONTENTS

15 Jun 12 TOC-3

HyperPoolShaker

Section

Page

Date

7 - Vibrator Motor (Cont’d)

Electrical Connections................................................................

..........

7-9

Preventive Maintenance................................................................

.......

7-15

Bearing Replacement................................................................

...........

7-15

Troubleshooting................................................................

....................

7-24

8 - Reference Drawings.............................................................................

8-1

15 Jun 12

9 - Installation and Maintenance Log.......................................................

9-1

15 Jun 12

SECTION 1 - INTRODUCTION

15 Jun 12 1-1

HyperPoolShaker

OVERVIEW

This manual provides instructions for installing, operating, and maintaining the Derrick HyperPool

shaker (Figure 1-1). The manual is divided into several sections to assist the user in readily

accessing the information.

Persons responsible for transporting, installing, operating, or performing maintenance on this

equipment are required to read and understand the instructions provided in this manual. One

copy of this manual should be available and accessible at the equipment location.

For maximum safety and performance, no additions and/or changes may be made to the

equipment without the explicit written permission of Derrick Corporation. Genuine Derrick

repair/replacement parts are required.

Figure 1-1. HyperPool Shaker

SAFETY

Section 2 of this manual contains relevant safety information relating to both operation and

maintenance of this equipment. Be sure this information is read and understood by all personnel.

DO NOT operate the equipment if defective or faulty mechanical or electrical components are

detected.

INTRODUCTION

1-2 15 Jun 12

HyperPoolShaker

EQUIPMENT USE

The HyperPool shaker and associated components are designed expressly for removal of drilling

solids from drilling fluid. Derrick does not authorize any other use of this equipment. Intended

usage of equipment includes compliance with the operating, maintenance, and safety instructions

provided in this manual.

EQUIPMENT ORIENTATION

Throughout this manual, references to front, rear, left, and right are based on viewing the HP-704

shaker from the feed end and looking toward the discharge end.

DESCRIPTION AND OPERATION

The HyperPool shaker is a four-panel, dual-motor, high frequency, linear-motion vibrating screen

machine designed for fine particle separation in the oil and gas drilling industry. The machine is

offered with a choice of motors and the manually operated Adjustable While Drilling (AWD)

feature. Box, weir, and weir bypass feeders are available, as well as desanders and desilters.

Feed slurry may be introduced into the HyperPool shaker through the feeder if so equipped. The

feeder evenly distributes slurry across the entire width of the screen frame. The hopper attached

to the underside of the unit captures liquid underflow passing through the screen bed.

MAJOR COMPONENTS

The following paragraphs describes the major components and accessories of the HP-704

shaker. Refer to Figure 1-3 for component locations.

Figure 1-3. HyperPool Shaker Major Components

Screen Frame

The screen frame (Figure 1-4) is suspended between the vertical legs of the hopper assembly.

The vibrating motion of the screen frame is isolated from the surrounding structural members by

eight float mounts—four at each end. The data plate with part number and serial number is

installed on the right side ledge of the hopper.

INTRODUCTION

15 Jun 12 1-3

HyperPoolShaker

Figure 1-4. Screen Frame Assembly

The vibrator motors are attached directly to the screen frame and positioned over the screening

bed to maximize the G-forces transferred to the screen surfaces. Float mounts isolate the

vibratory motion of the screen frame from the support structure. The adjustable while drilling

(AWD) mechanism is a manually operated jack screw that allows the operator to adjust the

screen bed angle between +2°and +8°to maximize fluid-handling and solids-removal.

The concave screen bed directs the feed material toward the center of the bed. The unique

screen retention system conforms the screens to the concave shape of the screen bed, which is

covered with oil-resistant cushions. Four screen panels are retained by retention pins that are

extended and retracted by compression assemblies—one for each panel—on the right side of the

screen frame. The pins are extended and retracted by manually operated torque tubes. A

removable handle, inserted into a socket on each torque tube permits the operator to extend and

retract the screen retention pins to alternately retain and release each screen panel. Retention

pins on the right side of the screen frame retain the screen panels by forcing the outer edges of

the panels inward, causing them to conform to the distinctive concave shape that characterizes

the HP-704 shaker, and locking them securely to the screen bed.

Vibrator Motors

Two continuous-duty vibratory motors deliver 7Gs of force to the screen frame. Opposing

electrical polarities cause the motors to rotate in opposite directions, thereby imparting linear

vibrating motion to the screen frame for proper conveyance of solids toward the discharge end of

the machine.

Hopper

The hopper (Figure 1-5) captures underflow from the screen panels. Mounting provisions are

included on the hopper for the feeder (optional) and electrical control box. In addition, the hopper

contains supporting members for the screen frame, AWD, desander, desilter, and other

components.

INTRODUCTION

1-4 15 Jun 12

HyperPoolShaker

Hopper (Cont’d)

Fixed structural members at the feed end of the hopper support the rear of the screen frame,

while the AWD supports the discharge end. This configuration permits adjustment of the screen

frame angle by raising and lowering the discharge end of the screen frame. Refer to Section 4 for

AWD operating instructions. Lifting lugs are provided at the front and rear of the hopper for lifting

and positioning the equipment.

Figure 1-5. Hopper Components

Adjustable While Drilling (AWD)

The Adjustable While Drilling (AWD) allows the operator to extend the time that the feed slurry

remains on the screening medium by elevating the discharge end of the screen frame. This

additional time improves the separation of solids from the liquid.

By elevating the discharge end of the screen frame slightly, the AWD causes the slurry to pool

toward the feed end of the screen frame. This pooling allows the slurry to remain on the screen

panels longer, permitting more liquid to drain through the panels and resulting in a drier solids

discharge.

Feeders

Box and weir bypass feeders are available for the HyperPool shaker. A brief description and

sketch of each feeder is presented in Figure 1-6. The rear surface of the feeder is imprinted with

8”, 10”, and 12” (203mm, 254mm, and 305mm) pipe targets for locating the customer feed

connection.

INTRODUCTION

15 Jun 12 1-5

HyperPoolShaker

Box Feeder

The box feeder

receives and distributes feed slurry evenly

across the screen frame. Slurry may be received either directly

from the process stream or from a desilter collection pan.

Weir Bypass Feeder

The weir bypass feeder is divided in

to inlet and outlet tanks.

This design allows the inlet slurry to rise in the inlet tank until

sufficiently high to overflow into the outlet section.

Slurry is

evenly distributed across the screen frame, as slurry flows

uniformly over the weir.

The bypass valve (if installed) permits slurry to be diverted from

flowing over the screen panels and go directly to the hopper or

receiving tank. Rotating the bypass wheel

opens and closes

the feeder’s internal gate valve. When open, the feeder is in

bypass operation where slurry flows directly to the hopper.

Figure 1-6. Box and Weir Bypass Feeders

Desilter and Desander

The 4” hydrocyclone desilter removes 10 to 74 micron solids from drilling fluid (mud), and the 10”

hydrocyclone desander is used to separate solids in the 40 to 100 micron range, The body is the

main component of the 4” hydrocyclone (Figure 1-7). A cone tip is threaded into the bottom of the

body. The soft apex is positioned in the tapered hole inside the triangular nut, which is threaded

onto the cone tip.

The 10” desander consists of three main components: Upper, middle, and lower sections (Figure

1-8). The soft orifice bushing (apex) is positioned in the tapered hole inside the orifice nut, which

is threaded onto the lower section. The orifice nut is threaded onto the lower section.

By varying the apex opening, the hydrocyclone spray pattern may be adjusted during operation.

Turning the orifice nut clockwise compresses the apex, thereby reducing the diameter of its

opening. Turning the nut counterclockwise releases compression, allowing the apex to return to

its original size.

INTRODUCTION

1-6 15 Jun 12

HyperPoolShaker

Desilter and Desander (Cont’d)

Figure 1-7. 4” Hydrocyclone Desilter Components

Figure 1-8. 10” Hydrocyclone Desander Components

INTRODUCTION

15 Jun 12 1-7

HyperPoolShaker

PRODUCT SUPPORT

Derrick offers 24-hour per day, 7-day per week product support. Product support includes screen

replacement / ordering information and repair / replacement parts and service for the entire

product line. Refer to the following table for the parts / service center nearest you.

PARTS SALES & SERVICE LOCATIONS

Colorado

Grand Junction - 970.241.2417

Louisiana

Broussard - 877.635.3354

New York - Corporate Headquarters

Buffalo - 716.683.9010

Oklahoma

Oklahoma City - 405.208.4070

Texas

Houston (Oilfield Headquarters) - 866.DERRICK (337.7425) 281.590.3003

North Texas (Bridgeport) - 405.208.4070

South Texas (Corpus Christi) - 361.299.6080

West Texas (Midland) - 405.397.4089

East Texas, Arkansas, and Louisiana - 281.546.1166

Wyoming

Casper - 307.265.0445

North Dakota

Williston - 701.572.0722

SECTION 2 - SAFETY

15 Jun 12 2-1

HyperPoolShaker

INTRODUCTION

This section contains a summary of WARNINGS used in this manual and a list of material safety

data sheets applicable to the equipment. The HyperPool shaker has been designed to perform

the stated functions safely.

WARNINGS

All persons responsible for operation and maintenance of this equipment must read and

understand all safety information in this manual prior to operating and/or maintaining the

equipment. The safety warnings listed below are included in applicable procedures throughout

this manual.

Sound

WARNING! TO PROTECT AGAINST HEARING LOSS, HEARING PROTECTION

SHOULD BE WORN AT ALL TIMES WHEN WORKING ON OR NEAR DERRICK

MACHINES.

Electrical Hazards

WARNING! TO AVOID SERIOUS PERSONAL INJURY BE SURE THAT

EQUIPMENT IS DE

-ENERGIZED, LOCKED OUT, AND TAGGED OUT PRIOR

TO PERFORMING MAINTENANCE AND/OR ADJUSTMENTS.

WARNING! MOTOR MUST BE OPERATED AT THE DESIGNATED SUPPLY

VOLTAGE.

WARNING! HIGH VOLTAGE MAY BE PRESENT. BE SURE THAT FUSED

DISCONNECT SUPPLYING ELECTRIC POWER TO THIS EQUIPMENT

IS

OPEN. LOCK OUT AND TAG OUT POWER SUPPLY TO PREVENT

ACCIDENTAL APPLICATION OF POWER WHILE MAINTENANCE AND/OR

ADJUSTMENTS ARE IN PROGRESS.

WARNING! ELECTRICAL CONNECTIONS MUST BE MADE IN ACCORDANCE

WITH THE NATIONAL ELECTRICAL CODE (NEC) AND ALL APPLIC

ABLE

LOCAL CODES. FAILURE TO COMPLY MAY RESULT IN AN UNSAFE

CONDITION THAT COULD INJURE PERSONNEL AND/OR DAMAGE

EQUIPMENT. ENSURE THAT ALL ELECTRICAL AND CONDUIT

CONNECTIONS ARE SECURE.

SAFETY

2-2 15 Jun 12

HyperPoolShaker

Equipment Handling

WARNING! USE SPREADER BARS TO PREVENT DAMAGE W

HEN LIFTING

THE EQUIPMENT.

WARNING! TO ENSURE PROPER BALANCE AND ORIENTATION WHEN UNIT

IS RAISED AND PREVENT DAMAGE TO COMPONENTS, ATTACH LIFTING

SLING ONLY AT DESIGNATED LIFT POINTS. DO NOT ATTEMPT LIFTING BY

ATTACHMENT TO MOTOR OR ANY OTHER LOCATION.

WARNING! BE SURE THAT HANDLING DEVICES HAVE SUFFICIENT LIFTING

CAPACITY TO SAFELY HANDLE THE WEIGHT OF THE EQUIPMENT.

WARNING! DO NOT REMOVE SHIPPING BRACKETS UNTIL EQUIPMENT HAS

BEEN POSITIONED AT FINAL INSTALLATION SITE.

Operation

WARNING! MOTOR

HOUSING BECOMES HOT DURING OPERATION AND

MAY CAUSE SEVERE BURNS. DO NOT TOUCH MOTOR HOUSING DURING

OPERATION

OR IMMEDIATELY AFTER MOTOR HAS BEEN OPERATING.

WARNING! ALL OPERATING AND MAINTENANCE PERSONNEL MUST READ

AND UNDERSTAND ALL SAFETY INFORMATION

IN THIS MANUAL BEFORE

WORKING WITH THE EQUIPMENT.

WARNING! BE SURE THAT ALL PERSONNEL ARE CLEAR OF MACHINE

BEFORE ADJUSTING ANGLE OF SCREEN BED.

HANDS AND FEET CAN BE

CRUSHED BY

THE MOVING SCREEN FRAME.

WARNING! DO NOT ATTEMPT TO OPERATE EQUIPMENT W

ITH SHIPPING

BRACKETS INSTALLED

.

Maintenance

WARNING! HIGH VOLTAGE MAY BE PRESENT. ALWAYS OPEN FUSED

DISCONNECT SUPPLYING ELECTRIC POWER TO THE EQUIPMENT, AND

LOCK OUT AND TAG OUT POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE AND/OR ADJUSTMENTS OF EQUI

PMENT.

WARNING!

GRINDING, BURNING, OR WELDING WILL PRODUCE

HAZARDOUS GASES AND DUST. ALWAYS WEAR PROPER PPE WHEN

PERFORMING ANY OF THESE PROCEDURES.

SAFETY

15 Jun 12 2-3

HyperPoolShaker

Storage

WARNING! MOTOR MAY BE DAMAGED BY STORING IN A HIGH HUMIDITY

ENVIRONMENT (GREATER THAN 50% RH)

. OUT-OF-SERVICE MOTOR(S)

MUST BE STORED IN A LOW

-HUMIDITY ENVIRONMENT.

MATERIAL SAFETY DATA SHEETS (MSDSs)

Material Safety Data Sheets (MSDSs) advise personnel of the properties and any possible

hazards associated with these materials. Emergency first aid procedures, special precautions,

emergency telephone number, and other relevant data are contained in the MSDSs. These

documents are prepared by the product manufacturers, which have sole responsibility for

accuracy of the information.

The MSDSs listed below apply to products used in the manufacture of the Derrick equipment.

Where shown, dates are current as of the publication date of this manual. The latest MSDSs may

be obtained from the product manufacturer.

MATERIAL DESCRIPTION - WHERE USED MSDS No. / Date

Paints and Coatings

PPG Dimetcote 302H Green 302F0250 Resin - Top Coat 1302H-5A / 04-11-10

PPG Dimetcote 302H Clear 302G0910 Cure - Top Coat 1302H-B / 01-21-10

PPG PSX 700 Neutral Tint Resin - Undercoat PX700T3 / 02-28-08

PPG PSX 700FD Cure - Undercoat PX700FD-B / 01-11-07

Sundur Beige Polyester TGIC - Vibrator Motor P-1609 / 10-30-02

Lubricants and Sealants

Exxon Mobil Mobilith SHC-100 - Vibrator Motor Bearings

Mobilith SHC 100 / 03-25-09

Loctite 76764 Anti-Seize Lubricant - Fasteners 76764 / 05-27-09

Table of contents

Other DERRICK Engine manuals

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton 09P700 Series Illustrated parts list

Siemens

Siemens SIMOTICS FD 1LH1 Operating instructions & installation instructions

Zenoah

Zenoah Zenoah instruction manual

Aerotech

Aerotech 75mm DMS Assembly & operation instructions

Briggs & Stratton

Briggs & Stratton Vanguard 580000 Operator's manual

GEIGER

GEIGER SOLIDline GU45 Series operating instructions