Desco Europe 19588 Installation and operating instructions

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

TB-3076.E Page 1 of 5 © 2019 DESCO INDUSTRIES INC

Employee Owned

Ion Python Compressed Air Ioniser

Installation, Operation and Maintenance

Description

The Desco Ion Python Compressed Air Ioniser is a

ready-to-use unit designed for use in applications and

areas where static can create manufacturing or handling

problems. These units quickly and effectively neutralise

bulk static charges and aid in controlling contamination

by dislodging dust and debris attracted by static

electricity. Airflow may be easily adjusted from a gentle

stream to a powerful blast. These units are designed

for use in applications and areas where electrostatic

attraction contamination create manufacturing or

handling problems (Ref: IEC TR 61340-5-2, paragraph

5.3.3.4.6.12 Point of Use Ionisation). The Ion Python

meets or exceeds the recommended technical

requirements of IEC 61340-5-1 tested in accordance

with IEC 61340-4-7.

Ionisers are useful in preventing electrostatic charge

generation, electrostatic discharge, electrostatic

attraction, as well as preventing equipment latch-up

and safety related shock. Paragraph 5.3.4.2 Insulators

in IEC 61340-5-1: “If the measured electrostatic field or

surface potential exceeds the stated limits, ionization or

other charge mitigating techniques shall be used.”

Ionisation is used to neutralise charges on process

necessary insulators and isolated semiconductors.

Some examples of process necessary insulators are:

the PC board itself, plastic test stands, plastic housing

where a PCB may be mounted, as well as computer

monitor screens and regular cleaning wipes. Examples

of floating or isolated conductors are: loaded PCB

mounted in a stand where the pins are not contacting

the dissipative workstation. Ionisation is not effective on

items that have large capacitance, like people and carts;

however, ionisers should be considered as a method for

charge neutralisation in cases where grounding cannot

be achieved.

July 2019

Air ionisation can neutralise the static charge on

insulated and isolated objects by producing separate

charges in the molecules of the gases of the

surrounding air. When an electrostatic charge is present

on objects in the work environment, it will be neutralised

by attracting opposite polarity charges from the ionised

air. Note that ionisation systems should not be used

as a primary means of charge control on conductors or

people. (Reference: IEC 61340-5-2:1 paragraph 5.2.9).

The Ion Python is NIST calibrated. It comes equipped

with universal IEC cord connectors.

NOTE: These units are not recommended for

continuous use.

The Ion Python and its accessories are available in the

following item numbers:

Item Description

19588 Ion Python Compressed Air Ioniser

92115 Flexible Arm Attachment

92118 Replacement Hand Gun Attachment

92119 Air Filters, 2-Pack

200220 Power Cord, Europe

200225 Power Cord, UK

Packaging

1 Ion Python Controller

1 Hand Gun Attachment

1 Certificate of Calibration

Made in the

United States of America

TECHNICAL BULLETIN TB-2079.E

Figure 1. Desco 19588 Ion Python Compressed Air

Ioniser

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

TB-3076.E Page 2 of 5 © 2019 DESCO INDUSTRIES INC

Employee Owned

Installation

Air Requirements

Always supply the Ion Python Hand Gun with filtered,

dry noncombustible gases, such as compressed shop

air or nitrogen. (If nitrogen is used, the tip will need to

be replaced and the unit recalibrated. This MUST be

done by the factory. Contact customer service at

+44 (0) 1462 672005). If the air is not dry, damage

to the equipment may result and the warranty will

be voided. Dirty air can introduce moisture and oil,

contaminating the units’ emitter assembly along with

the materials to be cleaned or neutralised. Filters

must therefore be used at all times upstream of the

air nozzle. A water trap-type pre-filter should be used

in conjunction with an oil coalescing-type filter. Also

drain all moisture traps regularly to prevent moisture in

the line. Several drainings per day may be necessary,

especially in areas of high humidity.

The Neutralising Ion Python Hand Gun may be operated

over a range of 30 PSI to 100 PSI. The specific

pressure needed will depend upon the application.

Pressures exceeding 100 PSI are not recommended

since these higher pressures are detrimental to effective

ion production. An air pressure setting of 60 PSI is

recommended. Use the needle valve located on the

back of the controller to properly adjust the air flow.

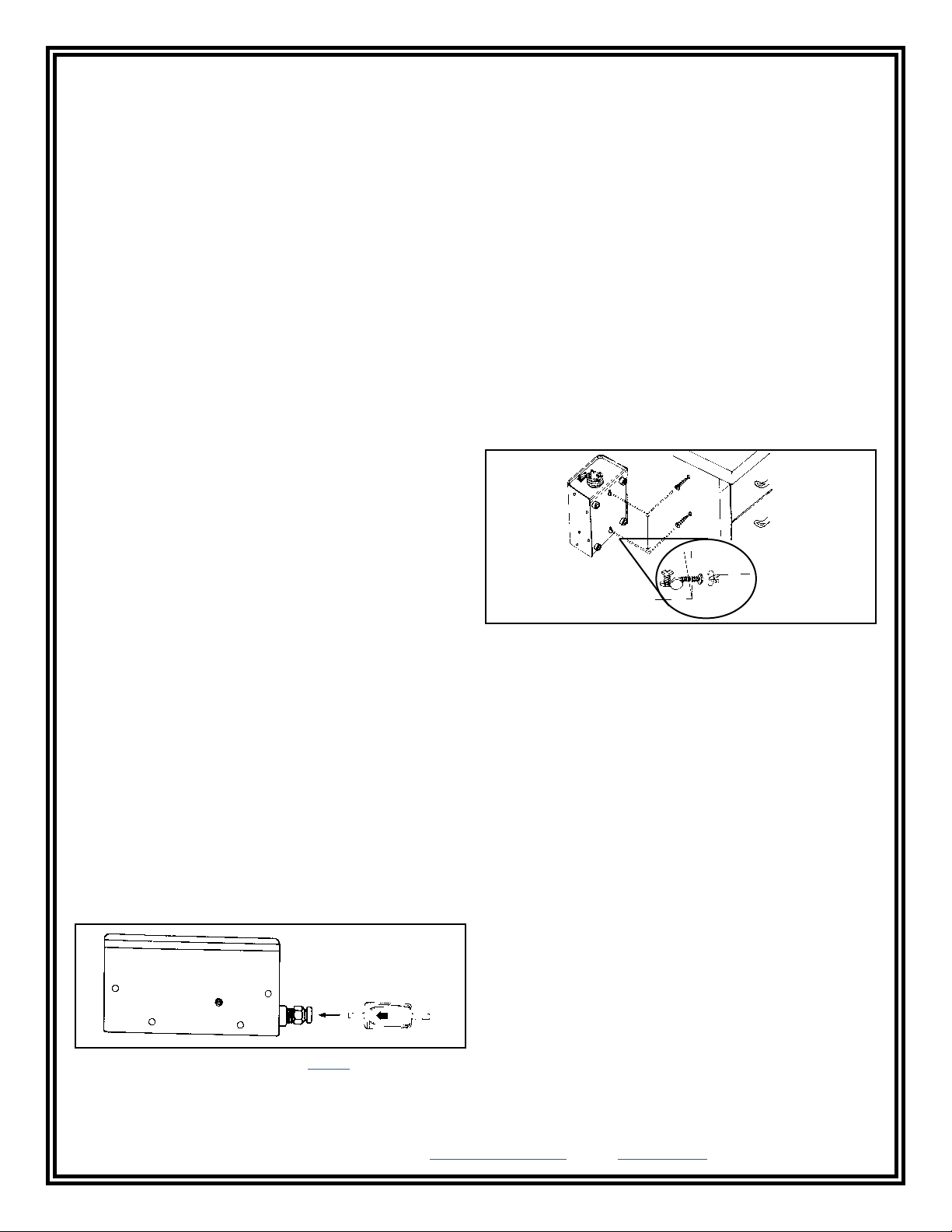

Air Supply Connection

Turn off air at regulator (or compressor). Insert the

brass male connector (1/4” tubing to 1/8” pipe thread)

into an available port on the regulator. If all ports are

being used, a “T” or “+” may be added to create more

ports. Connect the 1/4” tubing to the male connector on

the needle valve on back side of the unit, following the

instructions given below.

To connect tubing or filter to quick connect fitting:

Cut end of plastic tubing square and clean. Push

against the collar with thumbnail. While holding collar

in, push tubing into the fitting until it bottoms out

completely.

To release tubing or filter from quick connect fitting:

Push against the collar with thumbnail. While holding

collar in, push tubing inward slightly, then pull tubing

out.

IMPORTANT NOTE: User should exercise caution when

using any compressed air device.

Electrical Requirements

The Ion Python and Neutralising Hand Gun must be

connected to a properly grounded receptacle for the

units to operate properly. It is recommended that the AC

outlet be checked for proper wiring and grounding.

Do not under any circumstances remove the ground pin

from the plug of these units.

NOTE: Grounding of these units is necessary not only

to ensure that they operate properly, but to eliminate the

possibility of an electrical shock.

Mounting the Controller

The mounting slots on the bottom of the controller allow

for easy mounting of the base. Install screws either on a

wall or bench. Using the mounting slots, place controller

on the screws for secure mounting of the unit. Mounting

the controller underneath a bench or on a wall saves

valuable bench space. After mounting the unit, a locking

screw is provided on the back of the unit to prevent

accidental removal.

Filter (when used)

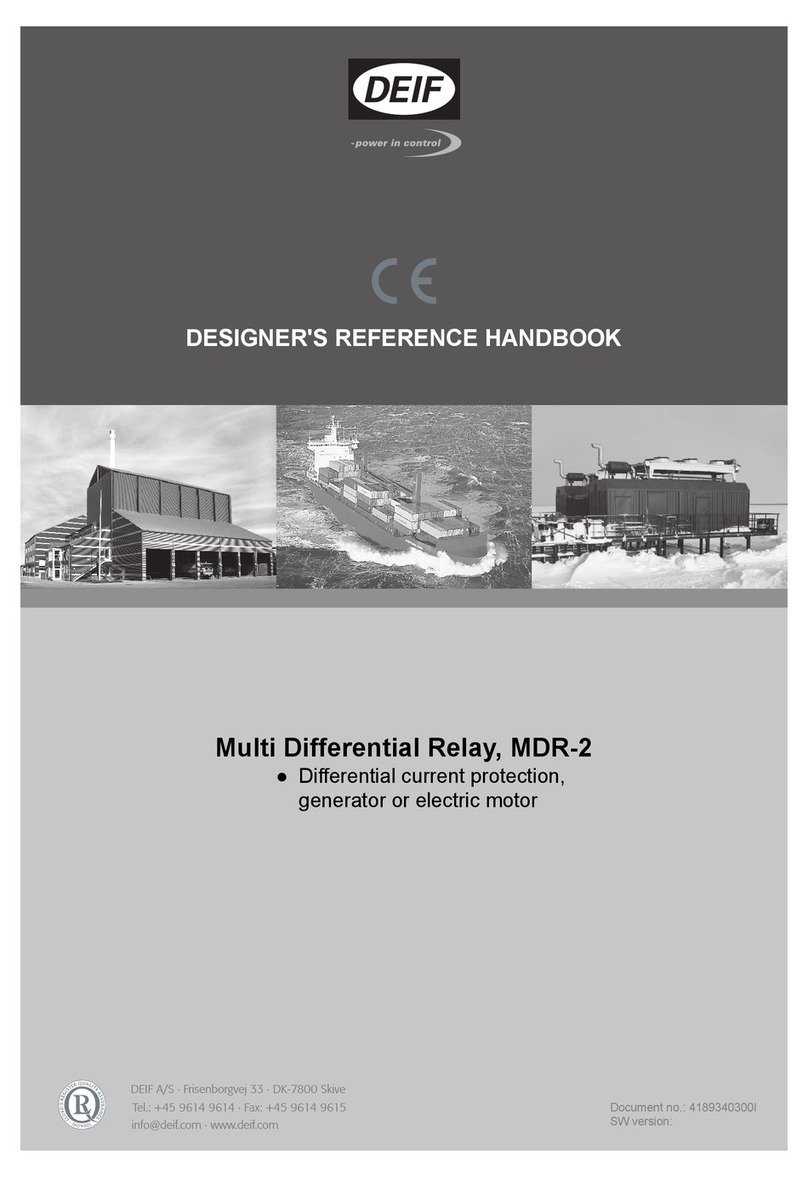

Figure 2. Connecting the optional 92119 air lter

Locking screw inside unit

helps secure Python Controller

Figure 3. Mounting the controller to a workbench

Operation

Turn on unit with switch on the front panel. The green

light indicates that the air nozzle is ready for use. Point

nozzle at object to be cleaned or neutralised.

For the Neutralising Hand Gun, push button on the

nozzle body to initiate the flow of air and neutralising

ions. Best results are normally obtained when holding

the nozzle within 2 or 3 feet (61 cm or 91 cm) of the

item being neutralised; hold the nozzle closer when

required.

NOTE: These units are not recommended for

continuous use.

A needle valve is located on the back of the unit for fine

adjustments to the air flow, or for shutting off the air to

the nozzle. Airflow on the unit can be adjusted from a

gentle blow to a strong blast, allowing for use in most

applications. Do not obstruct the air jet with fingers or

other objects. Do not force any object into the air jet

hole; this action can easily damage the emitter pin and

prevent the controller from producing the ionisation

necessary for neutralising static charges.

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

TB-3076.E Page 3 of 5 © 2019 DESCO INDUSTRIES INC

Employee Owned

The ion balance is affected by many factors, such as

distance, air flow, humidity, and emitter contamination.

Therefore, before using this device around components

and assemblies which are highly sensitive to ESD, it is

recommended that the user thoroughly evaluates the

application prior to its use. Avoid sharply bending or

crushing the black convoluted tubing under feet, rolling

chairs or other furniture.

IMPORTANT NOTE: These air nozzles are not

explosion proof. Do not use in environments where

volatile materials are present.

Desco Europe solid-state electronic equipment is

compact and rugged but should be treated as sensitive

electronic equipment. With proper installation and a

continued preventive maintenance programme you will

ensure the proper performance of the unit.

Maintenance

The frequency of monitoring ionisers really depends

on how and where they are used. Since the majority

of them use a fan to transport the ions to the working

area, the cleanliness of the air directly affects their

performance over time and how often the emitters

should be cleaned.

EIA-625 recommends checking ionisers every 6

months, but this may not be suitable for many programs

particularly since an out-of-balance may exist for months

before it is checked again. IEC TR 61340-5-2 paragraph

5.3.3.4.6.16.1 General considerations for mantanence

and cleaning, paragraph 5.3.3.4.6.16.1.1 Introductory

remarks states: "All ionization devices will require

periodic maintenance for proper operation. Maintenance

intervals for ionizers vary widely depending on the type

of ionization equipment and use environment. Critical

clean room use will generally require more frequent

attention. It is important to set up a routine schedule for

ionizer service. Routine service is typically required to

meet quality compliance verification requirements."

Under normal conditions, the ioniser will attract dirt and

dust (especially on the emitter electrodes). To maintain

optimum performance, cleaning must be performed on a

regular basis. The electrodes should be cleaned at least

every six months. However, more frequent cleaning

may be required if used in environments with more

contaminants.

These units need very little maintenance. In order to

maintain the optimum performance of your unit, the

following maintenance procedures must be performed

on a regular basis.

Make sure that the air supply is clean and free of

contamination and moisture. Drain compressor tank

and filters periodically. The filters may require draining

several times daily, depending on your compressed air

system.

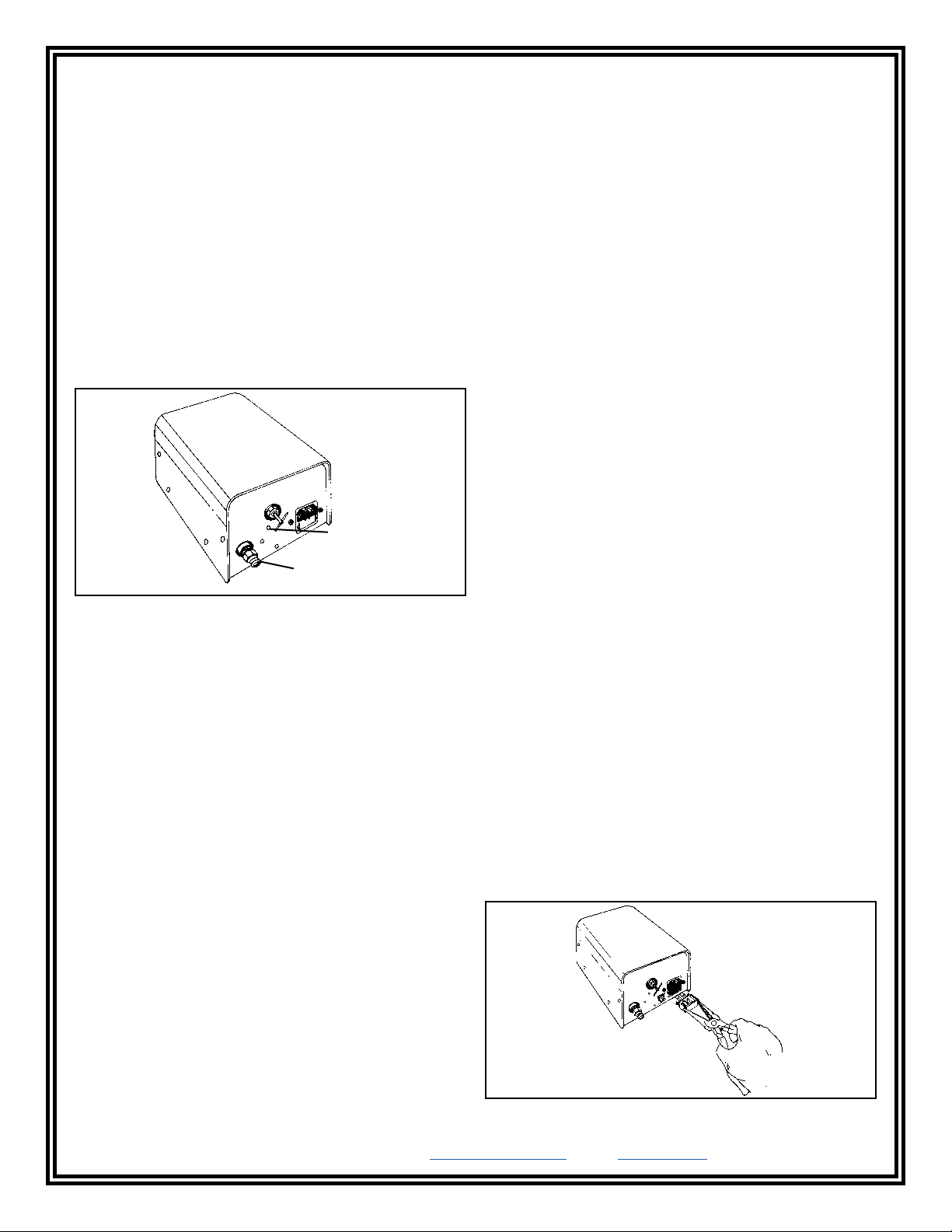

The fuse may be replaced by removing the power cord

at the back of the unit and opening the fuse box at the

IEC receptacle. The controller uses a 1 amp fast acting

fuse. For safety, do not use other ratings.

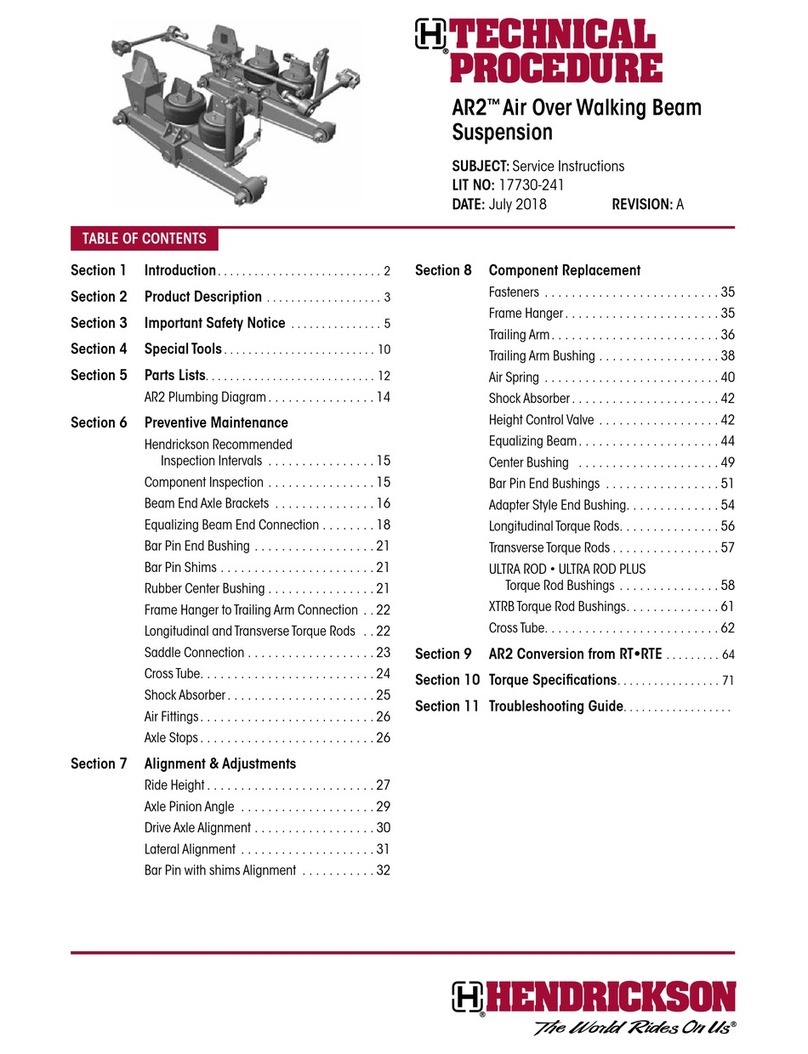

Air supply

conection

Needle

valve

Figure 4. Airow adjustment valve

Figure 5. Replacing the fuse

Theory of Operation

The Ion Python and Neutralising Hand Gun employs

high voltage AC to create a balanced ion field. AC

systems utilise emitters that are switched rapidly

between positive and negative high voltage, usually

at the power line frequency (50/60 Hz). The emitter is

located at the end of the nozzle. This emitter produces

large amounts of positive and negative ions, which

mix with the air supply and create a highly effective

neutralising field. Any material within this field will be

neutralised rapidly. The air nozzles also eliminate

contamination by dislodging dust and debris which

are attracted to a material’s surface by static charges.

Once static charges are neutralised, dust particles and

other forms of contamination are freed and carried

away by the air stream. Desco Europe ionisers meet

the IEC 61340-5-1 minimum recommended technical

requirement range of less than ±35 volts voltage offset

tested in accordance with IEC 61340-4-7. Air Nozzle

Ionisers provide ±20 volt balance.

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

TB-3076.E Page 4 of 5 © 2019 DESCO INDUSTRIES INC

Employee Owned

Do not attempt to perform any repairs or adjustments on

your Desco Europe equipment except for those covered

in the operation manual. Self-made repairs could create

a hazard and will void the warranty.

Replacing the Air Nozzle Assembly

The air nozzle and hose assembly is designed to be

removed or replaced by the user in the event of damage

or wear. To replace the assembly, simply unscrew the

collar at the base of the hose and gently disconnect the

connector from the receptacle.

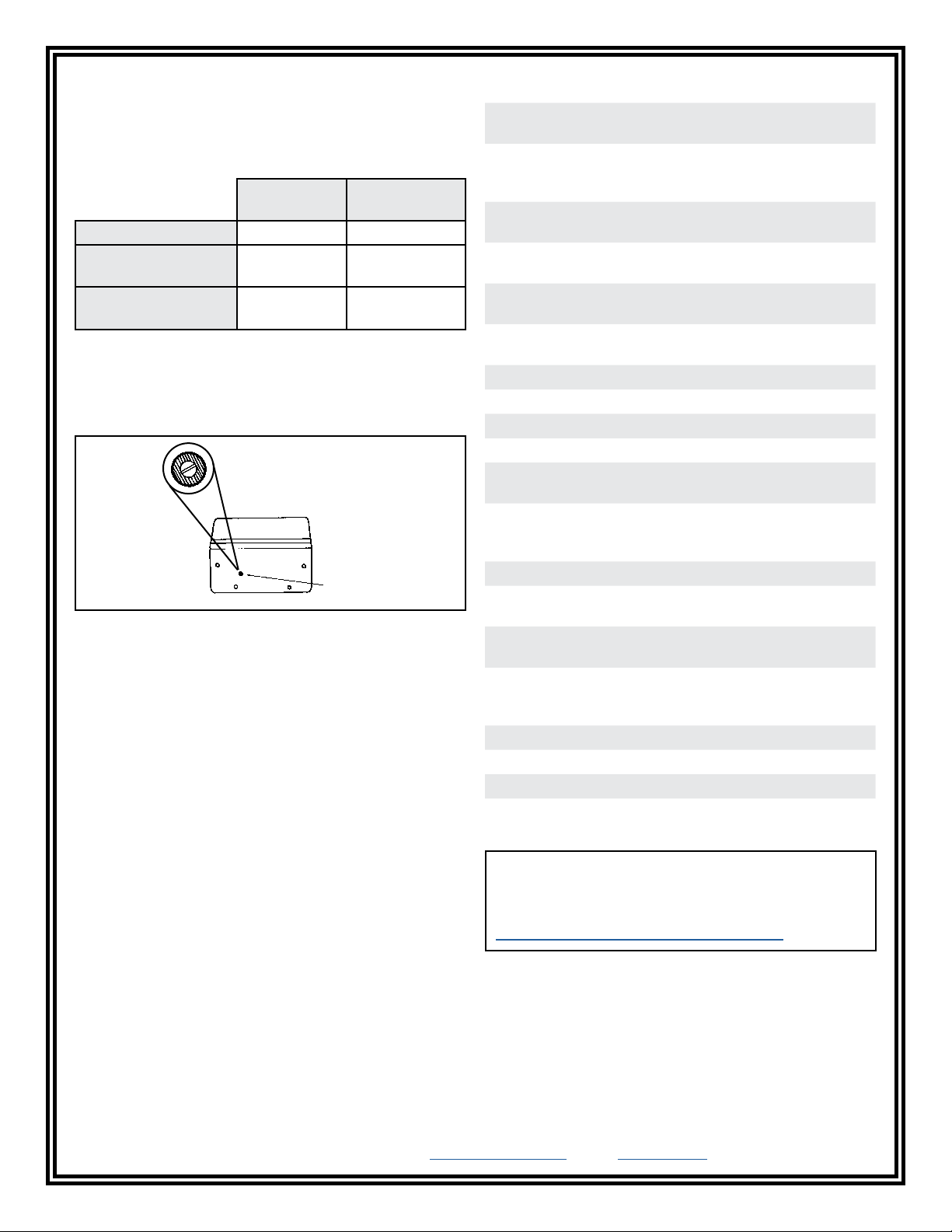

Neutralisation Efficiency (Decay Time)

The comparative neutralisation efficiency of ionisers

is determined by a standard test published by

IEC 61340-4-7. The decay rates measured using

this standard are shown in the chart below. This

performance was measured with the air nozzle at a

distance of 6" (15 cm) from the charged plate and

utilising an air pressure of 30 psi.

Decay Rate per IEC 61340-4-7

Test Pressure Decay Rate

30 psi 2 seconds

Charge Decay Time Constants

1. Decay times are from ±1,000 volts to ±100 volts.

2. The air nozzle’s air stream is perpendicular to the

charged plate.

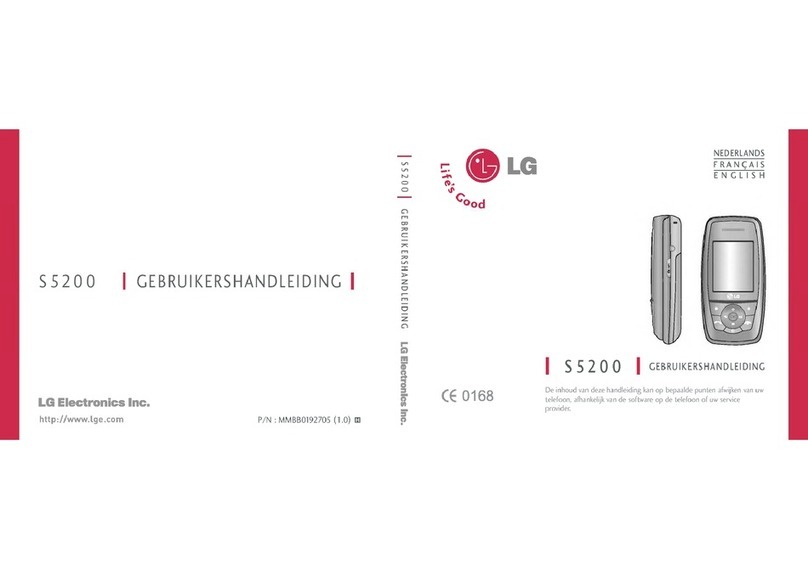

Depress

to release

Figure 7. Replacing the air lter

ION

PYTHON

CONTROLLER

Figure 6. Replacing the hand gun attachment

To replace the nozzle assembly simply repeat the

process in reverse.

NOTE: Make sure the fittings inside the connector are

properly aligned with their receptacles before tightening

the threaded collar.

Replacing the Air Filter of the Ion Python

Periodic replacement of the air filter is recommended

for optimum performance of the ioniser. Compress

outer sleeving away from the filter housing. Examine

the filter for any evidence of contamination. The filter

will turn red if there is any oil contamination. If there

has been moisture build-up, there will be a change in

air volume or a brownish colour to the filter. If either of

these conditions exist, you should replace the filter by

unsnapping connectors. Depress air line connectors

allowing removal of filter. The filter replacement is sold

as Desco Europe item 92119. Be sure to observe the

flow direction on filter when installing a replacement.

Nozzle

Charged Plate

Figure 8. IEC 61340-4-7 decay time test setup

Calibration

Test using a version of IEC 61340-4-7. Observe and

record offset voltage (float voltage) in voltage, measure

of discharge time for +1000 volts to +100 volts and

-1000 volts to -100 volts in seconds.

Equipment and tools used

• Charged Plate Monitor (CPM)

• Medium sizes insulative flat head screw driver

Set-up

1. Refer to IEC 61340-4-7. Test should be performed

on static dissipative worksurface. Testing technician

and worksurface needs to be properly grounded.

2. Refer to figure 8 - Test location for compressed gas

- Guns or nozzles on page 13. CPM needs to be 6”

from the center of the CPM plate to worksurface.

Tip of air nozzle needs to be at 6" (15 cm) away

from surface of CPM plate.

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

TB-3076.E Page 5 of 5 © 2019 DESCO INDUSTRIES INC

Employee Owned

Testing

Lab environment should be at 75 °F at ±5 °F (23.9 °C at

±5 °C), relative humidity at 45 % at ±5 % RH. Observe

offset voltage for no less than 10 seconds before

recording.

Specification Recorded

value

Balance 25 V

Discharge time

(+1,000 V to +100 V)

≤ 2 s

Discharge time

(-1,000 V to -100 V)

≤ 2 s

Adjustment

Adjustments to the offset voltage could be made by

using an insulative flat head screw. Balancing pot is

located on the side of controller, where the white plastic

cap is covering it.

Specifications

Input voltage and

frequency

220 VAC, 50/60 Hz

Neutralisation

(discharge) time at

6" (15 cm), 30 psi

< 2 seconds

Balance at 15 cm,

30 psi

±25 V

Power consumption 2.5 W (standby)

25 W (in-use)

Amperage < 50 mA (standby)

< 400 mA (in-use)

Fuse 1 A, 5 x 20 mm, fast-acting

(2 each)

Ion emission AC

Emitter point Stainless steel

Ozone < 0.005 ppm

Air hose ABS plastic, 2 m length

Gas input 30 to 100 psi, Clean Dry Air

(CDA)

Gas connection 1/4" O.D. tubing with 1/8"

NPT with adjustable needle

valve

Gas consumption 3.5 CFM @ 30 psi

Mounting Metal mounting plate attaches

to back of console

Enclosure Powder coated steel and

stainless steel

Dimensions (console) 5.1" x 6.4" x 7.1"

(130 mm x 163 mm x 180

mm)

Weight (console) 11 lbs (5.0 kg)

Certications Intertek, CE

Country of origin United States of America

Adjustment screw

Figure 9. Balance adjustment trimpot

Limited Warranty, Warranty Exclusions, Limit

of Liability and RMA Request Instructions

See the Desco Europe Warranty -

DescoEurope.com/Limited-Warranty.aspx

Table of contents