!Before reinstalling and restarting the skimmer, rinse well all the parts and make sure

you completely removed any trace of cleaning chemical agents.

!Before reinstalling and restarting the skimmer, rinse well all the parts and make sure

you completely removed any trace of cleaning chemical agents.

6

• Keep the drain outlet free from any obstruction

• The best skimmer performances are obtained if the water intake pump is placed in a compartment

with water at a constant height, or by using a high prevalence pump

• The skimmer needs at least from 3 to 7 days of startup to work properly, effectively and steadily

• A too much quick Collect Cup B ll-up means a wrong skimmer adjustment. The reasons for this may

be one or more of the following typical installation mistakes:

• Too high water level in Contact Column A (see chapter 5)

• Too high air ow from G (the foam will be too wet - see chapter 5)

• A too big and sudden organic load for the current calibration

• Some rubber tubes, even if not connected to the skimmer, may release substances that may inhibit

the skimming process. It is strongly recommended that only tubes specically designed for aquariums

and for food should be used.

6. Warning on startup & adjustment

7. Maintenance

www.lgmaquari.it | lgmaquari@libero.it

!

Before lifting the skimmer, if lled with water, empty the skimmer before lifting it by

by unscrewing the tting and put aside to help water pour out. In case of lifting

with water inside, place one hand below the bottom base of the skimmer and the

other along the Contact Column . Never lift up the skimmer from any upper edge.

To ensure your skimmer is working properly, it is essential to perform some simple periodic mainte-

nances. This is essential to maintain the aquarium healthy.

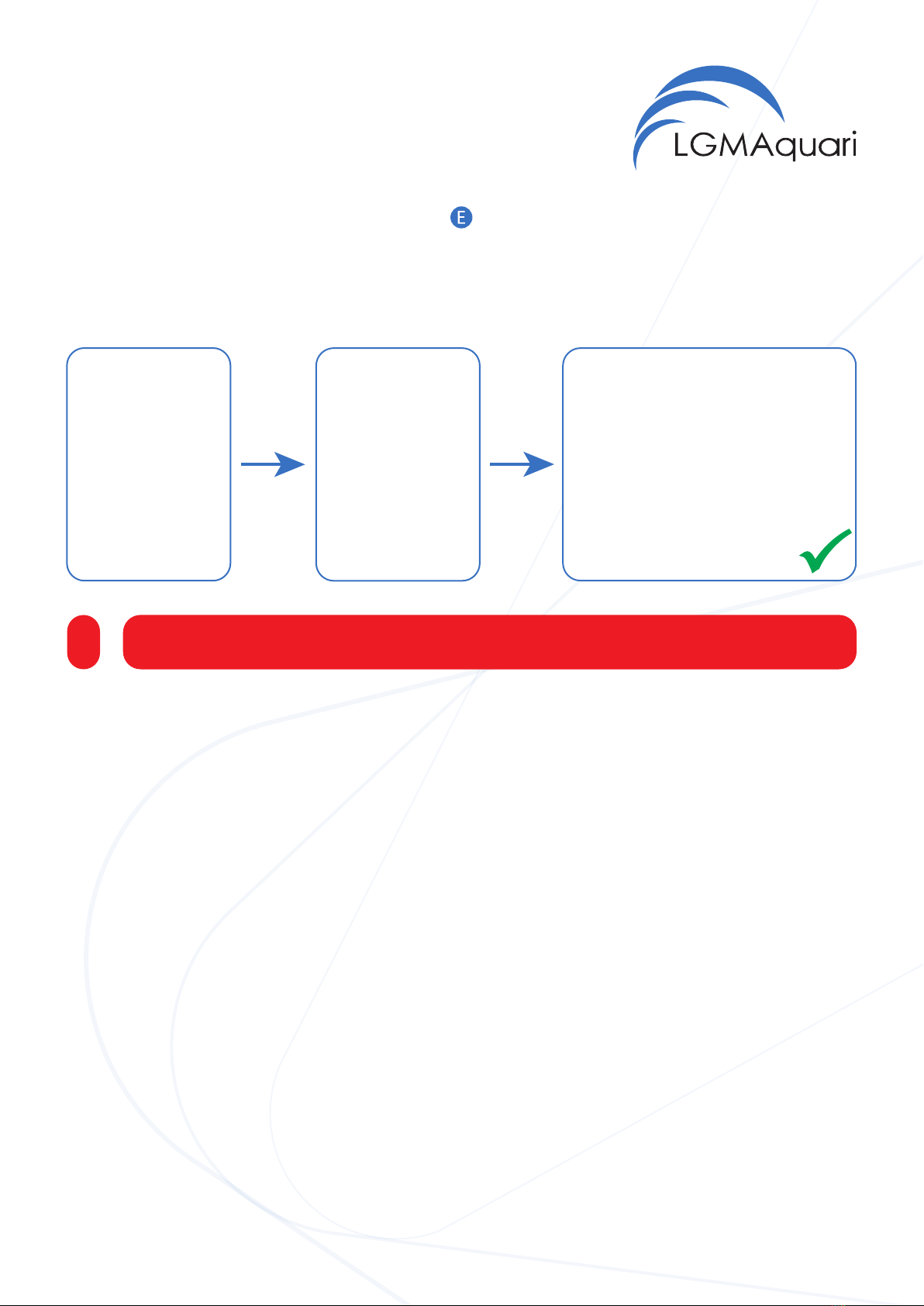

• 7.1 Contact Column cleaning

Periodically wash the inside of A with bleach (chlorine-based products) to remove any traces of algae

which inhibit the skimming. Also residues of calcium deposited on the inside will inhibit skimming. To

remove them, perform a ush with diluted hydrochloric acid or vinegar.

• 7.2 Air suction block cleaning

Periodically or in case of very low air ow, clean G and the connection rubber tube to F .

Calcium and/or salt deposits may progressively block up these parts.

v.1.1 ENG | 450~3000 | 03-2014