4.1 95-86035

INSTALLATION

CAUTION

Installation and wiring of the flame detection

system should be performed only by qualified

personnel. Refer to the ame detector instruction

manual for general installation instructions.

VIDEO CABLE CONSIDERATIONS

Proper video cable will ensure that the best quality video

is displayed on a remote monitor. Because composite

video frequencies span the range of 25 Hz to 6 MHz,

most cables will display transmission line characteristics.

Ensure that the same cable type (impedance) is used

throughout the entire length. For example, do not mix

twisted pair cable and coaxial cable without using a

balun for matching. In addition, the monitor end must

be properly terminated. Failure to properly implement

the video cabling system may result in smearing (loss of

detail) and/or loss of color and/or loss of picture sync.

The xWatch employs a balanced differential video

driver designed to drive twisted pair cable of 100 ohm

impedance. The best video performance in terms of

distance, video quality, and cost is attained using a 22

AWG to 16 AWG unshielded twisted pair cable of 100

ohm impedance. The wiring can be Category 2 or better,

stranded or solid.

The monitor end must terminate the video cable with 100

ohms. Most monitors have a built in termination resistor.

If the monitor uses 75 ohms instead of 100, a balun or

other matching network must be used.

Galvanic isolation of the video may also be necessary

to avoid horizontal bars caused by line frequency

interference. This may be accomplished using isolating

active transceiving systems or passive video isolation

transformers/baluns. Specify a baseband video isolation

system with a frequency response of at least 25 Hz to 6

MHz. Small cable TV transformers will generally not work

as their frequency response is not low enough.

WIRING PROCEDURE

CAUTION

Power must not be applied to the device while the

housing is open.

ATTENTION

Observe precautions for handling electrostatic

sensitive devices.

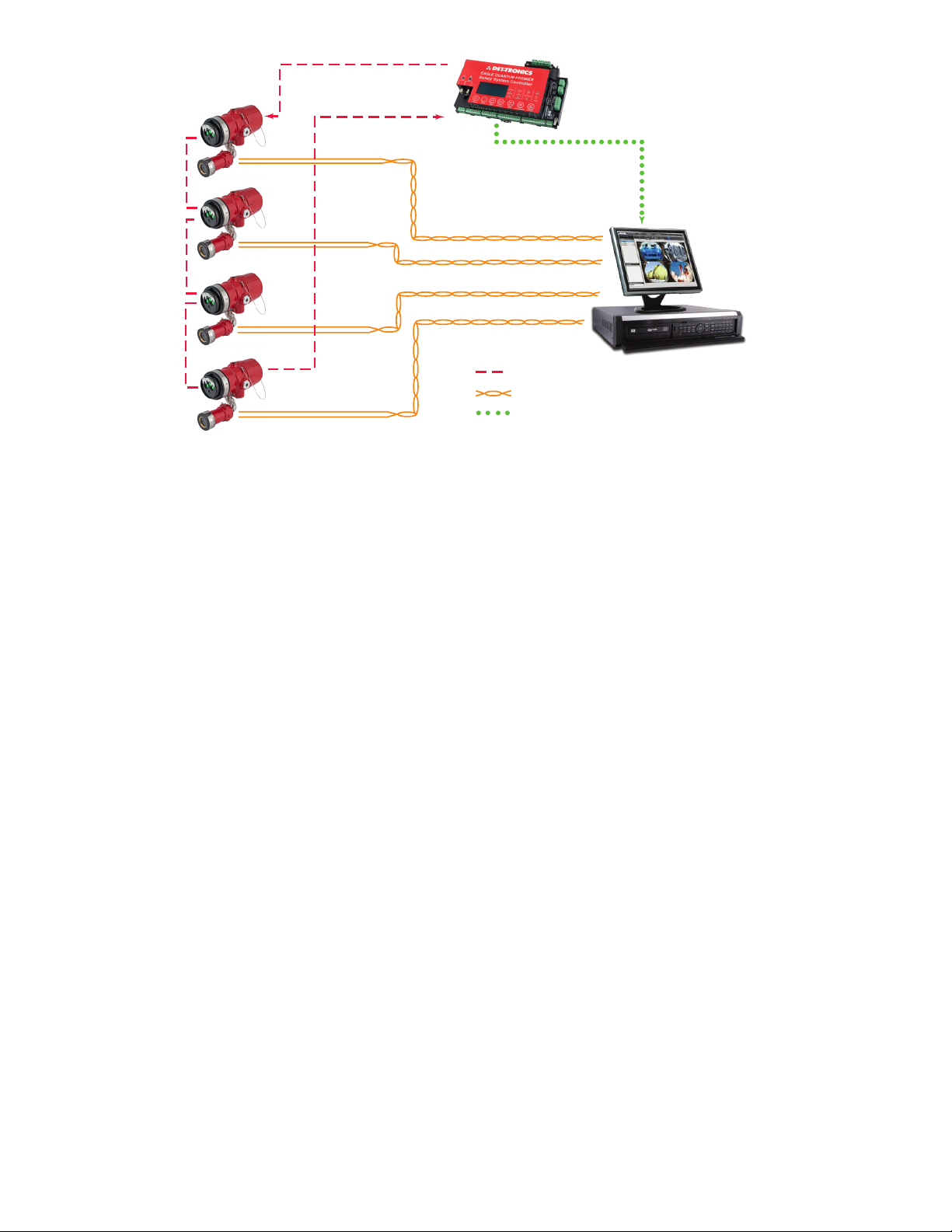

1. Wire the flame detector as shown in the detector

manual.

2. Connect the external wiring for the xWatch to the

appropriate screw connectors on the terminal block.

See Figures 4 and 5.

IMPORTANT

Do not test any wiring connected to the xWatch

with a meg-ohmmeter. Disconnect wiring at

the camera before checking system wiring for

continuity.

3. Complete installation and commissioning of the

system as described in the detector instruction

manual.

9

8

7

6

5

4

3

2

1

19

18

17

16

15

14

13

12

11

mA + mA –

mA + REF mA – REF

COM FIRE COM FIRE

NO FIRE NO FIRE

NC FIRE NC FIRE

COM FAULT COM FAULT

NO FAULT NO FAULT

+Vin +Vin

–Vin –Vin

–Vin

29

28

27

26

25

24

23

22

21

VIDEO +

VIDEO -

COM AUX

NO AUX

NC AUX

RS485 A

RS485 B

MAN Oi

D2386

Figure 4—Wiring Terminal Identication for Standard Flame

Detectors

B2387

COM 2 B

–Vin

VIDEO +

VIDEO –

+Vin

PWR SHIELD

SHIELD

COM 2 A

COM 1 B

–Vin

+Vin

PWR SHIELD

SHIELD

COM 1 A

14

13

15

16

17

18

11

12

2

1

3

4

5

6

Figure 5—Wiring Terminal Identication for EQP Models