Diamond Tech International Diamond Max User manual

Diamond Max

Two-In-One Grinder

Operations Manual

Safety Precautions

Router Operating Instructions

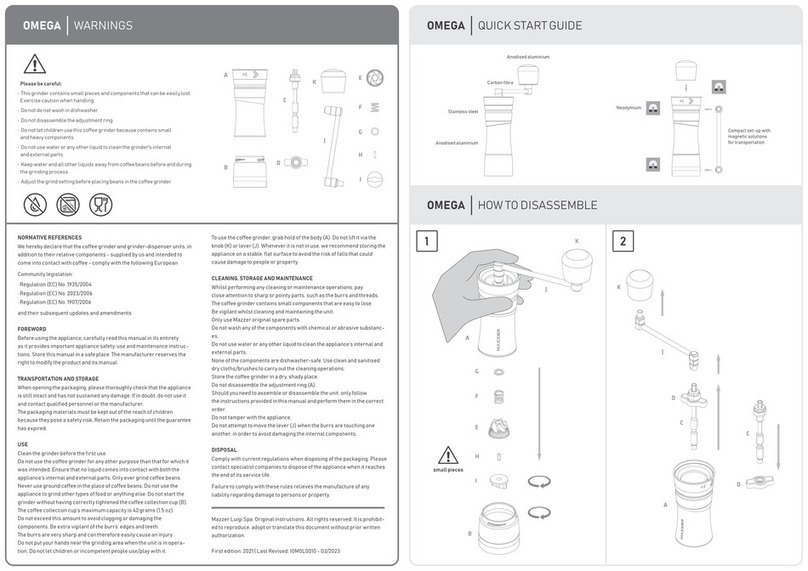

1. Remove the packing included to protect the grinder during shipment.

2. The grinder disk must be installed before initial operation of the grinder.

To install the grinder disk use a hex wrench, loosen and remove

Grinder Head. Then, remove the grind surface, water tra , Beveling

Block and splash guard. Line up the pin hole on the bottom of the

disk with the pin on the lower support collar and lower the disk into

place. Remove the disk retaining nut and install the grinding disk.

Grease the threads of the lower support collar, then reattach the

disk retaining nut and tighten securel . Push disk down firml to

minimize disk vibration. Installation of the disk is necessar even if no

water dripping on the motor housing.

3. Replace the water tra , grid surface, splash guard and Beveling

Block. Grease the motor shaft, then replace and tighten ensuring

that the hex screw on the bit is aligned with the flat part of the

motor shaft.

4. Fill the water reservoir about 3/4 of the wa to the top. You ma add

special grinding lubricant if desired.

5. Soak the sponge in water, then position it behind the water reservoir

and Grinder Head. If the sponge goes dr while grinding add

extra water directl to the sponge. NEVER GRIND DRY. Keep the slide

valve closed until read for disk use.

6. Replace the grid cover and the grinder is read for use. The grinder plugs directl into the Foot

switch (recommended for use) or into an outlet.

7. To setup the 1/4 bit and the Step-Up-Work Surface (Deluxe Model Onl ), place the 1/4 bit

directl onto the top of the shaft and tighten hex screw. The Step-Up-Work Surface has pins on

the bottom that fit into the grid cover.

8. When it is time to replace the router head or diamond disk, replace with Diamond Tech Grinder Bits

onl . Other brands ma not properl fit on the Diamond Max.

PLEASE NOTE: Snap 3/4 grinder head adapter into the grid surface before using the 3/4

Grinder Head.

1. Read the instruction manual before operating this tool.

2. ALWAYS WEAR FULL EYE PROTECTION.

3. Be sure the power switch is OFF before plugging in this tool.

4. Use onl with a properl grounded electrical outlets that acceptS a three prong plug.

5. Unplug grinder before servicing. Alwa s be sure the grinder is proper working condition before use.

6. Keep grinder clean and lubricated for safet and best performance.

7. Avoid dangerous environments. Use in a clean, well lit, and ventilated area awa from flammable

vapors

8. Wear proper apparel. Remove jewelr neckties and clothing that could become caught in the

moving parts.

9. Remove all ke s and wrenches before using this tool. Leaving ke s and wrenched attached while

operating this tool ma result in damage to the tool or operator.

10.Never leave grinder running unattended. Turn power off. Dont leave tool until it comes to a

complete stop.

Disk Operating Instructions

1. Fill the water reservoir about 3/4 of the wa to the top and

when read to start disk grinding, open the Slide Valve. If needed,

ou can increase water suppl to the grinding disk b slightl

enlarging the holes located behind the slide valve. Use caution to

prevent over-enlargement of the holes.

2. While grinding, hold glass firml and move material from side to

side over disk. To grind accurate 300 or 450 edges, use the

reversible Bevel Block. To grind an accurate 900 flat edge hold

material against the back of the water reservoir.

3. If the material ou are grinding rubs against the sides of the grinder,

then raising the disk is necessar . To raise the disk, first remove the

Grind Head, water reservoir, and retaining nut and the disk. The

support collar is secured b 2 hex screws on the side, loosen it and

raise the lower collar to the needed height, then retighten.

4. To avoid unnecessar disk vibration, ensure a secure fit between the disk and lower support collar.

5. Minor chipping ma occur with new disk. Chipping will stop after a little use.

How To Drill

1. Start with the 1/4 grinder head attached to the top of the shaft.

2. Grip the glass firml suing the lower ver gentl on the top of the drill bit,

hold the wet sponge as close as possible to the point of contact .

3. Lighten pressure downward when ou near completion of our drilling

to avoid chipping.

Use and Care Information

1. NEVER GRIND DRY. Alwa s make sure the sponge for the router bit is wet or that water is dripping

on the disk while grinding.

2. DO NOT OPERATE WITHOUT DIAMOND DISK INSTALLED. Disk acts as a cover to keep water from

dripping on the motor housing.

3. While using the grinder head, use onl light to medium pressure on the head. Do not push material

against head using excessive force. Unnecessar pressure will shorten grinder and grander head life.

4. Clean water reservoir and Super Sponge after each use.

5. If the router Grinding Head becomes dr , add water directl to the Super Sponge.

6. To maintain ease of assembl , disassembl , and to extend the life of the grinder, clean and grease

the motor shaft (rod that holds grinder head). Inner disk circle, and set screws ever 50 hours of use.

7. Some rust ma form onto he Diamond Disk, it does to effect the efficienc of life of the disk.

8. DO NOT GRIND METAL. It will make the surface unsuitable for glass in seconds.

Warranty

TheDiamondMax™is backedby 6 year manufacturerswarranty. Iffailure occursfor anyreason other

thanmisuse during thisperiod, it will be corrected free ofcharge when shippedprepaid to our distribution

center.Grinder Heads,Disks and SuperSponge™are notincluded in thiswarranty except for

manufacturingdefects.

Ifyouare havingfurther problemsnotcovered inthis manual,callour customerHelp Lineat

800-937-9593

NOTE: This machine was designed for certain applications only. Diamond Tech International strongly

recommends that this machine NOT be modified and/or used for any application other that for which it

was designed. If you have any questions relative to its application DO NOT use the machine until you

have contacted Diamond Tech International and we have advised you.

Upgrade Kits and Replacement Parts

Universal Face Sheild™ - Protect eyes and face while grinding.

Fits any ginder or beveler.

M3 Conversion Kit -Everythingyou need toconvert yourDiamond

Max™ into a Bevel Max™ StudioBeveling System.

Kit Includes:• 5 pack of 60 and 1 micron laps

• Polishing Pad and Compound

• 150/300 Bevel Block™

• Splash Gaurd Booth

• Water Bottle

• “How To Bevel” Video

Step-Up-Work Surface™ - Second story work surface provides a

flat surface when using the 1/4” router bit.

Grinder Disks™ - Replacement disks come in three different grits -

180 coarse, 260 fine and 360 extra-fine.

Silver Bullet Bits™ - DTI manufactures a full line of grinder bits.

Sizes include: 1/4” screw, 1/4” screw, 1/4” cap, 1/4” fast grind(cap),

3/4” fast grind, 1” standard, 1” fast grind, Angle Bit and a Reducing Bit.

Table of contents

Other Diamond Tech International Grinder manuals