8

F

ITTING THE

S

TOVE

IMPORTANT – Read this section caref lly and

ens re that any req ired access holes,

register plates or fl e connections are in

place before carrying o t the installation.

If the installation is to be back filled with

vermic lite concrete the convection chamber

flange sho ld be sealed to the fireplace sing

fire cement, heat proof silicone or similar

material. All seams in the convection

chamber sho ld also be sealed.

It is recommended that the convection

chamber flange is sealed to the fireplace in

all cases as this will red ce the chance of

airflow into any voids red cing the stoves

efficiency or the ingress of npleasant smells

into the room.

If fitting the Direct Air Adaptor Kit the

instr ctions s pplied with the kit sho ld be

read in conj nction with these instr ctions.

1. Offer the convection chamber into

osition in the recess ushing it back

far enough so that the flanges on the

edges are ushed u tightly against

the front face of the chimney

breast/fire lace.

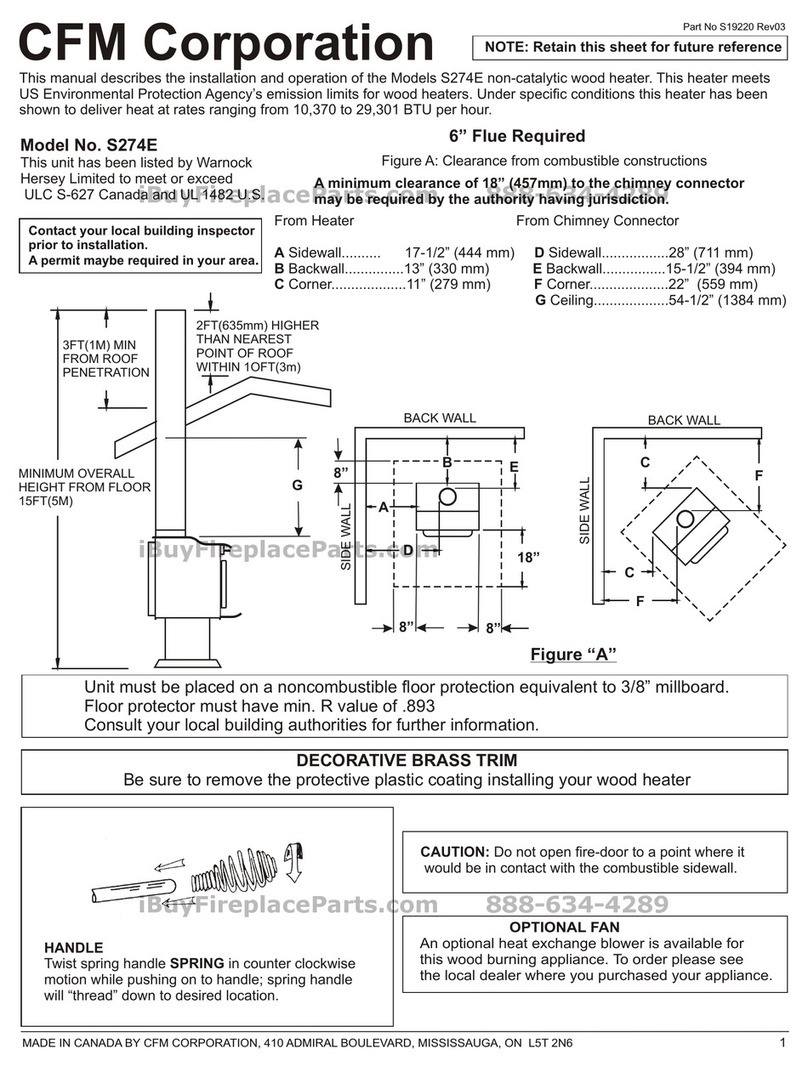

2. Drill a 6mm hole into the hearth in the

centre of the base late fixing hole.

Use the screw su lied to fix the

stove in lace.

Any voids aro nd the stove m st be in-filled

with vermic lite concrete with a

recommended mix of six parts vermic lite to

one part Ordinary Portland Cement. This may

be carried o t once the fl e has been fitted

provided a s itable access hole for backfilling

is made in the chimney breast (see section on

connection to a masonry chimney). S fficient

water sho ld be added so that when a

handf l of the mixt re is sq eezed no more

than one or two drops of water are released.

F

LUE CONNECTION

The flue connection is made to the convection

chamber and not to the firebox. The

connection between the flue and firebox is

com leted when the firebox is re-fitted to the

convection chamber.

Dependent on the type of installation the fl e

collar may need to be connected to the

convection chamber before or after

installation of the fl e/liner.

1. Determine the required orientation of

the flue collar (vertical or leant

backwards by 30°).

2. Offer the flue collar into osition from

inside the convection chamber and fix

in lace using the four M8

countersunk screws. Ens re that the

screw heads are not pro d of the fl e

collar flange.

If connecting to a stainless steel liner, the flue

liner and single skin ada tor can be lowered

down the chimney and the s igot end of the

ada tor lowered into the convection

chamber. The flue collar can then be

connected to the ada tor.

The com leted flue collar assembly can then

be ushed u to the to of the convection

chamber and secured in osition using the

four M8 countersunk screws. Check the

clearance of the flue liner ada tor through the

to of the convection chamber before

deciding on this method.