Pyroclassic Fires Operating Instructions | Updated July 2016 | V.2 | 8

OPERATING USE AND MAINTENANCE

REFUELLING ONTO A LOW FIREBED

The wood fuel inside a Pyroclassic® fire burns best on a thin bed of ash and hot coals. Refuelling must be carried out onto

a sufficient quantity of glowing embers so the new fuel will ignite. Add suitable kindling if necessary. If a new fuel load is

left without suitable ignition then a buildup of unburnt volatile gases can occur. This puts stress on the unit, which can

lead to an internal explosion when these gases do combust. Always ensure adequate ignition and combustion of fuel and

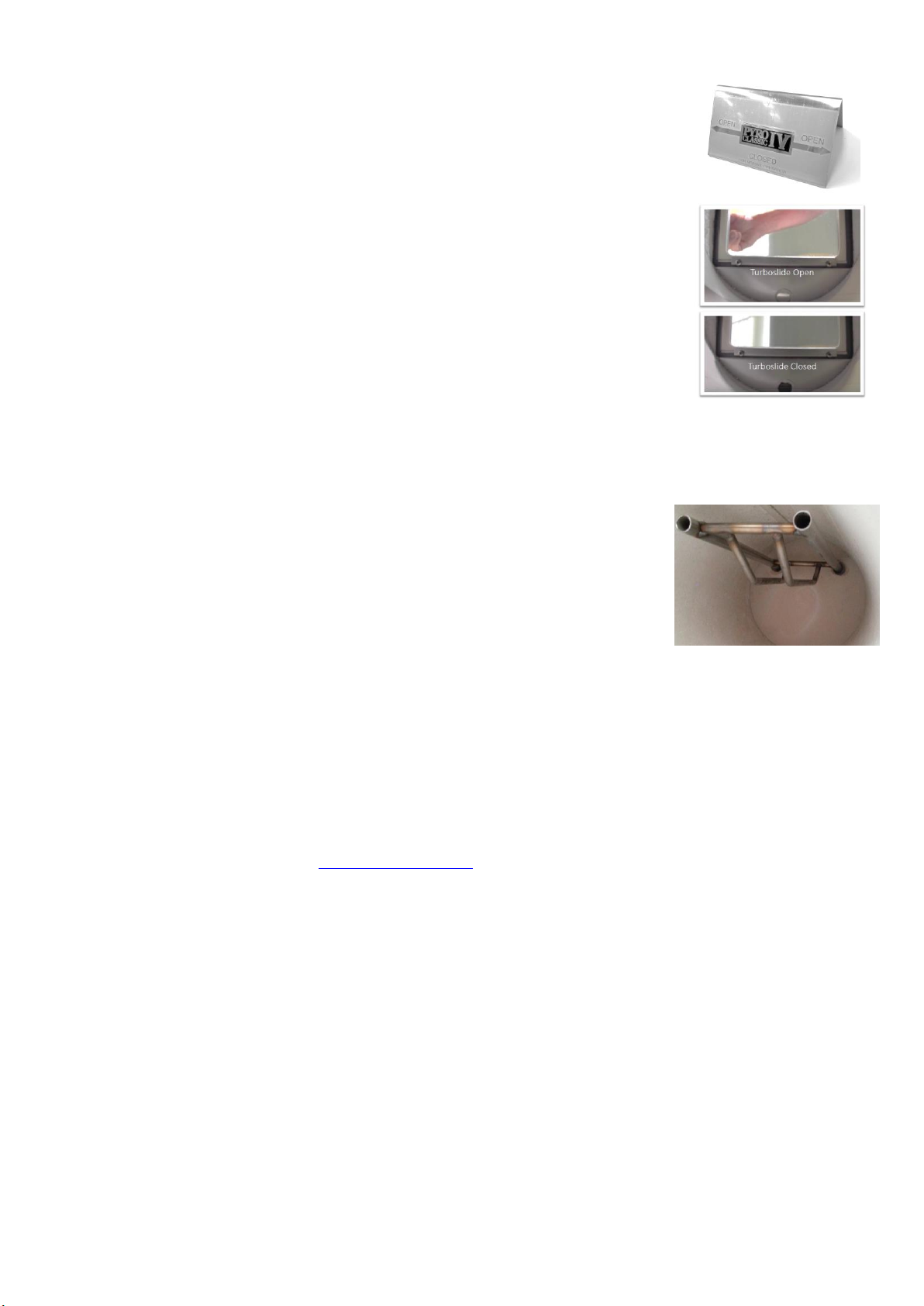

use the turboslide as instructed. If there is insufficient burning material in the firebed to light new fuel, excessive smoke

emission can occur.

THE PYROCLASSIC® IV IS SELF-REGULATING.

The vigorous fire towards the front of the chamber automatically slows down as the burning advances towards the back

of the fire chamber. Each cycle ends with ash and hot ember at the far end of the chamber. The Pyroclassic® IV is

designed to save on firewood and keep emission levels to a minimum by storing surplus heat in the cylinder, which

normally goes up the flue. This heat is released into the room even when the fire is low at the end of each burn cycle.

REFUELLING and using your PYROCLASSIC CURVED RAKE

Use the rake to evenly distribute the hot ember and ash along the base of the fire chamber, ensuring there is sufficient

hot ember at the front to provide adequate ignition to the fresh fuel load. Load the fuel so one end of each log is in

contact with the back wall of the firebox. If you keep your fire burning under the air tubes, this will ensure the maximum

amount of heat is captured within the ceramic cylinder.

Please Note: Only use Pyroclassic Fires tools as using others may cause damage to the cylinder. Always take care not to

heavily impact the ceramic surface.

DOOR/DOORKNOB

DO NOT run the fire with the door open. It will never reach the correct operating temperature and this can be very

dangerous.

The door seals with little pressure so it may be hard to open when the unit is very hot. The door knob is a great indicator

of what is going on inside your fire so if you find the door knob is too hot when you go to refuel, you are probably trying

prematurely. Do not overtighten the door knob as it can cause damage to the door gasket and fixing screws.

If your door knob is starting to show signs of charring, you are probably burning your fire too close to the door. Try closing

the turboslide sooner and letting the fire burn further back in the fire chamber.

Do not lean on the door or use it to help you stand when it is open as this can cause the door to move. If your door does

become misaligned, loosen the top bolt going horizontally through the hinge bar and lift the door back into the correct

position and retighten the bolt.

AIR INLETS

Do not block any fixed air inlets as this will affect the fire’s performance and may cause permanent damage.

BURNING WITH THE PYROCLASSIC® IV

Solid wood must change to gas and vapour before any burning can take place. This change occurs by heating wood to

high temperatures, making gas fuel. Low temperatures will make smoke and tars that are simply unburnt fuel. The

Pyroclassic® IV is a North/South burning fire, which means the fire is started in the front of the fire chamber and

continues along the length of the wood to the rear. To get the most out of your firewood, ensure logs are placed

lengthways into the fire chamber, not sideways. To achieve a high temperature in the fire chamber quickly, use the

turboslide and dry wood. You will never get the fire to burn correctly if you try starting fires with green or wet wood. The

only fuel authorised for use with this appliance within Urban Clean Air Sheds and Smoke Control Zones is well-seasoned

wood with a moisture content of 25% or less, 12-18% is ideal.